Method for controlling surface pitting defect of medium-carbon low-alloy ultra-thin specification strip steel in short-process rolling

A control method and low-alloy technology, applied in the direction of rolling force/roll gap control, rolling mill control device, mass flow control device, etc., can solve problems such as difficult control of pitting defects, and achieve easy operation, strong practicability, and method easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

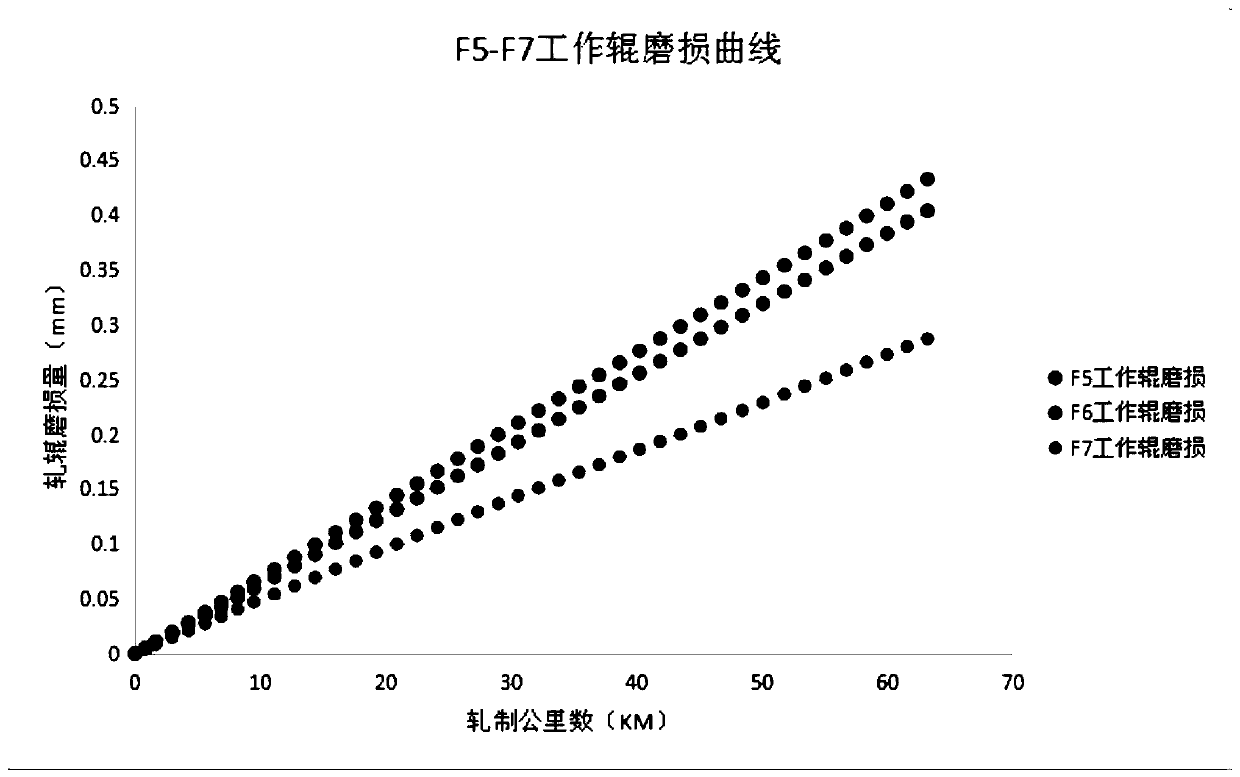

[0046] A control method for pitting defects on the surface of medium-carbon and low-alloy ultra-thin strip steel in short-process rolling, using a CSP production line, including control of cooling water volume of work rolls in a rolling mill, rolling rhythm control, stand reduction rate control, and roll gap control. Lubrication control and speed-up rolling control, taking the production of Q235B with a thickness of 3.0mm as an example:

