A Comprehensive Optimization Method of Emulsion Flow for Ultra-Thin Strip Rolling in Cold Tandem Mill

A technology of cold tandem rolling unit and emulsion, which is applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., and can solve the problems of self-excited vibration of ultra-thin strip rolling mill and optimization setting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

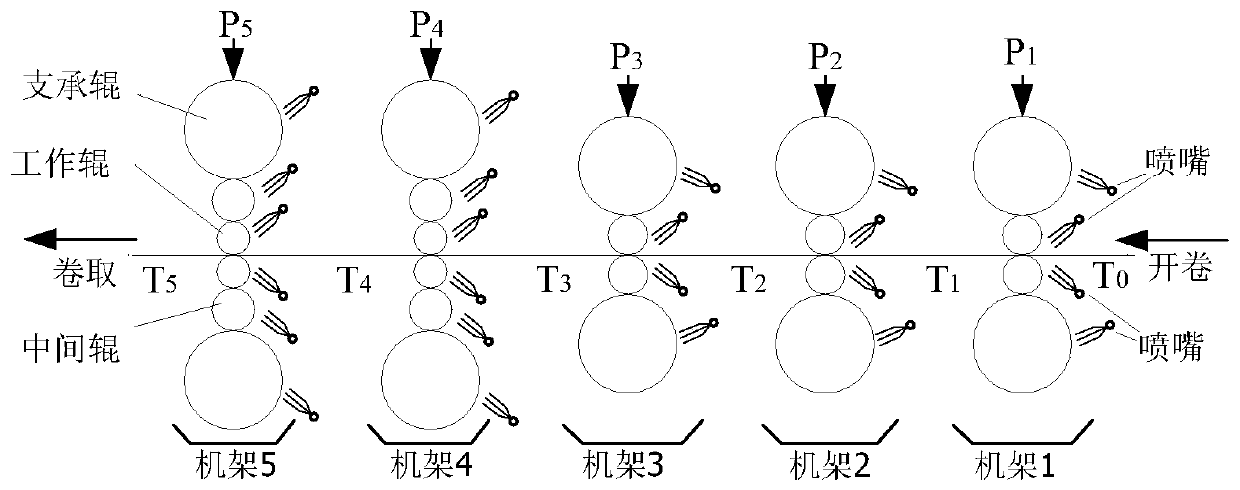

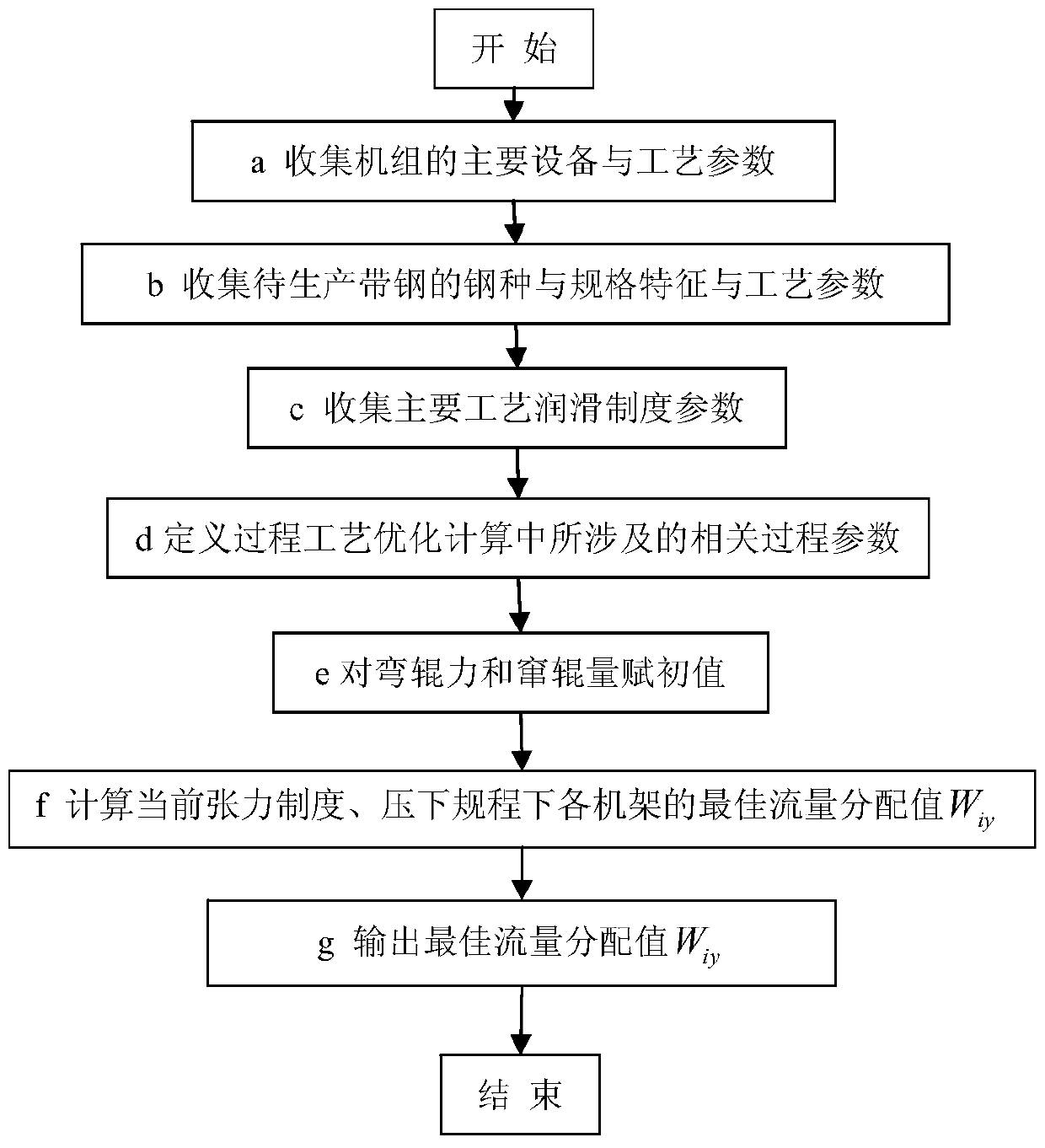

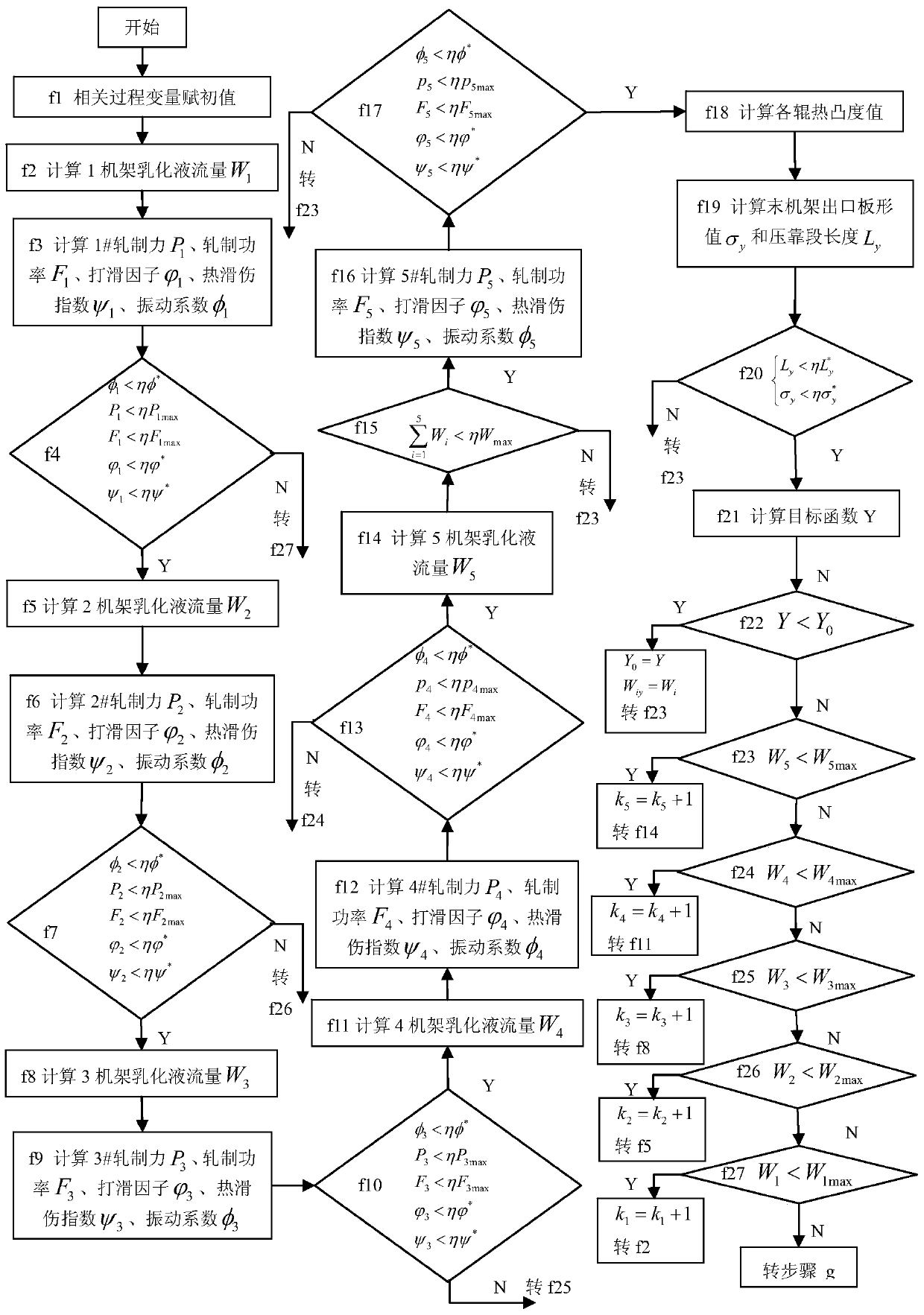

[0075] figure 2 It is an embodiment of the comprehensive optimization method for the emulsion flow rate of the ultra-thin strip steel rolling of the cold tandem rolling mill of the present invention. In order to further illustrate the application process of the related technology described in the present invention, a 3+2 five-stand