Sterilization by down radiation

A technology for irradiating down and down sterilization, which is applied in the field of down and down sterilization, can solve the problems of short lamp life, secondary pollutants, and increased number of suspended particles, and achieve quality assurance, low processing costs, and fast processing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Radiation sterilization process:

[0034] 1. Check the parameters: turn on the display screen 33 to check the input parameters.

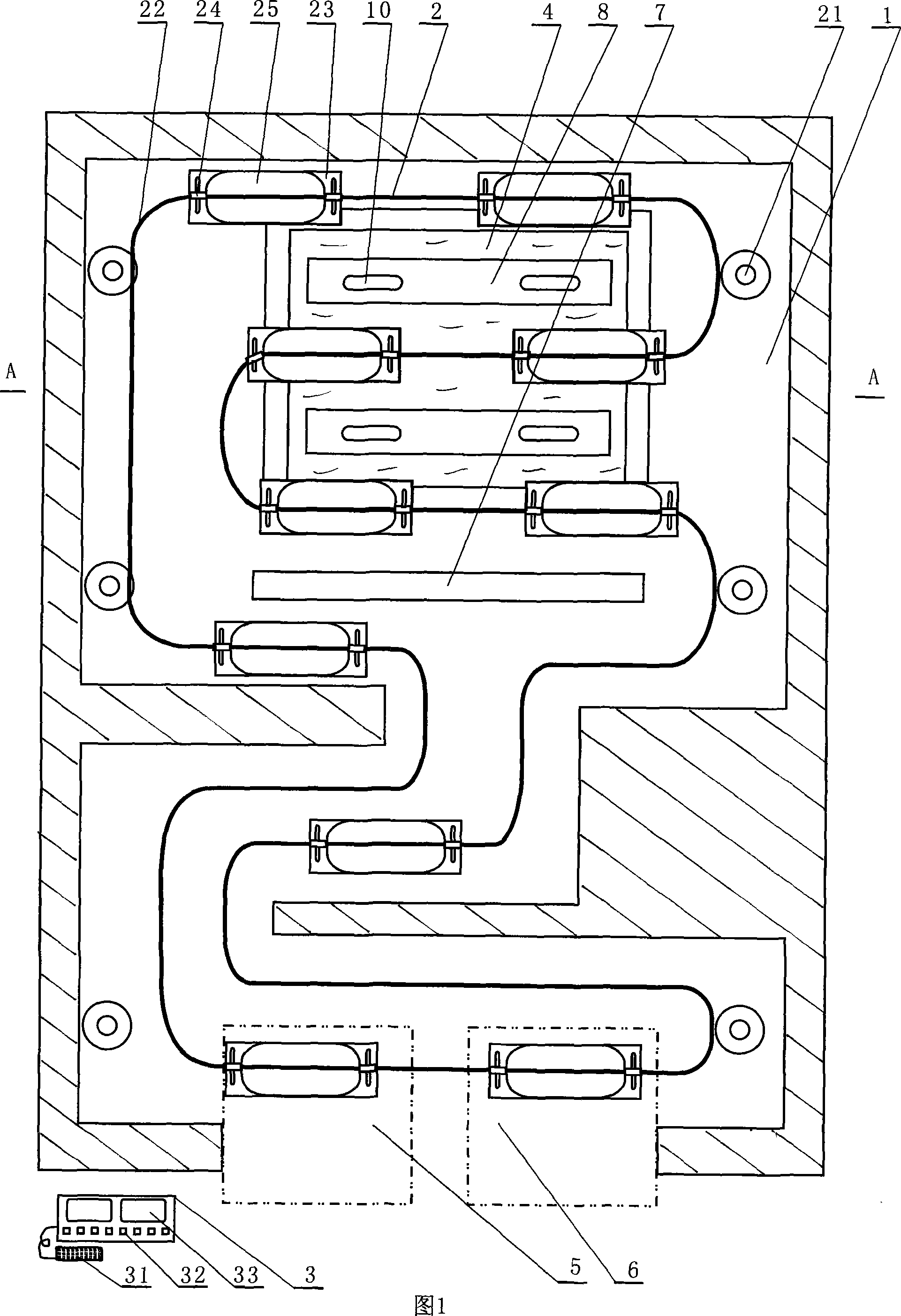

[0035] 2. Loading material packages: By manipulating the button 32 and manually transferring the system 2, the staff will load the material packages 25 prepared in the loading area 5 into the hanger 23 one by one.

