Process and control method for eliminating winding of thin hot-rolled strip steel on pinch roll of coiling machine

A technology of hot-rolled strip and control method, applied in rolling mill control device, roll safety equipment, metal rolling, etc. The effect of eliminating the accident of wrapping steel and reducing the probability of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

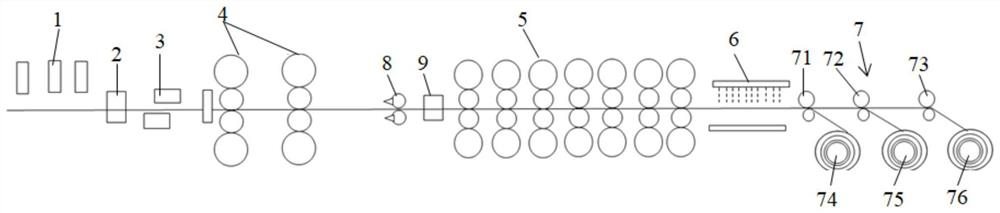

Image

Examples

Embodiment 1

[0040] Embodiment 1: Production of strip steel with H=2.0mm and target coiling temperature of 730°C.

[0041] (1) Coiling process parameters

[0042] a. Strip head temperature

[0043]

[0044] b. Spray water on layer cooling

[0045] Before the strip head passes through the last set of laminar flow upper water spray, the laminar flow upper water spray is normally turned on to reduce the temperature of the strip steel head. After the strip steel head passes through, the PLC controller controls the last set of Set of switches for spraying water on laminar flow.

[0046] c. Pinch roller cooling water

[0047] Increase the flow rate of the pinch roll by 30% during the coiling gap, that is, increase the cooling water flow rate for the pinch roll in the resting state, and increase the cooling water flow rate by 30% to ensure that the temperature of the pinch roll roll surface temperature drops below 30°C , the pinch rollers in the rest state start to work and the cooling wat...

Embodiment 2

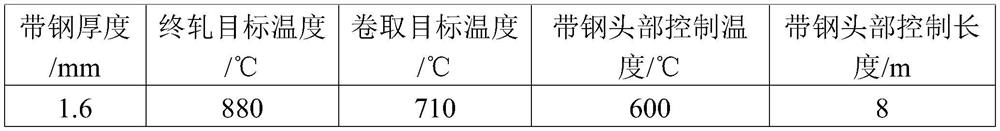

[0052] Embodiment 2: Production of steel strip with thickness H=1.6mm and target coiling temperature 710°C.

[0053] (1) Coiling process parameters

[0054] a. Strip head temperature

[0055]

[0056] b. Spray water on layer cooling

[0057] Before the strip head passes through the last set of laminar flow upper water spray, the laminar flow upper water spray is normally turned on to reduce the temperature of the strip steel head. After the strip steel head passes through, the PLC controller controls the last set of Set of switches for spraying water on laminar flow.

[0058] c. Pinch roller cooling water

[0059] Increase the flow rate of the pinch roll by 30% during the coiling gap, that is, increase the cooling water flow rate for the pinch roll in the resting state, and increase the cooling water flow rate by 30% to ensure that the temperature of the pinch roll roll surface temperature drops below 30°C , the pinch rollers in the rest state start to work and the cool...

Embodiment 3

[0064] Embodiment 3: Production thickness H=2.3mm, target coiling temperature 650°C.

[0065] (1) Coiling process parameters

[0066] a. Strip head temperature

[0067]

[0068] b. Spray water on layer cooling

[0069] Before the strip head passes through the last set of laminar flow upper water spray, the laminar flow upper water spray is normally turned on to reduce the temperature of the strip steel head. After the strip steel head passes through, the PLC controller controls the last set of Set of switches for spraying water on laminar flow.

[0070] c. Pinch roller cooling water

[0071] Increase the flow rate of the pinch roll by 30% during the coiling gap, that is, increase the cooling water flow rate for the pinch roll in the resting state, and increase the cooling water flow rate by 30% to ensure that the temperature of the pinch roll roll surface temperature drops below 30°C , the pinch rollers in the rest state start to work and the cooling water flow returns ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com