Patents

Literature

36results about How to "Avoid side bends" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

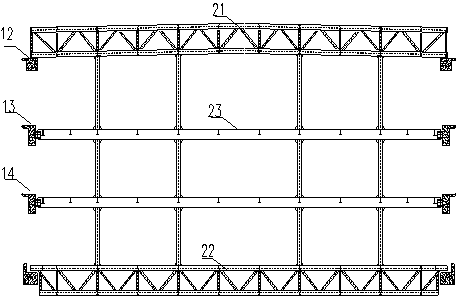

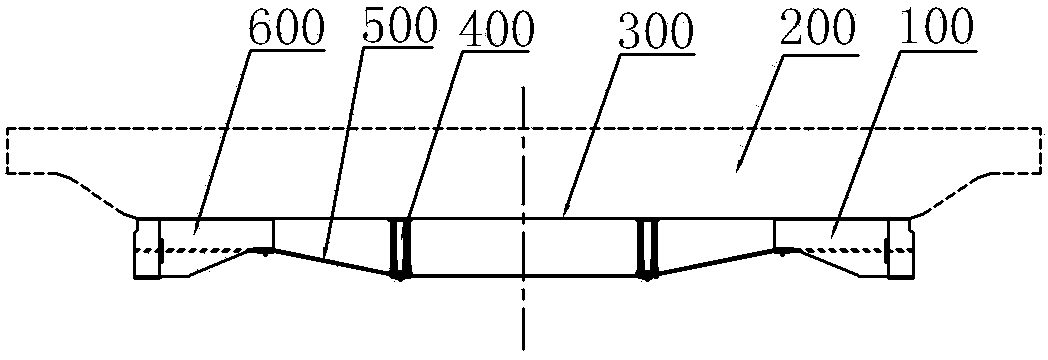

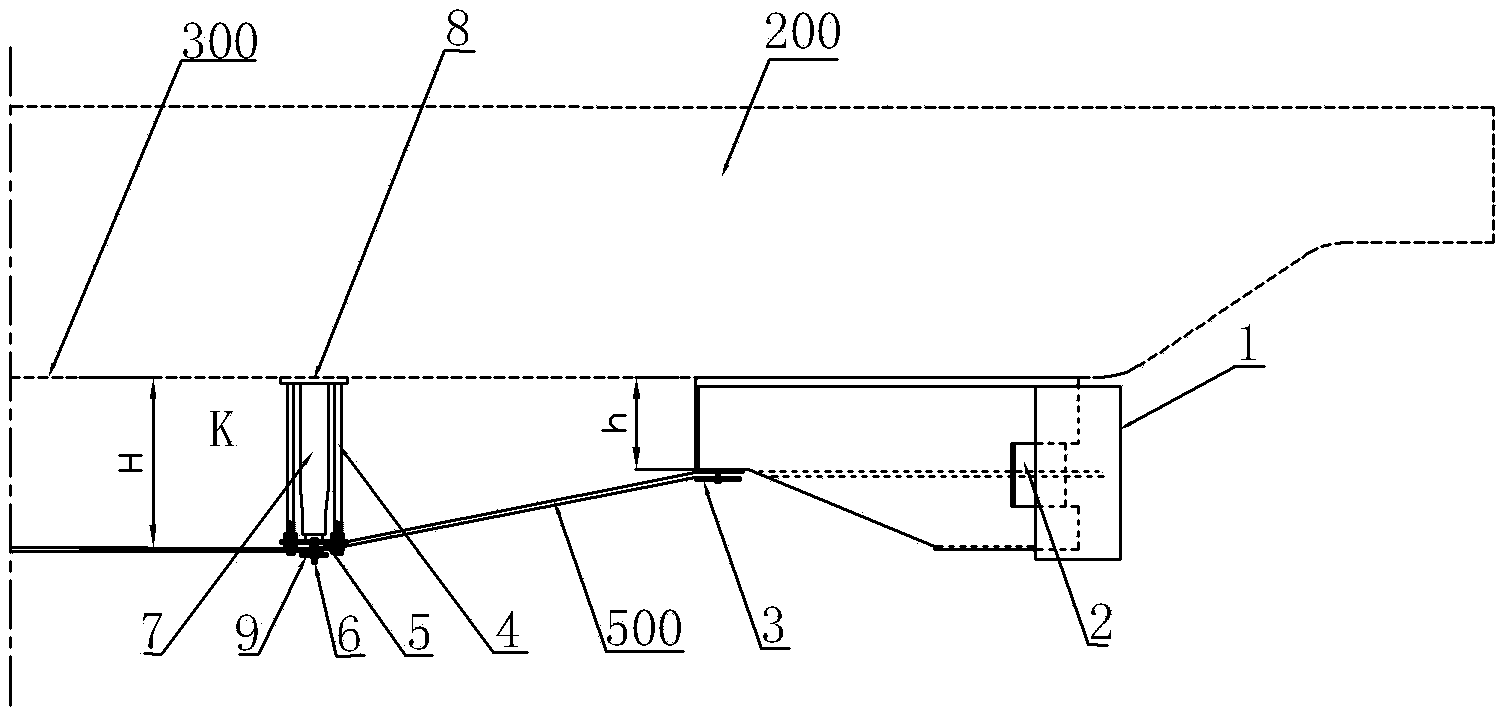

Extensible high-altitude conjoined steel structure

ActiveCN103835369AAvoid side bendsResolve Temporary Hold IssuesBuilding constructionsArchitectural engineeringEconomic benefits

The invention relates to construction facilities in building industry, in particular to an extensible high-altitude conjoined steel structure of a high-altitude large-span corridor steel structure frame and a reverse construction method of the extensible high-altitude conjoined steel structure set up on the high-altitude large-span corridor structure frame. The steel corridor structure is stable in structure and meets requirements of expansion and contraction after being heated and cooled, and safe and long-time use is realized really. Consequently, the extensible high-altitude conjoined steel structure has the advantages that the structure is simple and convenient in process, convenient in operation and free of space occupation, and quality of the structure is qualified in an acceptance check, so that repeated construction is avoided; mechanical cost is saved when compared with adoption of a large-tonnage crane, so that the structure has high economic benefit; the structure is low in noise, free of water pollution and waste gas pollution, few in lost and scattered solid waste and the like.

