Steel wire straightening machine

A straightening machine and steel wire technology, applied in the field of steel wire processing, can solve problems such as unfavorable straightening process, and achieve the effect of avoiding lateral bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] see Figure 1 to Figure 3 , the present invention provides a kind of technical scheme:

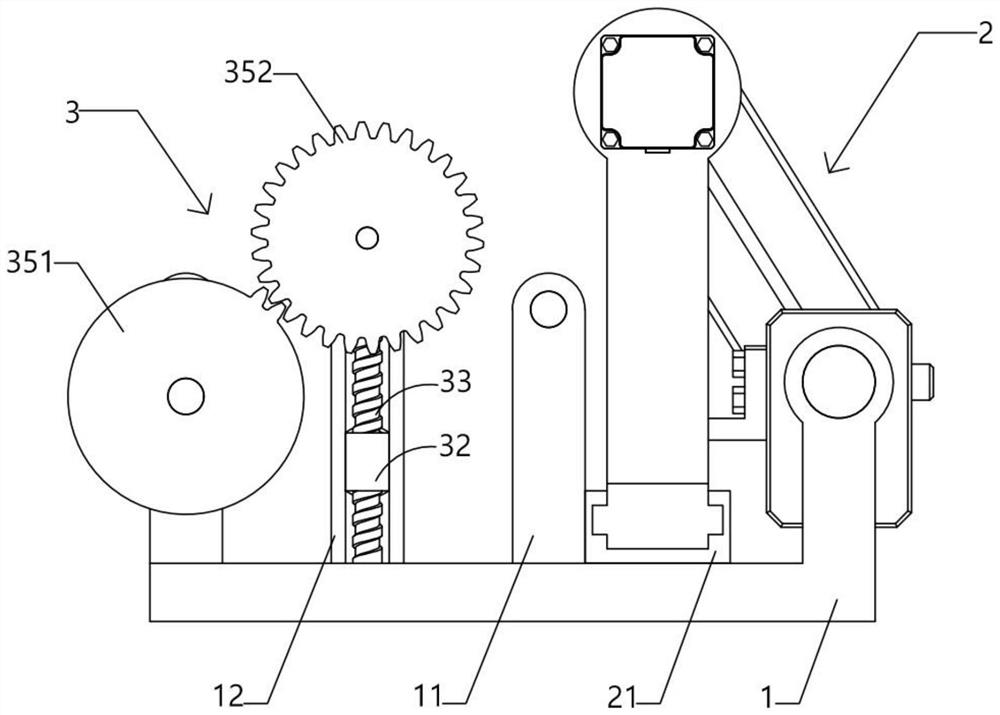

[0023] A steel wire straightening machine, comprising a base plate 1, an unwinding mechanism 2 and an adaptive straightening mechanism 3, wherein:

