Emulsion Process Optimization Method Aiming at Fuel Consumption Control in Secondary Cold Rolling Mill

A secondary cold rolling and target control technology, which is applied to rolling mill control devices, manufacturing tools, metal rolling, etc., can solve the problem of high rolling oil consumption, rolling oil waste, and failure to consider rolling oil consumption indicators, etc. Problems, to achieve the minimum consumption, reduce the effect of on-site production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

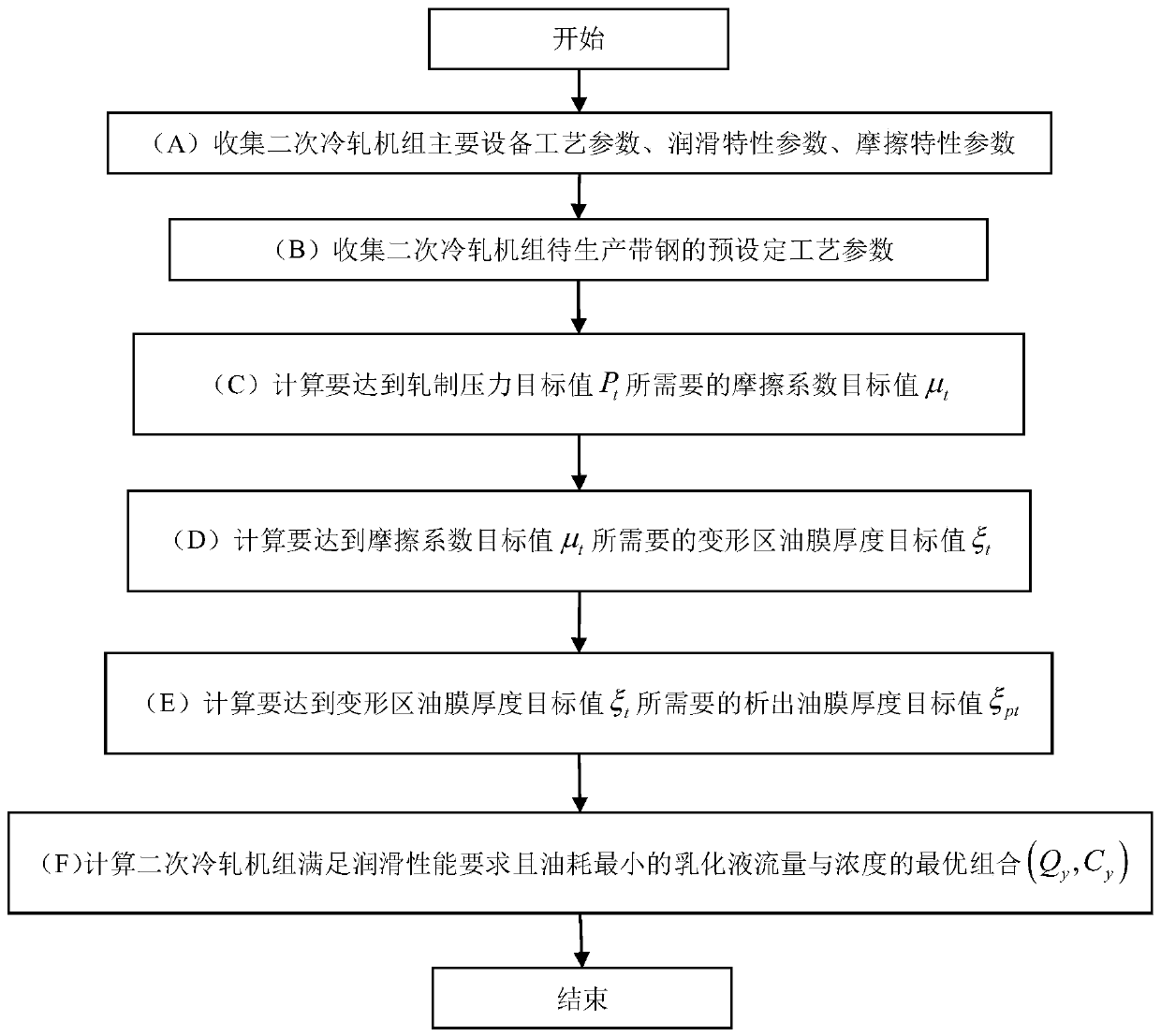

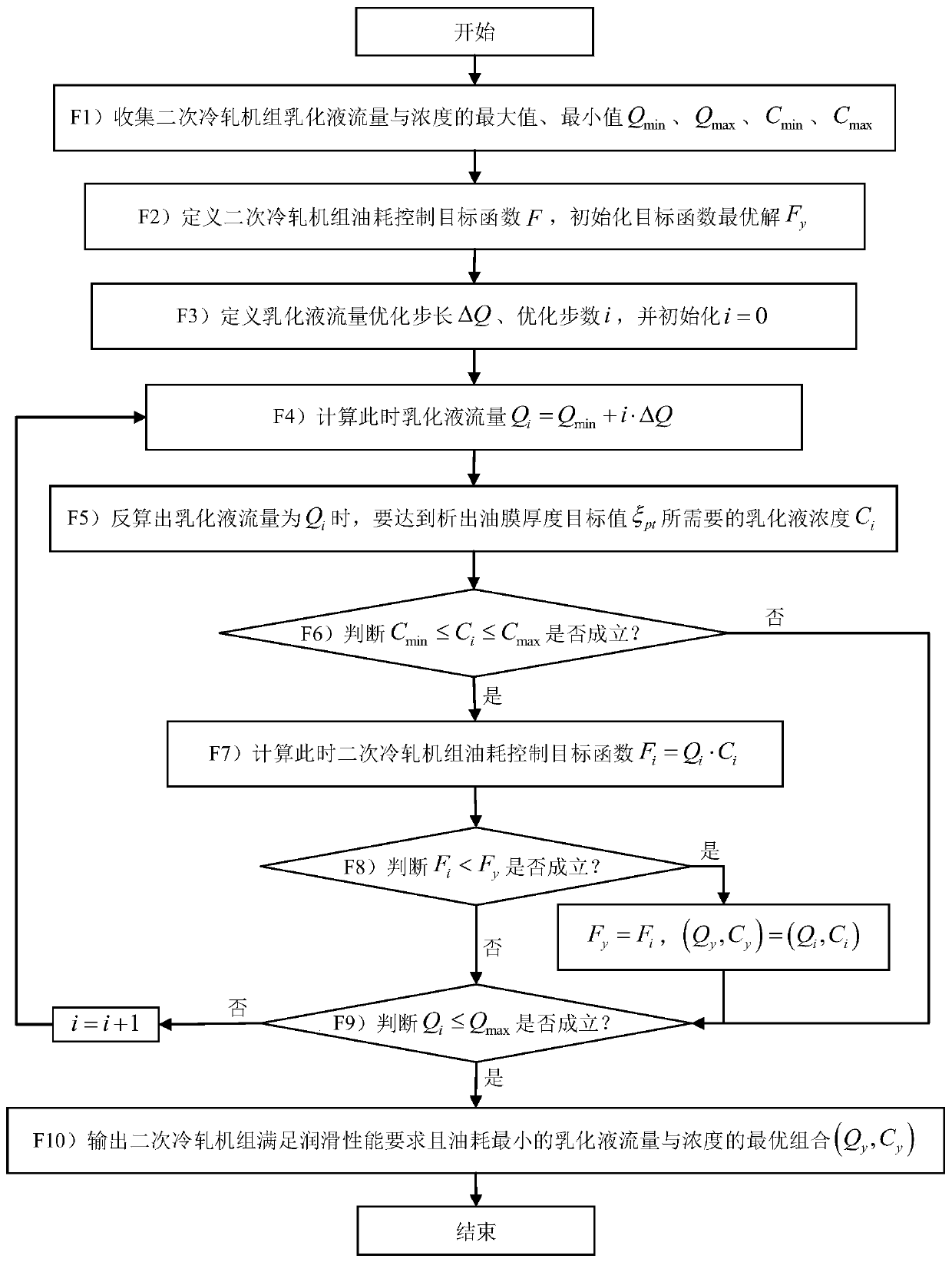

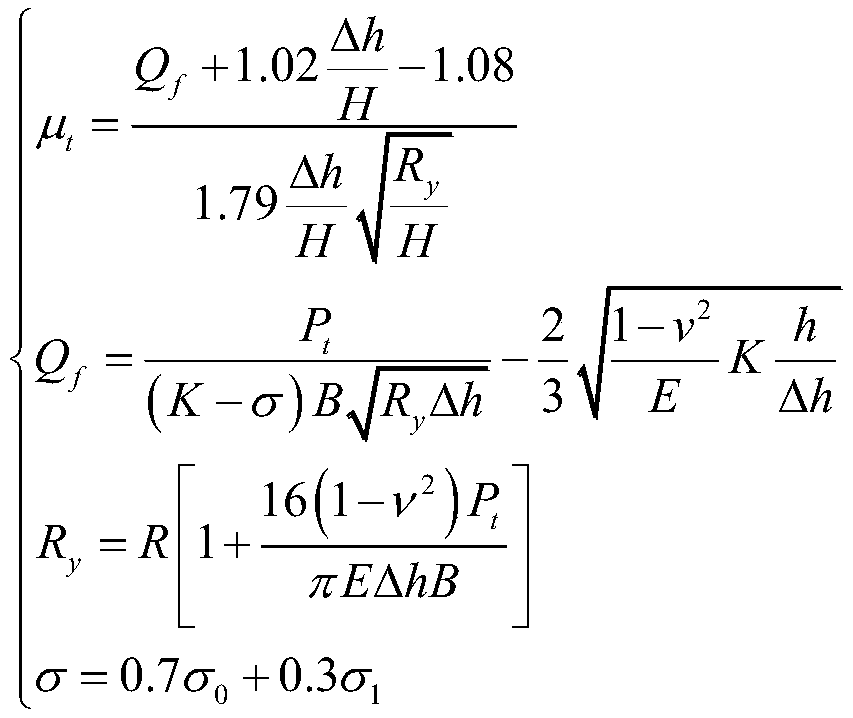

[0034] Taking a secondary cold rolling mill as an example, according to figure 1 The overall calculation flow chart of the emulsion process optimization method for the oil consumption control of the secondary cold rolling mill is shown. First, in