Speed hierarchical control device and method for front roller way of finish rolling flying shear

A speed grading and control method technology, applied in rolling mill control devices, mass flow control devices, metal rolling, etc., can solve problems such as lower production efficiency, long running time at low speed, and affect rolling rhythm, etc., to improve production efficiency, Improve the rolling rhythm, the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

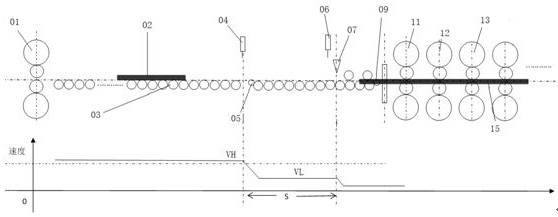

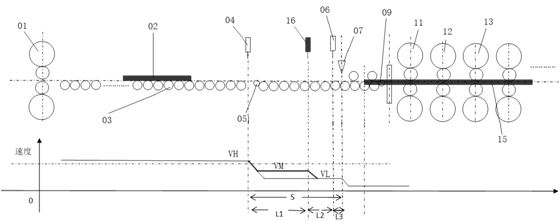

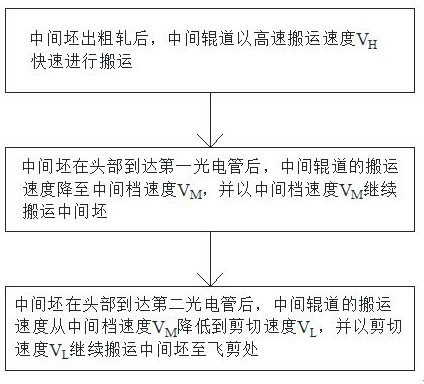

[0041] Apply the present invention to a steel production line, after the intermediate billet 02 is out of the rough rolling 01, the intermediate roller table 03 is transported at a high speed V of 4.5m / s H Fast handling, the shearing speed of flying shear 07 is 1m / s. The head of the intermediate billet 02 is switched to the intermediate speed V at the intermediate roller table 03 before the first speed measuring roller 05 M , where V L ≤V M ≤V limit H , in this embodiment, the intermediate limit speed V limit Take the value of 3m / s, go to the newly added second photoelectric detection device 16, switch to the low shear velocity V L , which not only shortens the running time of the intermediate billet 02, but also ensures the low-speed shearing of the flying shear 7 without affecting the shearing accuracy.

[0042] Increase the intermediate gear speed V M (1m / sM M =L1 / (T0-L2 / V L -L3 / V L ) calculation, as shown in Table 1:

[0043] Table 1 Intermediate gear speed V M C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com