Hot-rolled H-shaped steel and production method thereof

A production method and technology for H-beams, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of flange surface wave or web surface wave defect, side bending, non-disclosure, etc., and meet product specifications A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

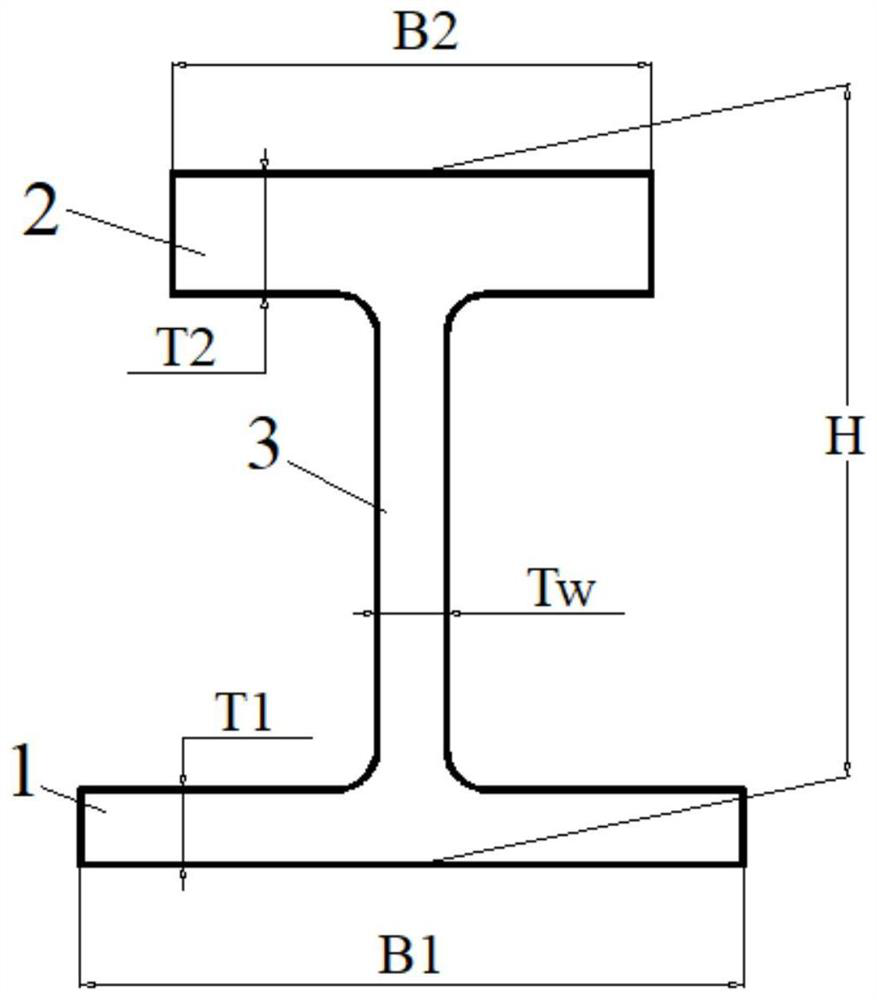

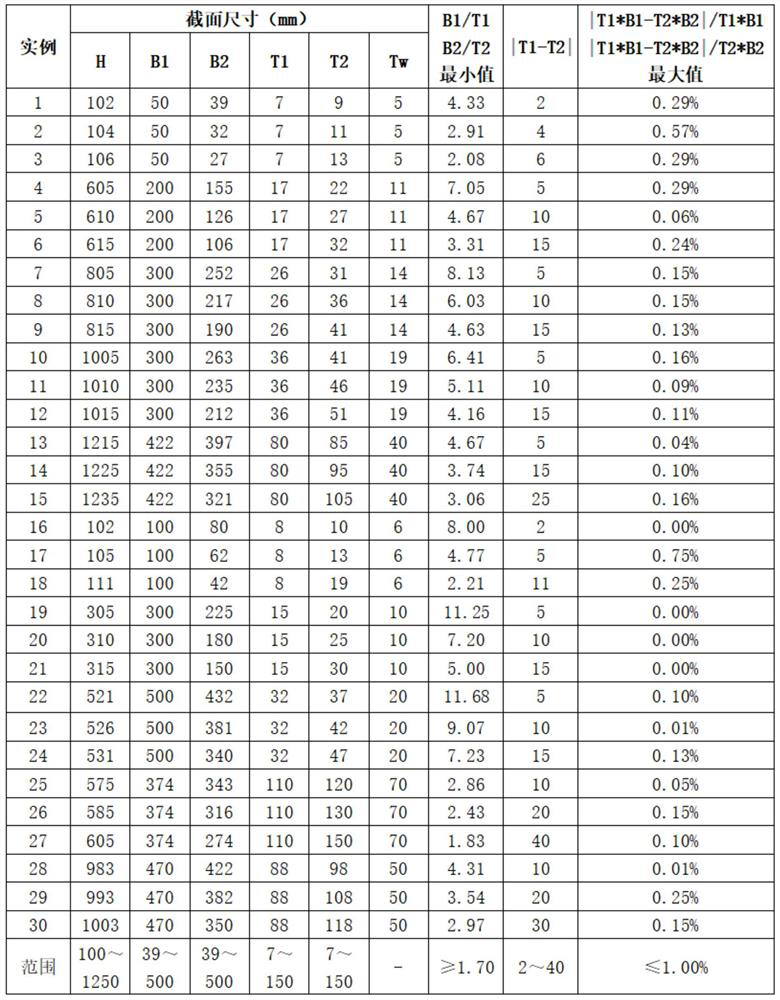

[0049] As shown in Table 1, the web height H is 102 mm, the width B1 of the first flange plate 1 is 50 mm, the width B2 of the second flange plate 2 is 39 mm, and the thickness T1 of the first flange plate 1 is 7 mm. The thickness T2 of the second flange plate 2 is 9mm, the web thickness Tw is 5mm, |T1-T2|=2mm, |T1*B1-T2*B2| / T1*B1 and |T1*B1-T2*B2| / The maximum value of both T2*B2 is 0.29.

Embodiment 2

[0051] As shown in Table 1, the web height H is 104 mm, the width B1 of the first flange plate 1 is 50 mm, the width B2 of the second flange plate 2 is 32 mm, and the thickness T1 of the first flange plate 1 is 7 mm. The thickness T2 of the second flange plate 2 is 11mm, the web thickness Tw is 5mm, |T1-T2|=2.91mm, |T1*B1-T2*B2| / T1*B1 and |T1*B1-T2*B2| / T2*B2 The maximum of the two is 0.57.

Embodiment 3

[0053] As shown in Table 1, the web height H is 106 mm, the width B1 of the first flange plate 1 is 50 mm, the width B2 of the second flange plate 2 is 27 mm, and the thickness T1 of the first flange plate 1 is 7 mm. The thickness T2 of the second flange plate 2 is 13mm, the web thickness Tw is 5mm, |T1-T2|=2.08mm, |T1*B1-T2*B2| / T1*B1 and |T1*B1-T2*B2| / T2*B2 The maximum of the two is 0.29.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com