Owner:JIANGSU NANTONG NO 6 CONSTR GRP

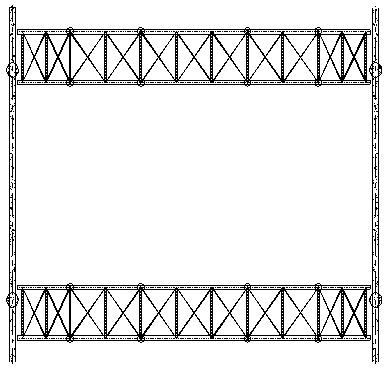

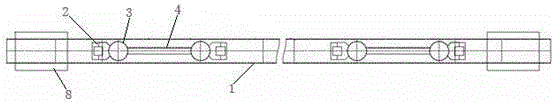

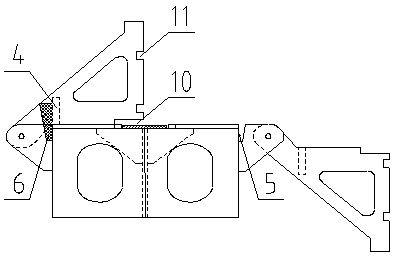

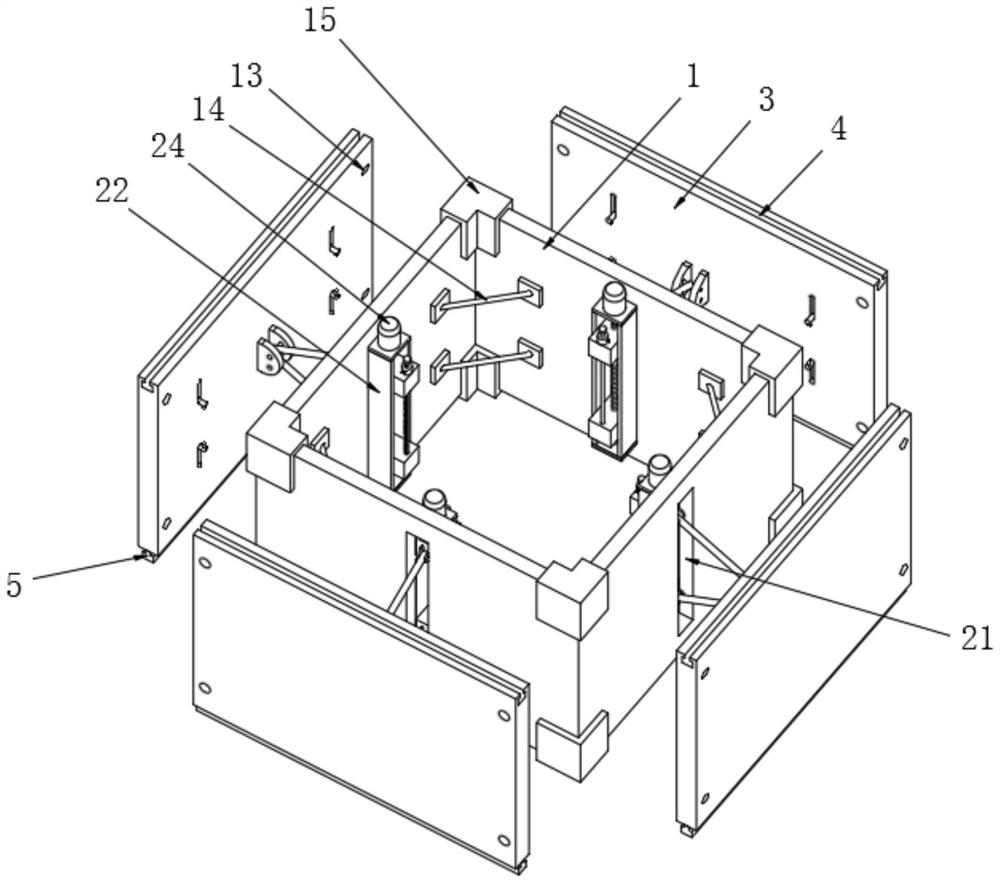

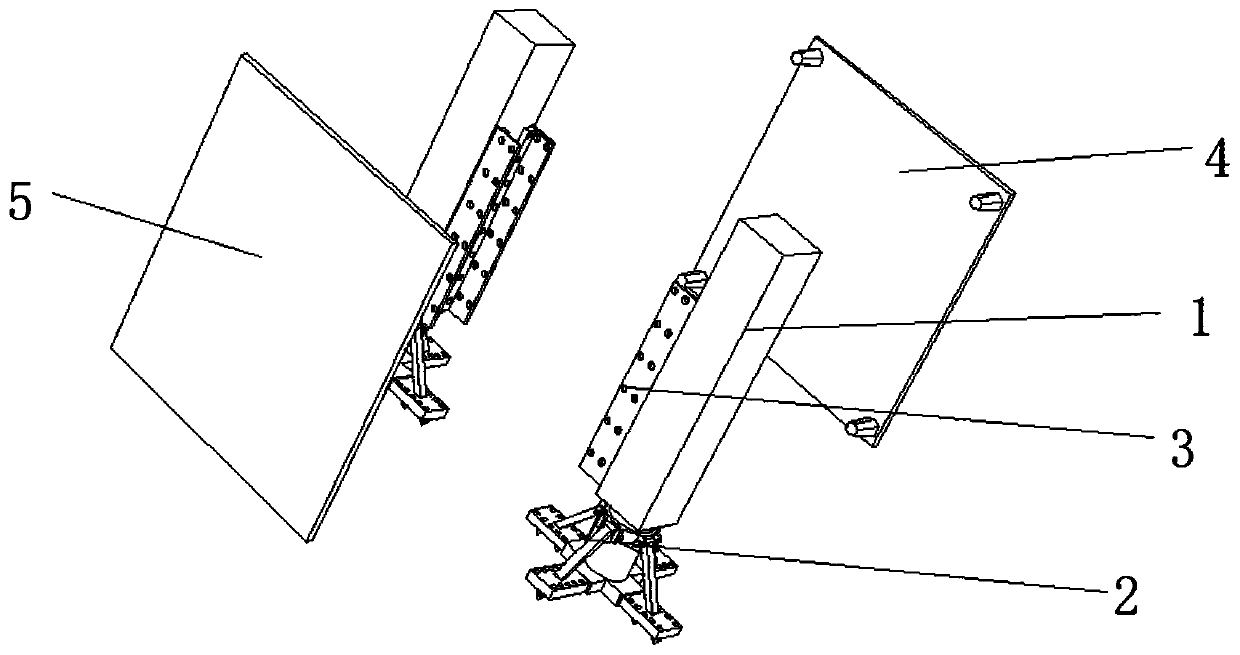

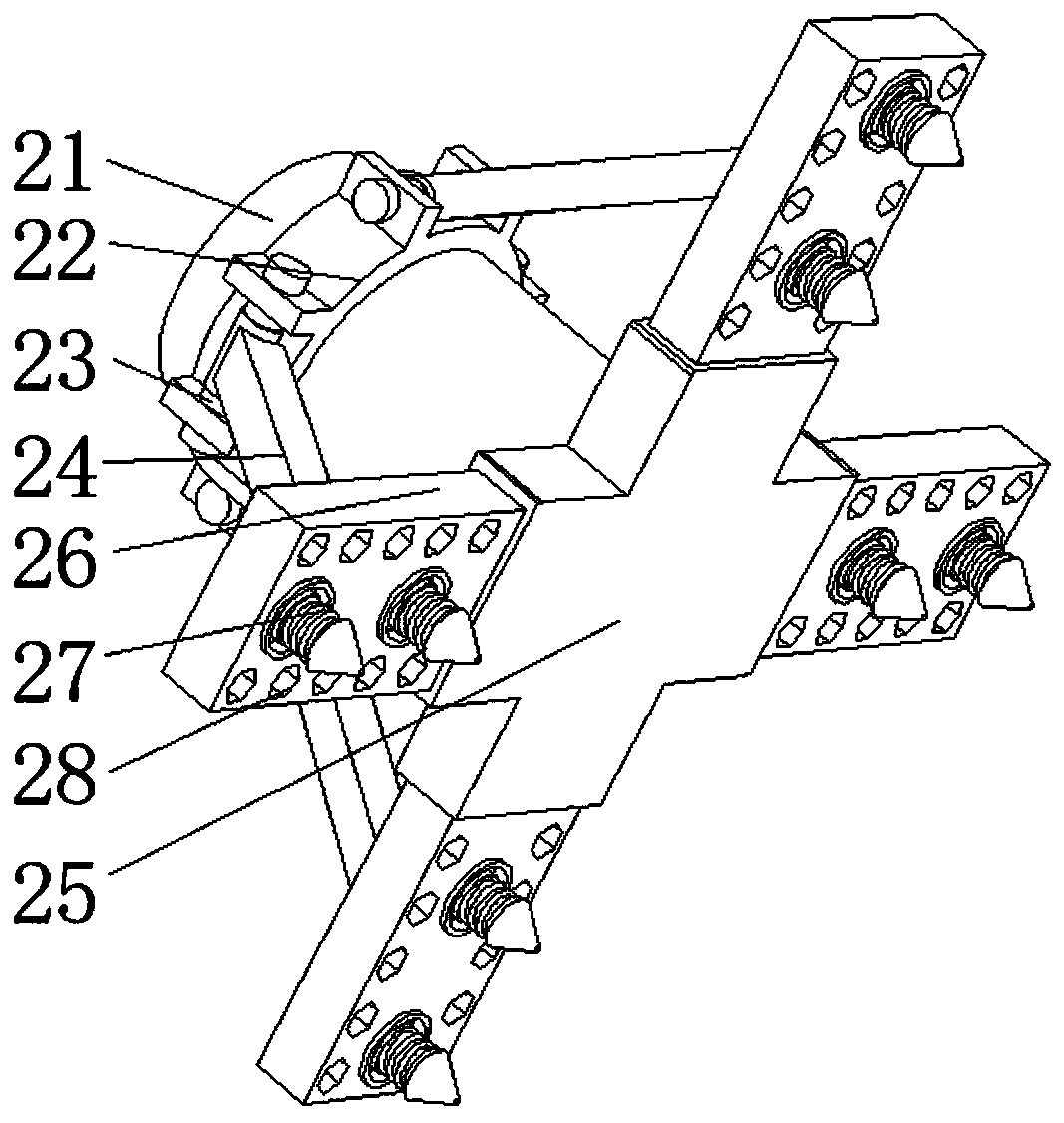

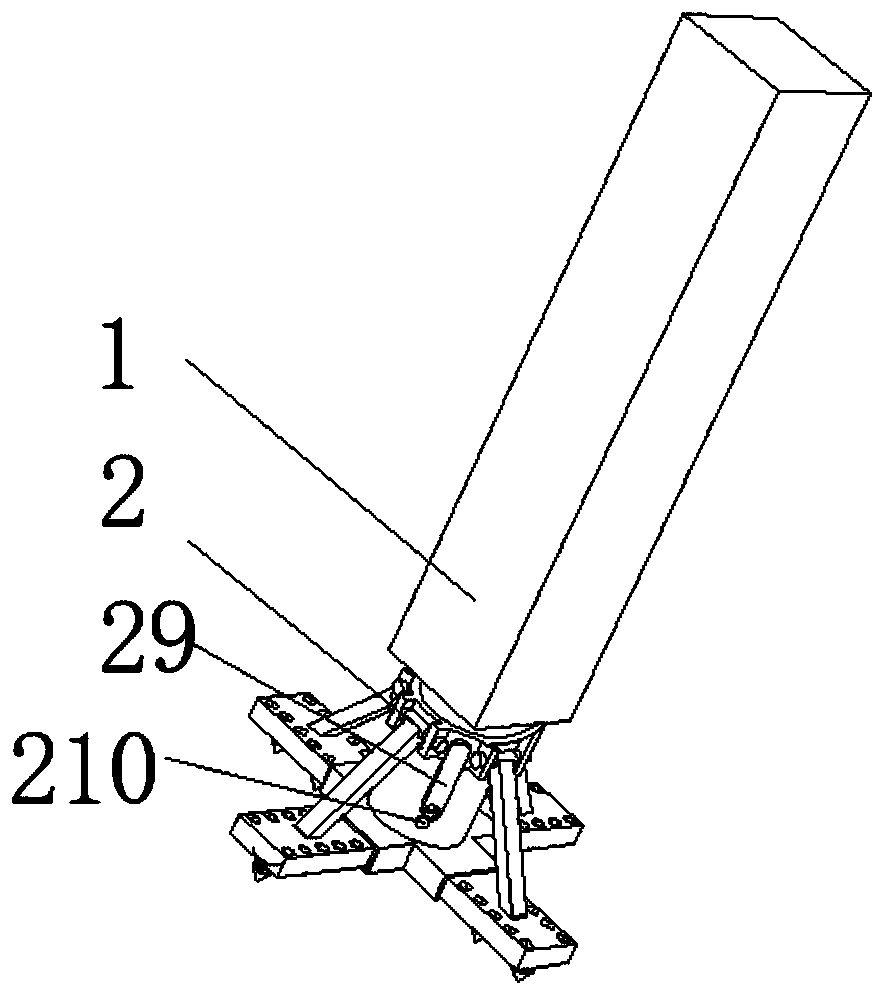

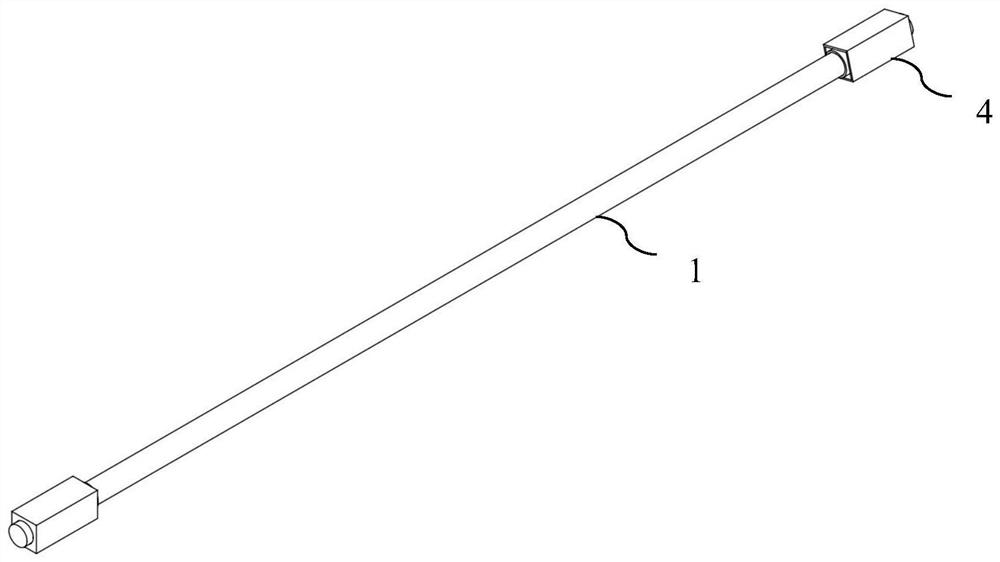

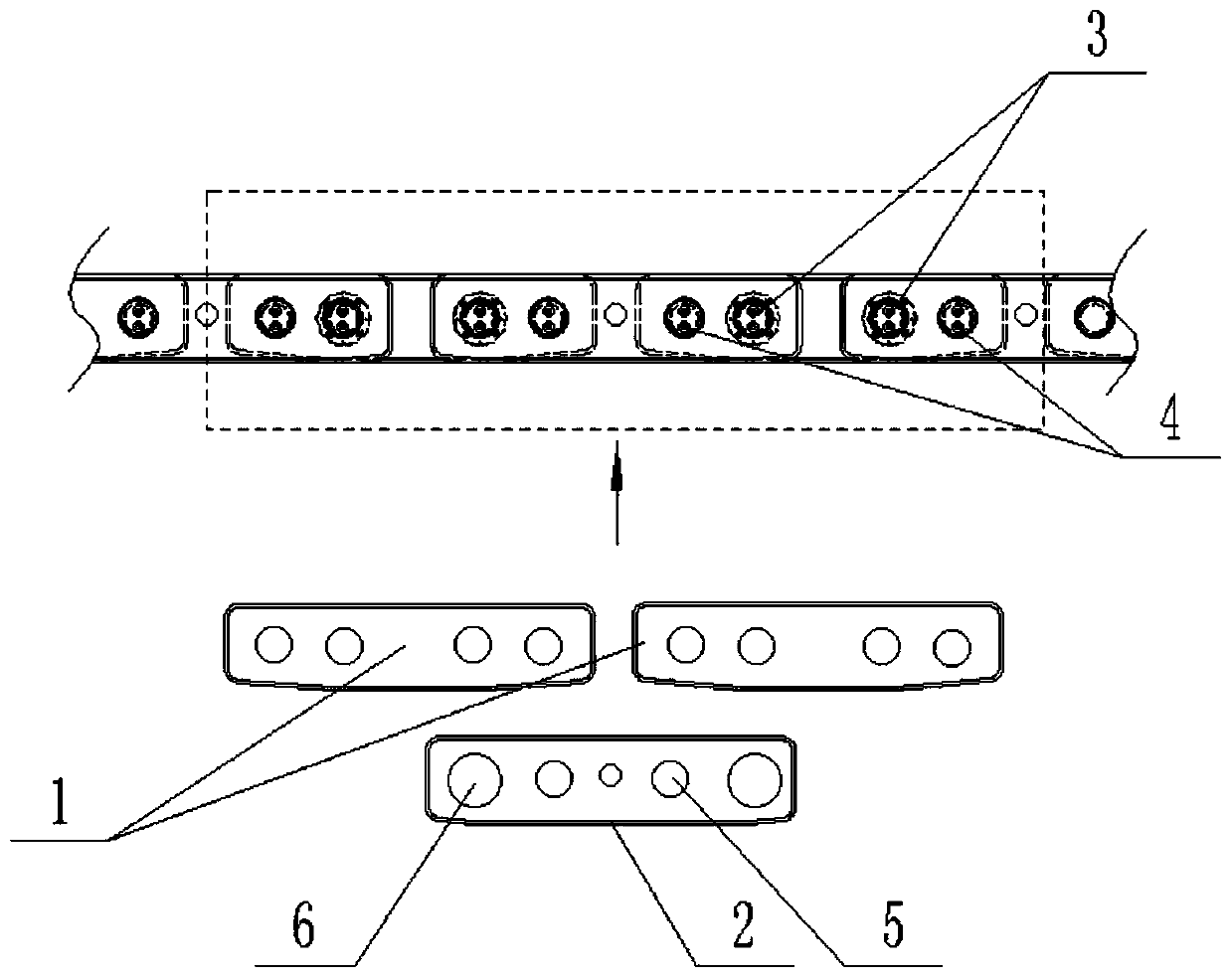

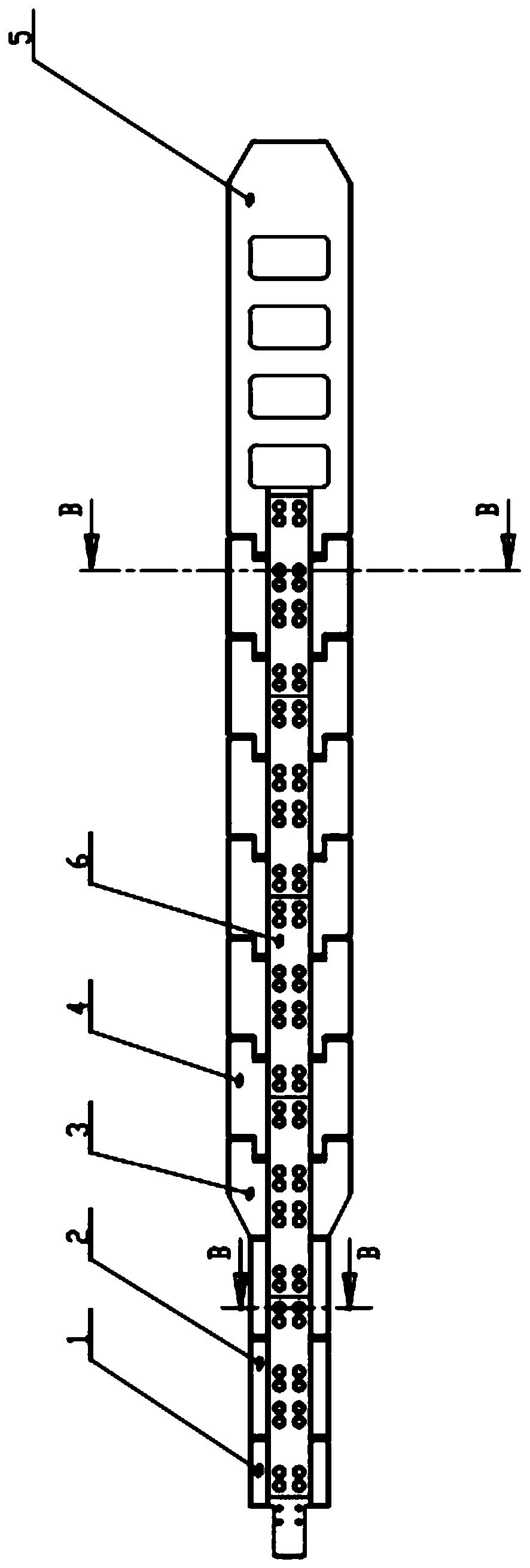

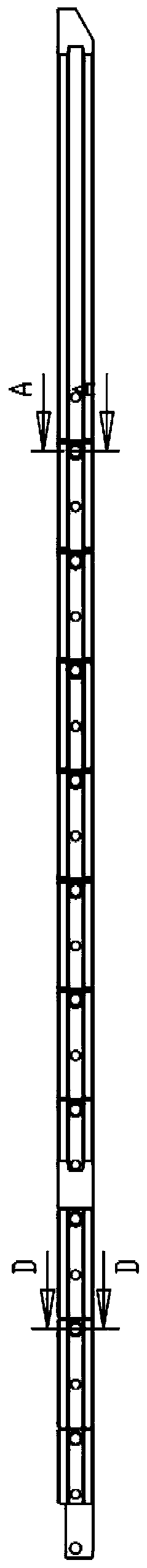

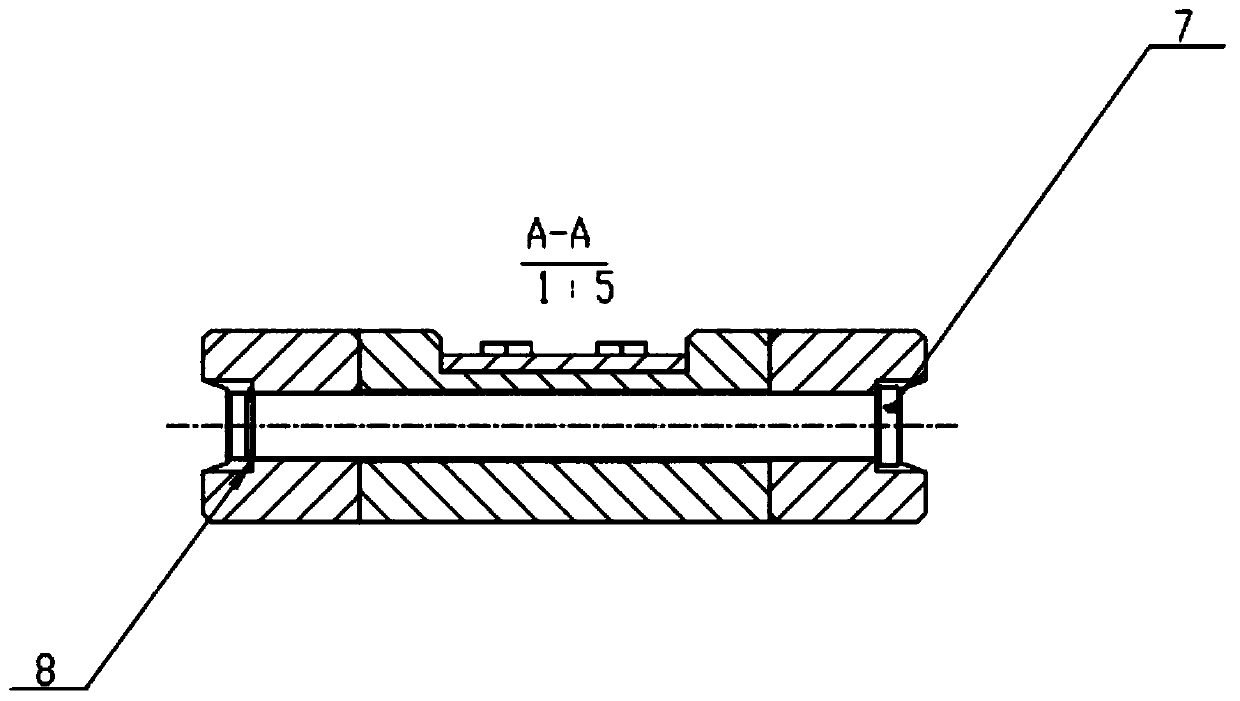

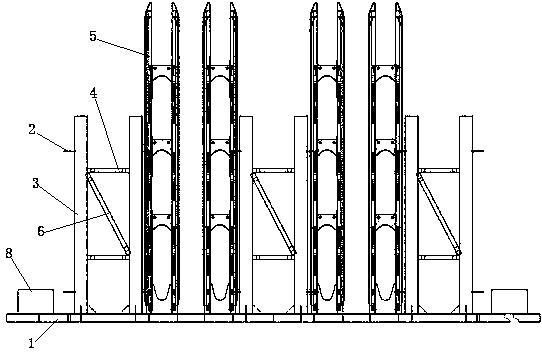

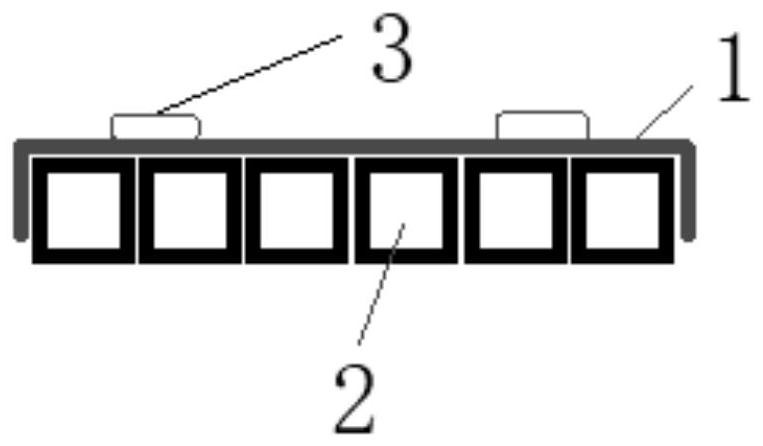

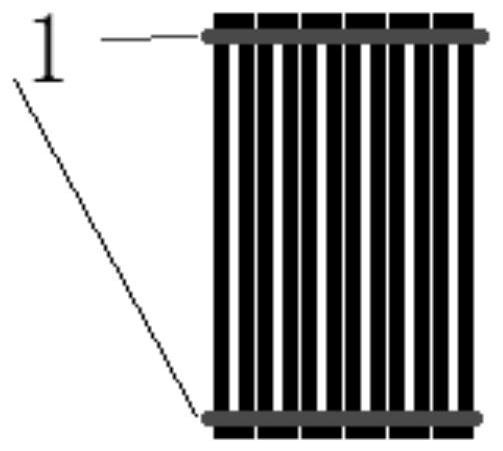

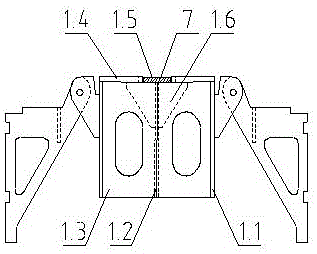

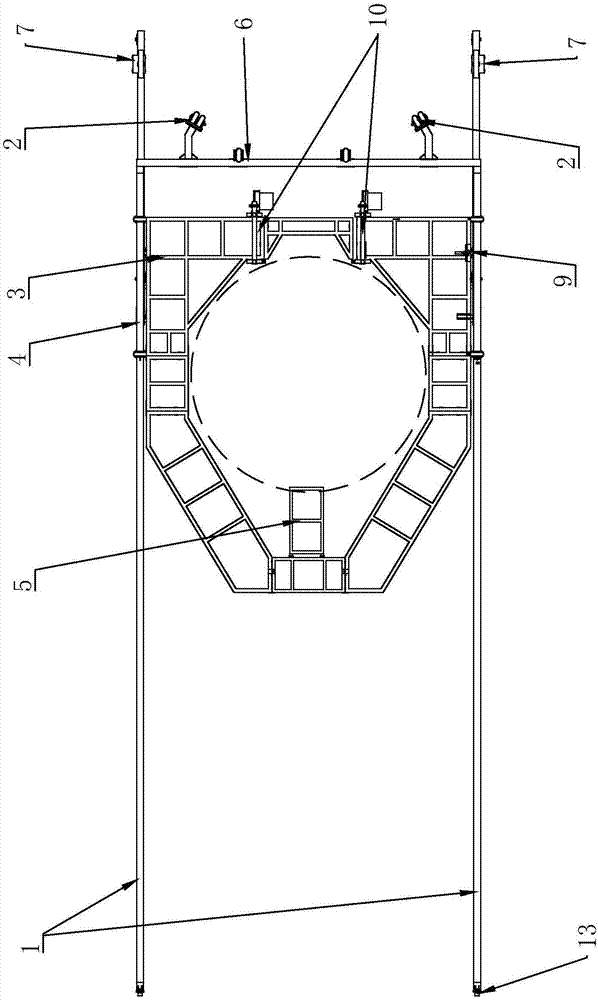

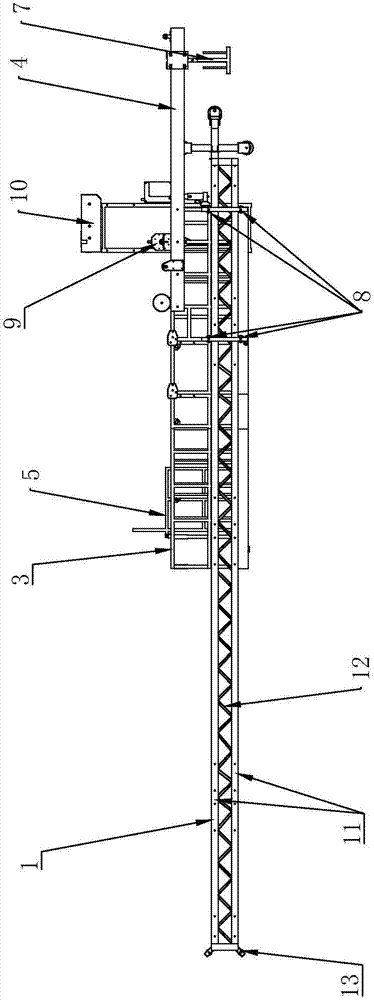

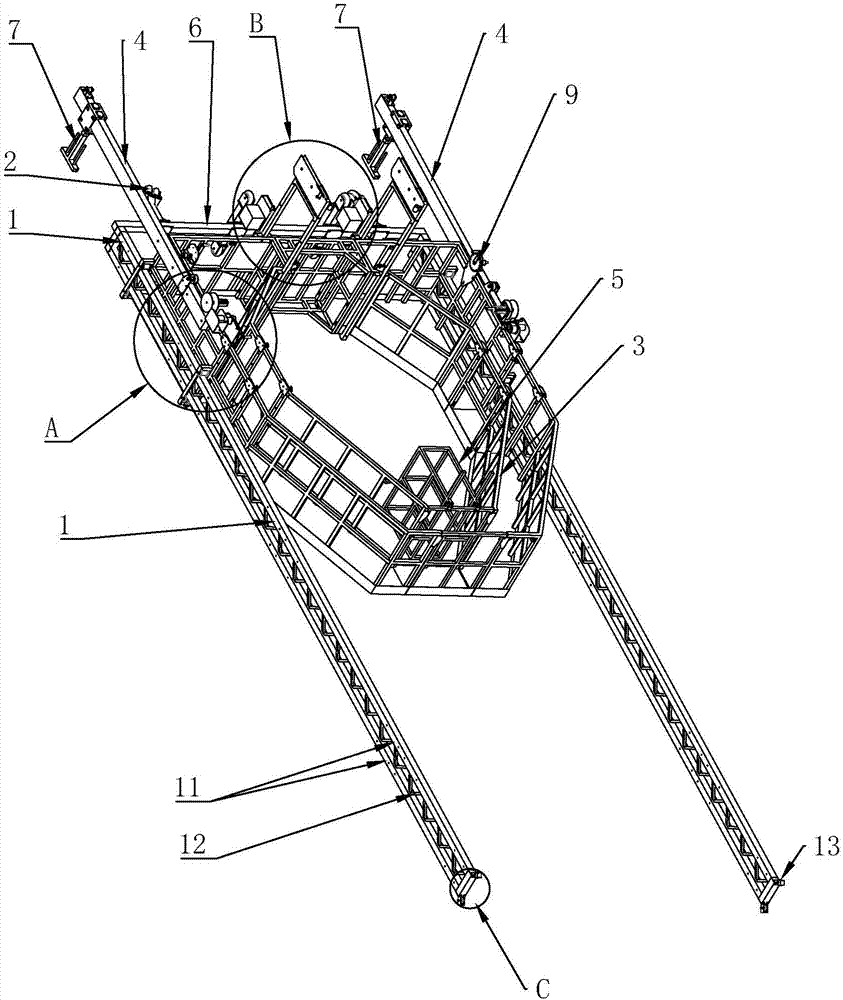

Vertical general assembly jig frame for container ship lashing bridge

ActiveCN105905261AReduce adjustment workloadSimple structureDry-dockingSlipwaysGeneral assemblyOn board

The invention relates to a vertical general assembly jig frame for a container ship lashing bridge. The vertical general assembly jig frame comprises a strip-shaped jig frame, a plurality of frame backers and a plurality of square tube fixing devices, wherein the strip-shaped jig frame is fixedly installed on a piece of embedded iron in a general assembly site; the plurality of frame backers are evenly distributed on the strip-shaped jig frame; each frame backer comprises two support rods and two connecting rods for connecting the two support rods, wherein the lower ends of the two support rods are fixedly installed at the upper end of the strip-shaped jig frame; each square tube fixing device is installed at the outer sides of the two corresponding support rods; the square tube fixing devices are used for fixing square tubes of the lashing bridge. The vertical general assembly jig frame is simple in structure, convenient in construction and short in general assembly period, and not only can greatly save the precious general assembly site, but also greatly reduces the on-board adjustment work load; furthermore, a turnover lifting lug is not needed during vertical general assembly, so that the strength of welding and grinding is greatly reduced; after the vertical general assembly jig frame is used, the process advancing aim of 'doing on-board operation after going ashore, and doing overhead operation at low altitude' is realized, the building period is shortened, and the working efficiency is increased.

Owner:CHINA SHIPPING IND JIANGSU

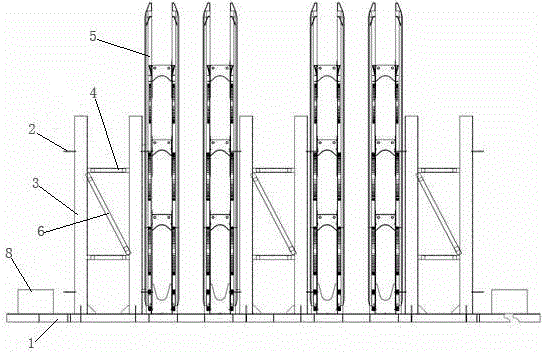

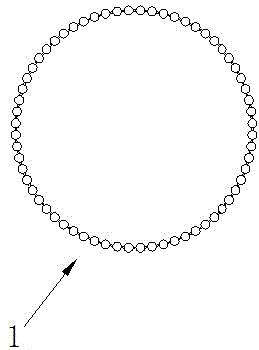

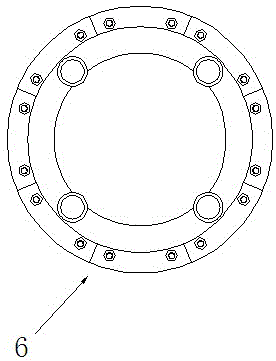

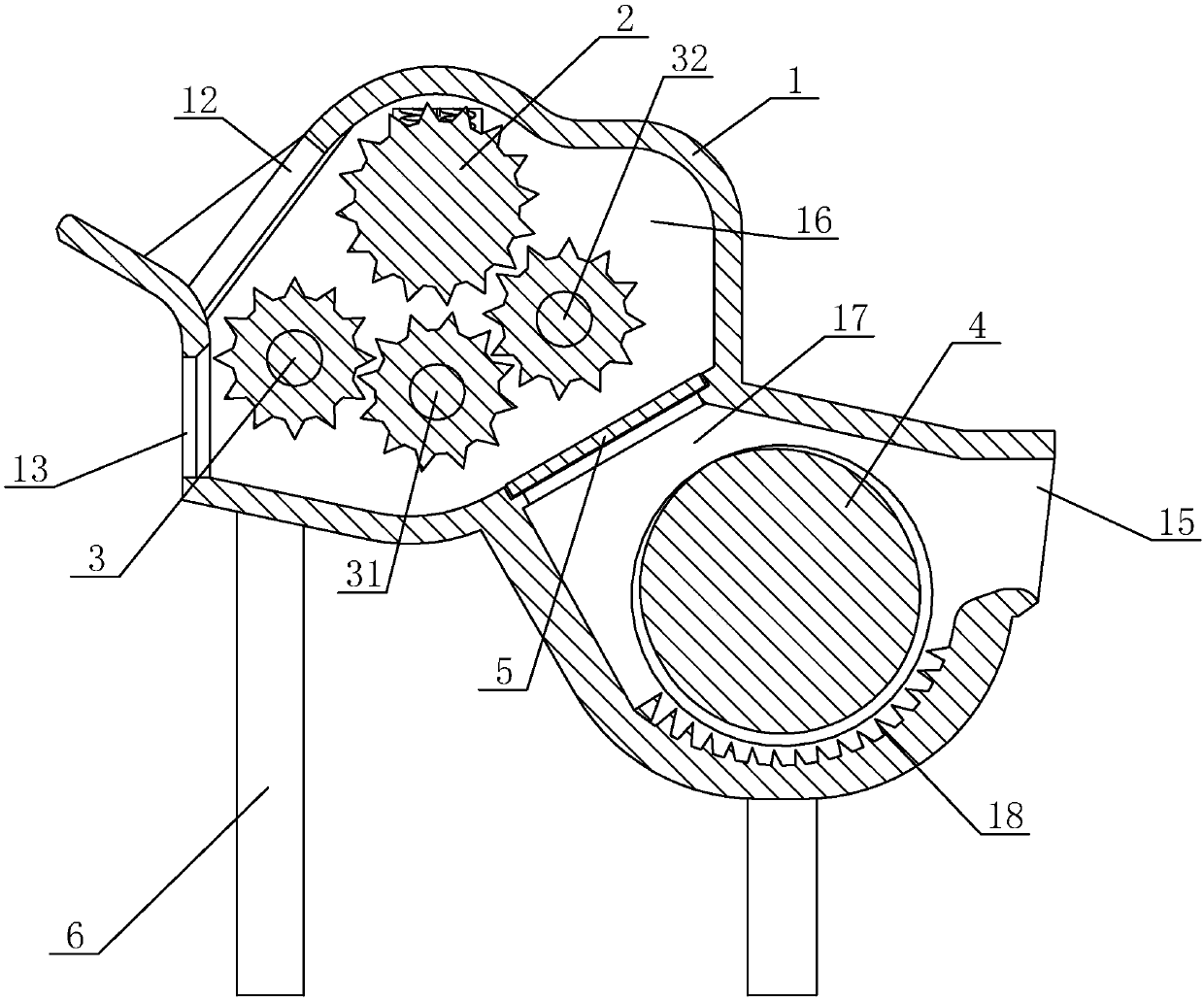

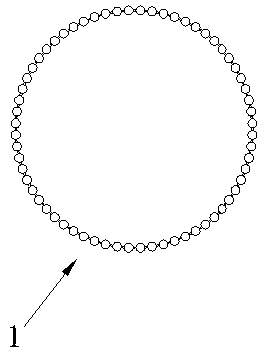

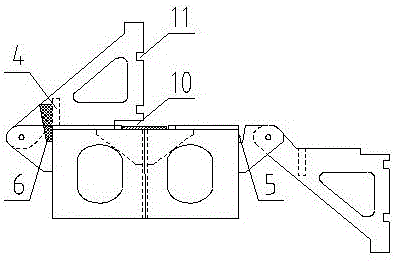

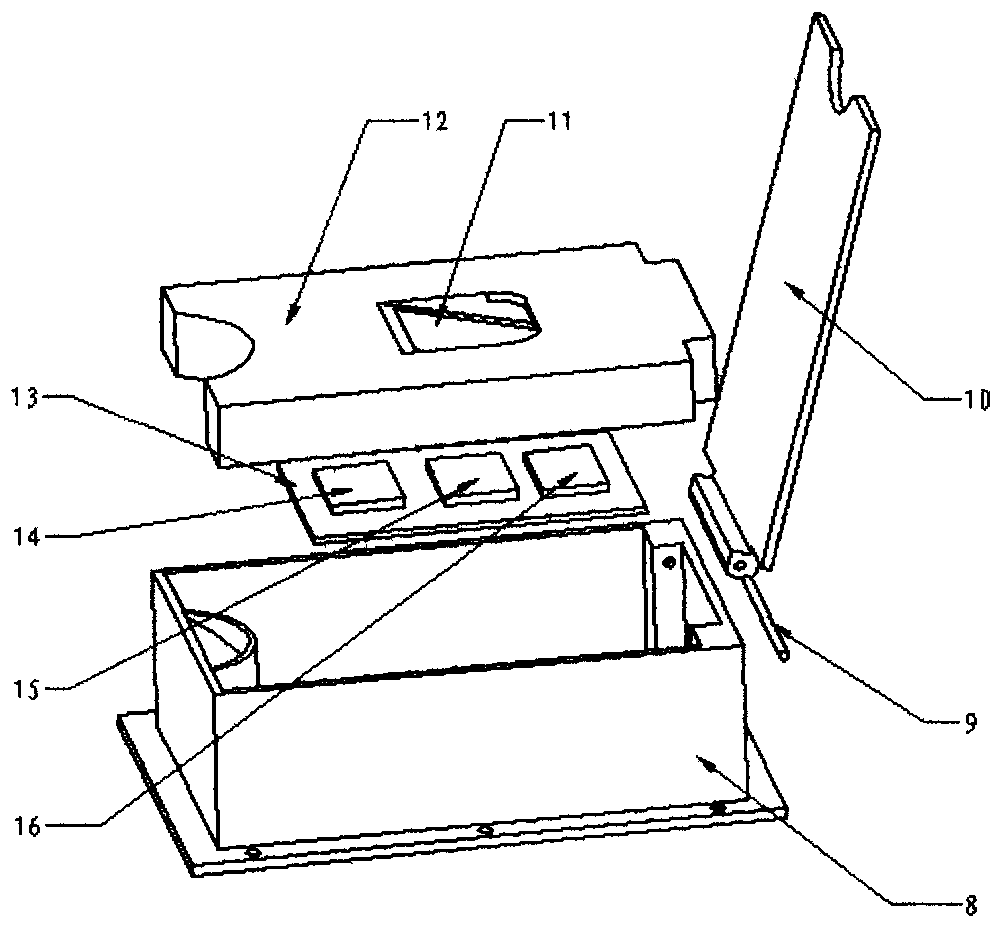

Full-symmetrical cylindrical membrane wall assembly tooling and assembly method

InactiveCN103143873AAvoid side bendsAvoid bendingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCoal chemical industry

The invention relates to a full-symmetrical cylindrical membrane wall assembly tooling and an assembly method which are applicable to high-efficiency gasifiers in the coal chemical industry. The method includes the following steps: (1) a membrane wall welder is used for welding round pipes and steels into membrane wall units, and each membrane wall unit consists of the round pipes and the flat steels; (2) the first group of membrane wall units are mounted on a positioner, the lower ends of directional blocks are vertically welded on positioning rings, and thereby the first group of membrane wall units only can be axially moved on the positioner; (3) a second group of membrane wall units which are fully symmetric with the first group of membrane wall units are mounted on the positioner; (4) the two groups of membrane wall units are welded together, and weld joints are located at the middle between the two groups of membrane wall units; (5) according to the method, the welding of the whole cylindrical membrane wall is sequentially carried out. The full-symmetrical cylindrical membrane wall assembly tooling and the assembly method which are disclosed by the invention can adjust the welding sequence, so that the weld joints can always be located at the geometrical middle of the welded workpiece, and thereby great bending is prevented in the process of welding.

