Method for realizing flow per second balance among hot rolling continuous mill stands through rolling mill speed compensation

A technology of speed compensation and hot continuous rolling mill, which is applied in the direction of mass flow control device, roll speed control, metal rolling, etc., can solve the problem of unbalanced amount of sleeves, etc., so as to reduce the number of large or unavailable sleeves and improve the The effect of rolling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

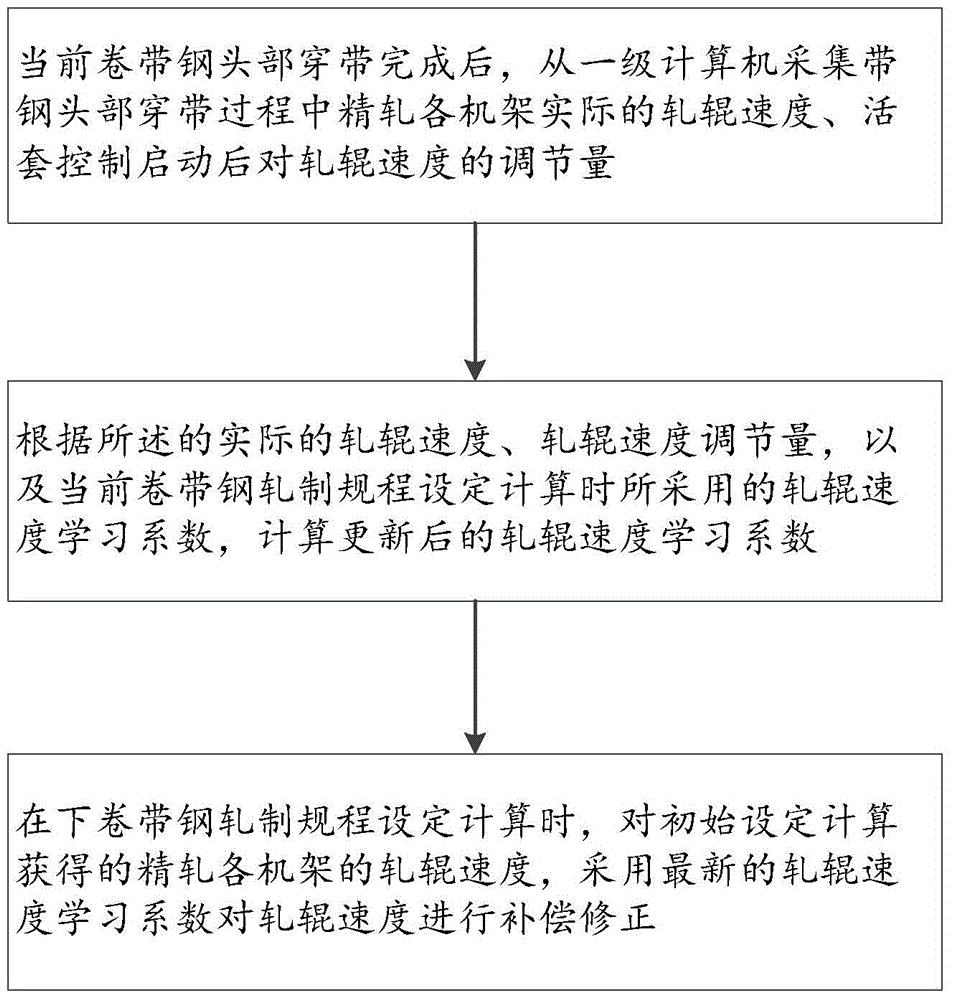

[0031] A method for realizing second flow balance between hot continuous rolling stands by rolling mill speed compensation, comprising the following steps:

[0032] S1. Acquisition of actual rolling data: after the threading of the head of the current coil is completed, the actual roll speed of each stand during the finishing rolling process of the head of the strip is collected from the first-level computer, and the speed of the roll after the looper control is started the amount of regulation;

[0033] After the strip head threading is completed, collect all kinds of actual rolling data from the first-level computer, including the roll speed of each stand Roll speed adjustment Δv required for looper control i , where i is the finishing stand number;

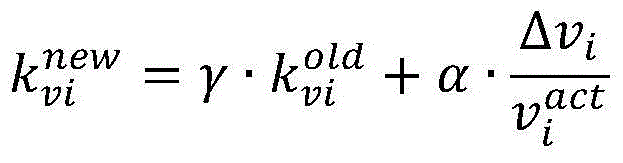

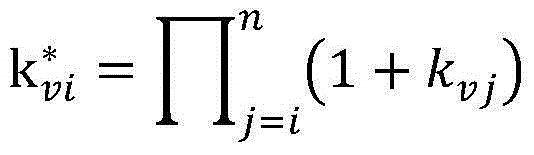

[0034] S2. Calculate the updated roll speed learning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com