A control method, device and system for wet leveling liquid entering and exiting a liquid supply tank

A technology of wet leveling liquid and control system, which is applied in the direction of rolling mill control device, mass flow control device, workpiece lubrication device, etc., and can solve the problem of low stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to make the above objects, features and advantages of the present application more obvious and comprehensible, the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

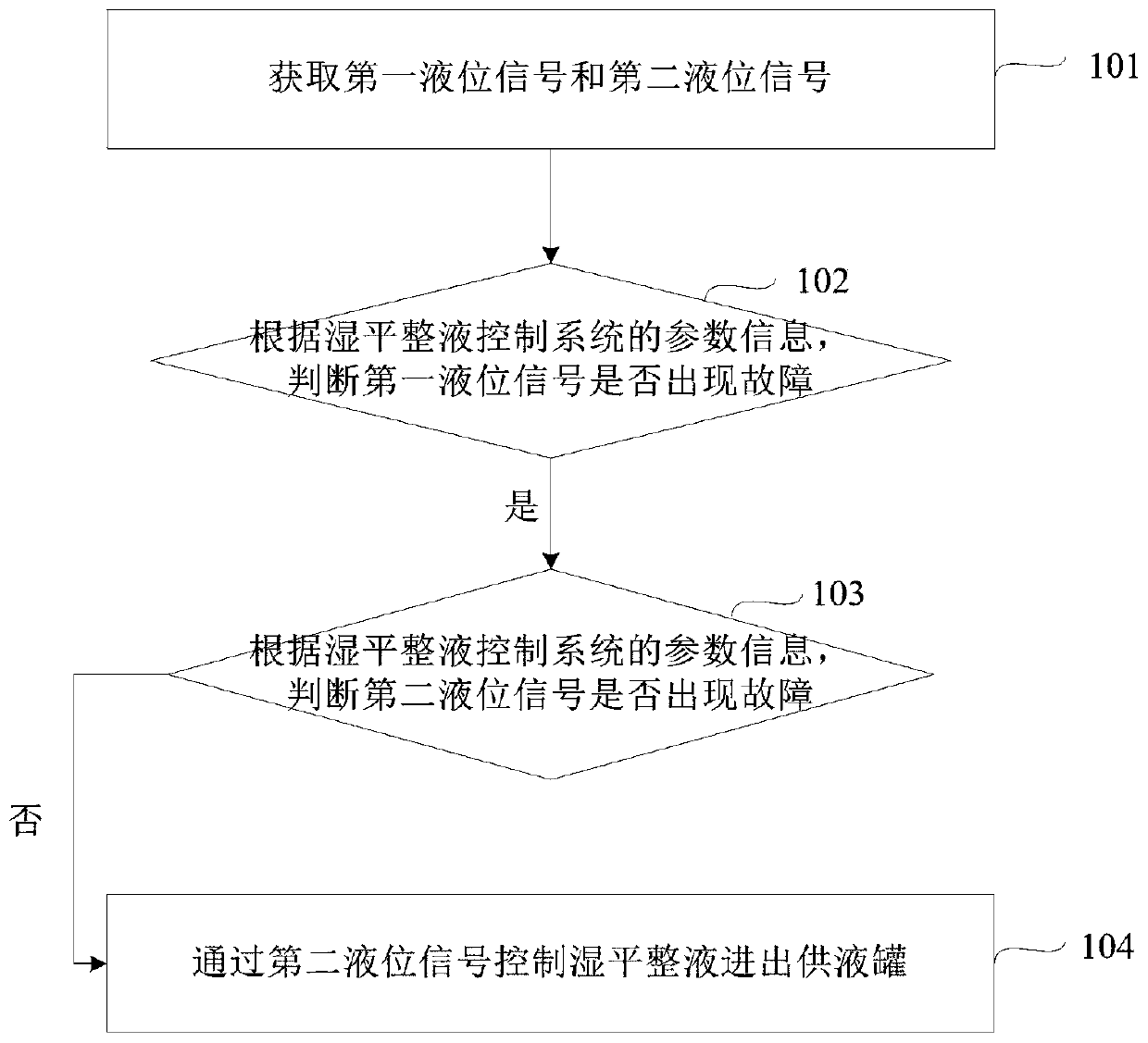

[0068] In order to solve the problem of low stability of the existing wet leveling liquid control method, the present application provides a control method, device and system for wet leveling liquid entering and exiting a liquid supply tank.

