Process lubricating system control method for wet leveling unit aiming at coarseness

A technology of process lubrication and roughness, applied in rolling mill control device, mass flow control device, metal rolling, etc., can solve the problems of easy out-of-tolerance, difficult control and sealing of finished strip surface roughness, etc., and achieve good economic benefits , the effect of good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

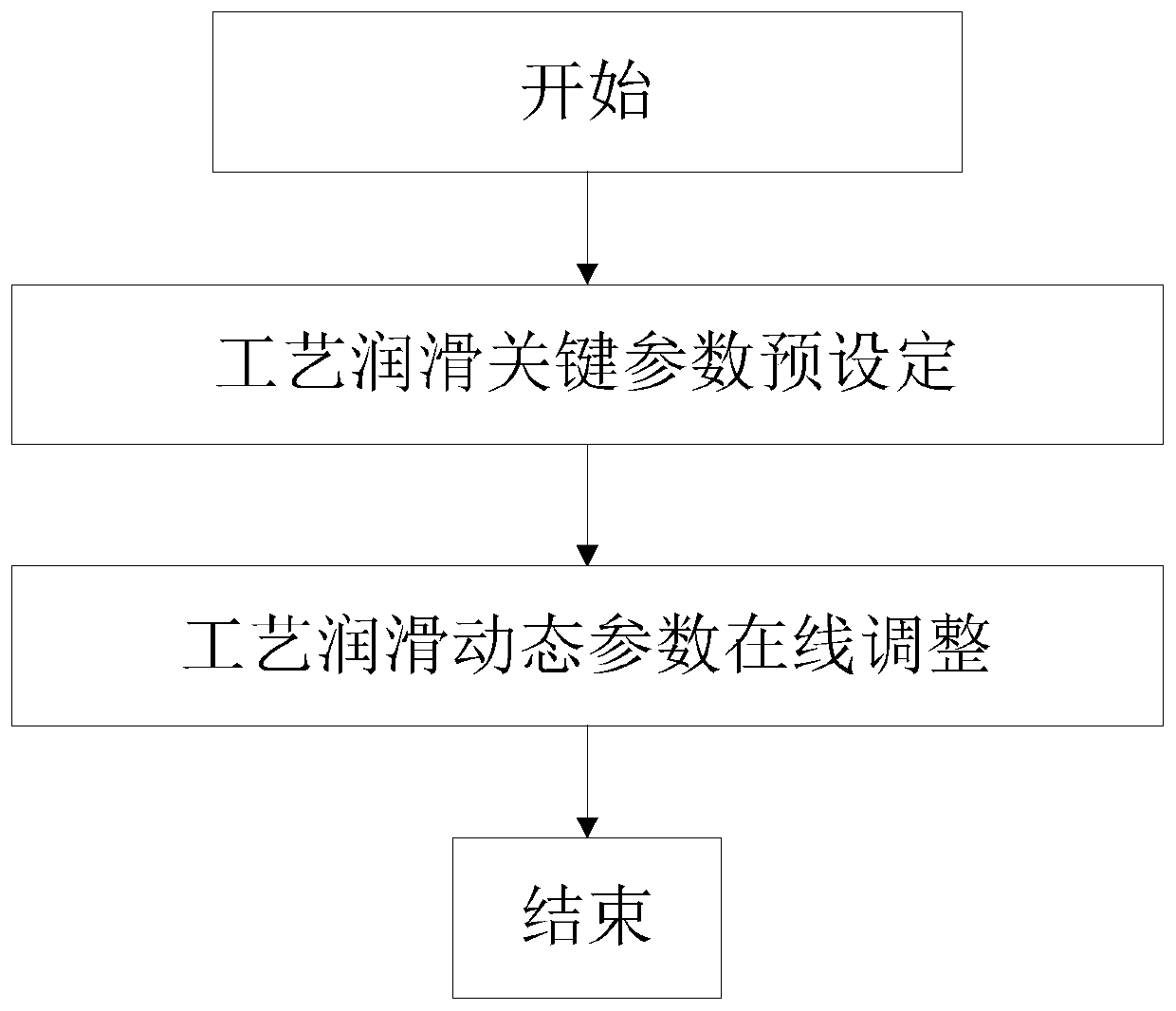

[0033] Taking a two-machine wet leveling unit as an example, according to figure 1 The process lubrication system control method with roughness as the target of the shown double-frame wet-leveling unit of the present invention:

