Method and casting/rolling system for casting and rolling a continuous strand material

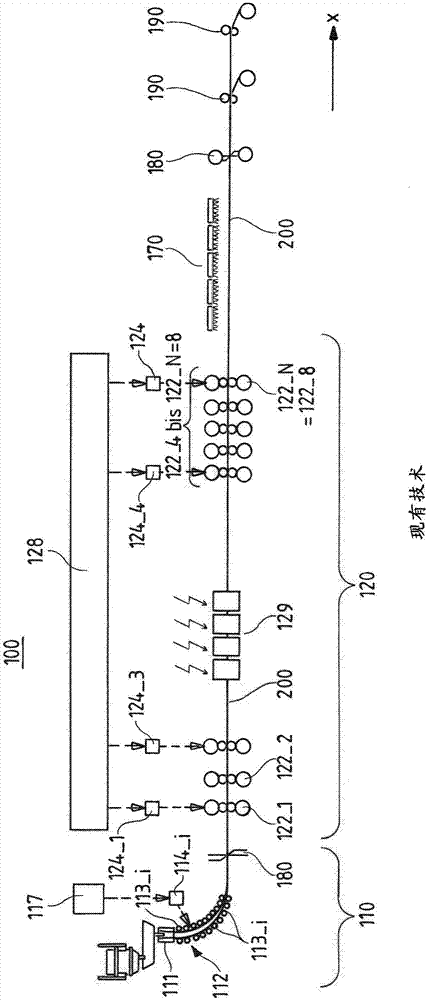

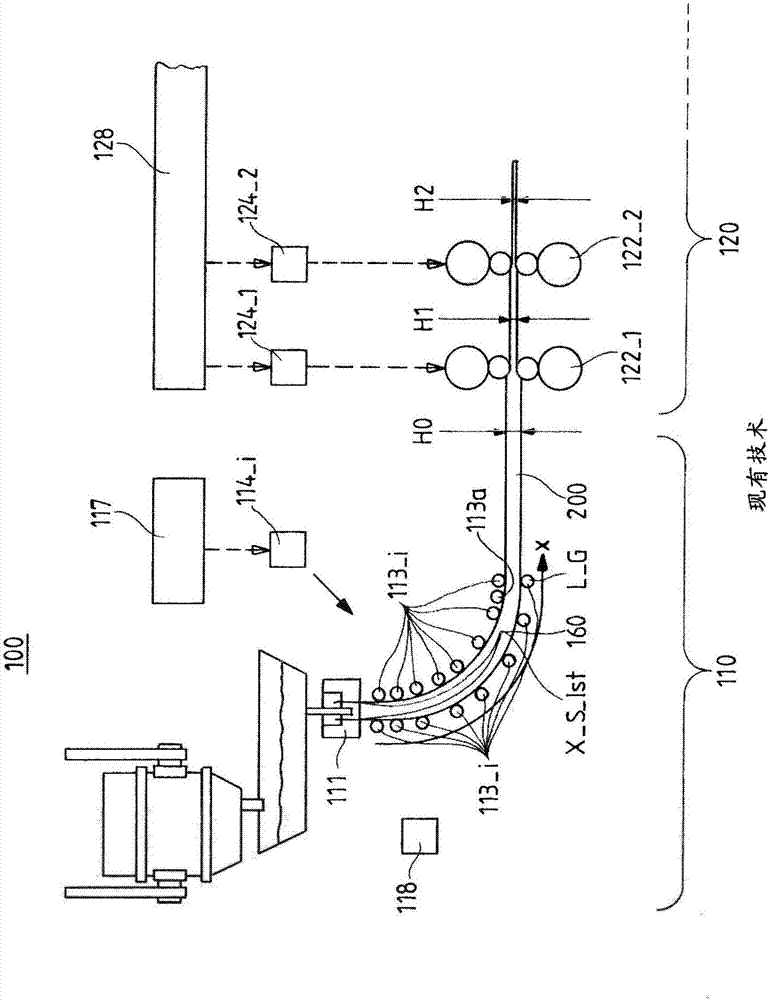

A technology for rolling equipment and continuous casting billets, which is applied to driving devices for metal rolling mills, metal rolling, metal rolling, etc., and can solve the problems of not proposing detailed implementation plans for technical teaching, disadvantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

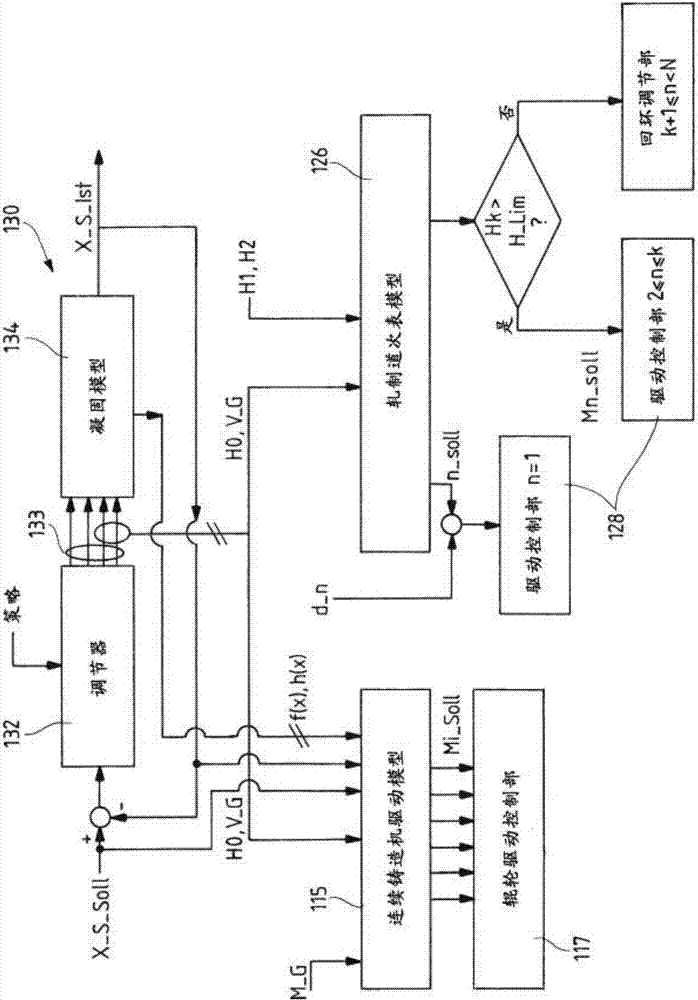

[0040] Refer to the following in the form of an embodiment Figures 3 to 6 The present invention is described in detail.

[0041] image 3 A diagram according to the invention for actuating drives in a continuous casting machine 110 and in a rolling train 120 is shown. The starting point of the solution according to the invention is the control circuit 130 for setting the position of the wick tip to a predetermined setpoint position X_S_Soll within the slab guide 112 . The target position X_S_Soll corresponds to the predetermined position of the path component x. The wick tip control circuit 130 is designed to simulate or theoretically calculate the respective current actual position of the wick tip 130 with the aid of a solidification model 134 , which forms a control section of the wick tip control circuit 130 . The thus determined actual position X_S_Ist is compared with a predetermined target position X_S_Soll and a deviation which may be determined during the compariso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com