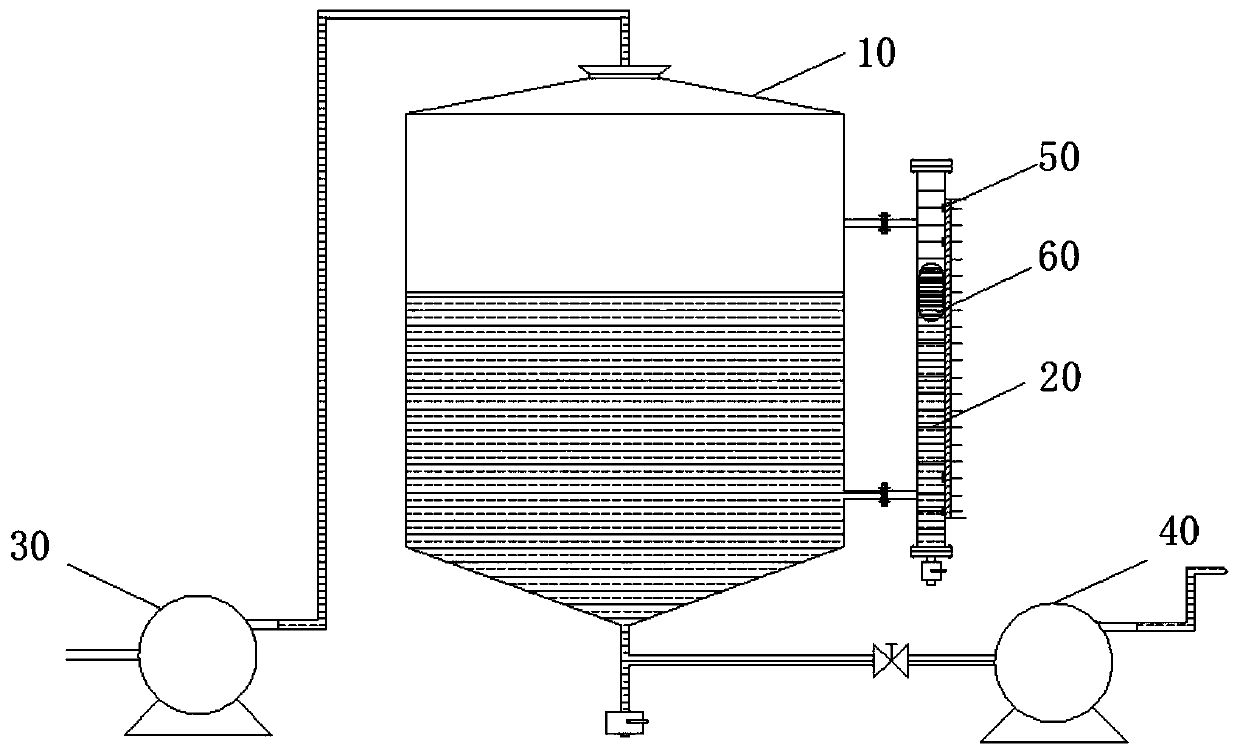

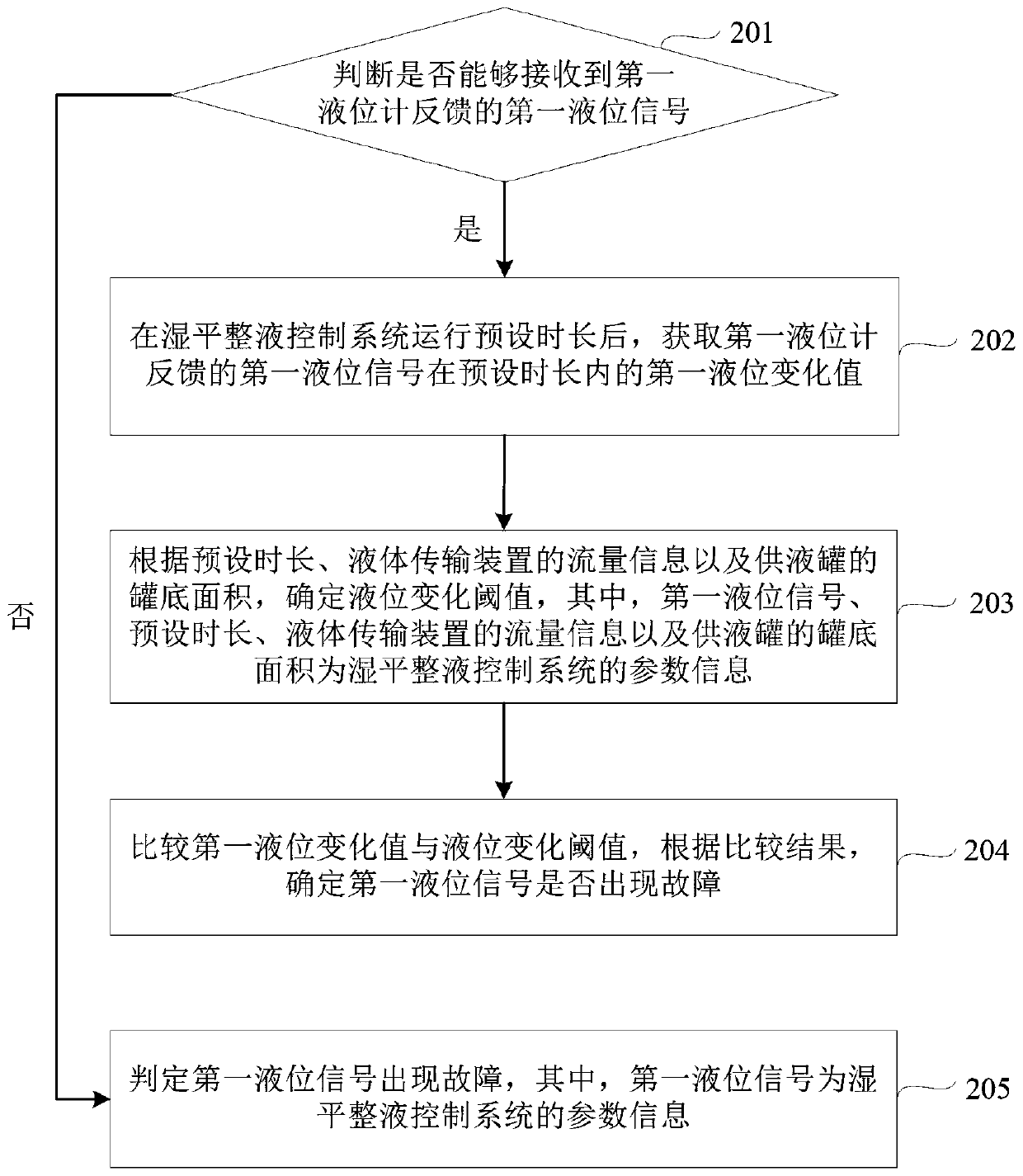

[0069] The first embodiment of the present invention discloses a method for controlling the entry and exit of wet leveling liquid into and out of the liquid supply tank. This method is applied to a controller, and the controller is set in a wet leveling liquid control system. The wet leveling liquid control system also includes a first A level gauge and a second level gauge.

[0070] In this embodiment, the controller is configured to receive a liquid level signal,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com