Ultra-strength shaving board manufacturing technology changing morphological structure of wood shavings

A technology of morphological structure and manufacturing process, applied in the direction of manufacturing tools, flat products, wood processing utensils, etc., can solve the problems of poor dimensional stability, difficult to meet the needs of customized home furnishing market transformation and upgrading of particleboard, low mechanical strength, etc., to achieve high strength and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

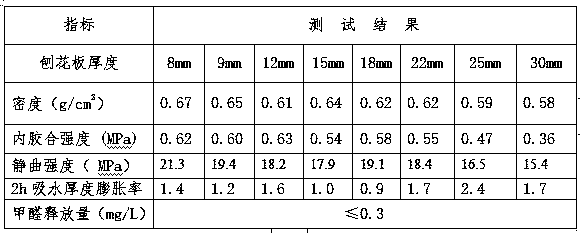

Embodiment 1

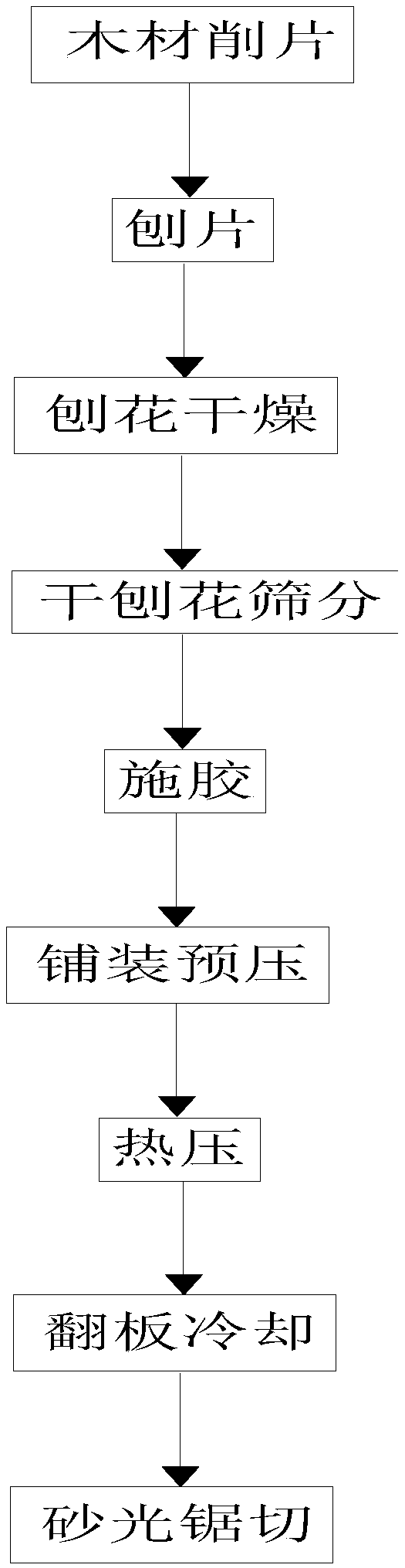

[0062] Such as figure 1 Shown, a kind of super-strength particle board manufacturing process that changes particle shape structure, comprises following process step:

[0063] (1) wood chips

[0064] Raw materials such as woody sub-small fuelwood, edge waste, cutting materials and scraps are proportioned in proportion, and then the wood chips are once chipped, separated, and simply screened by a chipper, and then the wood chips are sent to the transition warehouse for storage. Fuelwood is short twigs that cannot be used as wood during the harvesting process of eucalyptus, pine, miscellaneous wood, etc., and the scraps are veneer sheets or bagasse or Straw or Chinese herbal medicine slag and other waste materials, the cutting materials are the residues in wood harvesting or rotary cutting processing, such as wood cutoffs and board edges, and the raw materials are wood chaff produced in wood processing, etc.

[0065] (2) shavings

[0066] Before shaving, use a magnetic separat...

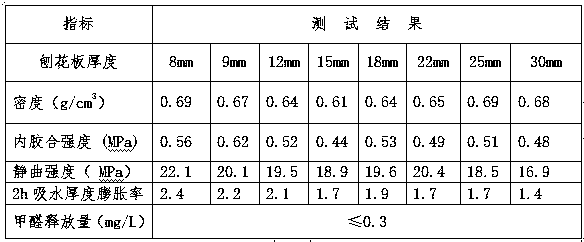

Embodiment 2

[0093] Such as figure 1 Shown, a kind of super-strength particle board manufacturing process that changes particle shape structure, comprises following process step:

[0094] (1) wood chips

[0095] Raw materials such as woody sub-small fuelwood, edge waste, cutting materials and scraps are proportioned in proportion, and then the wood chips are once chipped, separated, and simply screened by a chipper, and then the wood chips are sent to the transition warehouse for storage. Fuelwood is short twigs that cannot be used as wood during the harvesting process of eucalyptus, pine, miscellaneous wood, etc., and the scraps are veneer sheets or bagasse or Straw or Chinese herbal medicine slag and other waste materials, the cutting materials are the residues in wood harvesting or rotary cutting processing, such as wood cutoffs and board edges, and the raw materials are wood chaff produced in wood processing, etc.

[0096] (3) shavings

[0097] Before shaving, use a magnetic separat...

Embodiment 3

[0124] Such as figure 1 Shown, a kind of super-strength particle board manufacturing process that changes particle shape structure, comprises following process step:

[0125] (1) wood chips

[0126] Raw materials such as woody sub-small fuelwood, edge waste, cutting materials and scraps are proportioned in proportion, and then the wood chips are once chipped, separated, and simply screened by a chipper, and then the wood chips are sent to the transition warehouse for storage. Fuelwood is short twigs that cannot be used as wood during the harvesting process of eucalyptus, pine, miscellaneous wood, etc., and the scraps are veneer sheets or bagasse or Straw or Chinese herbal medicine slag and other waste materials, the cutting materials are the residues in wood harvesting or rotary cutting processing, such as wood cutoffs and board edges, and the raw materials are wood chaff produced in wood processing, etc.

[0127] (2) shavings

[0128] Before shaving, use a magnetic separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com