Owner:KAIFENG AIR SEPARATION GROUP

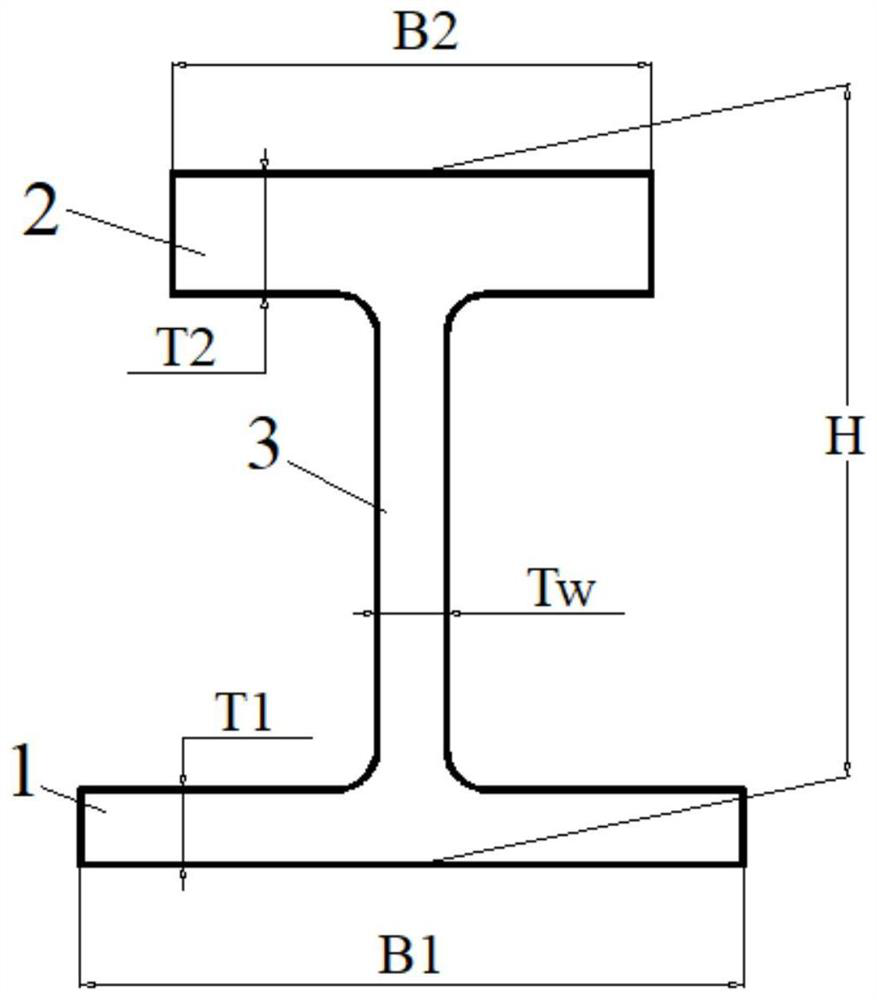

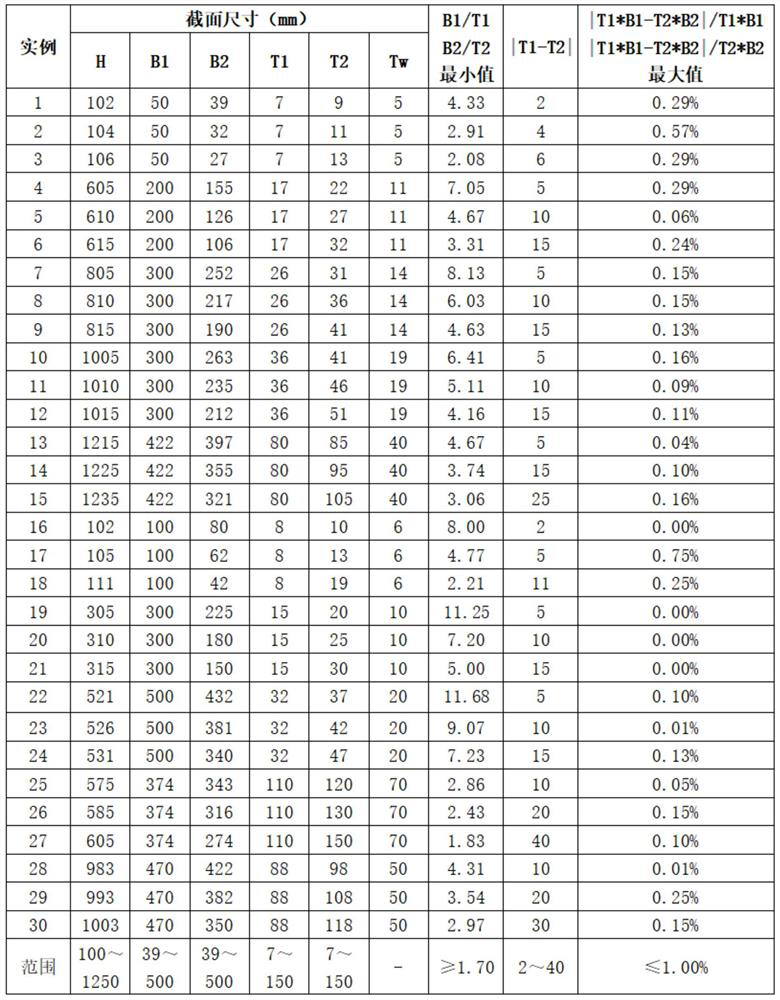

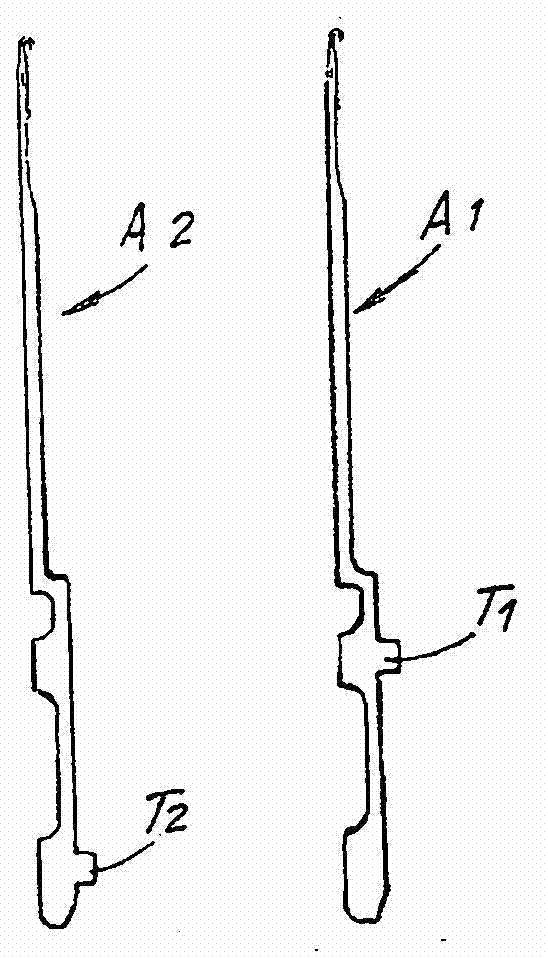

Hot-rolled H-shaped steel and production method thereof

ActiveCN113399453AMeet production requirementsStable Production RequirementsElongated constructional elementsMass flow control deviceMetallurgyEngineering

The invention discloses hot-rolled H-shaped steel, which comprises a web plate, a first flange plate and a second flange plate; the difference value T1-T2 between the thickness value of the first flange plate and the thickness value of the second flange plate is larger than 0; the ratio of the area difference S1-S2 of the first flange plate and the second flange plate to the area S1 of the first flange plate is not larger than 1, or the ratio of the area difference S1-S2 of the first flange plate and the second flange plate to the area S2 of the second flange plate is not larger than 1. According to the hot-rolled H-shaped steel provided by the invention, the production requirement that the flanges on the two sides of various specifications are different in thickness can be met, meanwhile, lateral bending in the rolling process can be avoided, the metal second flow difference of the flanges on the two sides in the rolling process is controlled within a certain range, and therefore the hot-rolled H-shaped steel with the flanges on the two sides being different in thickness is stably produced. The invention further discloses a production method of the hot-rolled H-shaped steel.

Owner:MAANSHAN IRON & STEEL CO LTD

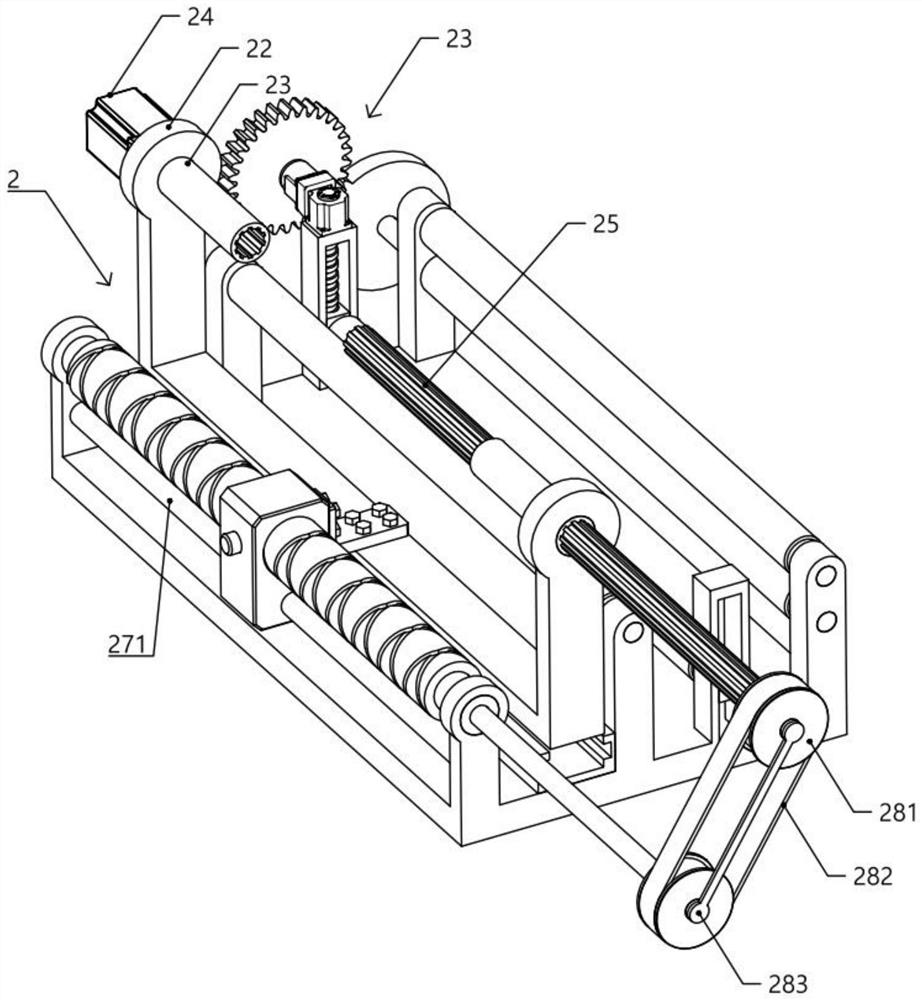

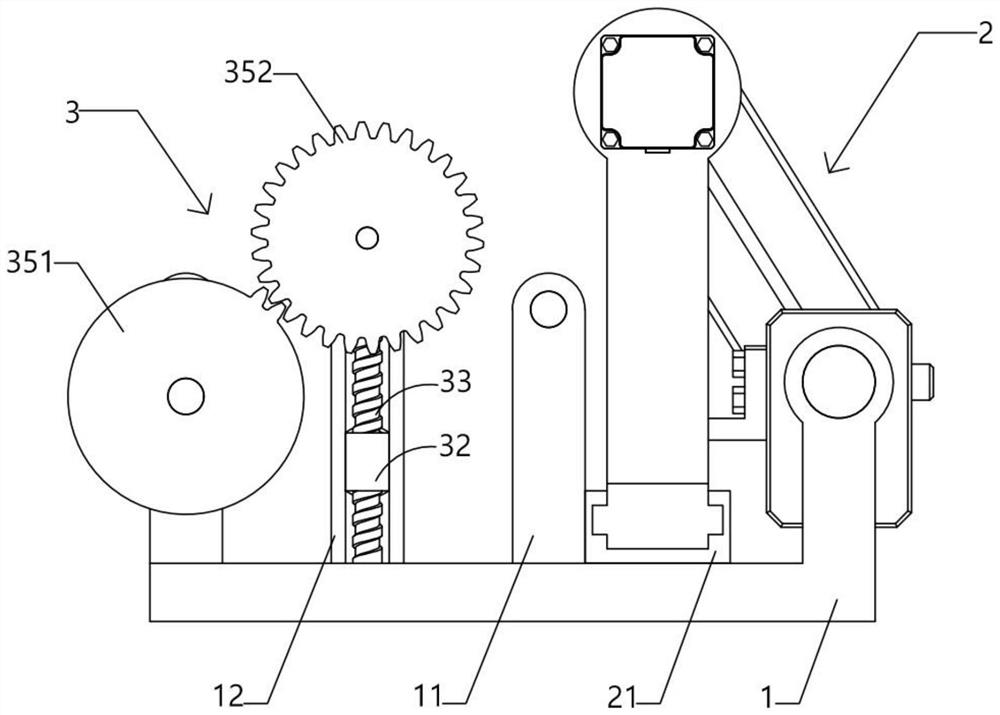

Steel wire straightening machine

The steel wire straightening machine comprises a bottom plate, an unwinding mechanism and a self-adaptive straightening mechanism, the unwinding mechanism comprises a linear guide rail, a winding frame, a sleeve, a motor, a spline shaft, a double-helix guide rod, a crescent plate and a transmission assembly, the linear guide rail is arranged on the bottom plate, and the winding frame is installed in the guide rail in a matched mode; the self-adaptive straightening mechanism comprises a rubber roller, a sliding block, a lead screw, a lower pressing rod and an intermittent transmission assembly. When a steel wire coil is unwound through the unwinding mechanism, the spline shaft rotates along with the unwinding mechanism and drives the double-helix guide rod to rotate through the transmission assembly, finally, the crescent plate translates in a reciprocating mode along the double-helix guide rod, the winding frame translates along with the crescent plate, and therefore lateral bending force cannot be generated when the steel wire enters the self-adaptive straightening mechanism in the unwinding process; and the self-adaptive straightening mechanism drives a lower pressing rod to vertically translate according to the contact between the conveyed steel wire and a rubber roller, so that the self-adaptive straightening mechanism can apply straightening force according to the bending degree of the steel wire in a self-adaptive manner.

