Novel technology for treating waste gas containing chlorine with adsorption-catalysis function of active carbon fibers

A technology of activated carbon fiber and new technology, applied in chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve the problems of increasing the cost of on-site use, and achieve the effects of reducing air pollutants, practical promotion value, and large environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

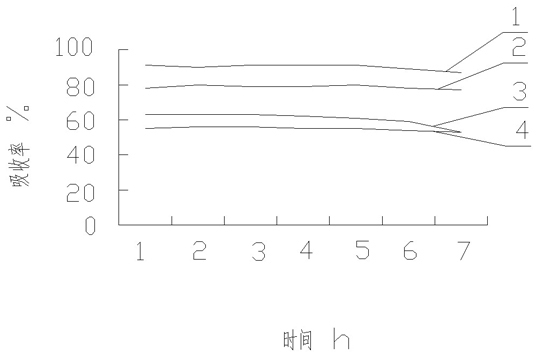

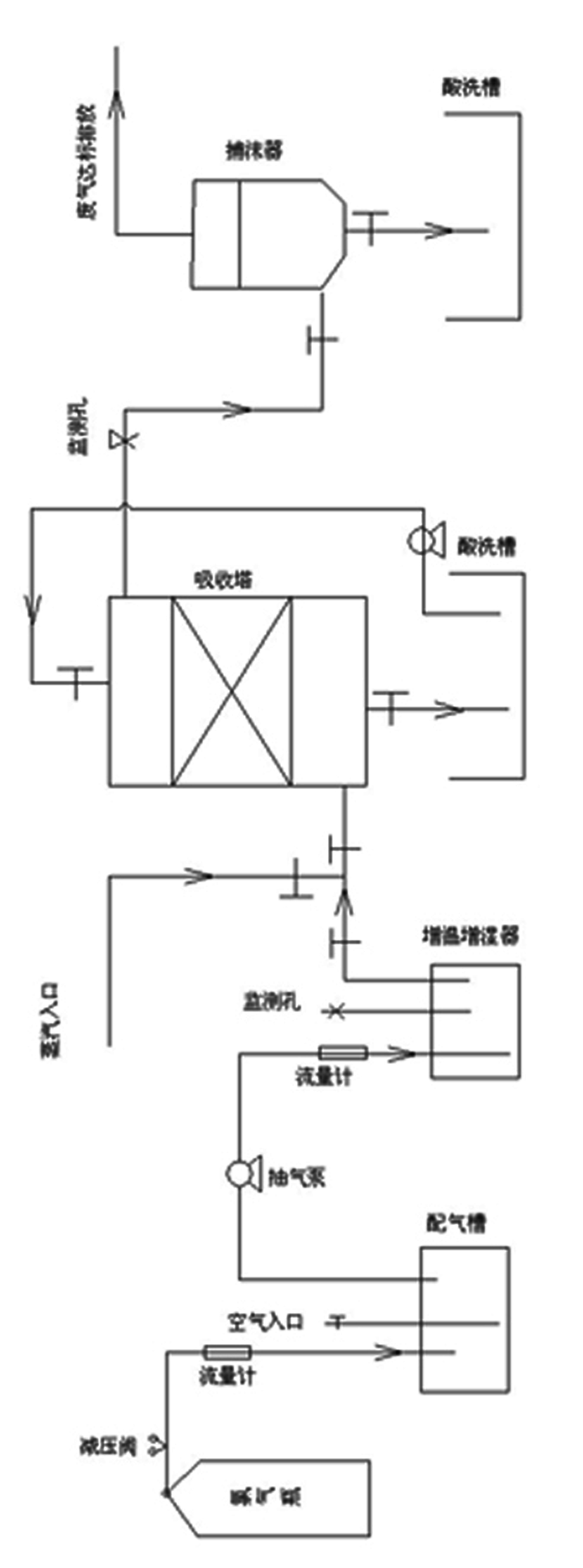

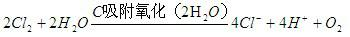

[0040] A new process for treating chlorine-containing waste gas with activated carbon fiber adsorption-catalysis function. Its process is as follows: First, the activated carbon fiber is loaded into the absorption tower with a filling thickness of 800mm, so that 2.0~10.0 g / Nm 3 After chlorine-containing exhaust gas enters the humidification tower at a flow rate of 40 L / min, the temperature reaches 50oC and the humidity is 60 g / m 3 Then it is pumped into the absorption tower to carry out the adsorption-catalytic conversion process. The treated chlorine-containing waste gas is sprayed by a foam spreader and then discharged up to the standard. The exhausted chlorine-containing waste gas that meets the standard is sampled and analyzed every half hour. The concentration of chlorine-containing waste gas reaches 0.05~0.3 g / Nm 3 , it is regarded as the adsorption capacity is saturated; the chlorine gas adsorbed by the activated carbon fiber has been catalyzed into a hydrogen chloride ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com