[0036] 3. Evacuate personnel: After the material packages 25 are loaded into the hanger 23 one by one, the staff located in the loading area 5 are evacuated.

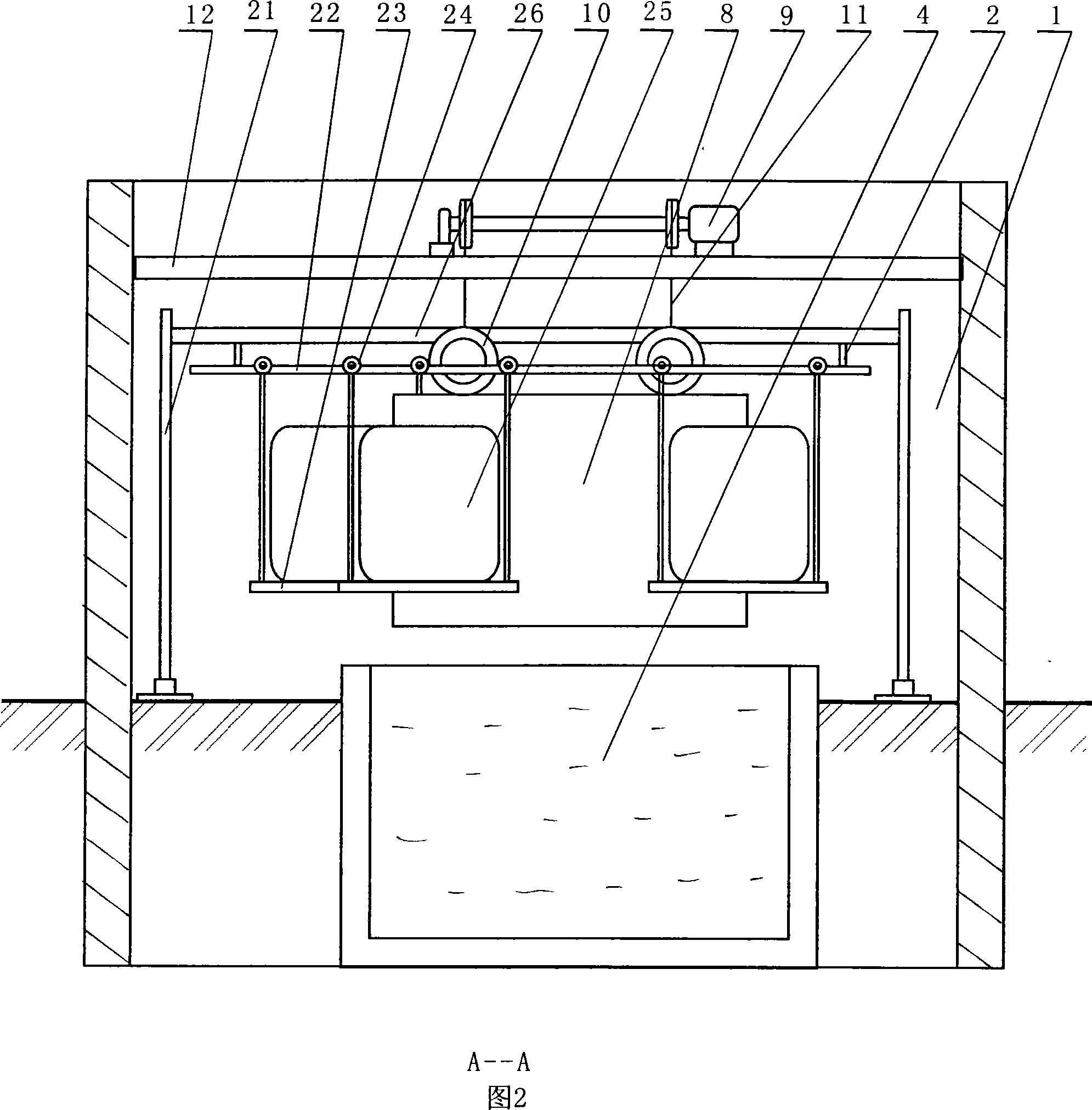

[0037] 4. Turn on the radiation source: start the elevator 9 to hoist the radiation source 8 out of the pool 4 to a set height.

[0038] 5. Irradiation sterilization: the transmission system 2 performs irradiation sterilization according to the set parameters, and detects the operation process through the display screen 33 .

[0039] 6. Turn off the radiation source: the elevator 9 lowers the radiation source 8 from the working height into the pool 4 .

[0040] 7. Unload...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com