Owner:江苏通工金属科技有限公司

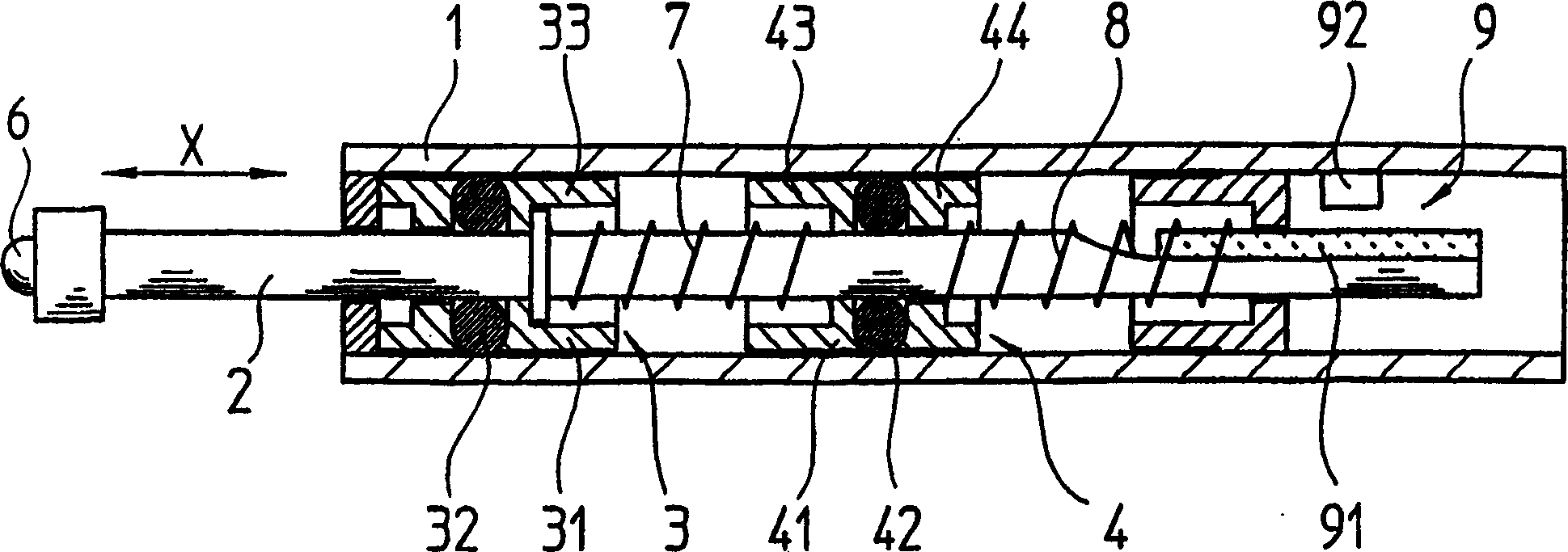

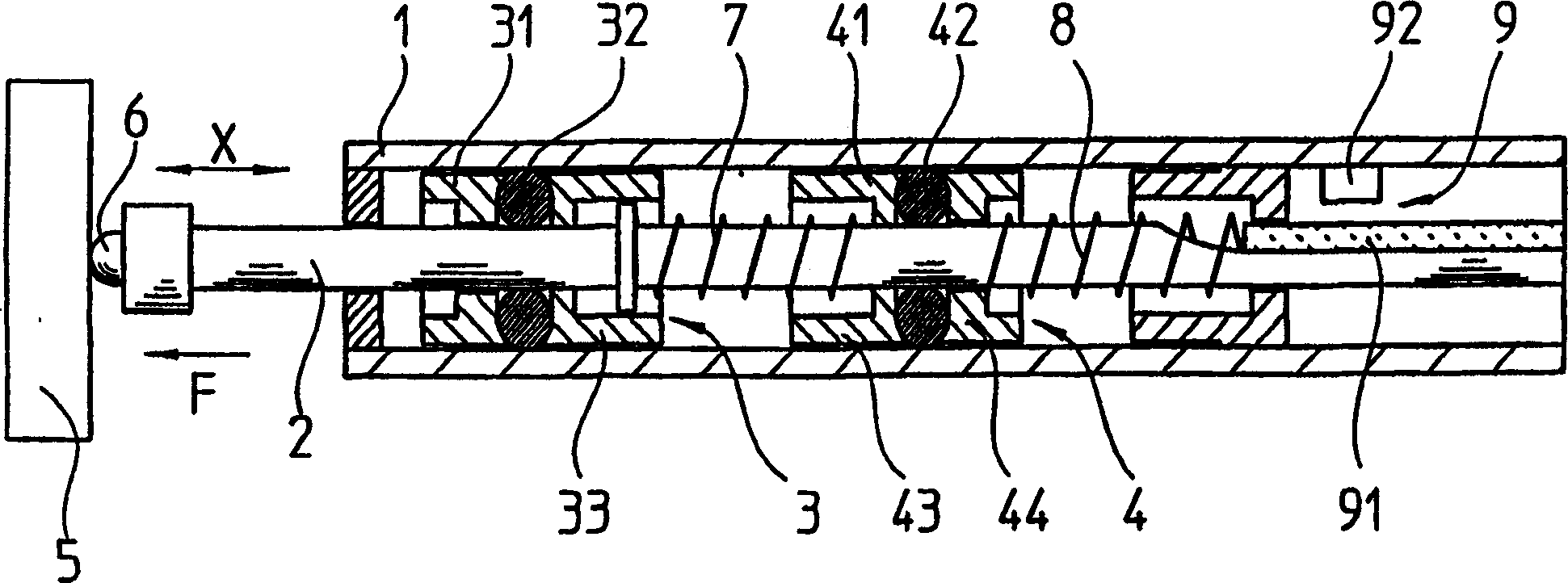

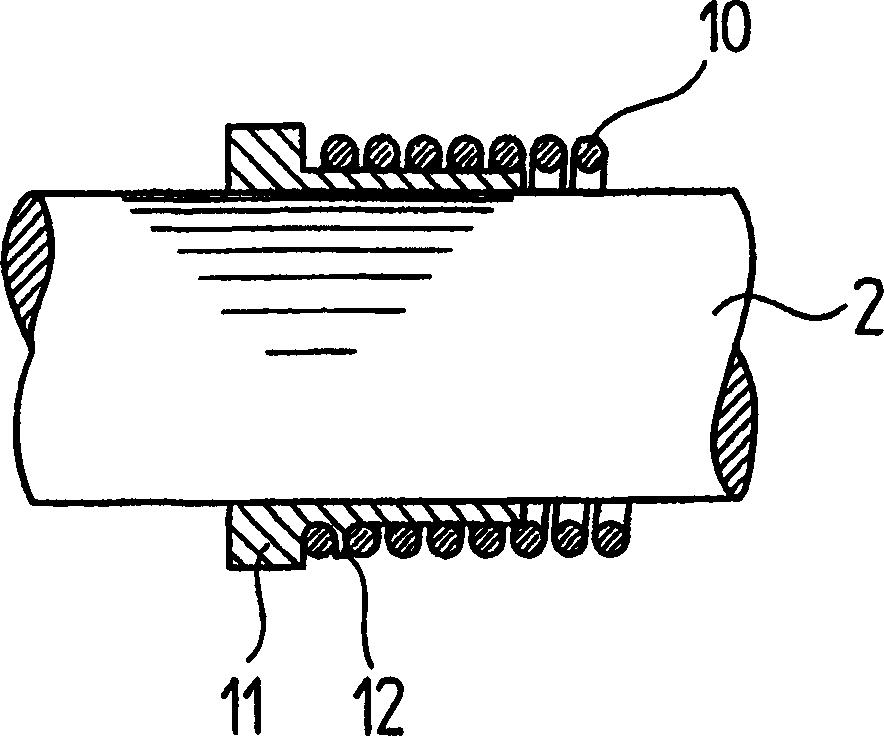

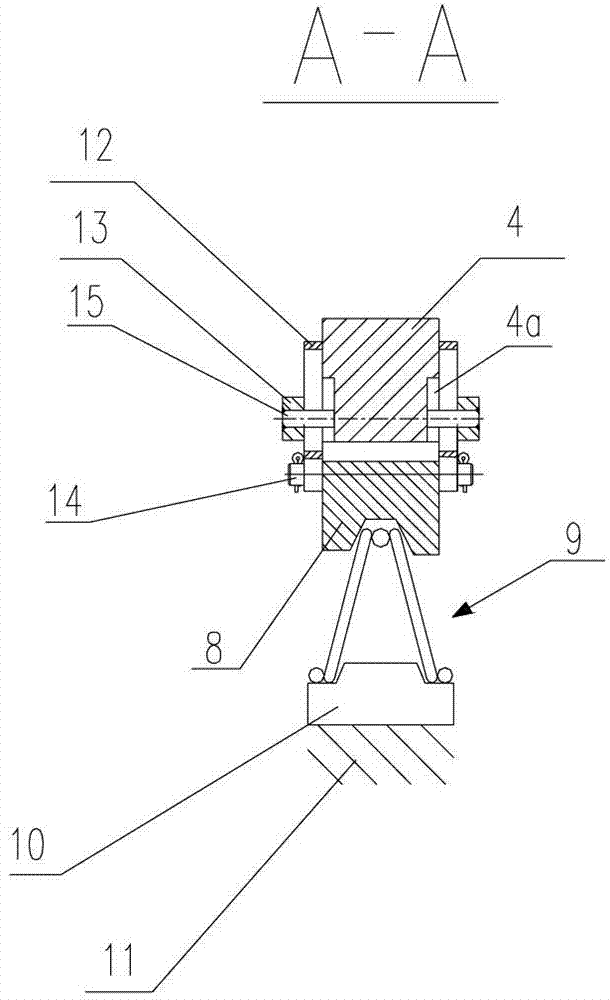

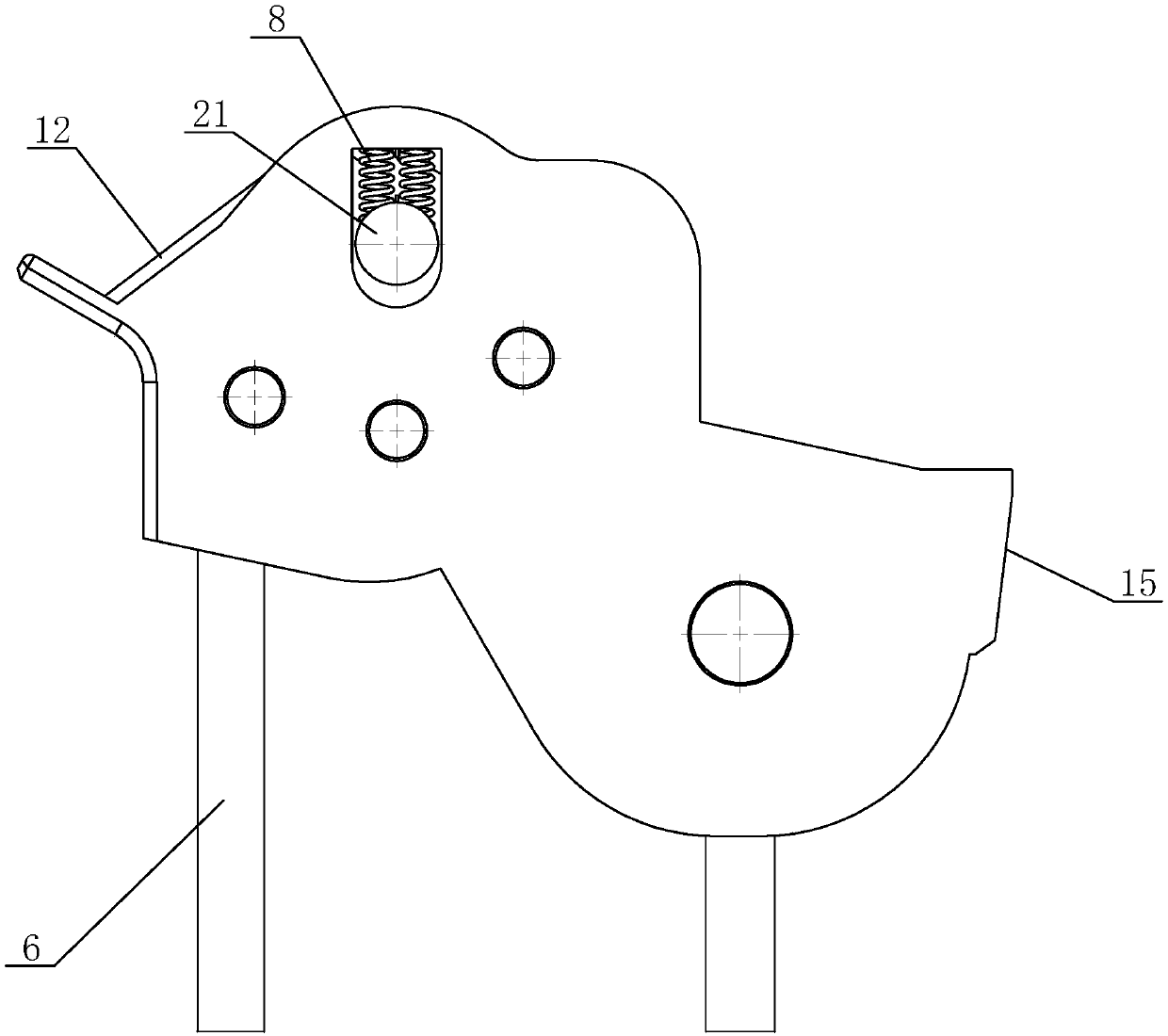

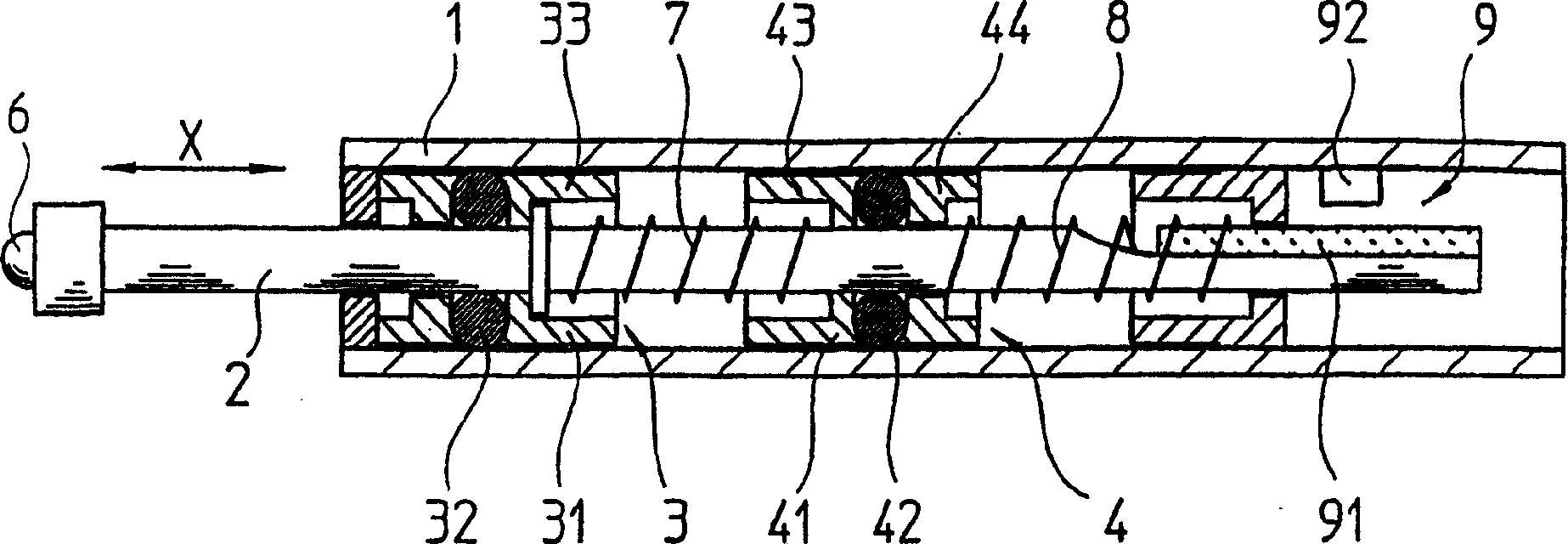

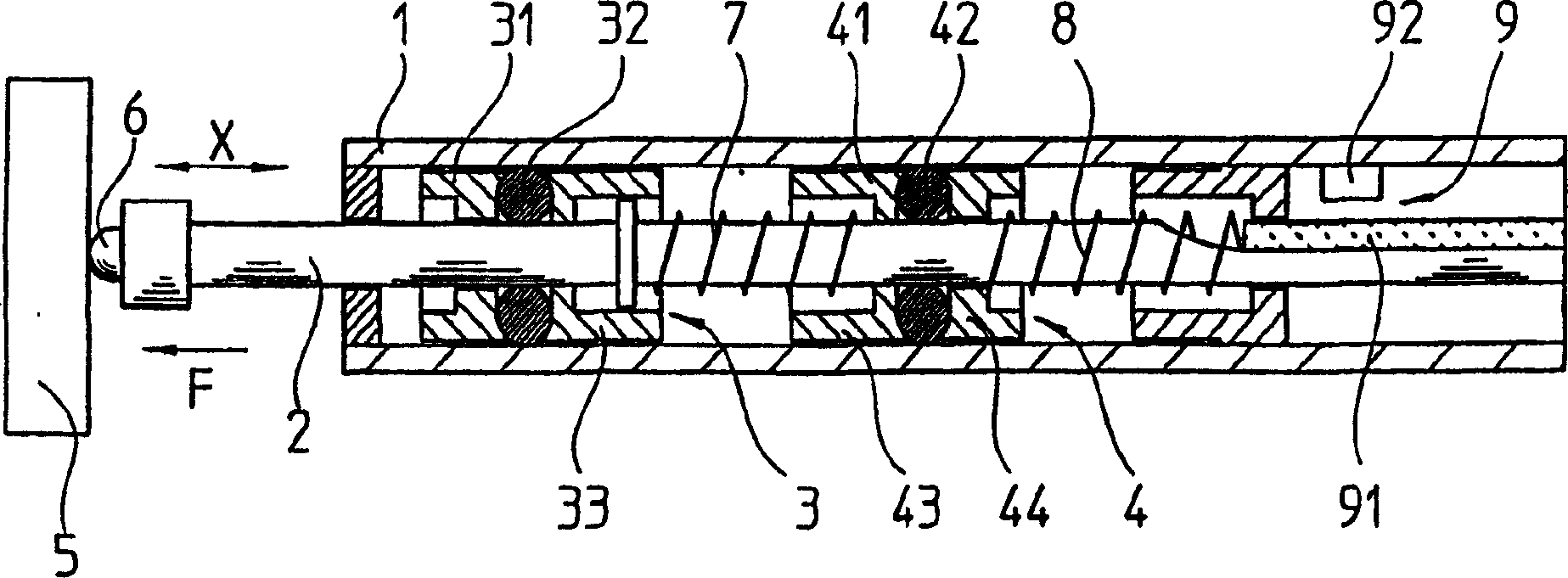

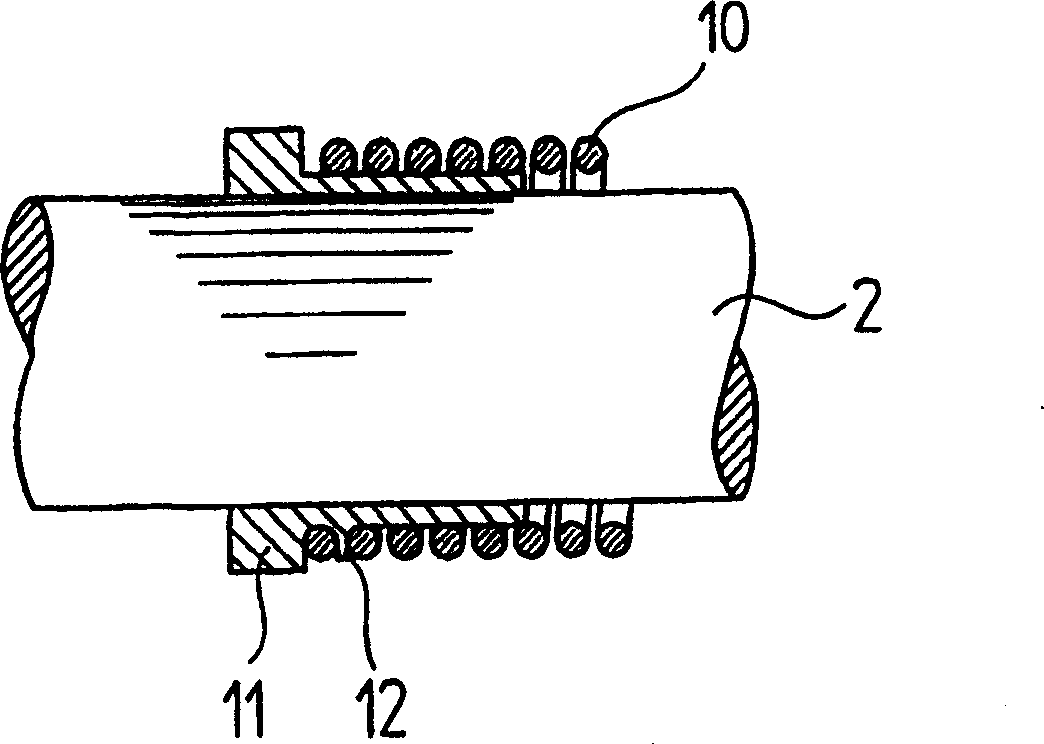

Length sensor

InactiveCN1502034ACompact layoutAvoid side bendsFeeler-pin gaugesUsing optical meansCoil springSpring force

The probe has a probe pin (2) with a probe element (6) for scanning an object (5) by moving relative to a base body (1) against a spring force. The probe pin is biased in the measuring direction (X) by several spring elements (7,8). A guide element (4) is provided between each two spring elements. The guide element is displaceably mounted on the probe pin and on the base body.