step (A), the main equipment process parameters, lubrication characteristic parameters, friction parameters of the secondary cold rolling mill are collected. Characteristic parameters, including: work roll radius R=170mm, work roll elastic modulus E=210GPa, work roll Poisson’s ratio ν=0.3, distance from emulsion nozzle to rolling mill roll gap L=0.5m, rolling oil dynamic viscosity η 0 =0.02Pa·s, pressure viscosity coefficient θ=0.01MPa -1 , Emulsion concentration precipitation efficiency time influence coefficient λ t =487.5, the concentration influence coefficient λ of the emulsion concentration precipitation efficiency C =1.936, time influence coefficient δ of residual efficiency of emulsion flow t = 19.35, the residual efficienc...

Embodiment 2

[0061] First, in step (A), collect the main equipment process parameters, lubrication characteristic parameters and friction characteristic parameters of the secondary cold rolling mill, including: work roll radius R=170mm, work roll elastic modulus E=210GPa, work roll Poisson Ratio ν=0.3, distance from emulsion nozzle to rolling mill gap L=0.5m, rolling oil dynamic viscosity η 0 =0.02Pa·s, pressure viscosity coefficient θ=0.01MPa -1 , Emulsion concentration precipitation efficiency time influence coefficient λ t = 526.3, the concentration of the emulsion concentration precipitation efficiency concentration influence coefficient λ C =2.142, time influence coefficient δ of residual efficiency of emulsion flow t = 21.62, emulsion flow residual efficiency flow influence coefficient δ Q =0.533, liquid lubrication friction coefficient a = 0.0112, boundary lubrication friction coefficient b = 0.1256, friction coefficient attenuation index B ξ =-6.582.

[0062] Subsequently, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com