model is introduced in detail. The setting process of the comprehensive optimization method for the emulsion flow in the ultra-thin strip rolling process of the cold tandem mill. In this embodiment, the 1420 five-stand 3+2 five-stand tandem cold rolling mill is taken as an example, and a typical specification of T4 material is taken as an example, wherein the strip inlet parameter is MRT-4CA966×2.02mm, and the thickness of the finished strip is 0.18mm.

[0076] exist figure 2 In the shown control flow chart, the emulsion flow comprehensive optimization method of the present invention comprises the following steps:

[0077] In step (a), the main...

Embodiment 2

[0173] In this embodiment, a typical specification of T5 material is taken as an example, wherein the strip inlet parameter is MRT-5CA 988×2.0mm, and the finished strip thickness is 0.18mm.

[0174] In step (a), the main equipment parameters and process characteristic parameters of the five-stand tandem cold rolling mill are collected:

[0175] (a1) Collect the equipment parameters of the 3+2 type five-stand cold tandem rolling mill, in the present embodiment:

[0176] Work roll diameter D of frame 1-5 iw ={476.84,480.86,463.06,399.33,406.86}mm,

[0177] Rack 4-5 middle roll diameter D im ={510.46,508.92}mm,

[0178] Frame 1-5 support roller diameter D ib ={1241.43,1179.48,1176.12,1241.3,1241.3}mm,

[0179] Rack 1-3 work roll profile distribution value

[0180] ΔD wij = {-78.181, -18.329, 25.474, 54.963, 71.867, 77.927, 4.853,

[0181] 64.399, 48.292, 8.258, 6.035, -16.647, -38.056, -56.459, (unit μm),

[0182] -70.125, -77.321, -76.315, -65.376, -42.77, -6.767, 44.367}...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com