Owner:DR JOHANNES HEIDENHAIN GMBH

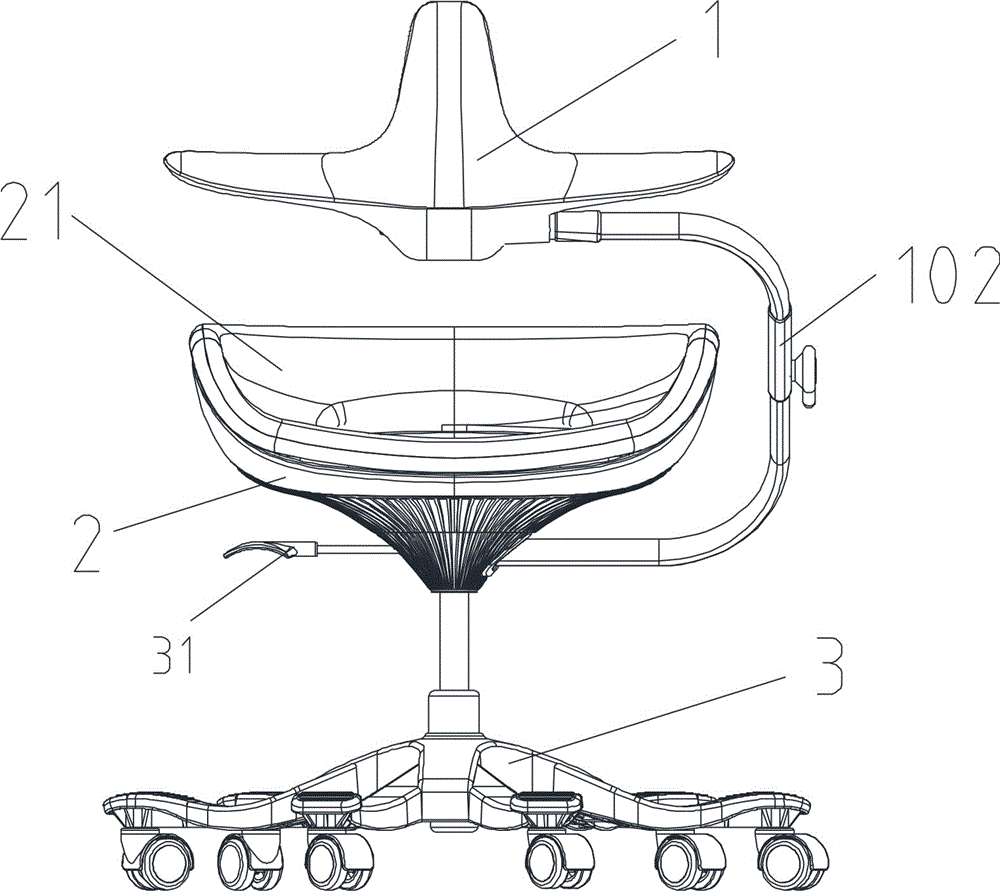

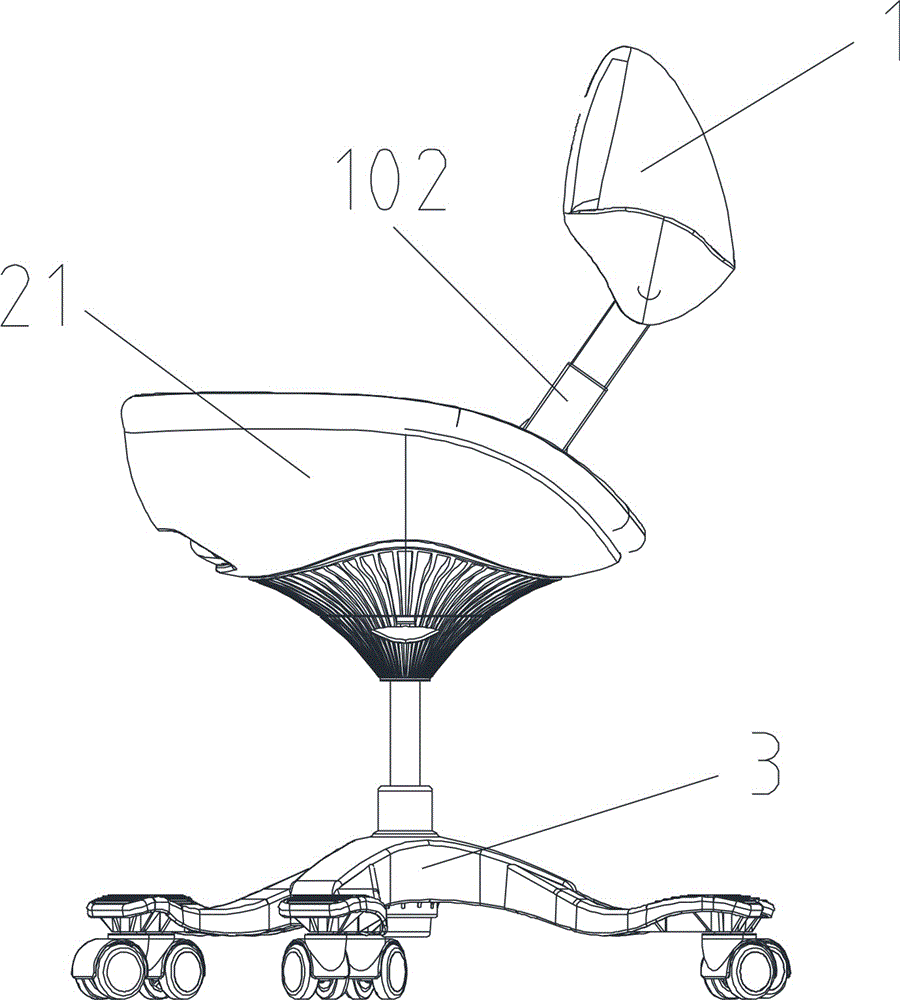

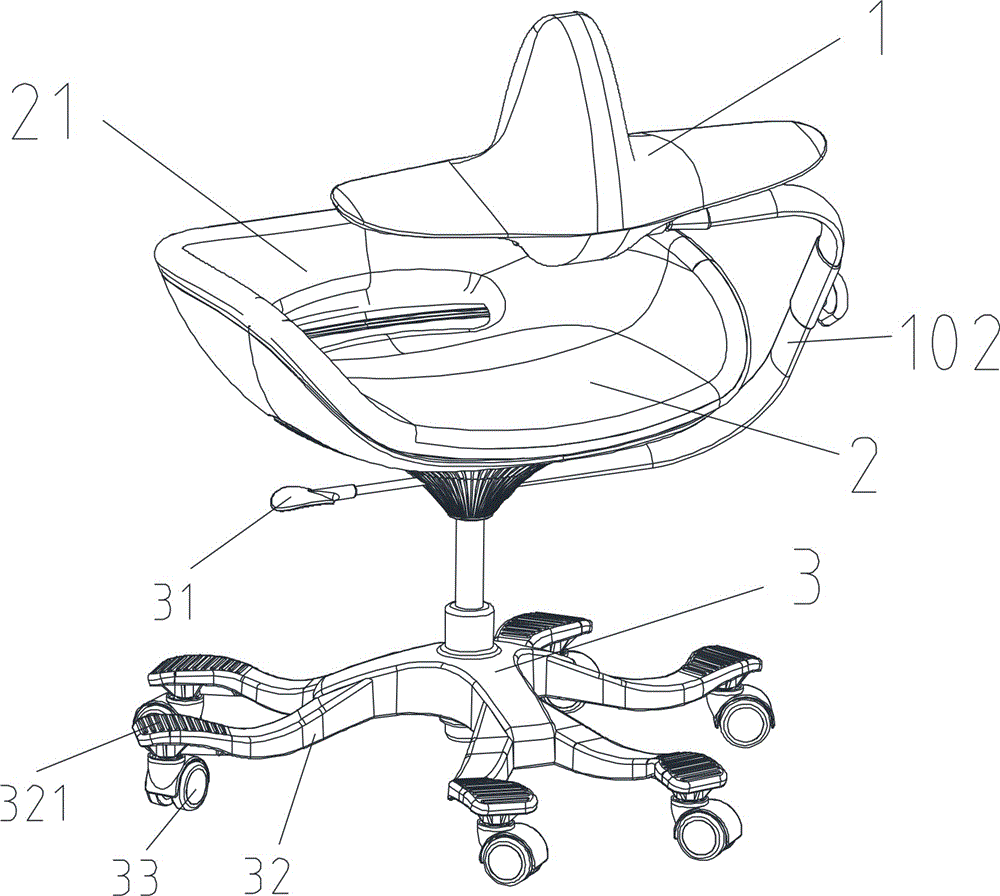

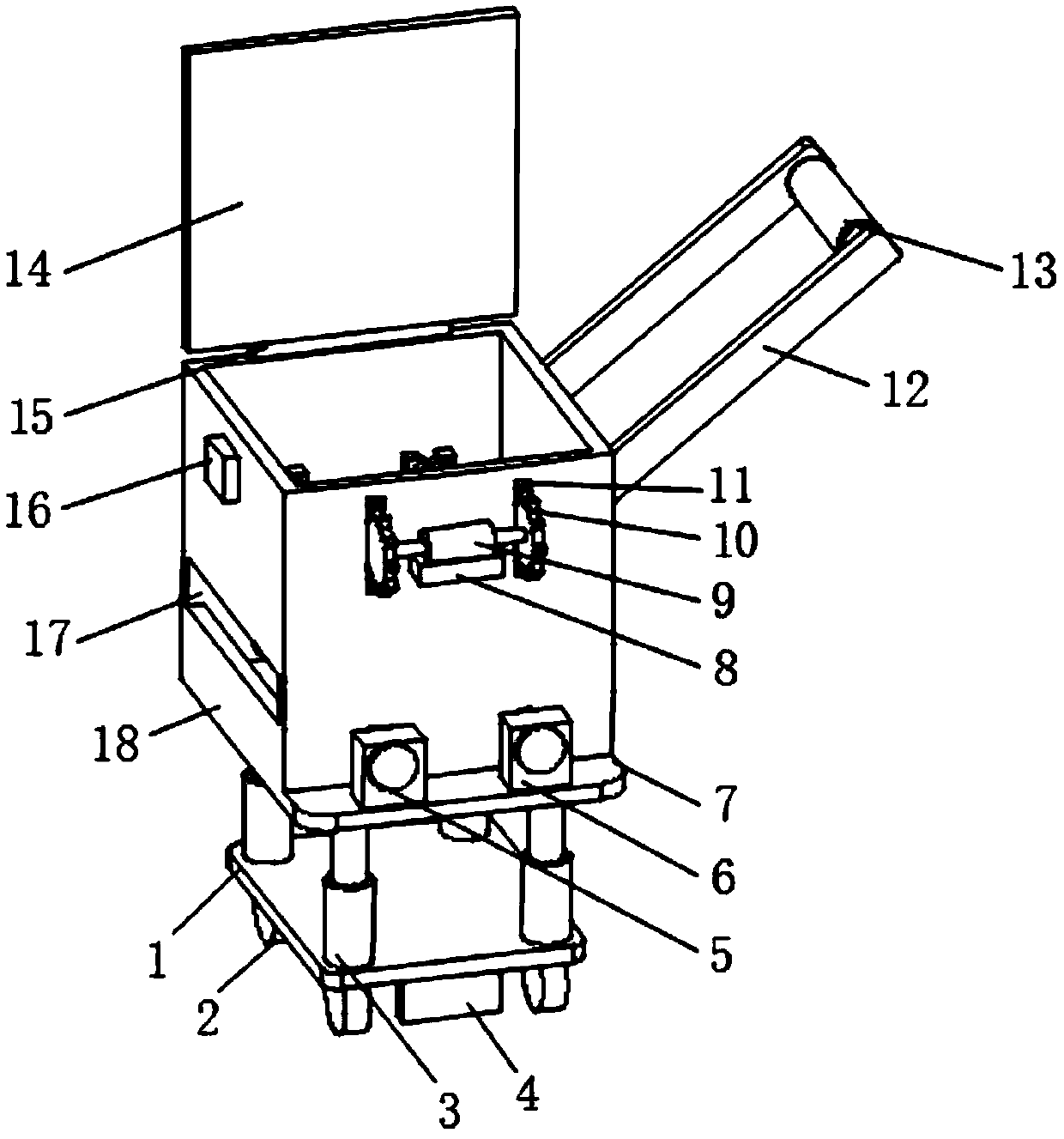

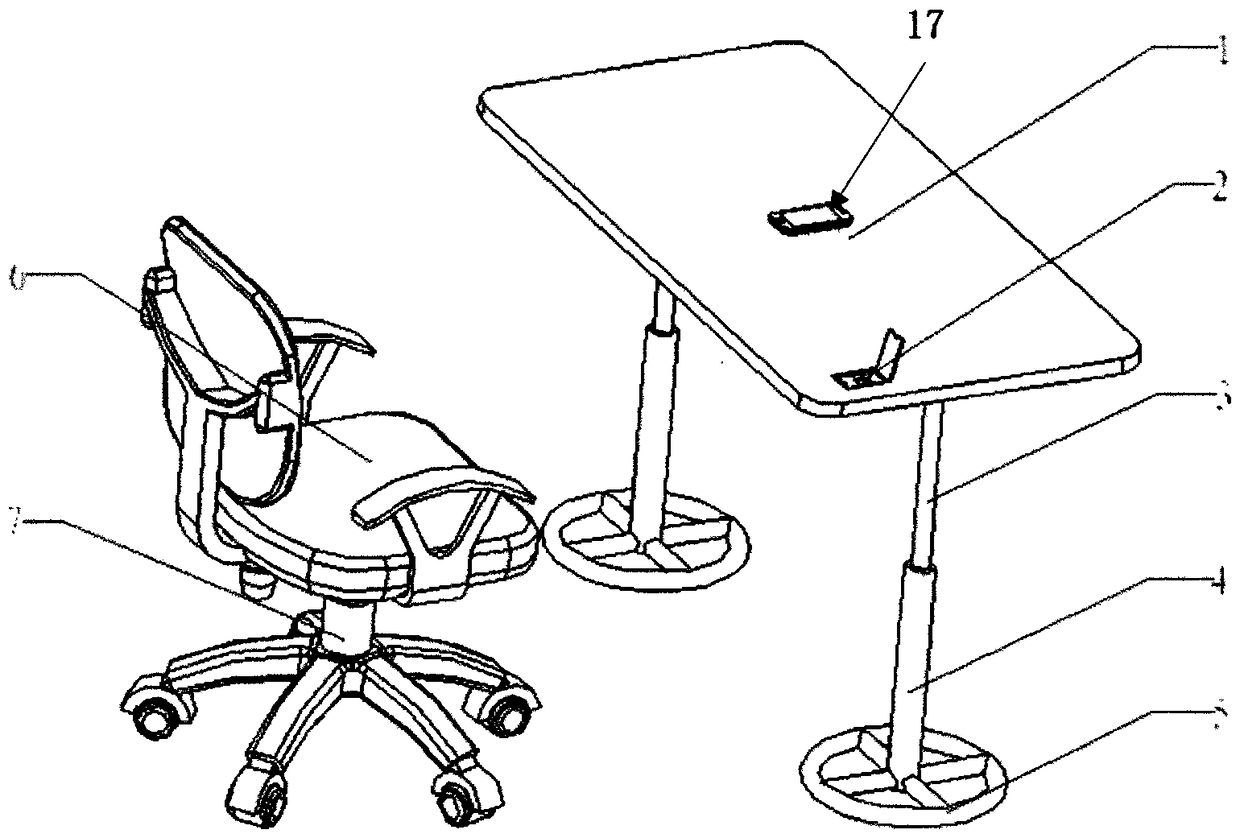

Chair preventing spinal curvature

The invention relates to a chair preventing spinal curvature. The chair comprises a sitting surface and a backrest arranged on one side of the sitting surface, wherein the bottom of the sitting surface is provided with a supporting rod, the bottom end of the supporting rod is provided with supporting legs, the bottoms of the supporting legs are provided with universal wheels, the backrest is provided with a telescopic rod, the upper end of the telescopic rod is provided with a headrest band, the two ends of the headrest band are respectively provided with a first adhesive buckle, the first adhesive buckles are mutually matched, the lower end of the telescopic rod is provided with a chest and abdomen band, the two ends of the chest and abdomen band are respectively provided with a second adhesive buckle, and the second adhesive buckles are mutually matched. According to the chair preventing spinal curvature, the telescopic rod is arranged on the backrest of the chair, and the upper end and the lower end of the telescopic rod are provided with the headrest band and the chest and abdomen band respectively, so that the telescopic rod can be adjusted according to the height of a person; the headrest band and the chest and abdomen band can be bound on the head and the chest and the abdomen respectively, so that sitting postures can be effectively corrected, and lateral bending of the whole spine is prevented.

Owner:王子越

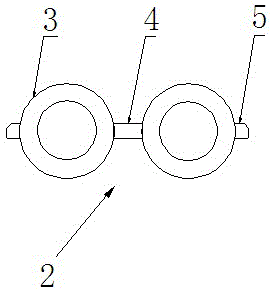

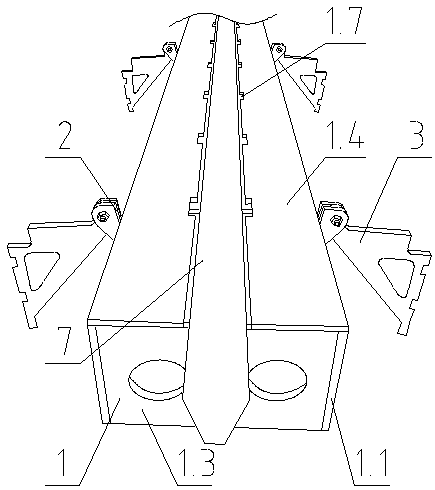

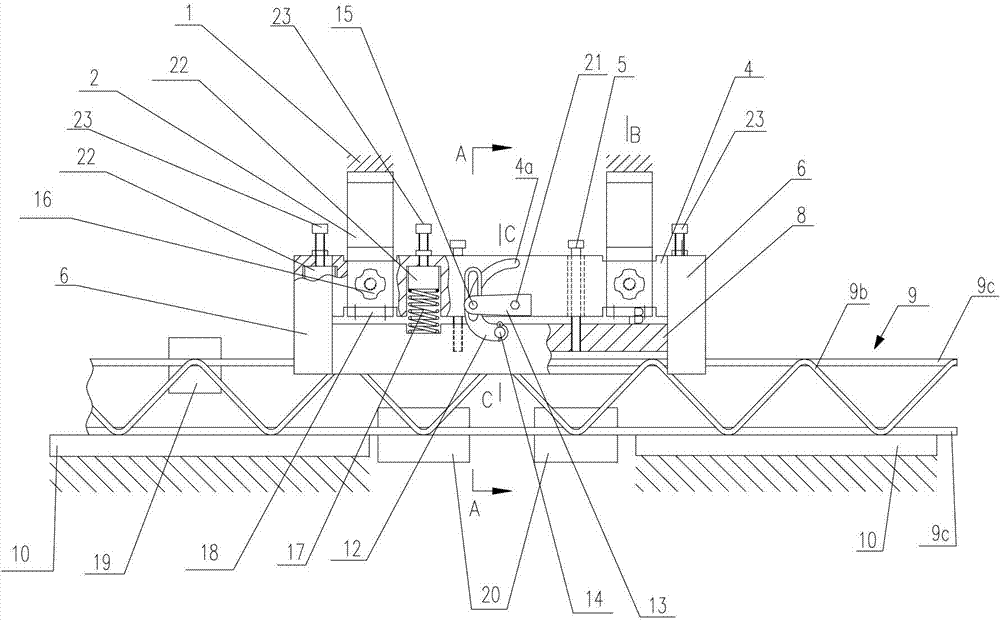

T-profile production tooling

ActiveCN106166655BReduce manpower consumptionPrevent dumpingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBuilding construction

Owner:CHENGXI SHIPYARD

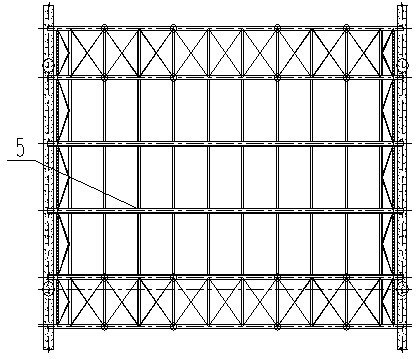

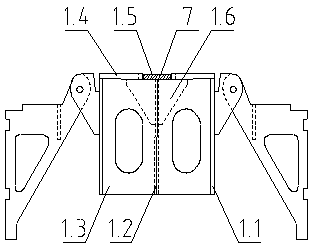

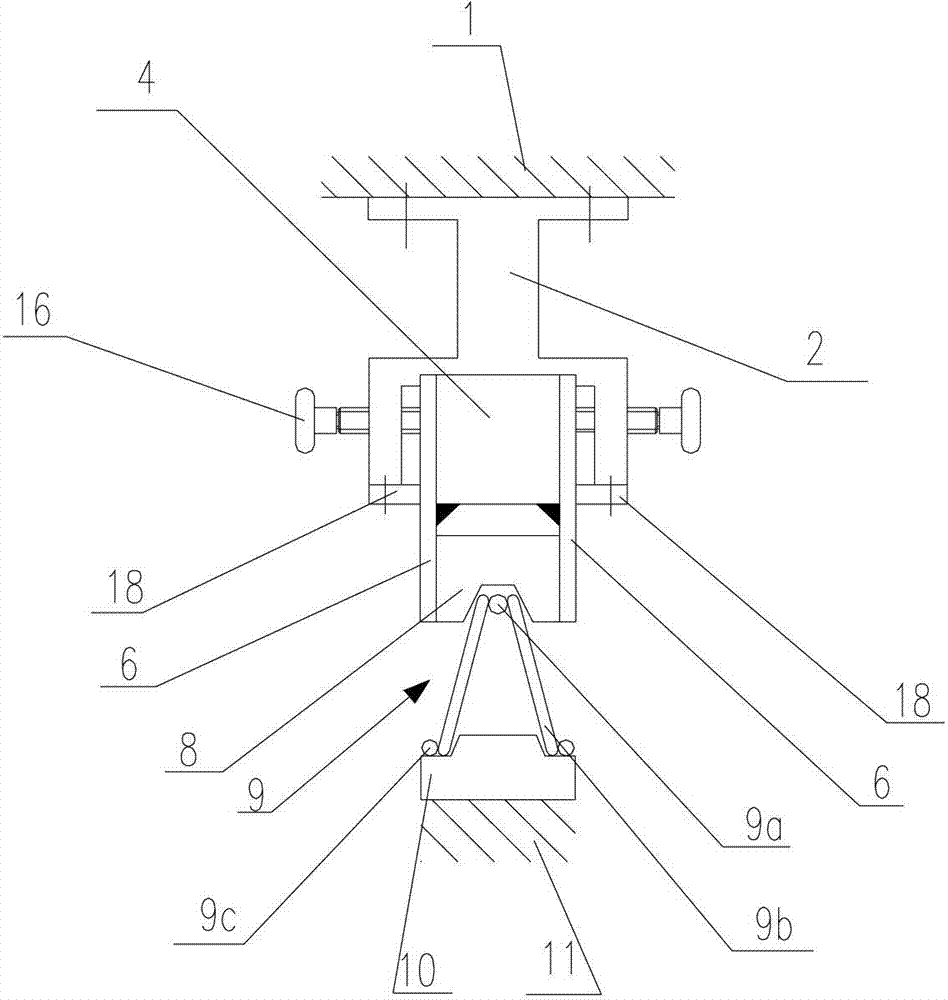

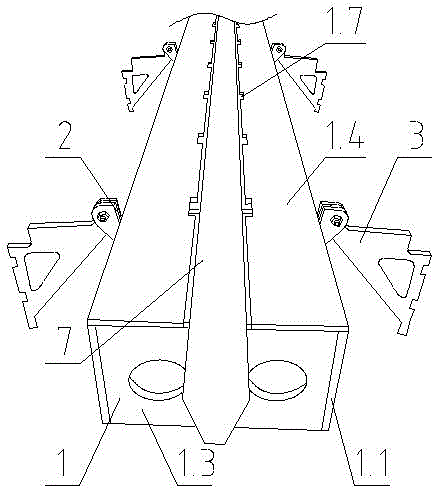

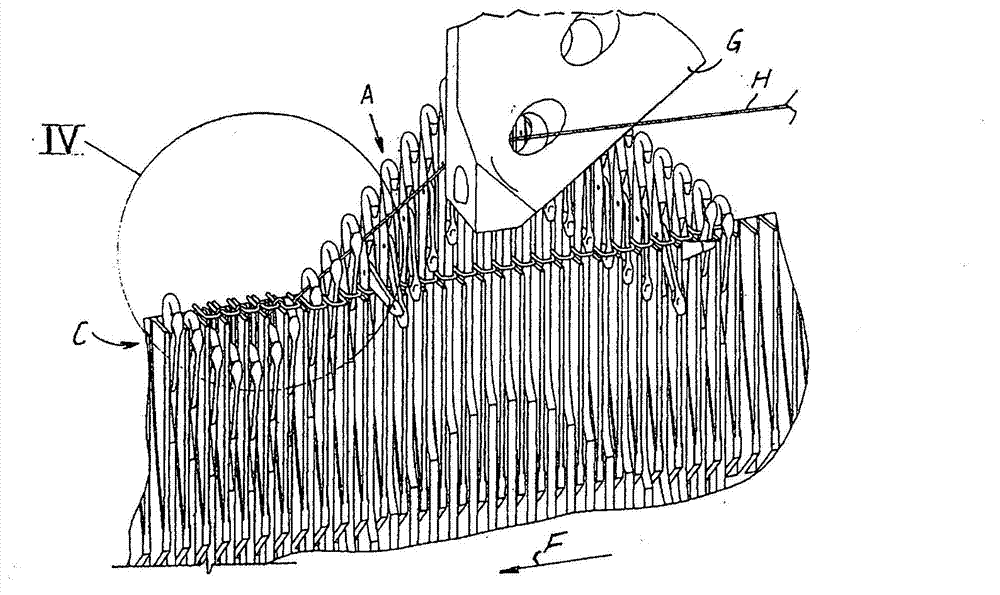

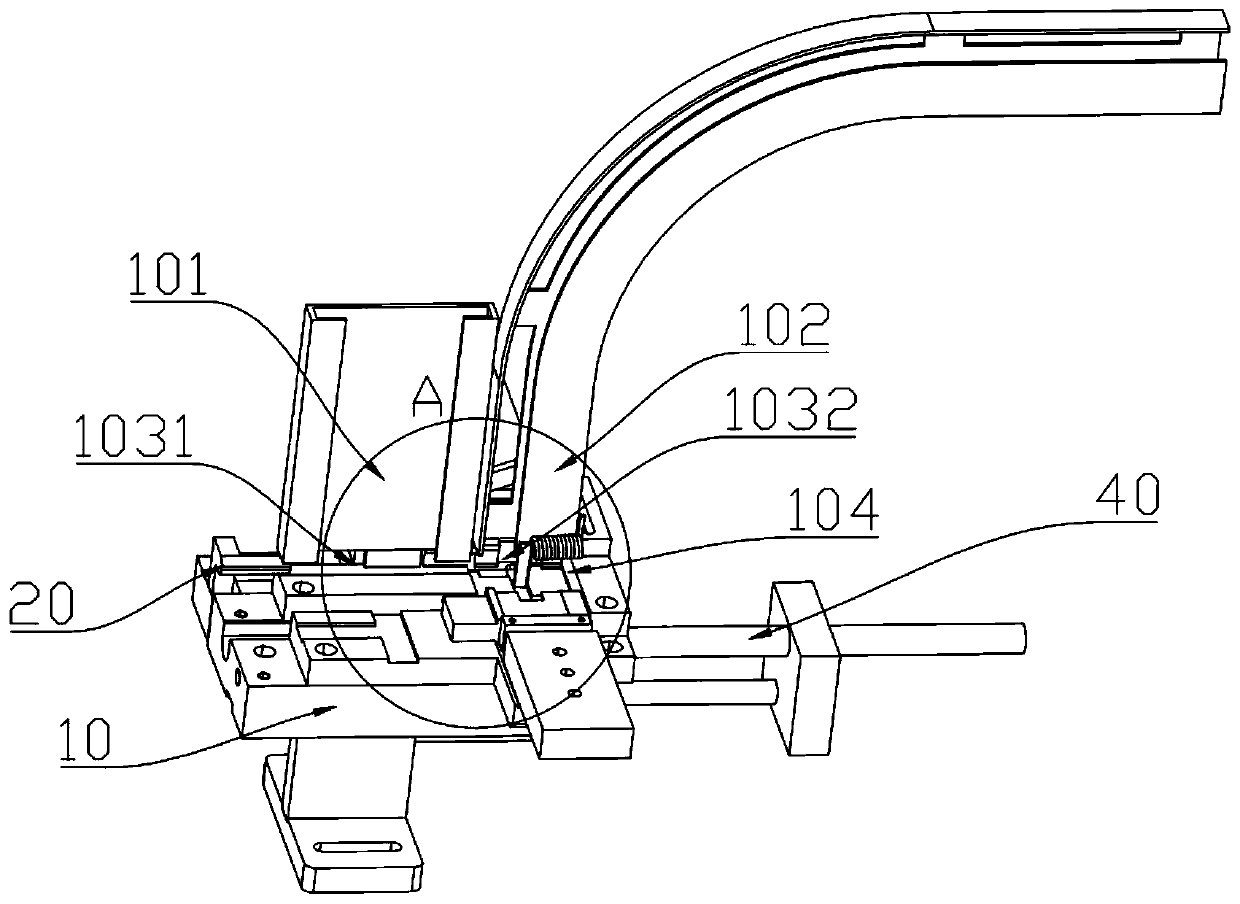

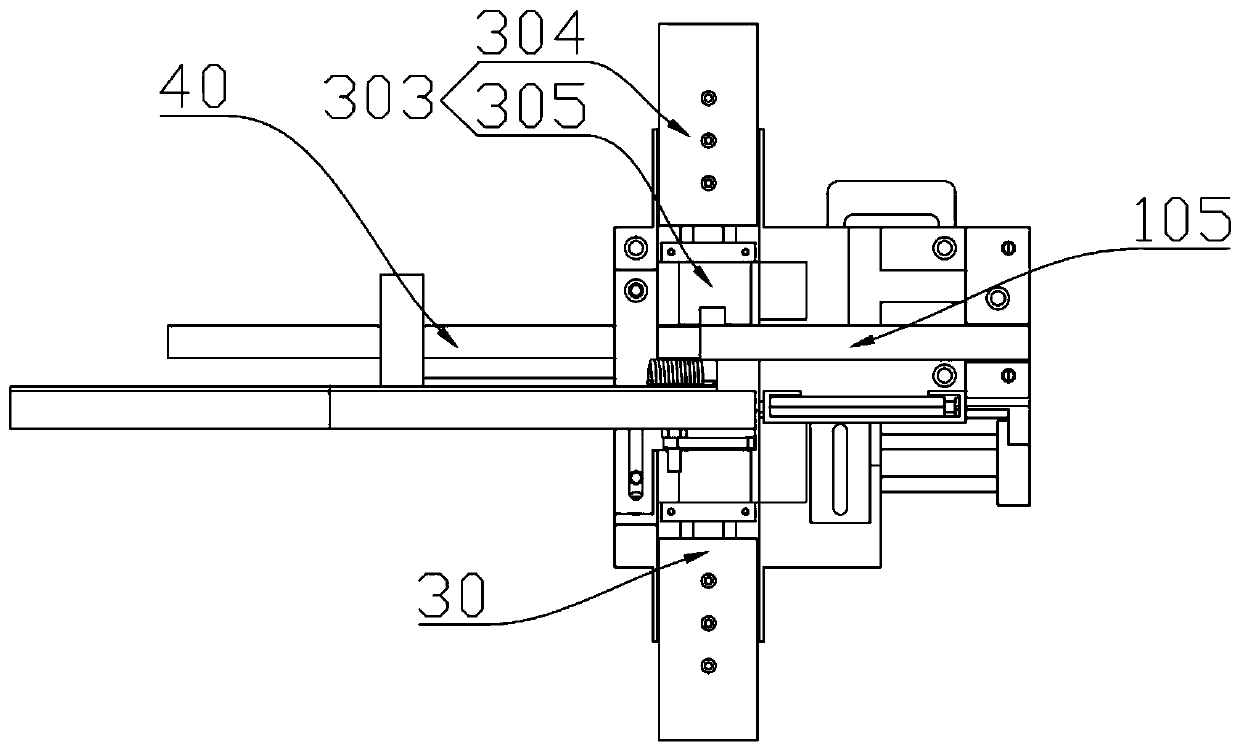

Side bending prevention device of truss welding production line

ActiveCN103495819AAvoid side bendsGuaranteed aestheticsWelding/cutting auxillary devicesAuxillary welding devicesEngineeringRebar

The invention discloses a side bending prevention device of a truss welding production line. The side bending prevention device is located above a lower welding electrode on one side of an upper welding electrode and structurally characterized in that a trapezoid tank is formed in the bottom of a strip-shaped bending prevention template and inserted in two sides of an upper rotary rib and two sides of a web bar, the bending prevention template is flexibly connected to a bending prevention main plate located on the bending prevention template, the bending prevention main plate is fixed in an adjusting rack, and the upper end of the adjusting rack is fixed to a lifting rack; an adjusting mechanism for adjusting the position of the bending prevention main plate is arranged on the adjusting rack, the bending prevention main plate and the bending prevention template are equally long, two side faces at the two ends of the bending prevention main plate are provided with a pair of limiting plates respectively, the two pairs of the limiting plates are symmetrical in position, and the two ends of the bending prevention template are limited between the each pair of the limiting plates respectively. The side bending prevention device has the advantages of being novel in structure, convenient to adjust and reliable, saving production cost, lightening labor intensity, preventing rebar from being laterally bent, and ensuring that a welded truss is attractive and is not bent.

