Operation method for efficiently recycling chromium element

An operation method and element technology are applied in the field of efficient recycling and utilization of chromium elements, which can solve problems such as resource waste, and achieve the effects of reducing molten iron consumption, reducing production costs, and simple operation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

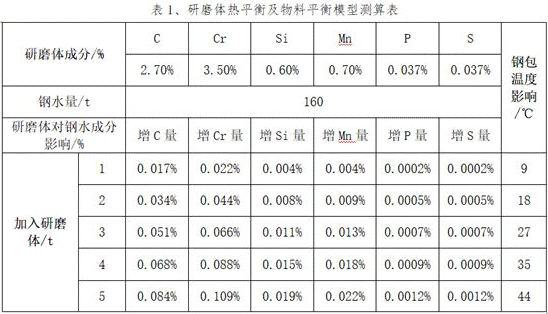

[0023] An operation method for efficient recovery and utilization of chromium elements. The method is to control the free oxygen content of the steel ladle to below 30ppm after the deoxidation and alloying process of the converter, and cast and forge the grinding body into the steel ladle through the alloy silo, and cast the grinding body of each furnace of steel The amount of forging to be added is determined according to the following formula, where the heat required for melting the grinding body of a 1kg grinder is as follows, and then the amount of grinding body to be added can be determined according to the heat margin in the furnace:

[0024] Q grinding body = m grinding body × {C solid (t melting - t initial) + melting latent heat of grinding body + C liquid (t out - t melting)}

[0025] In the formula: Q grinding body - cooling effect of grinding body;

[0026] m Grinding body—amount of grinding body added;

[0027] C solid, C liquid—the average specific heat capacity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com