Automatic releasing device for solar photovoltaic support coiled material and using method of automobile releasing device

A solar photovoltaic and automatic release technology, which is applied in the field of automatic release devices for solar photovoltaic support coils, to reduce safety hazards, reduce production costs, and improve labor efficiency and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

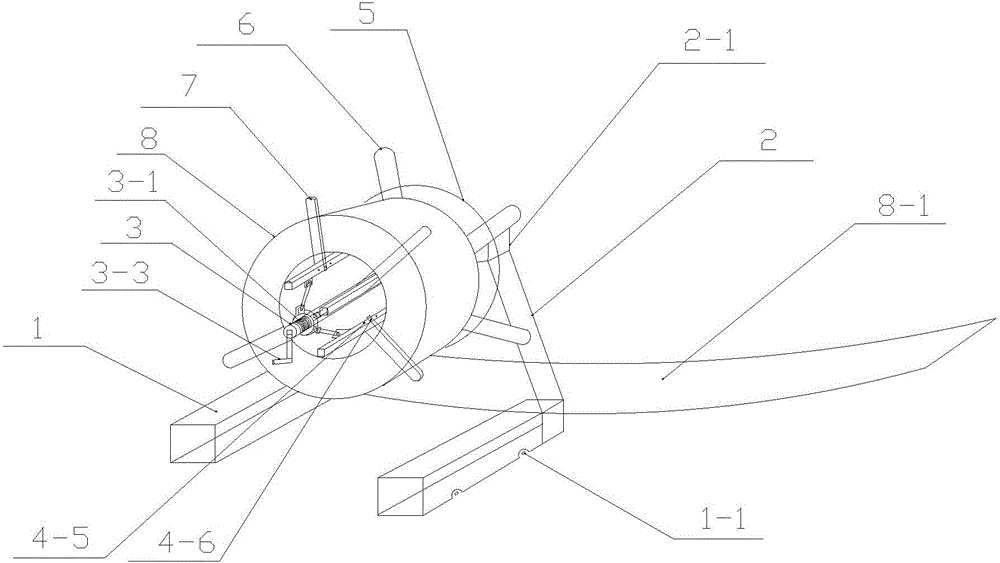

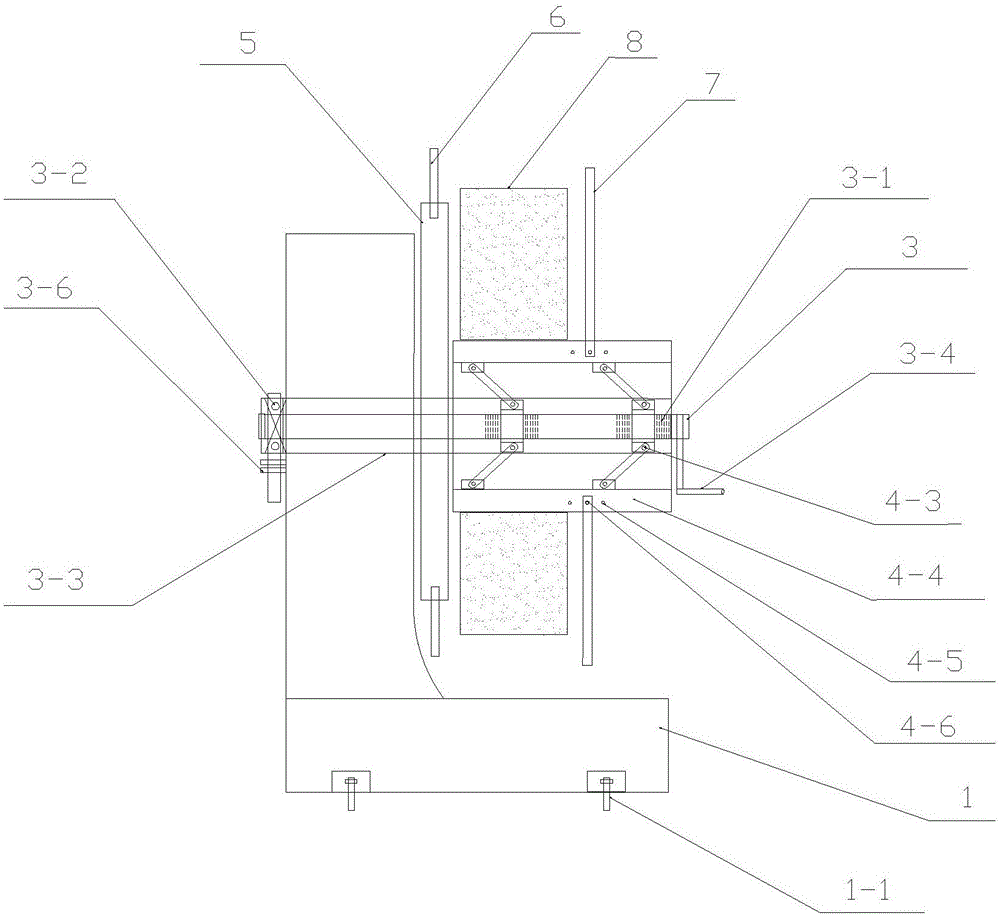

[0041] In the technical transformation project of a solar photovoltaic support production workshop of a company, a material discharging device and usage method made of solar photovoltaic support have been successfully applied. The specific technical steps are:

[0042] The device installation method is divided into four steps:

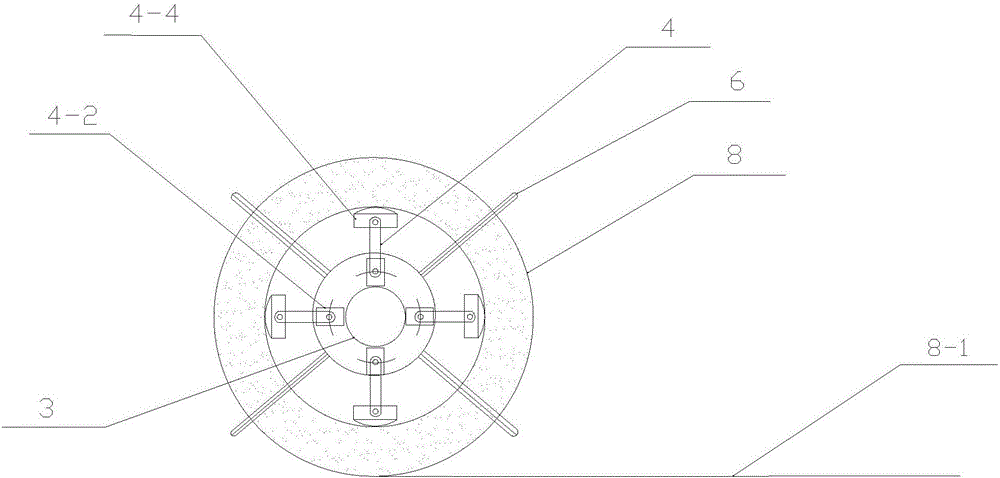

[0043] One is to install the base longitudinal beam 1, pre-embed the anchor bolts 1-1 at the parallel terminal position of the solar support production line, lift the base longitudinal beam 1 and frame body column 2 to the position of the embedded bolts 1-1 and pre-fix them with bolts , adjust the horizontal line and flatness and then fasten; the second is to install the central shaft 3, and install the built-in components of the central shaft 3, the front bearing 3-2, the middle bearing 3-3, the bearing 3-4, and the shaft sleeve 3-5 in place ; The 3rd, support link 4 is installed, and eight support links 4 are correspondingly installed on the outer cl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com