Self-cleaning phosphorus-free film forming agent and preparation method and application thereof

A film-forming agent and self-cleaning technology, which is applied in the coating process of metal materials, can solve the problems of complex composition of film-forming agents, poor salt spray resistance, and unreasonable design, so as to achieve good coating adhesion and improve durability. Corrosive, compositionally simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

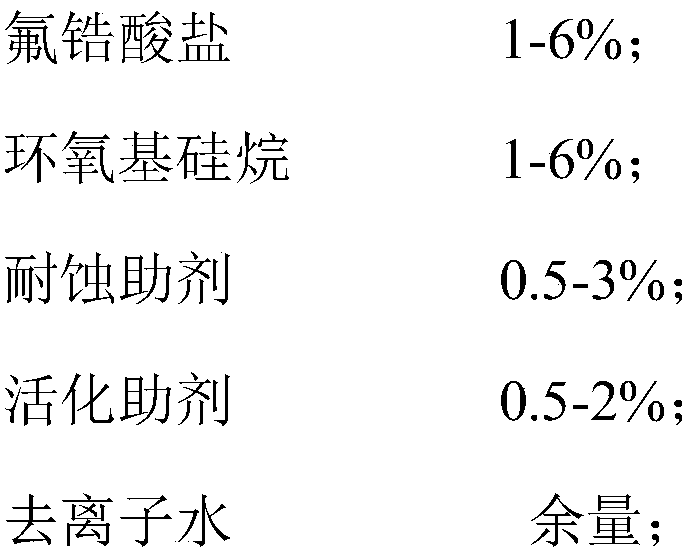

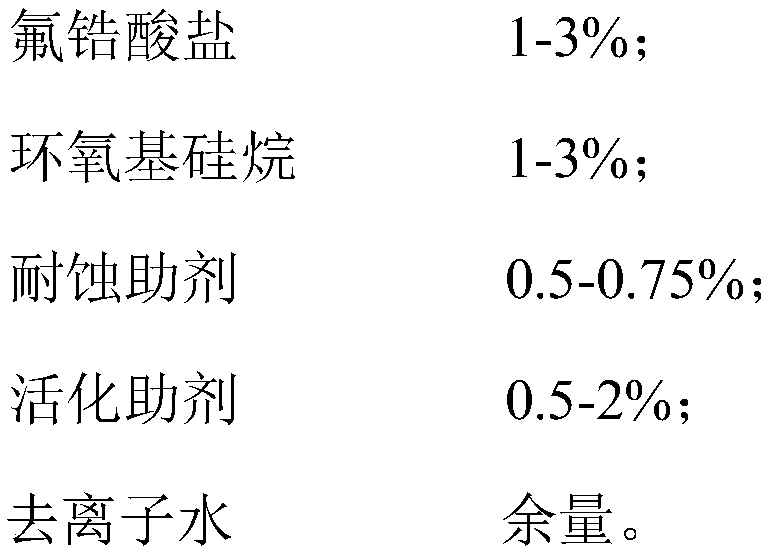

[0041] A kind of preparation method of self-cleaning phosphorus-free film-forming agent of the present invention, comprises the following steps:

[0042] 1) Take deionized water, the amount of which is half of the total amount of deionized water, stir, and under stirring conditions, add fluorozirconate, and continue stirring to obtain mixture A;

[0043] 2) Under stirring conditions, slowly add epoxy silane to the mixture A obtained in step 1), and continue stirring to obtain mixture B;

[0044] 3) Under the condition of stirring, in the mixture B obtained in step 2), add the anti-corrosion additive and the activation additive in sequence, and continue stirring to obtain the mixture C;

[0045] 4) Supplement the remaining deionized water, continue to stir for 1-2 hours, let stand for 1-2 hours, filter and fill to obtain a film-forming agent.

[0046] Preferably, the stirring speed during stirring in the step 1), the step 2) and the step 3) is 20-50r / min; the addition speed of...

Embodiment 1

[0053] A kind of preparation method of self-cleaning phosphorus-free film-forming agent of the present invention, comprises the following steps:

[0054] 1) Take 500Kg of deionized water, add it into a reaction kettle with a stirring device, turn on the stirring device, the stirring speed is 30r / min, add 20Kg of ammonium fluorozirconate, and continue stirring for 15min to obtain a mixture A;

[0055] 2) Keep the stirring speed constant, slowly add epoxy agent silane KH-56020Kg to the mixture A obtained in step 1), and continue stirring for 30 minutes to obtain the mixture B;

[0056] 3) Keep the stirring speed constant, add 6Kg of anti-corrosion additive sodium molybdate and 5Kg of activation additive nonylphenol polyoxyethylene polyoxypropylene ether (3132) to the mixture B obtained in step 2), and continue stirring for 1h to obtain mixture C;

[0057] 4) Supplement the remaining deionized water, continue to stir for 1 hour, let stand for 2 hours, filter and fill to obtain a...

Embodiment 2

[0069] A kind of preparation method of self-cleaning phosphorus-free film-forming agent of the present invention, comprises the following steps:

[0070] 1) Take 500Kg of deionized water, add it into a reaction kettle with a stirring device, turn on the stirring device, the stirring speed is 20r / min, add 10Kg of sodium fluozirconate, and continue stirring for 30min to obtain a mixture A;

[0071] 2) Keep the stirring speed constant, slowly add 10Kg of epoxy agent silane in the mixture A obtained in step 1), the addition speed of epoxy silane is 1000g / min, continue to stir for 60min, and obtain mixture B; epoxy silane is trimethyl A mixture of oxysilane, methyldimethoxysilane, and ethyltrimethoxysilane in a weight ratio of 1:2:3;

[0072] 3) Keep the stirring speed constant, add 5Kg of anti-corrosion additive ammonium molybdate and 10Kg of activation additive—polyoxyethylene polyoxypropylene ether into the mixture B obtained in step 2), and continue stirring for 2 hours to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com