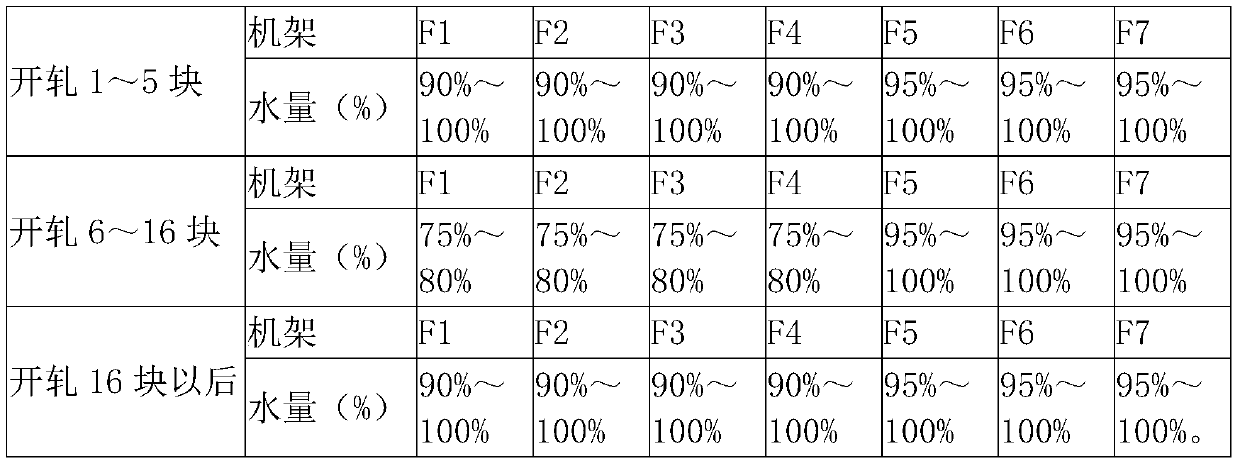

[0047] ①Work roll cooling water volume:

[0048]

[0049]

[0050] ②Rolling rhythm:

[0051] Finished product thickness / mm Rolling Rhythm(s) 3.0mm 140

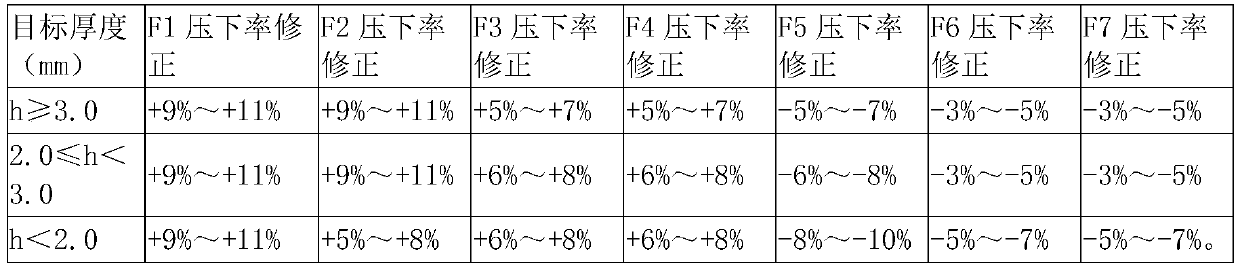

[0052] ③Reduction rate of each frame:

[0053]

[0054] ④Roll Gap Lubrication:

[0055] frame F2 F3 F4 F5 F6 Roll Gap Lubricating Oil Volume (ml / min) 60 90 90 40 40

[0056]⑤Operation method of increasing speed rolling:

[0057]

[0058] Except for the above-mentioned five specific controls and / or steps, other operations are r...

Embodiment 2

[0061] A control method for pitting defects on the surface of medium-carbon and low-alloy ultra-thin strip steel in short-process rolling, using a CSP production line, including control of cooling water volume of work rolls in a rolling mill, rolling rhythm control, stand reduction rate control, and roll gap control. Lubrication control and speed-up rolling control, taking the production of Q235B with a thickness of 2.0mm as an example:

[0062] ①Work roll cooling water volume:

[0063]

[0064] ②Rolling rhythm:

[0065] Finished product thickness / mm Rolling Rhythm(s) 3.0mm 140

[0066] ③Reduction rate of each frame:

[0067]

[0068] ④Roll Gap Lubrication:

[0069] frame F2 F3 F4 F5 F6 Roll Gap Lubricating Oil Volume (ml / min) 70 95 95 50 50

[0070] ⑤Operation method of increasing speed rolling:

[0071]

[0072] Except for the above-mentioned five specific controls and / or steps, other operations are routine oper...

Embodiment 3

[0075] A control method for pitting defects on the surface of medium-carbon and low-alloy ultra-thin strip steel in short-process rolling, using a CSP production line, including control of cooling water volume of work rolls in a rolling mill, rolling rhythm control, stand reduction rate control, and roll gap control. Lubrication control and speed-up rolling control, taking the production of Q235B with a thickness of 1.5mm as an example:

[0076] ①Work roll cooling water volume:

[0077]

[0078] ②Rolling rhythm:

[0079] Finished product thickness / mm Rolling Rhythm(s) 3.0mm 140

[0080] ③Reduction rate of each frame:

[0081]

[0082] ④Roll Gap Lubrication:

[0083] frame F2 F3 F4 F5 F6 Roll Gap Lubricating Oil Volume (ml / min) 80 115 115 55 55

[0084] ⑤Operation method of increasing speed rolling:

[0085]

[0086] Except for the above-mentioned five specific controls and / or steps, other operations are routine op...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com