Owner:TJK MACHINERY TIANJIN

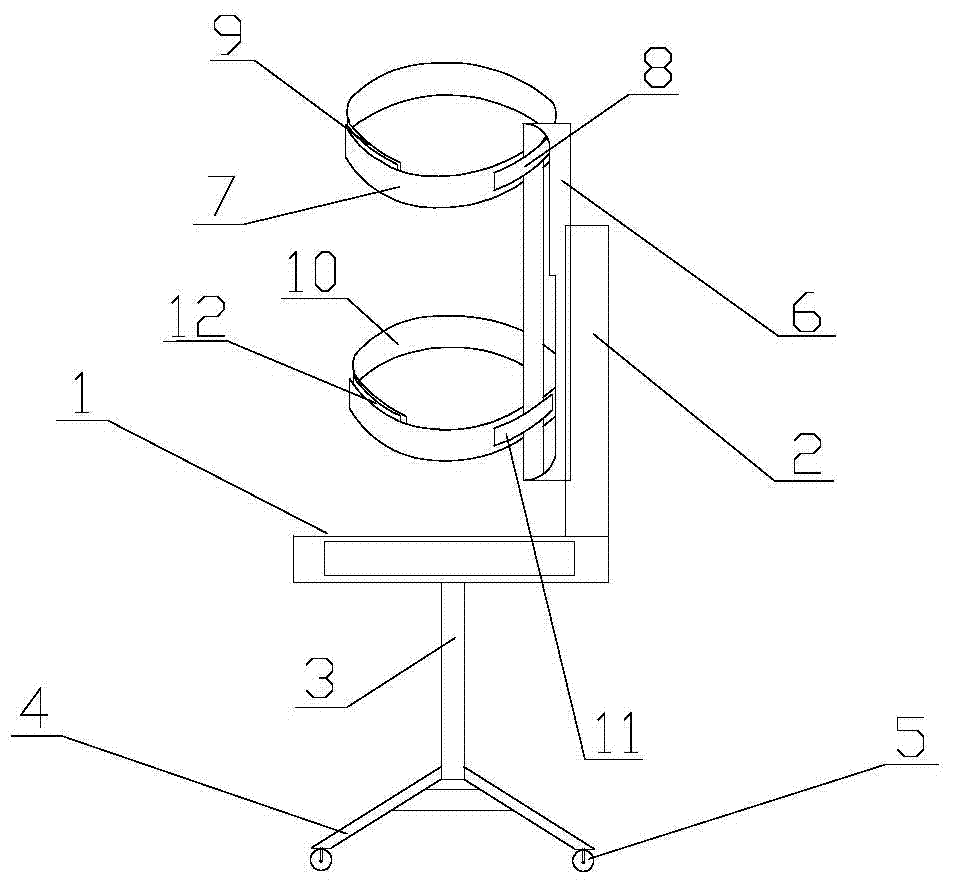

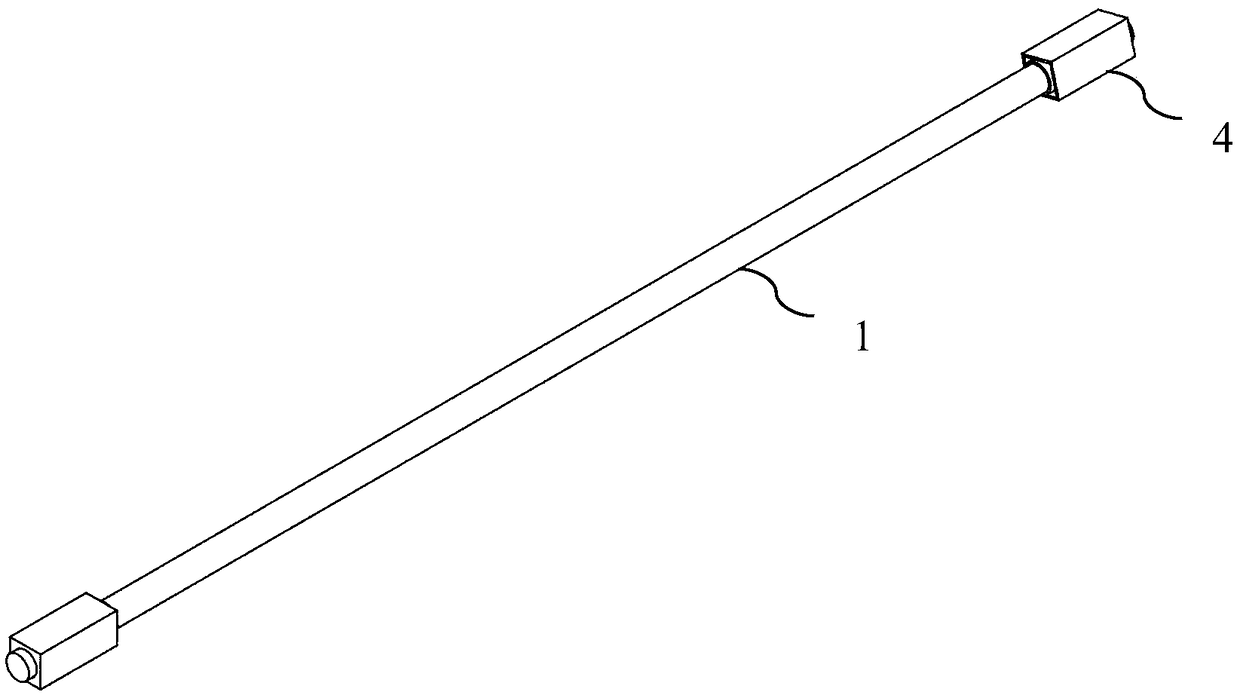

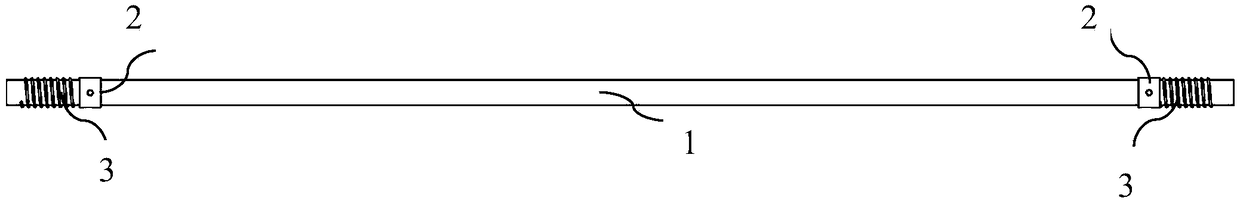

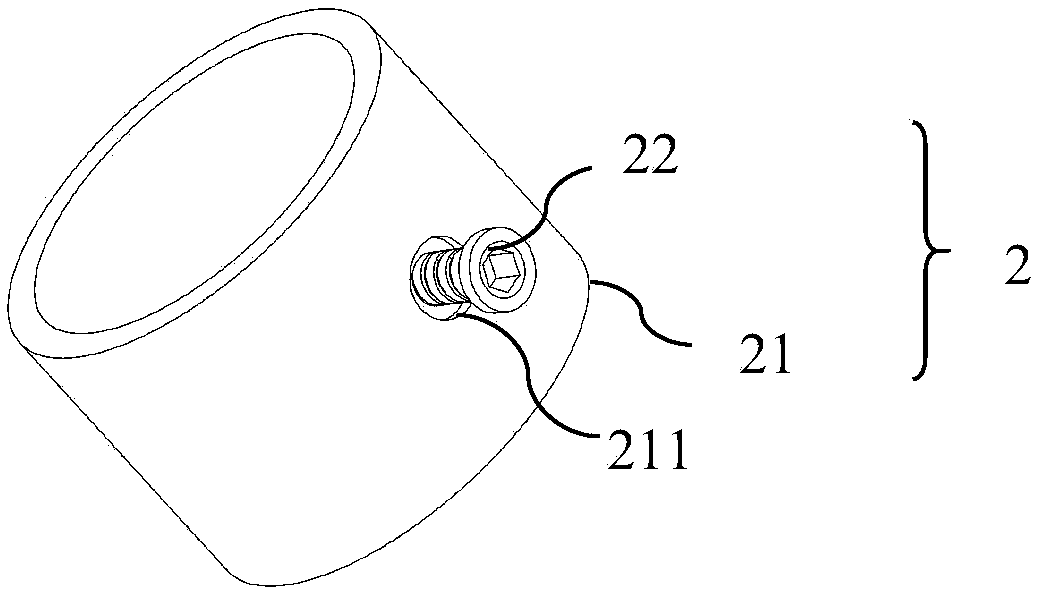

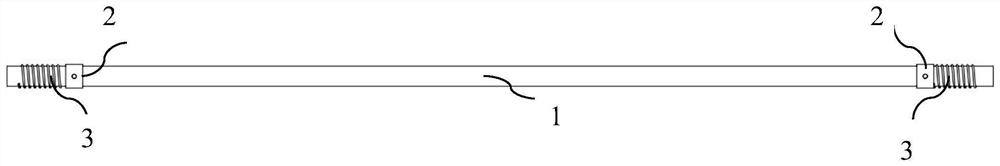

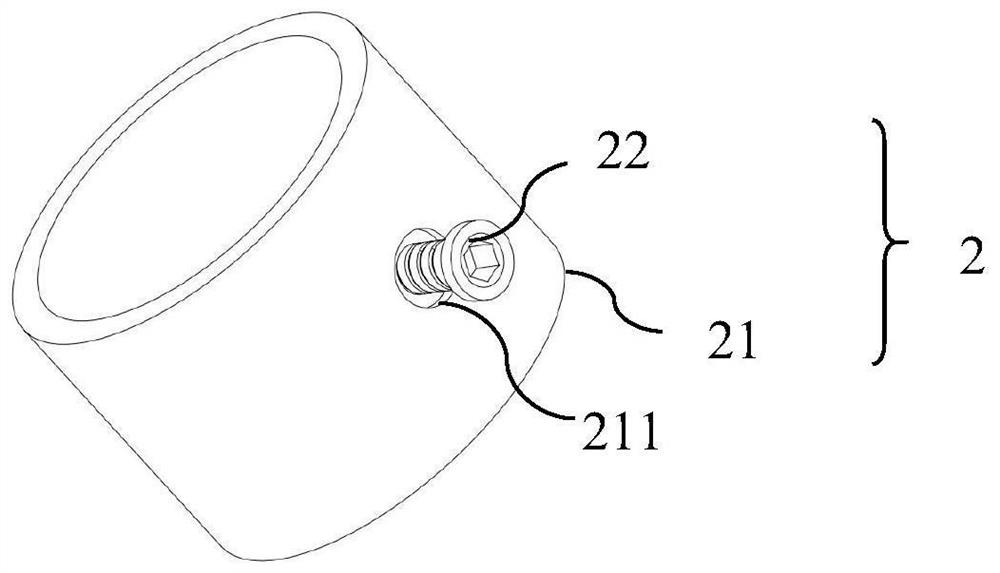

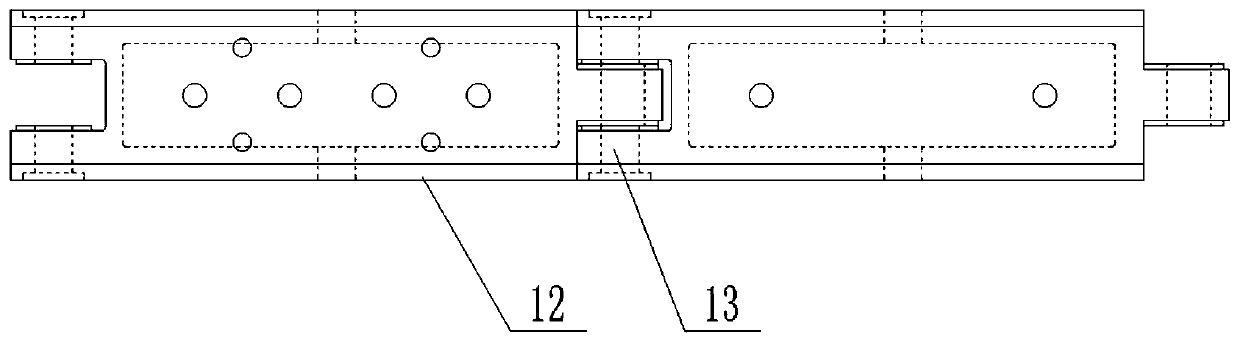

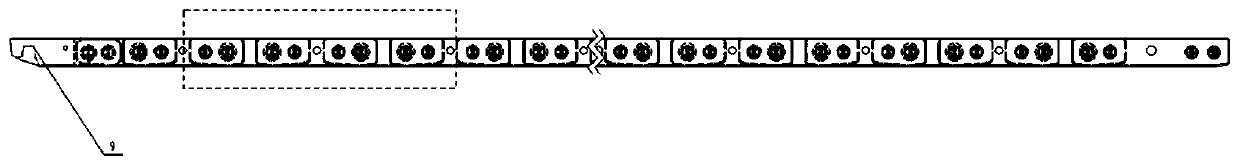

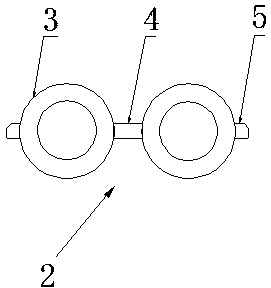

Elastic expansion spine growth rod system

ActiveCN108888327AExtended service lifeReduce the number of surgeriesInternal osteosythesisScoliosisEngineering

The invention discloses an elastic expansion spine growth rod system. The system comprises an orthopedic rod, a clip, a spring and a spring sleeve; the orthopedic rod is a round rod, the clip comprises a snap ring and a locking screw, the snap ring sleeves the orthopedic rod, the snap ring is provided with a screw hole, and the locking screw runs through the screw hole to be in locked connection with the orthopedic rod; the spring sleeves the orthopedic rod between the end of the orthopedic rod and the clip, and the spring is sleeved with the spring sleeve; the spring sleeve is a square tube.The elastic expansion spine growth rod system can not only prevent scoliosis from being aggravated, but also can continuously exert an expansion effect along with the growth of the spine of a child patient, the structure is simple, the use is convenient, the manufacturing cost is low, the operation frequency is greatly reduced, the bending expansion force is larger, and the corrective effect on patients with large curvature of the scoliosis is better.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI

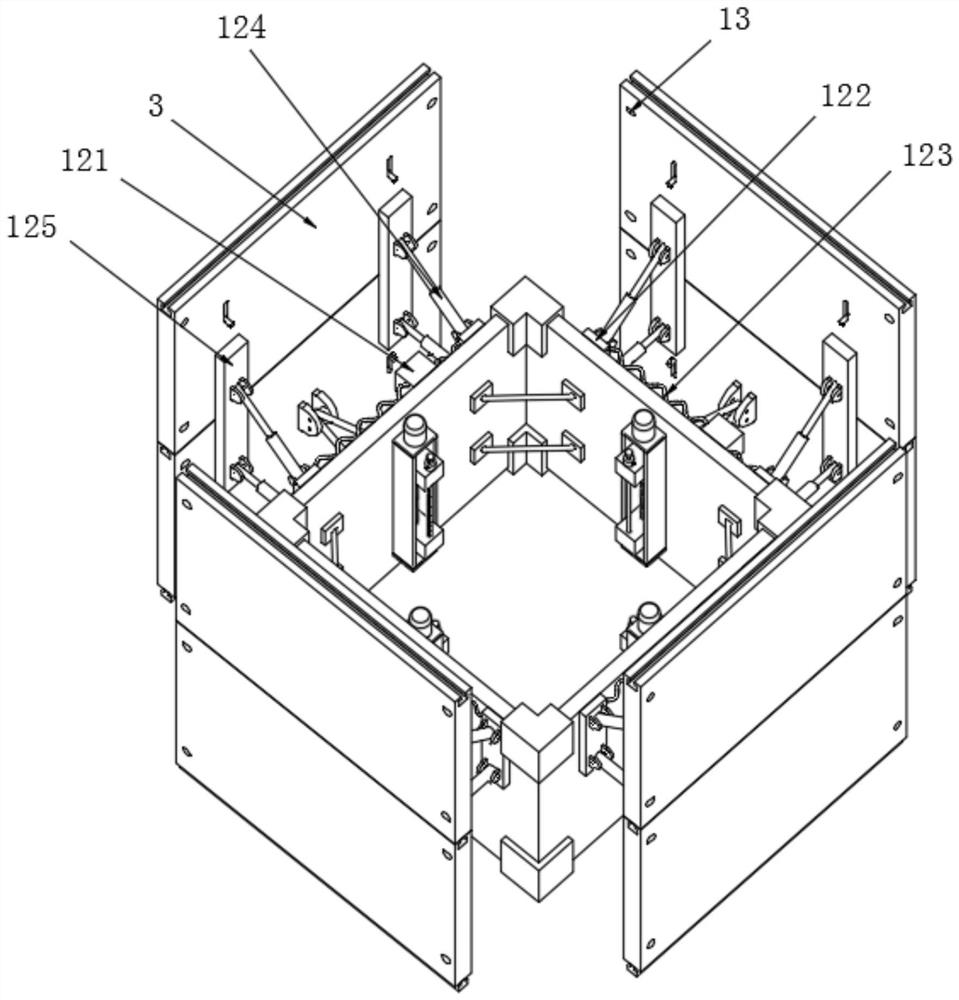

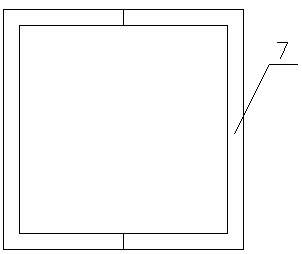

Anti-collapse device for geological exploration and method thereof

PendingCN113700487AExtended service lifeAchieve extrusionShaft equipmentWell drillingClassical mechanics

The invention discloses an anti-collapse device for geological exploration and method thereof. The collapse prevention device comprises a square frame, wherein supporting mechanisms are arranged on the left side, the right side, the front side, the rear side, the left side and the right side of the inner wall of the square frame, collapse prevention plates are arranged on the front side, the rear side, the left side and the right side of the square frame, and one ends of two rotating rods are rotationally connected with the inner sides of the collapse prevention plates. The invention relates to the technical field of geological exploration. According to the anti-collapse device for geological exploration and the method thereof, by arranging the supporting mechanism, the function of automatically supporting the anti-collapse plate is achieved. A supporting force is added on the basis that the anti-collapse plate is fixed in a nailing mode, the anti-collapse plate is firmer, free adjustment can be conducted according to the size of the well drilling caliber, and by arranging a safety locking mechanism, the moving block is limited, so that a situation that when the inner wall of a drilling well extrudes the rotating rods due to the reverse acting force, the two rotating rods drive the two moving blocks to extrude threads on the reverse lead screw is prevented, and therefore, abrasion of the moving block to the thread on the reverse lead screw is reduced, and the service life of the reverse lead screw is prolonged.

Owner:俞梅

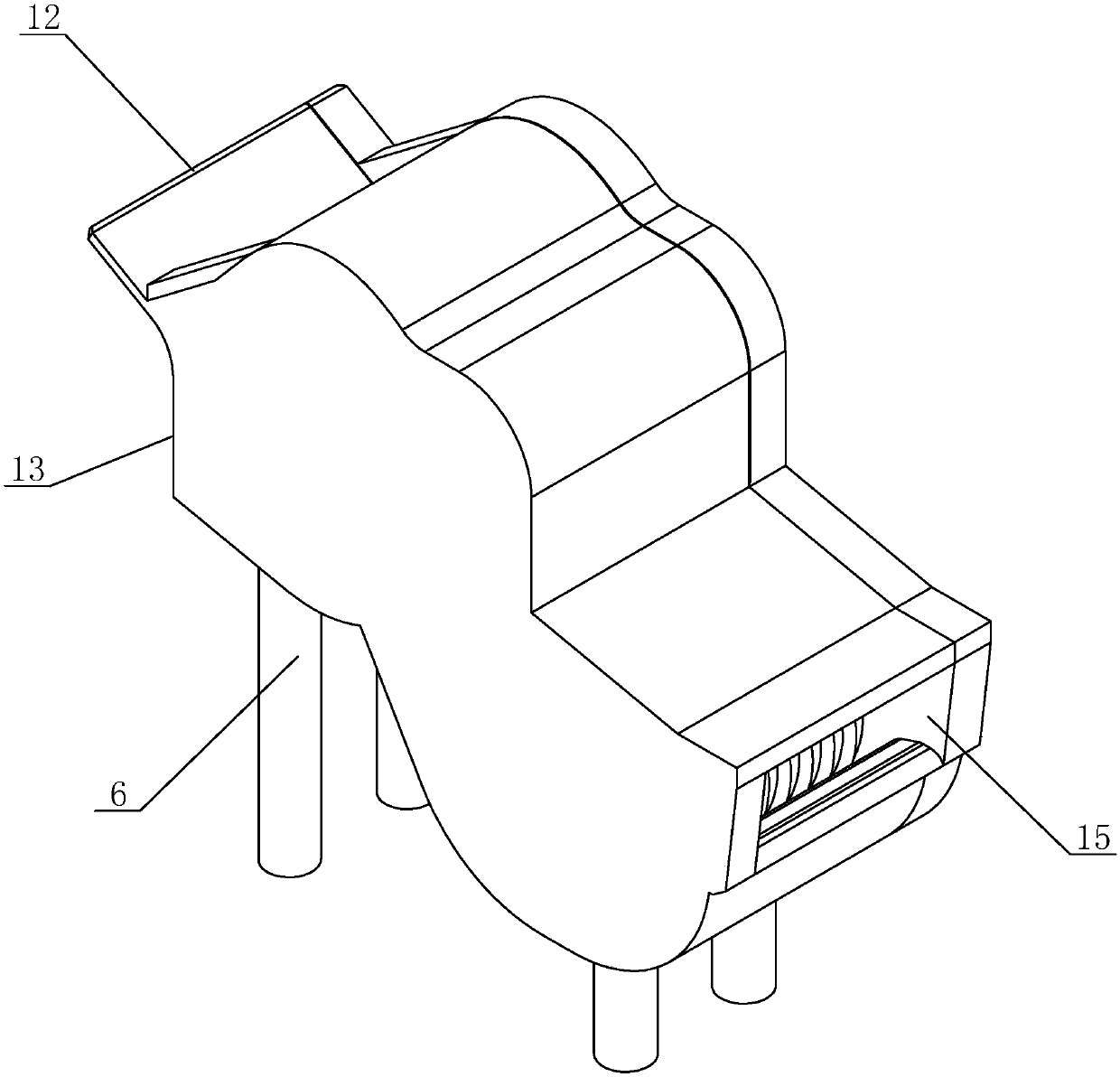

Building material smashing device

The invention discloses a building material smashing device. According to the building material smashing device, gear sets are used for extruding and smashing building materials; in order to prevent that the upper and lower gear sets are stuck by large particle diameter building materials and the device is damaged, according to the building material smashing device, a shaft driving an upper gear is fixed to a shell through an elastic device, so that when the large particle diameter building materials exist, the device can achieve buffering through the elastic device, and device damage is avoided; and meanwhile, it is avoided that the elastic device with certain length is laterally bent, the shaft of the upper gear deviates from a track, and a fault happens.

