Novel sludge brick making technique

A technology of sludge brick making and process, which is applied in the field of new sludge brick making process, and achieves the effects of low cost, energy saving and effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

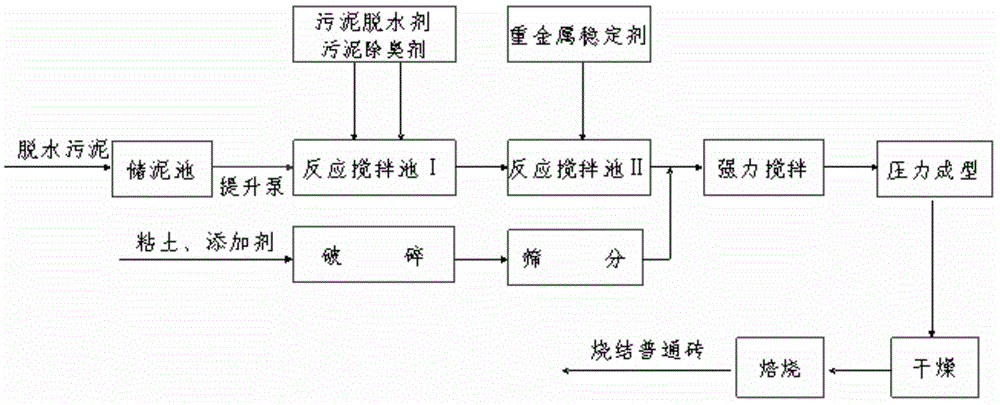

Method used

Image

Examples

Embodiment 1

[0039] Example 1: A sludge brick making process, including the following steps:

[0040] (1) Sludge transportation and storage: The sludge is transported from the sewage treatment plant to the sludge brick factory by a sludge truck, and discharged into the sludge storage tank. During the transportation process, the sludge is transported at night and covered with protective cloth. Avoid the adverse effects of sludge transportation on the urban environment and named lives

[0041] (2) Sludge deodorant gel breaking: The sludge is lifted from the sludge storage tank by the sludge pump into the feeding system I, and the sludge breaker and sludge deodorant are added to the feeding system I and mixed with the sludge Then enter the stirring reaction tank I for thorough mixing to achieve the effects of gel breaking, deodorization, and killing of microorganisms. The flocculant (PAC / PAM) is used in the dewatering and concentration of the sludge in the sewage treatment plant to make the sludg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com