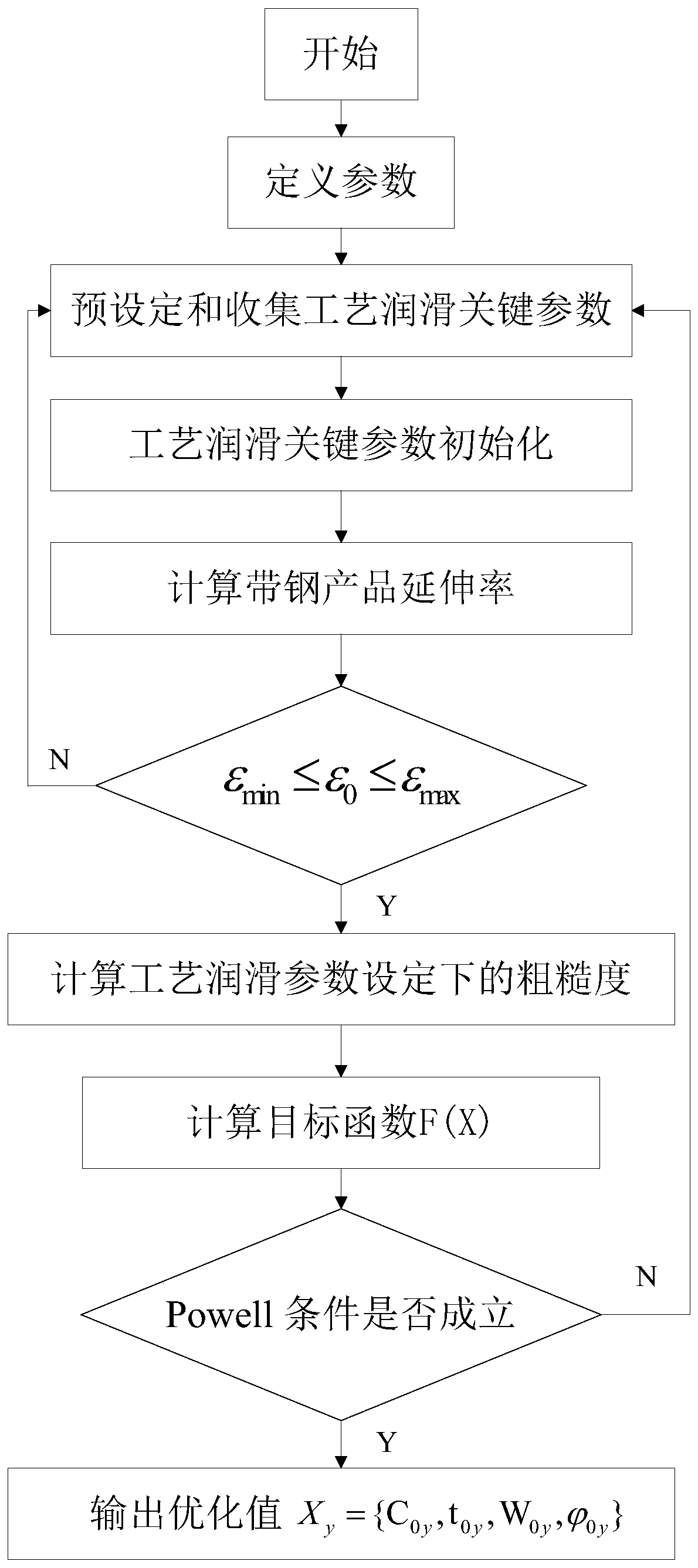

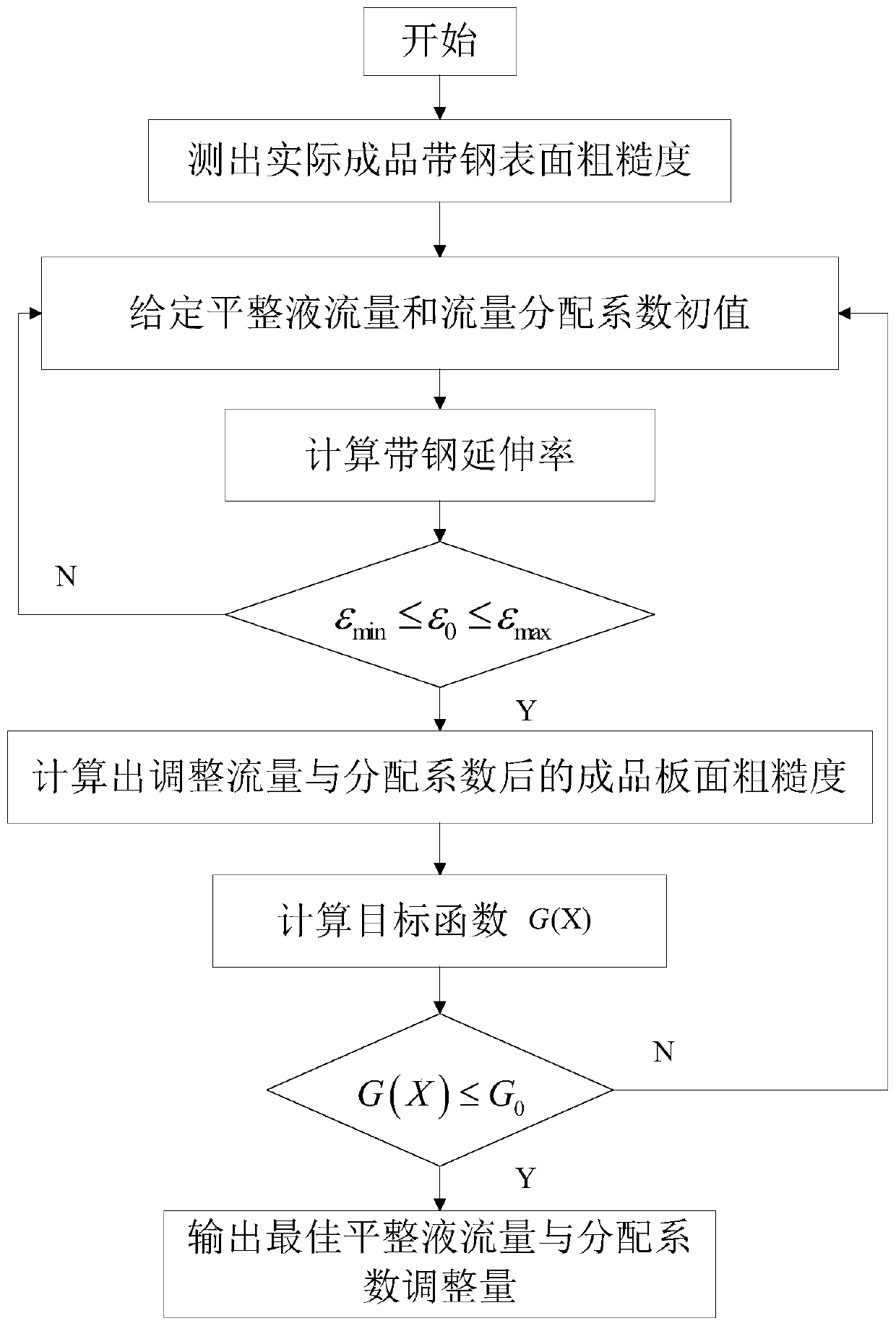

[0034] First, enter step (a) process lubrication key parameter pre-setting, which includes the following steps (such as figure 2 shown):

[0035] a1) Preset and collect key parameters of process lubrication:

[0036] Preset the initial concentration of leveling liquid C 0 =1.5%, preset the initial temperature of leveling liquid t 0 =25℃, preset the total flow rate of leveling liquid W 0 =20L / min, preset leveling fluid distribution coefficient Set the surface roughness target value Ra s0 =0.700μm, collect the minimum elongation ε allowed by the mechanical properties min = 0.7% and maximum elongation ε max = 4%, the maximum leveling liquid flow W allowed by the leveling unit max =45L / min;

[0037] a2) Let the key parameters of process lubric...

Embodiment 2

[0056]Taking a two-machine wet-leveling unit as an example, first, enter step (a) pre-setting key parameters of process lubrication, which includes the following steps:

[0057] a1) Preset and collect key parameters of process lubrication:

[0058] Preset the initial concentration of leveling liquid C 0 =1.8%, preset the initial temperature of leveling liquid t 0 =28℃, preset the total flow rate of leveling liquid W 0 =20L / min, preset leveling fluid distribution coefficient Set the surface roughness target value Ra s0 =0.400μm, collect the minimum elongation ε allowed by the mechanical properties min = 0.7% and maximum elongation ε max = 4%, the maximum leveling liquid flow W allowed by the leveling unit max =45L / min;

[0059] a2) Let the key parameters of process lubrication be initialized to X y =X={1.8%, 28°C, 20L / min, 0.45};

[0060] a3) Given target roughness Ra ms =0.4μm, and allowable deviation G 0 =1×10 -5 ;

[0061] a4) Calculation of elongation ε of str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com