Owner:余成鹏

Posture corrective chair

ActiveCN106136652APrevent retractionAvoid neckingStoolsAdjustable chairsPhysical medicine and rehabilitationEngineering

Owner:周建明

Solar self-adaptive traffic sign

PendingCN111341196AStable bottomAvoid deviations from the intended positionSignsStructural engineeringSteel columns

The invention provides a solar self-adaptive traffic sign. The invention relates to the technical field of traffic signs, stand column, a supporting structure is fixedly installed at the bottom of thestand column. The supporting structure comprises a steel column. A steel column is fixedly installed at the bottom of the stand column. The outer surface of the steel column is sleeved with a slidingsleeve. Three rotating shafts are arranged on the outer surface of the sliding sleeve in a circumferential mode, the sliding sleeve is rotationally connected with a supporting plate through the threerotating shafts, a supporting plate is fixedly installed at the end, away from the stand column, of the steel column, extending plates are slidably connected to the four corners of the interior of the supporting plate, and a limiting plate is fixedly installed on the side wall of one side of the outer surface of the sliding sleeve. According to the traffic sign, through double stabilization of the bottom of the stand column, the situation that when the bottom of the traffic sign is installed, the bottom of the stand column is laterally bent due to large stress, and consequently the whole traffic sign deviates from the preset position during installation is avoided, and the practicability of the traffic sign is improved.

Owner:JIANGSU SMILE OPTOELECTRONICS TECH

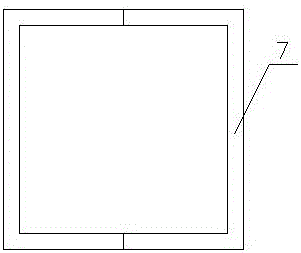

An Elastic Distraction Spinal Growth Rod System

ActiveCN108888327BSimple structureEasy to useInternal osteosythesisSpinal columnPhysical medicine and rehabilitation

The invention discloses an elastic expansion spine growth rod system. The system comprises an orthopedic rod, a clip, a spring and a spring sleeve; the orthopedic rod is a round rod, the clip comprises a snap ring and a locking screw, the snap ring sleeves the orthopedic rod, the snap ring is provided with a screw hole, and the locking screw runs through the screw hole to be in locked connection with the orthopedic rod; the spring sleeves the orthopedic rod between the end of the orthopedic rod and the clip, and the spring is sleeved with the spring sleeve; the spring sleeve is a square tube.The elastic expansion spine growth rod system can not only prevent scoliosis from being aggravated, but also can continuously exert an expansion effect along with the growth of the spine of a child patient, the structure is simple, the use is convenient, the manufacturing cost is low, the operation frequency is greatly reduced, the bending expansion force is larger, and the corrective effect on patients with large curvature of the scoliosis is better.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI

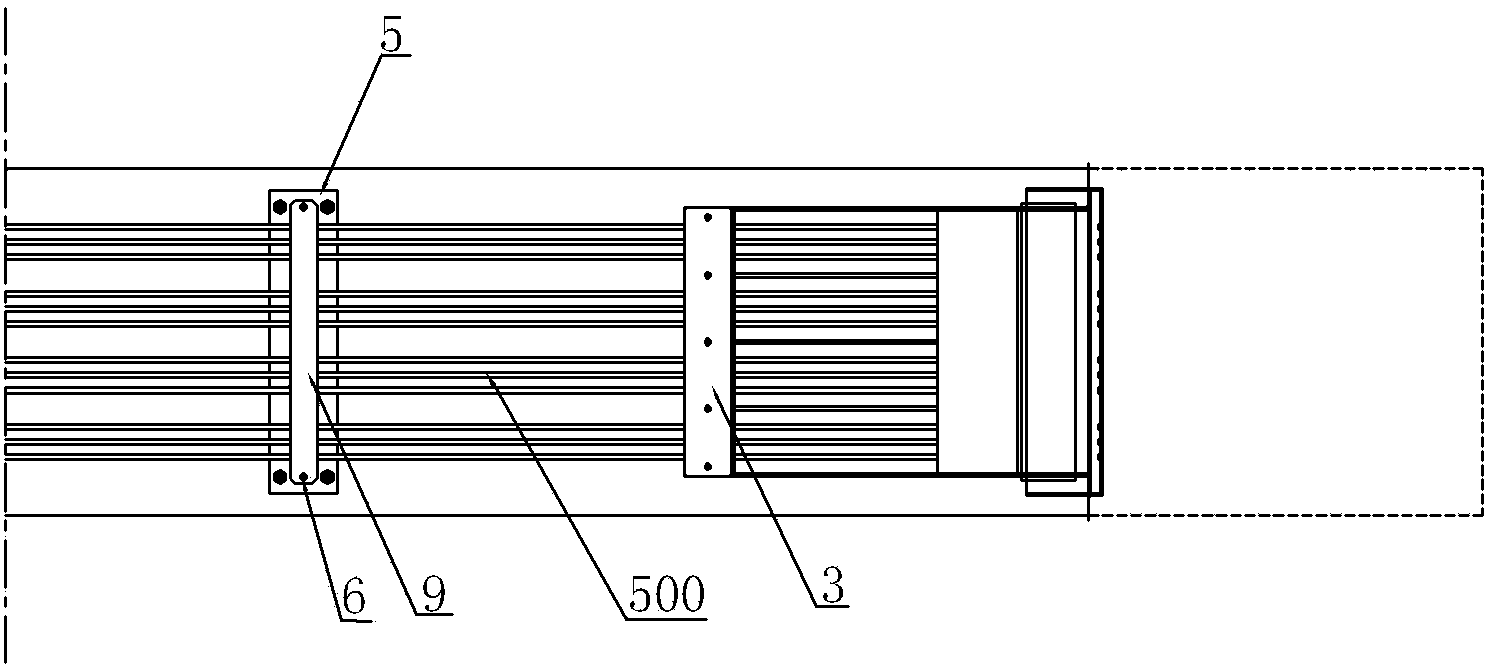

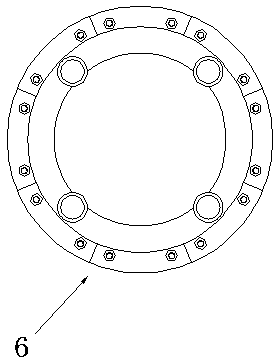

Dummy bar arc starting structure and working method thereof

The invention relates to the technical field of continuous casting, in particular to a dummy bar arc starting structure and a working method thereof. The dummy bar is formed by a plurality of groups of arc starting structure units which are connected; each arc starting structure unit comprises a bar body and a transition section; the bar body comprises two identical plates which are overlapped andaligned and are fixedly connected in the center by a connecting column; the two sides of the plates are each provided with two fixing holes; the transition section is a transition plate; the transition plate is correspondingly provided with a fixing hole and an arc starting hole from the middle to the two ends; the diameter of the arc starting hole is larger than that of the fixing hole; the fixing holes in the bar body have the same diameter as the fixing holes in the transition section; the fixing hole, close to the middle, of the bar body is connected with the fixing holes in the transition section through a fixing shaft; the fixing hole, close to the two ends, of the bar body is connected with the arc starting hole in the transition section through an arc starting shaft; the pluralityof arc starting structure units are connected according to the abovementioned connection way; and one end is connected with a dummy bar head shaft. The dummy bar arc starting structure provided by the invention can use the fixing shaft for limiting and preventing lateral bending; and the arc starting shaft is used for starting arc and prevents downward bending.

Owner:TAIHE CONTINUOUS CASTING APP

Rigid slab continuous casting slab ingot casting rod and manufacturing method thereof

The invention provides a rigid slab continuous casting slab ingot casting rod. The rigid slab continuous casting slab ingot casting rod is characterized in that in the rigid ingot casting rod, a spring plate is embedded into a key groove and a screw, so that the rigidity of a dummy bar is guaranteed, and the flexibility of the dummy bar is increased. Meanwhile, the spring plate is embedded in thedummy bar, so that lateral bending caused by heat deformation caused by direct radiation of heat on the spring plate is avoided; a roller of a withdrawal and straightening machine can be prevented from directly acting on the spring plate to extrude and deform, and if the clamping forces on the two sides of the withdrawal and straightening roller are different, the spring plate on the two sides extend out. At the same time, each transition section, each connecting section and the like are connected through pin shafts, and each section is provided with a hoisting hole, so that replacement and hoisting of spare parts are facilitated. In addition, the invention provides a manufacturing method of the rigid slab continuous casting slab ingot casting rod.

Owner:LAIWU IRON & STEEL GRP

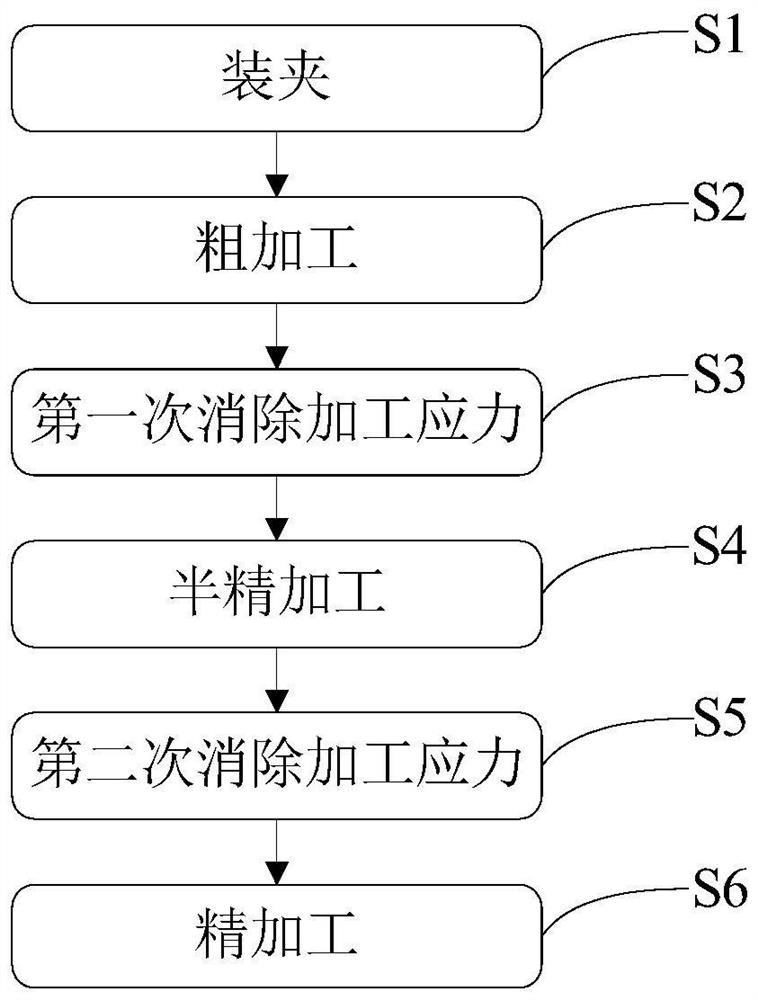

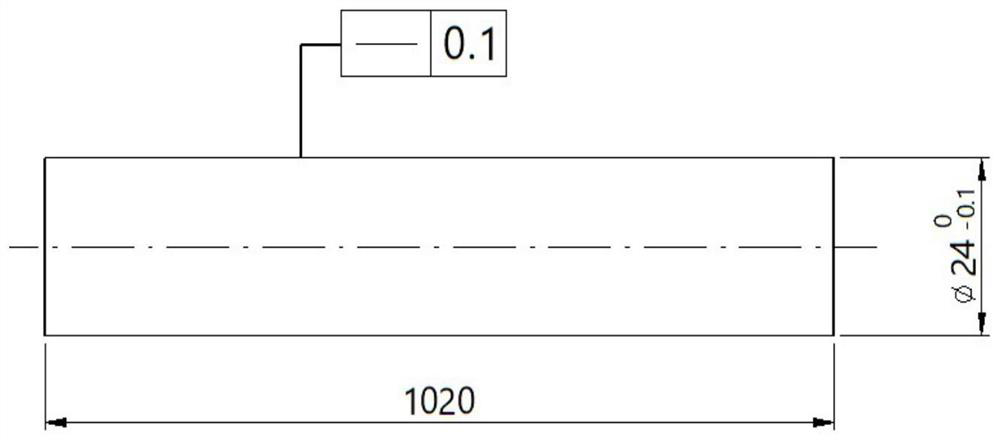

Machining process method suitable for slender iron-stainless steel rod piece

PendingCN114346603AReduce distortionImprove processing qualityMachining processDimensional precision

The invention relates to a machining process method suitable for a long and thin iron-stainless steel rod piece. According to the machining process method suitable for the slender rod piece made of the ferritic stainless steel, machining and detection are combined in real time, deformation of the slender rod piece made of the ferritic stainless steel in the machining process is effectively reduced from the angle of the machining process, so that the machining quality of the slender rod piece is improved, and it is guaranteed that the size precision and the form and position precision of the slender rod piece meet the requirements. According to the method provided by the invention, machining is carried out in a one-jacking and one-clamping manner, and the follow rest is used within the full-length machining length of the slender rod piece made of the iron and stainless steel, so that the situation that the slender rod piece made of the iron and stainless steel is laterally bent due to improper clamping force is avoided. Meanwhile, according to the method provided by the invention, the feed amount is as small as possible, the pressure generated by a cutter on the slender rod piece made of the molten iron in each machining step is reduced, and the lateral bending of the slender rod piece made of the molten iron is reduced, so that the straightness of the slender rod piece made of the molten iron is controlled; and the requirement on the surface roughness of the slender iron-stainless steel rod piece can be better met by small feeding amount.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Length sensor

InactiveCN1229615CCompact layoutAvoid side bendsFeeler-pin gaugesUsing optical meansSpring forceLength measurement

The probe has a probe pin (2) with a probe element (6) for scanning an object (5) by moving relative to a base body (1) against a spring force. The probe pin is biased in the measuring direction (X) by several spring elements (7,8). A guide element (4) is provided between each two spring elements. The guide element is displaceably mounted on the probe pin and on the base body.

Owner:DR JOHANNES HEIDENHAIN GMBH

A container ship lashing bridge vertical general assembly tire frame

ActiveCN105905261BReduce adjustment workloadSimple structureDry-dockingSlipwaysContainerizationGeneral assembly

The invention relates to a vertical general assembly jig frame for a container ship lashing bridge. The vertical general assembly jig frame comprises a strip-shaped jig frame, a plurality of frame backers and a plurality of square tube fixing devices, wherein the strip-shaped jig frame is fixedly installed on a piece of embedded iron in a general assembly site; the plurality of frame backers are evenly distributed on the strip-shaped jig frame; each frame backer comprises two support rods and two connecting rods for connecting the two support rods, wherein the lower ends of the two support rods are fixedly installed at the upper end of the strip-shaped jig frame; each square tube fixing device is installed at the outer sides of the two corresponding support rods; the square tube fixing devices are used for fixing square tubes of the lashing bridge. The vertical general assembly jig frame is simple in structure, convenient in construction and short in general assembly period, and not only can greatly save the precious general assembly site, but also greatly reduces the on-board adjustment work load; furthermore, a turnover lifting lug is not needed during vertical general assembly, so that the strength of welding and grinding is greatly reduced; after the vertical general assembly jig frame is used, the process advancing aim of 'doing on-board operation after going ashore, and doing overhead operation at low altitude' is realized, the building period is shortened, and the working efficiency is increased.

Owner:CHINA SHIPPING IND JIANGSU

Method for preventing square billet from lateral bending in stack cooling process

The invention belongs to the field of steelmaking continuous casting, and relates to a method for preventing square billets from laterally bending in a stack cooling process, which comprises the following steps: when casting billets are primarily cooled by a rolling cooling bed, advance to the tail end of the cooling bed, are collected by a collecting device to be in a six-piece closed state, and are ready to be offline by a travelling crane, fixing clips are clamped at two ends of the casting billets; casting blank offline stacking is carried out through a traveling crane (clamp), the clamp is recycled when the surface temperature of the casting blank is reduced to 300 DEG C or below, sidewise bending caused by internal stress in the cooling process is reduced, and convenience is created for production of the next procedure.

Owner:CHONGQING IRON & STEEL CO LTD

Crane girder

Owner:徐清普

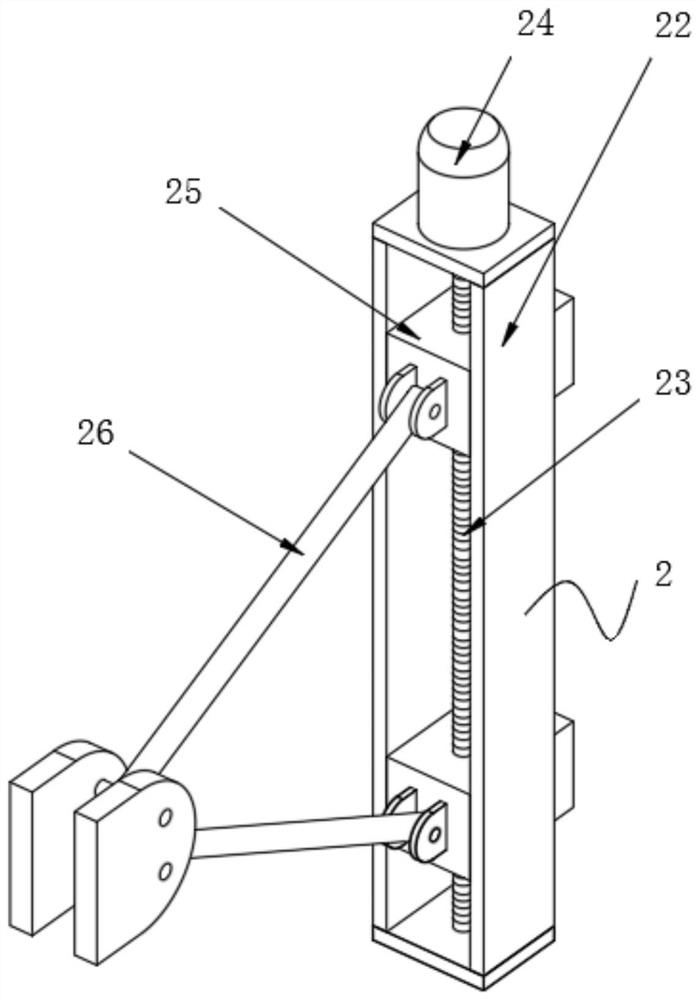

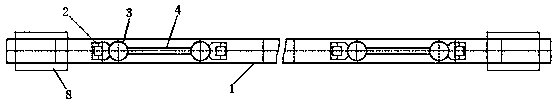

Traction device for copper and copper alloy narrow-band continuous casting

The invention discloses a traction device for narrow-band continuous casting of copper and copper alloys, which comprises a bottom plate, four electric telescopic rods distributed equidistantly on the upper surface, and a box at the top of the electric telescopic rods. Two mounting plates 2 are provided at the front and rear sides of the inner cavity close to the bottom surface. The traction device for continuous casting of copper and copper alloy narrow strips is reasonable in structure and strong in practicability. The upper traction wheel and the lower traction Copper and copper alloy narrow strips are driven by the pulley for traction, the slipping between the traction wheel and the strip and the side bending of the strip during the traction process can be prevented through the limit plate and the anti-skid ball, and the upper traction can be guaranteed through the gear, rack and chute The wheels move up and down smoothly, and are used to pull strips of different thicknesses. The device can be easily opened for cleaning and maintenance through the upper cover, and the height of the device can be easily adjusted through the electric telescopic rod. It is convenient to use and suitable for popularization and use.

Owner:周慈

Full-symmetrical cylindrical membrane wall assembly tooling and assembly method

InactiveCN103143873BAvoid side bendsAvoid bendingWelding/cutting auxillary devicesAuxillary welding devicesCoal chemical industryBiomedical engineering

The invention relates to a full-symmetrical cylindrical membrane wall assembly tooling and an assembly method which are applicable to high-efficiency gasifiers in the coal chemical industry. The method includes the following steps: (1) a membrane wall welder is used for welding round pipes and steels into membrane wall units, and each membrane wall unit consists of the round pipes and the flat steels; (2) the first group of membrane wall units are mounted on a positioner, the lower ends of directional blocks are vertically welded on positioning rings, and thereby the first group of membrane wall units only can be axially moved on the positioner; (3) a second group of membrane wall units which are fully symmetric with the first group of membrane wall units are mounted on the positioner; (4) the two groups of membrane wall units are welded together, and weld joints are located at the middle between the two groups of membrane wall units; (5) according to the method, the welding of the whole cylindrical membrane wall is sequentially carried out. The full-symmetrical cylindrical membrane wall assembly tooling and the assembly method which are disclosed by the invention can adjust the welding sequence, so that the weld joints can always be located at the geometrical middle of the welded workpiece, and thereby great bending is prevented in the process of welding.

Owner:KAIFENG AIR SEPARATION GROUP

A kind of manufacturing method of T profile

ActiveCN106239006BReduce manpower consumptionPrevent dumpingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

The invention relates to a method for manufacturing a T sectional material. The method includes the following steps that first, a manufacturing tool is obtained; second, a panel marked with the center installation line is laid in a groove of the tool; third, a rotating backer at one side of a fixed platform is closed and further locked with a wedge-shaped locking block; fourth, a matched web is vertically hoisted onto the panel through hoisting equipment, so that the web abuts against the closed rotating backer firmly; fifth, a rotating backer at the other side of the fixed platform is closed and further locked with a wedge-shaped locking block, and then the panel and the web are positioned by means of spot welding; and sixth, the backers at the two sides of the fixed platform are loosened, two welding tractors are arranged at the two sides of the web so that the two sides of the web can be welded at the same time, and the T sectional material can be manufactured after welding is completed. By the adoption of the method for manufacturing the T sectional material, production efficiency is greatly improved, final product quality is guaranteed, and construction safety is improved.

