Automatic gain control method and device for mass flow of rolling mill

A technology of automatic gain control and second flow rate, applied in the field of steel rolling, can solve the problems of standard deviation of thickness and low pass rate of thickness deviation of rolled products, and achieve the effect of improving pass rate, improving pass rate of finished products and flexible control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

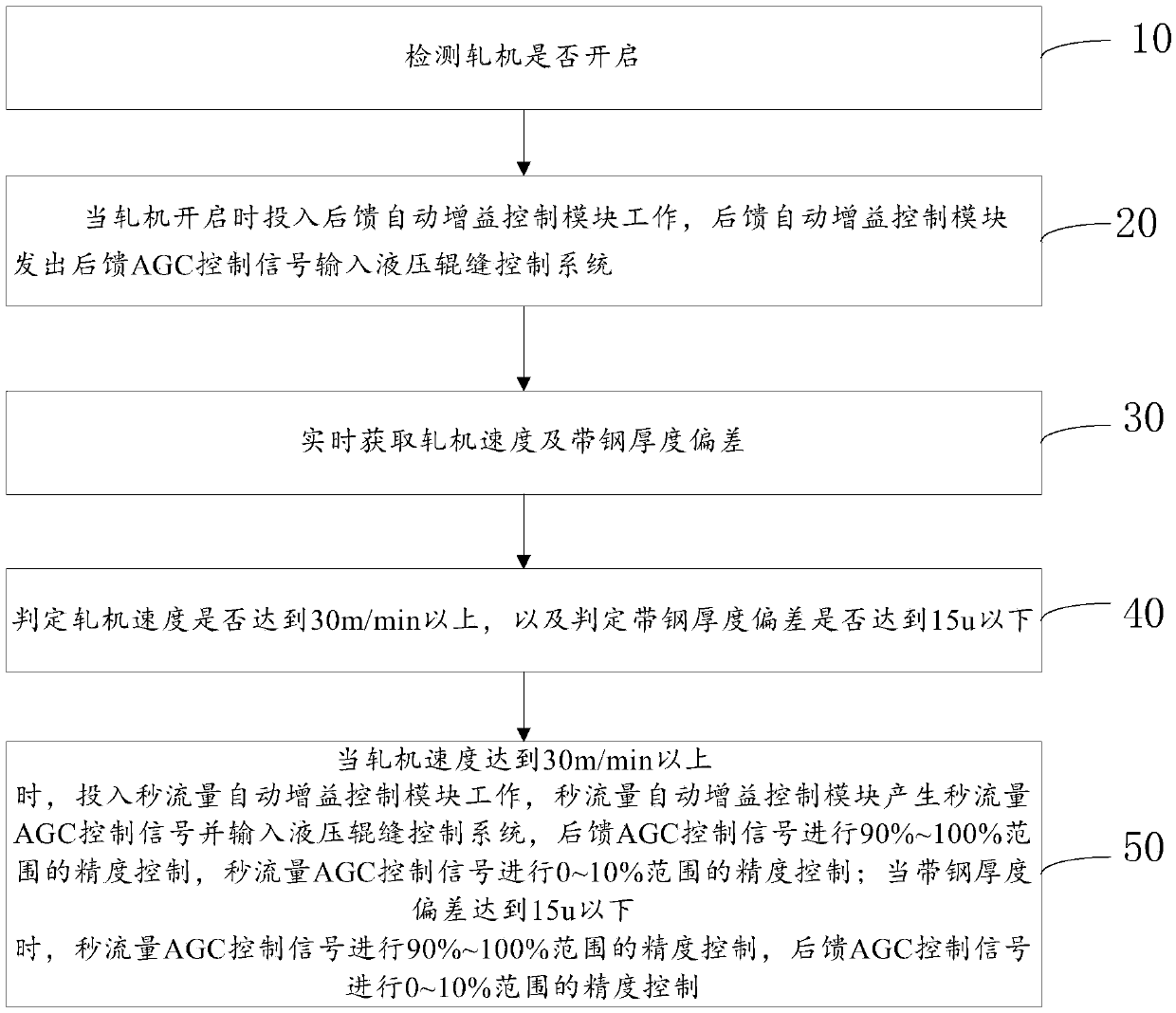

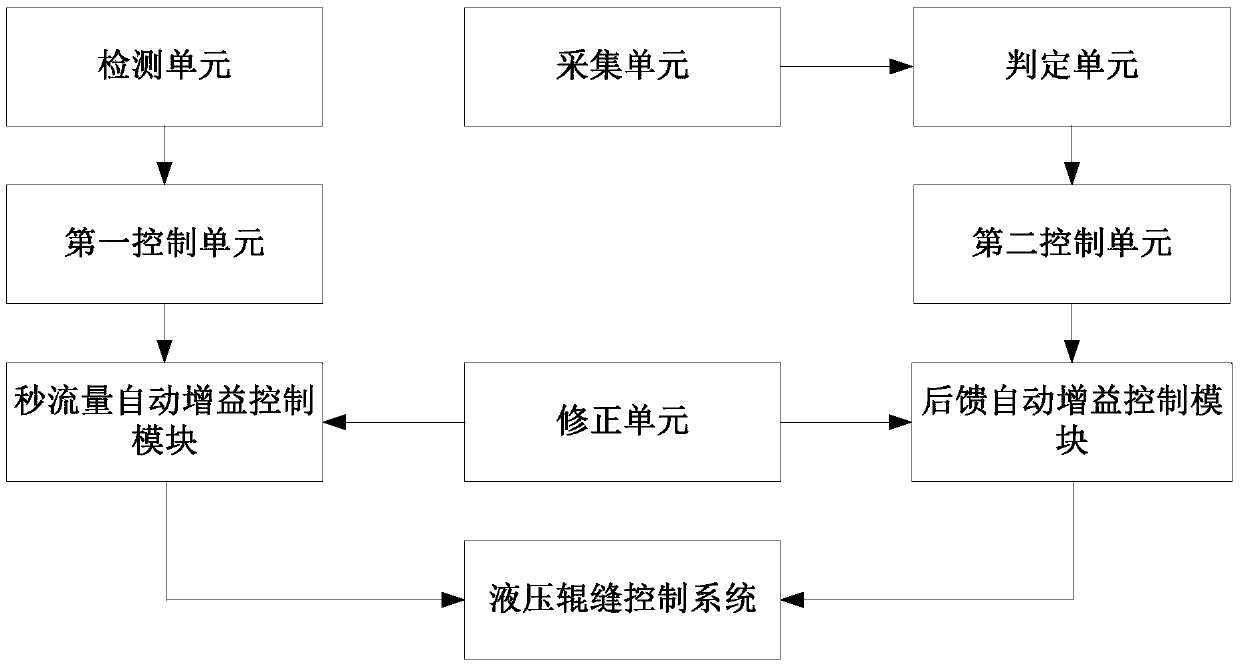

[0051] see figure 1 and figure 2 In this embodiment, the Sendzimir rolling mill is used for rolling, and the correction module introduces a correction coefficient β that decreases with time (the value range of β is 0≤β≤1). After the rolling mill second flow automatic gain control device provided in this embodiment starts to work, the detection unit detects whether the rolling mill is turned on. When the rolling mill is turned on, the first control unit controls the input and the feed-back automatic gain control module starts to work. After the feed-back automatic gain control module sends out Feed the AGC control signal, feed back the AGC control signal through the correction coefficient β (the initial value of β is set to 1 when the rolling mill is turned on), and then input it to the hydraulic roll gap control system, and the hydraulic roll gap control system integrates the corrected AGC control signal Then send a control signal to control the operation of the rolling mill...

Embodiment 2

[0054] see figure 1 and figure 2 In this embodiment, the Sendzimir rolling mill is used for rolling, and the correction module introduces a correction coefficient β that decreases with time (the value range of β is 0≤β≤1). After the rolling mill second flow automatic gain control device provided in this embodiment starts to work, the detection unit detects whether the rolling mill is turned on. When the rolling mill is turned on, the first control unit controls the input and the feed-back automatic gain control module starts to work. After the feed-back automatic gain control module sends out Feed the AGC control signal, feed back the AGC control signal through the correction coefficient β (the initial value of β is set to 1 when the rolling mill is turned on), and then input it to the hydraulic roll gap control system, and the hydraulic roll gap control system integrates the corrected AGC control signal Then send a control signal to control the operation of the rolling mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com