Truck intelligent braking system

A braking system and technology for large trucks, applied in the field of intelligent braking systems for large trucks, can solve problems such as delays, and achieve the effect of eliminating accidents and facilitating opening of the baffles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

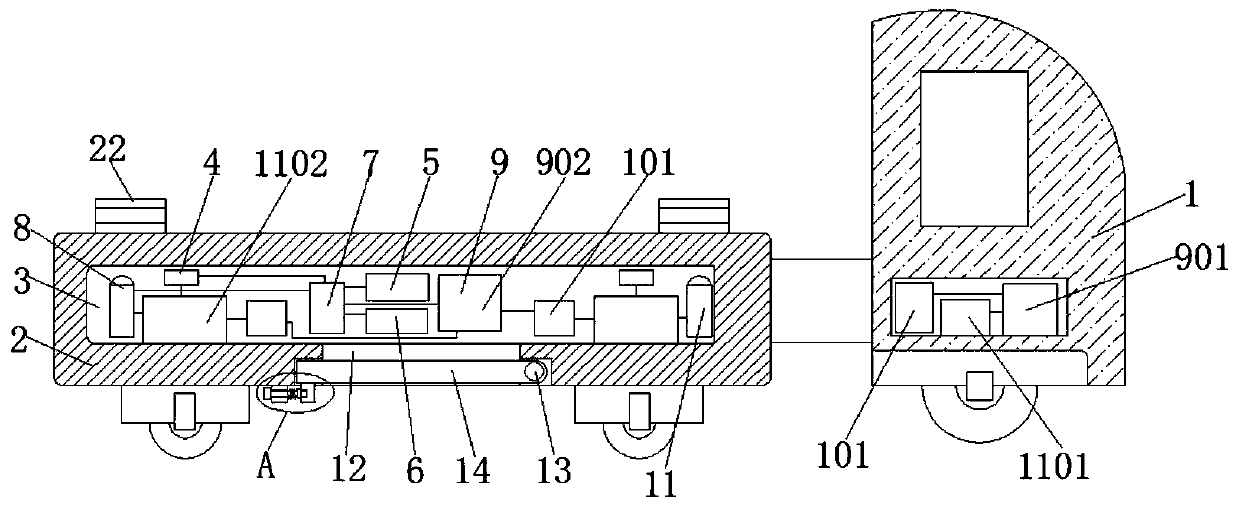

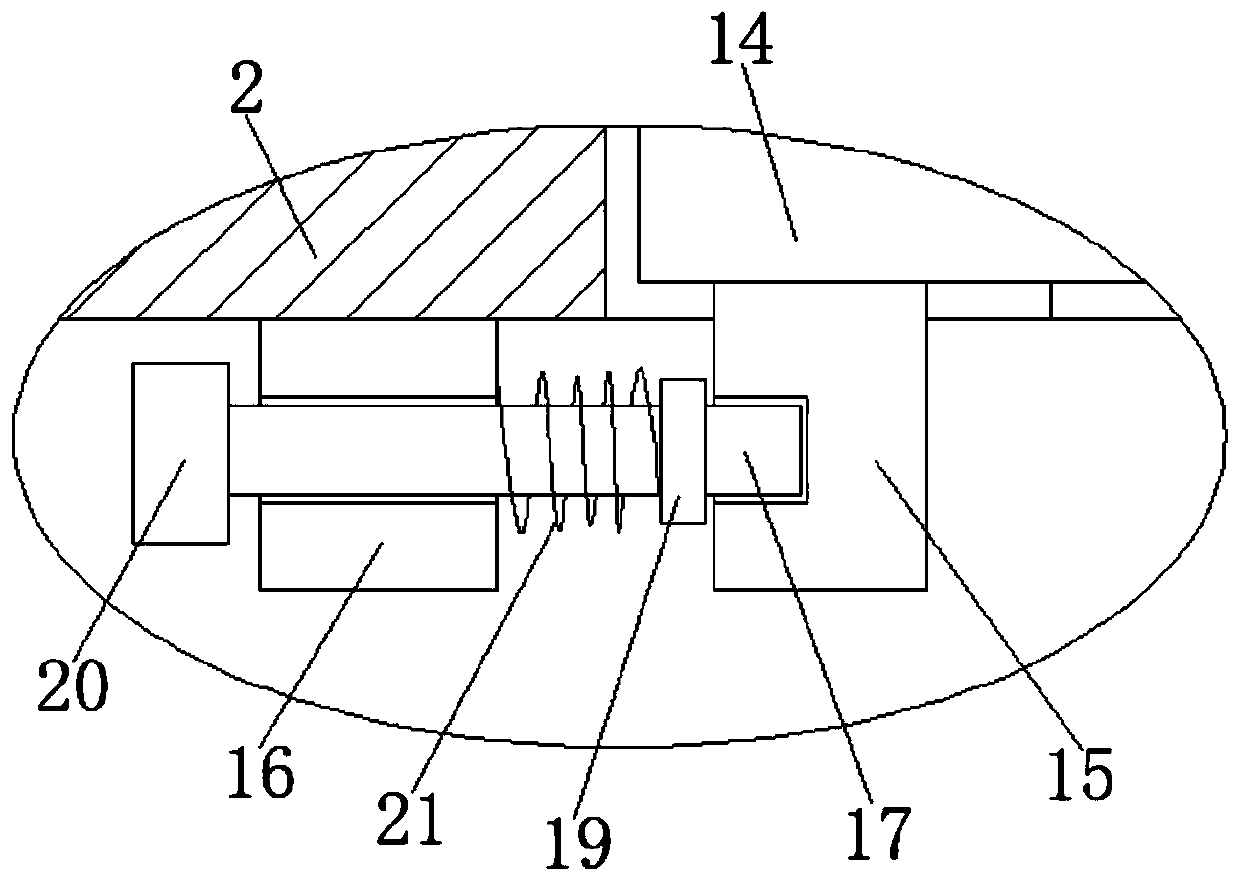

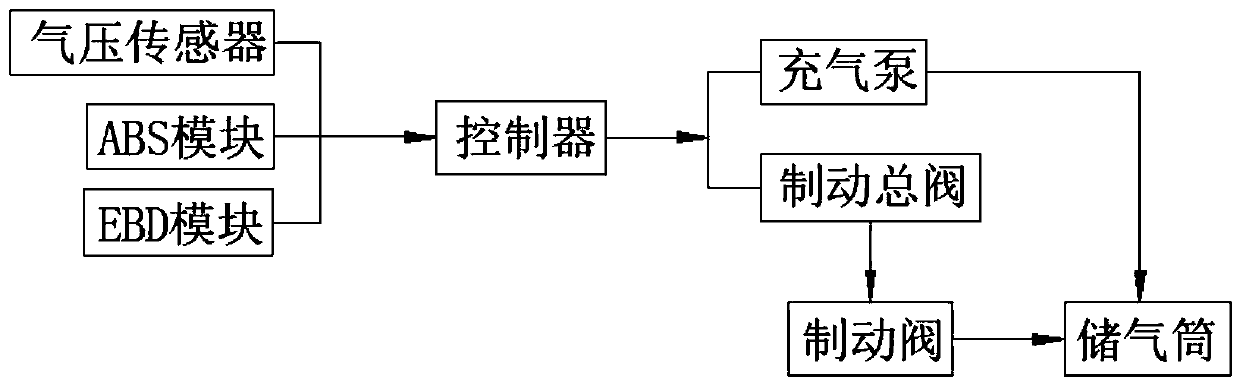

[0034] refer to Figure 1-6 , an intelligent braking system for large trucks, comprising a front 1 and a rear hanger 2, the top of the rear hanger 2 is fixedly connected with a plurality of installation blocks 22 to facilitate the installation of the carriage, and the installation block 22 is provided with an installation port to facilitate the fixing of the carriage. The bottom of the hanger 2 is provided with a cavity 3 for setting control elements. The cavity 3 is provided with an air pressure sensor 4, an ABS module 5, an EBD module 6, a controller 7, an air pump 8, a brake master valve 9, and a control system in sequence. The movable valve 10 and the air storage tank 11, the controller 7 is a PLC controller, which enhances the signal processing capability of the controller 7, and the model of the air pressure sensor 4 is MS5607B, which enhances the sensitivity of the air pressure sensor 4;

[0035] In the present invention, the main brake valve 9 includes a front brake ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com