Owner:CHENGXI SHIPYARD

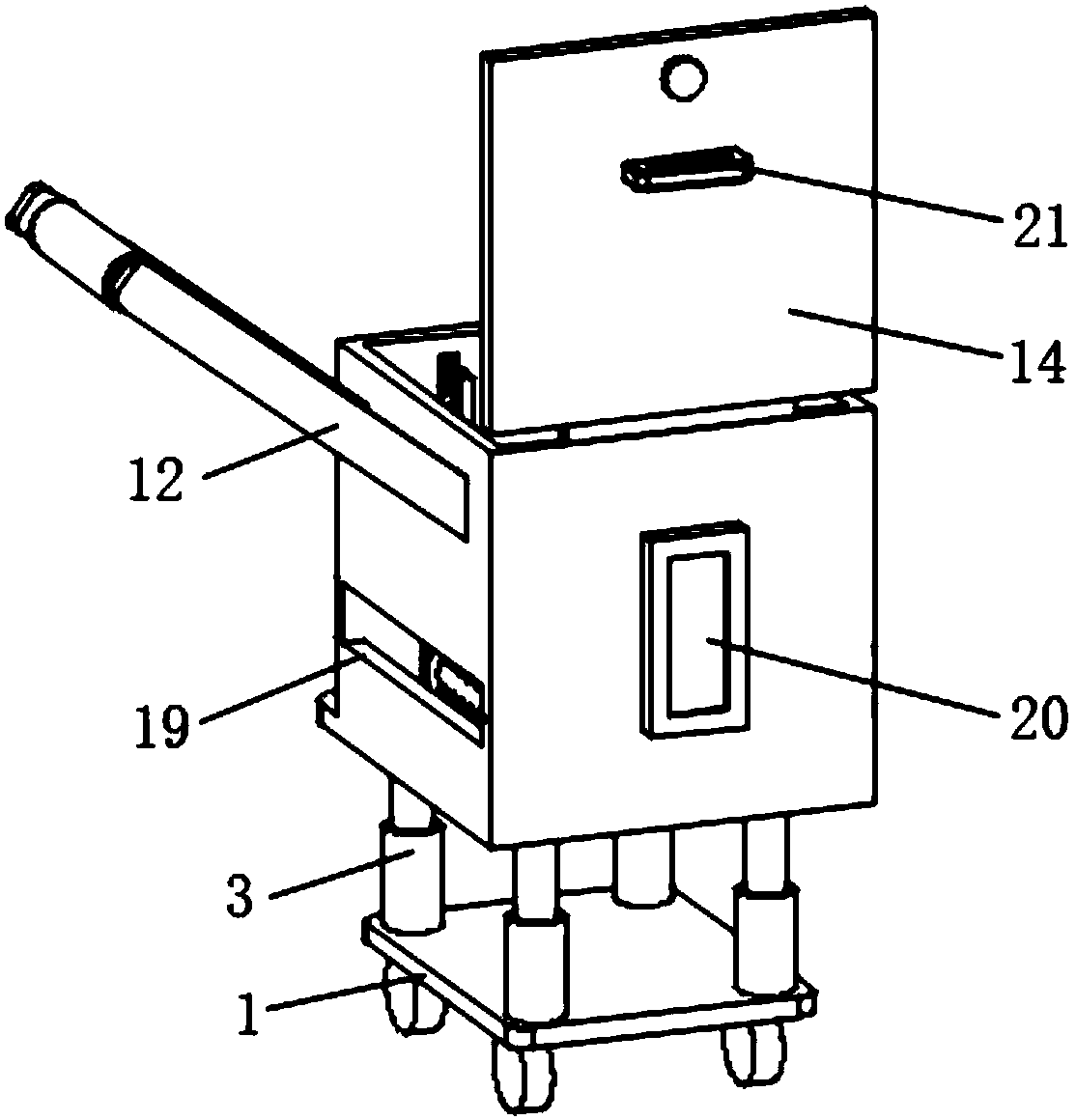

Multifunctional schoolbag

InactiveCN101455468ANormal growth and developmentAvoid side bendsPursesDevices for pressing relfex pointsEngineeringLateral bending

The invention discloses a multifunctional bag, comprising two bag bodies; wherein one bag body is provided with a plurality of massage columns at side surface closing to the body; the other bag body is connected with a bag cover through a connecting piece. In order that the bag does not shake left and right in using, the opposite sides of the two bag bodies are connected by two connecting strips; the connecting strips are installed with adjusting buttons. The weight of the whole bag in the invention is evenly distributed at front and back, left and right, which avoids lateral bending, shrinking bosom and humpback and is good for normal growing development of the students; one side surface of the bag closing to the body is provided with a plurality of massage columns, which can massage the back of the students and is help for the body health.

Owner:袁凤娇

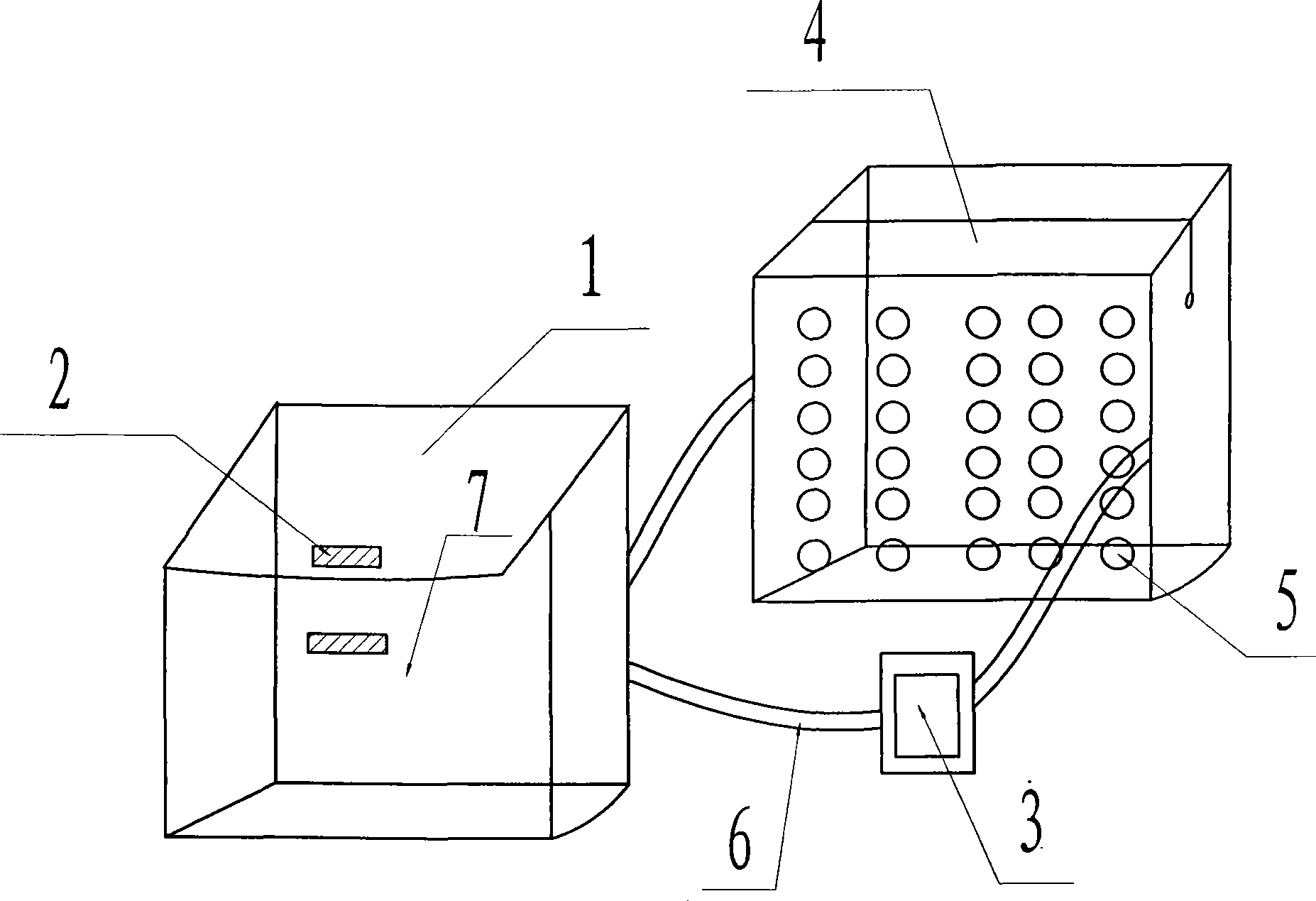

A health detection system with office equipment

ActiveCN103886214BReal-time detection of health dataAvoid side bendsHealth-index calculationDiagnostic recording/measuringVital sign detectionComputer module

The invention relates to a health detection system with an office device. The health detection system comprises a table top, a support, a lifter, a vital sign detection device, a communication module and a main control module. The support is arranged under the table top and used for supporting the table top, the lifter is located in the support and used for controlling the height of the support, the vital sign detection device, the communication module and the main control module are arranged in the table top, the vital sign detection device is connected with the main control module which is connected with the lifter through the communication module, and an opening is formed in the side face of the table top so that the vital sign detection device can detect a human body through contact with the human body to obtain health data of the human body. The vital sign detection device sends the health data to the main control module, the main control module sends a height control command to the lifter through the communication module according to the health data, and the height of the support is controlled. The health detection system can obtain health data of human bodies in real time.

Owner:优维精准医疗管理(深圳)有限公司

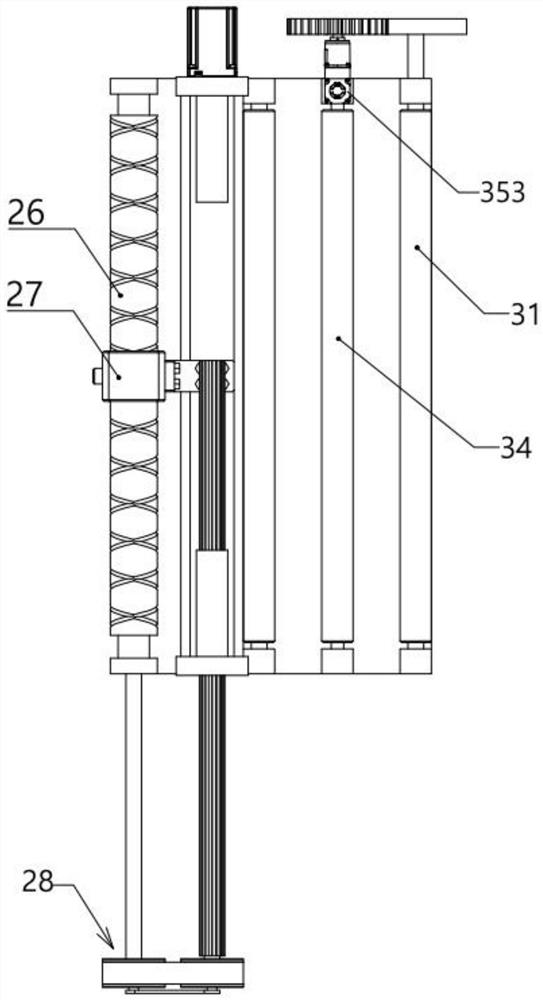

Aerial work platform for overhauling

PendingCN107954382AImprove securityAvoid side bendsSafety devices for lifting equipmentsMarine engineeringAerial work platform

The invention discloses an aerial work platform for overhauling, and relates to the field of operation platforms. The aerial work platform for overhauling has the advantages of being simple in structure, low in cost and easy and convenient to operate. The aerial work platform for overhauling comprises a lifting assembly, a balance adjusting assembly, a platform assembly and a horizontal adjustingassembly, wherein the platform assembly is connected to the horizontal adjusting assembly in a sliding mode, the horizontal adjusting assembly is fixedly connected to the balance adjusting assembly, the balance adjusting assembly is connected to the lifting assembly, and the lifting assembly drives the balance adjustment assembly to ascend and descend for adjustment.

Owner:欧咖莱(重庆)智能装备技术有限公司

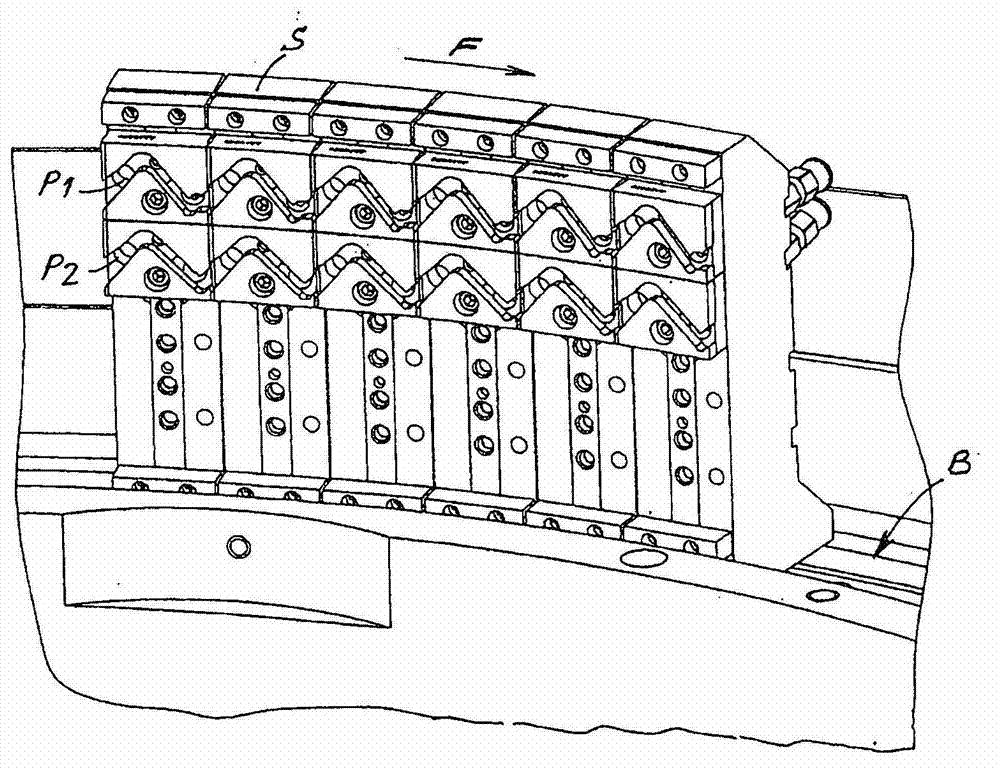

Knitting machine with mutually differentiated control channels for the needles

A circular knitting machine is described comprising a needle cylinder and a set of control cams for the needles that comprise ascending branches for the needles and descending branches for the needles and form at least two overlapped tracks (P1, P2) of control cams for the needles, and wherein in the needle cylinder at least two different types of needles (A1, A2) are arranged, different from each other for the different distance between butt and hook and actuated each by a respective cam track (P1, P2). The control cams (A) of a track (P1) present at least the lower part of the respective descending branch displaced in the direction of the movement of rotation of the cylinder with respect to the lower part of the respective descending branch of the corresponding cams (R) of the other track (P2), so that, on each feed, the downward movement of the needles of one type (A1) following a cam track (P1) is advanced by a preset angle of rotation of the cylinder with respect to the downward movement of the needles of the at least one other type (A2) following another cam track (P2).

Owner:PILOTELLI MACCHINE TESSILI

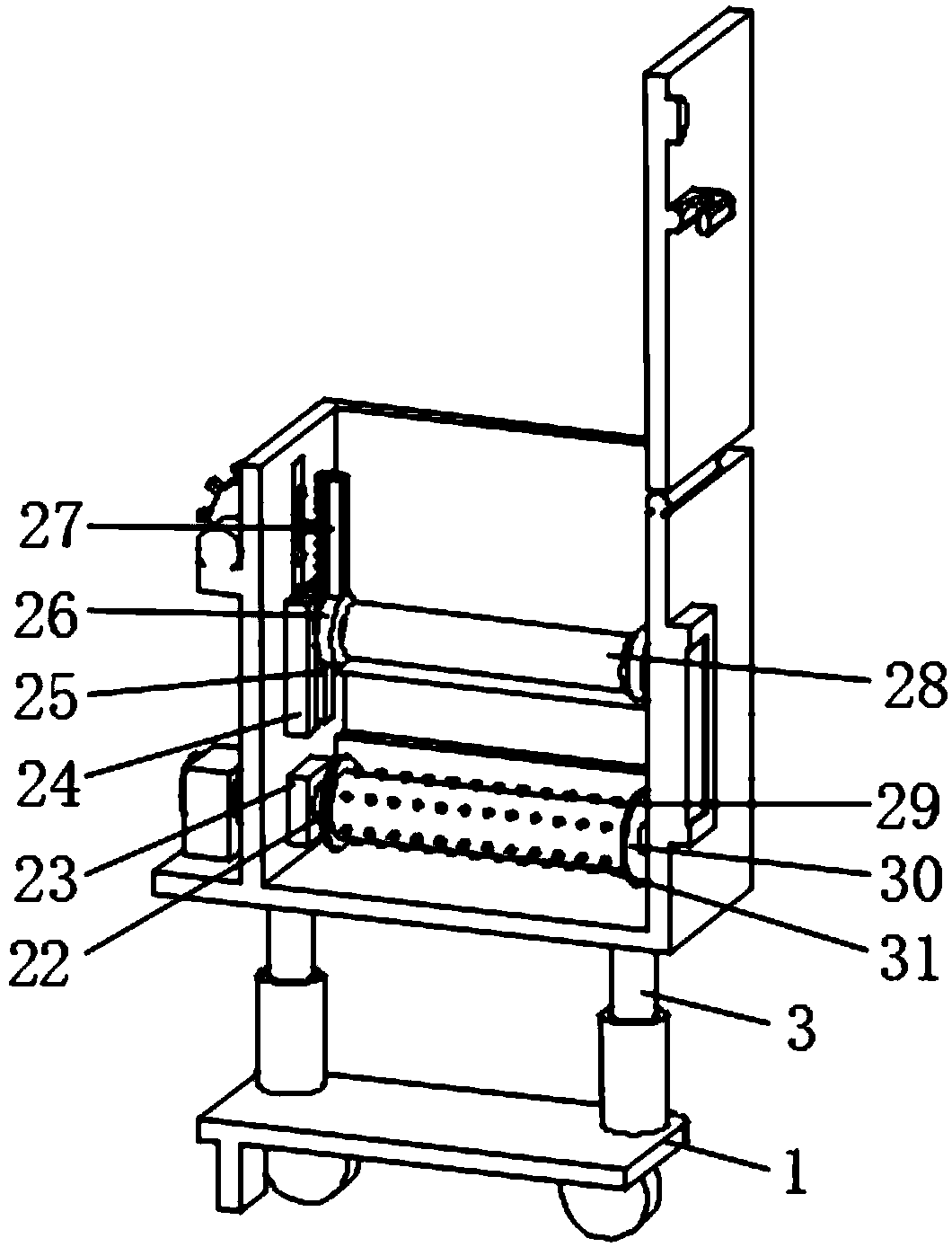

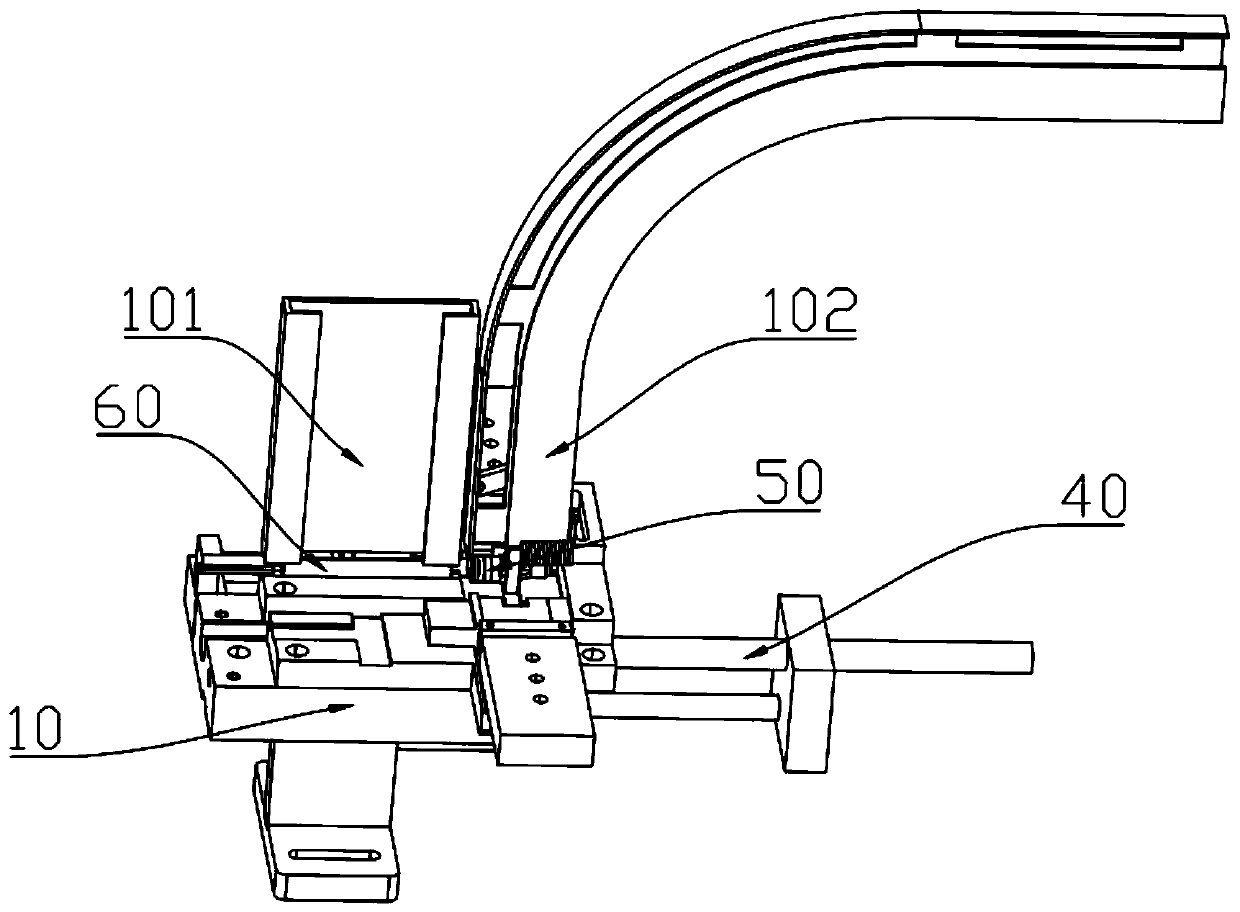

Automatic ink absorption strip installing device for marking pen point

The invention relates to the field of pen assembly, in particular to an automatic ink absorption strip installing device for marking pen points. The device comprises a workbench, wherein an ink absorption strip conveying rail and a pen point conveying rail are arranged above the workbench side by side, an ink absorption strip installing and positioning area is arranged below the ink absorption strip conveying rail, a pen point installing and positioning area is arranged below the pen point conveying rail, the ink absorption strip installing and positioning area and the pen point installing andpositioning area are arranged in a penetrating mode, an assembling mechanism is arranged on the workbench, a limiting step is formed at the end, away from the ink absorption strip installing and positioning area, of the pen point installing and positioning area, the assembling mechanism comprises a first air cylinder and a push block arranged on an output shaft of the first air cylinder, the pushblock can move left and right along the pen point installing and positioning area, a sliding groove is formed in the workbench, the sliding groove and the pen point installing and positioning area are parallel and arranged at intervals, a pushing mechanism for pushing the installed pen points to the sliding groove from the pen point installing and positioning area is arranged on one side of the pen point installing and positioning area, and a discharging mechanism for pushing the installed pen points out in the axial direction of the sliding groove is further arranged on the workbench.

Owner:浙江思迈拓科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com