Full-symmetrical cylindrical membrane wall assembly tooling and assembly method

A cylindrical membrane wall and membrane wall technology, applied in the field of coal chemical industry, can solve the problems of welding defects, easy to be pulled apart, large welding shrinkage, etc., and achieve the effect of avoiding bending and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

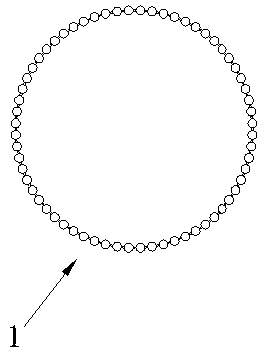

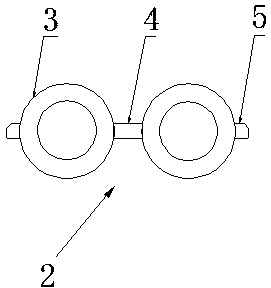

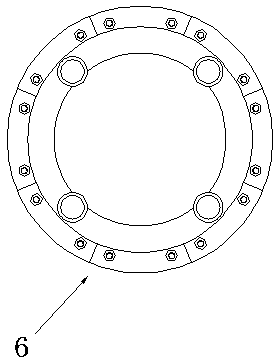

[0032] Such as figure 1 , 2 ,3,4,5,6,7,8,9, a cylindrical membrane wall fully symmetrical assembly tooling, the cylindrical membrane wall 1 includes 64 round tubes 3, each membrane wall unit Both are two-tube and three-flat steel unit 2. The two-tube and three-flat steel unit is composed of two round tubes, one flat steel 4 and two narrow flat steels 5. The two narrow flat steels are grooved according to the welding requirements; the tooling It includes a mold 6, which includes a plurality of positioning rings 7 and 4 connecting steel pipes 9. The positioning rings are respectively sleeved and fixed on the outside of the 4 connecting steel pipes. The distance between the two positioning rings at both ends of the connecting steel pipe is greater than The length of the cylindrical membrane wall; the outer diameter of the positioning ring is provided with the same number (32) of two tubes and three flat steel units (32) divided along the generatrix as the cylindrical membrane wall ...

Embodiment 2

[0035] On the basis of the first embodiment, a method for fully symmetrical pairing of cylindrical membrane walls, the steps of the method are as follows:

[0036] Step 1: Use a membrane wall welder to weld round pipes, flat steels and narrow flat steels into a two-tube three-flat steel unit, and cut the narrow flat steel at the end of the two-tube three-flat steel unit into a groove according to the welding requirements;

[0037] Step 2: Install the first group of two-tube three-flat steel unit on the mould, and determine the relative position of the first group of two-tube three-flat steel unit and the mould through the bisector on the alignment plate and the positioning ring. After confirming, insert the upper end of the directional plate into the middle of the two round pipes in the first group of two pipes and three flat steel unit, and the upper end is attached to the two round pipes, and the lower end is welded to the positioning ring vertically;

[0038] Step 3: Weld the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com