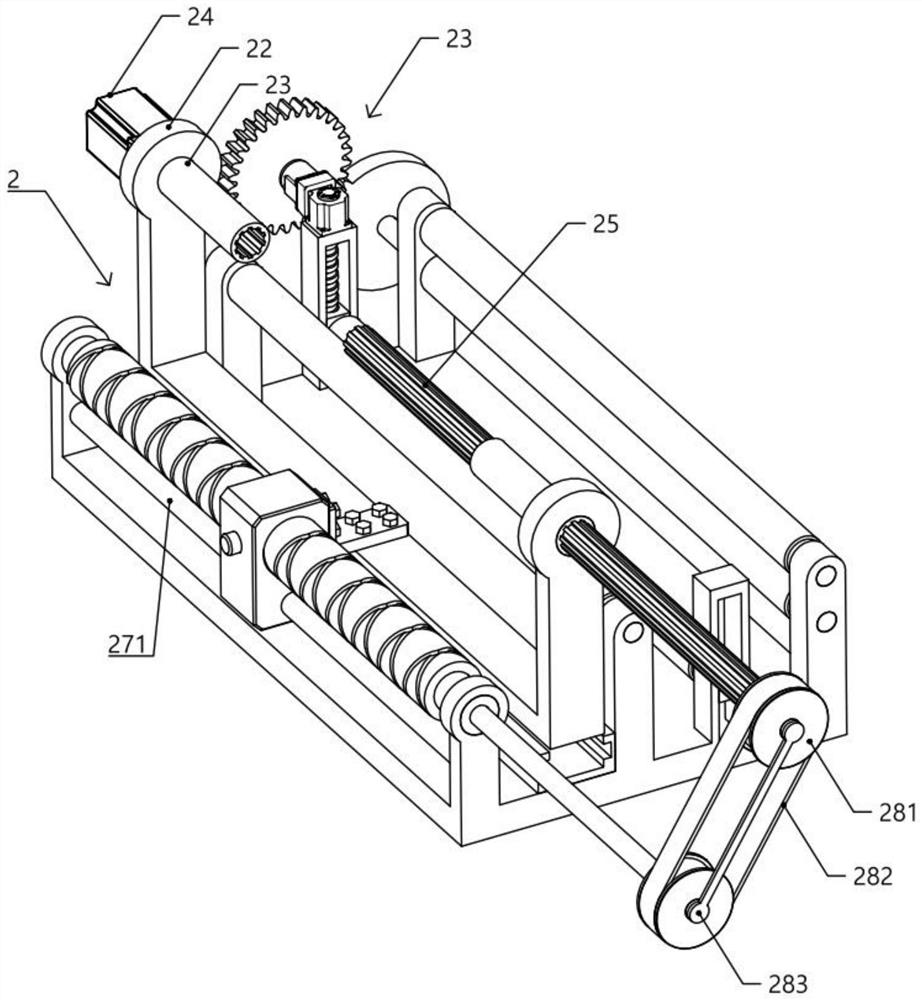

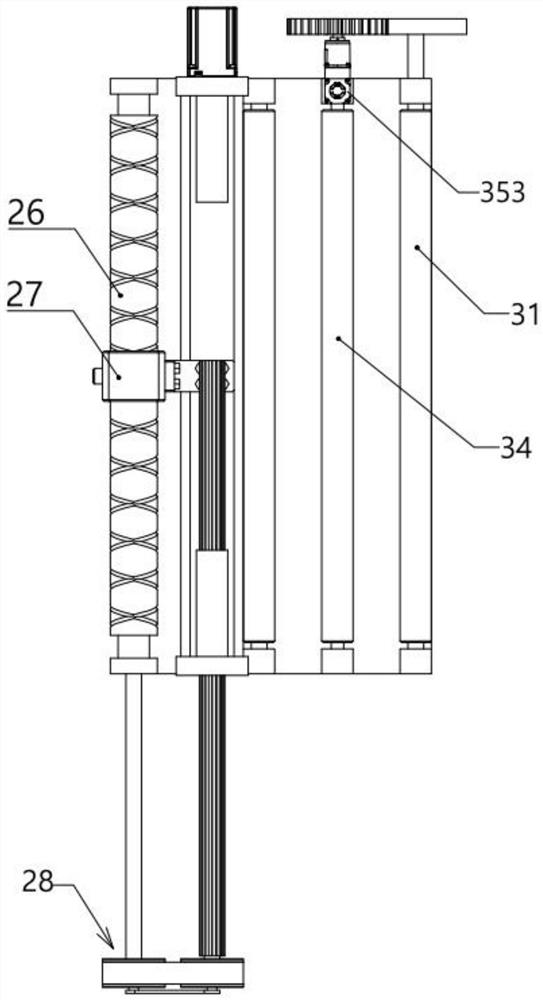

[0024] The four uprights 11 are arranged on two sides of the base plate 1 in pairs, wherein the two uprights 11 on different sides are oppositely arranged, and a vertical guide slot 12 is provided between the two uprights 11 on the same side;

[0025] The unwinding mechanism 2 includes a linear guide 21, a rewinding frame 22, a sleeve 23, a motor 24, a spline shaft 25, a double helical guide rod 26, a crescent plate 27 and a transmission assembly 28. The linear guide 21 is arranged on the bottom plate 1. The reel frame 22 is fitted in the guide rail 21 and forms a moving pair in the guide rail 21. The two sleeves 23 are rotatably installed on both sides of the reel frame 22. The power output end of the motor 24 is connected, the splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com