Length sensor

A technology of length measurement and measuring head, which can be used in measuring devices, mechanical measuring devices, measuring gauges, etc., and can solve problems such as lateral bending and measuring head friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

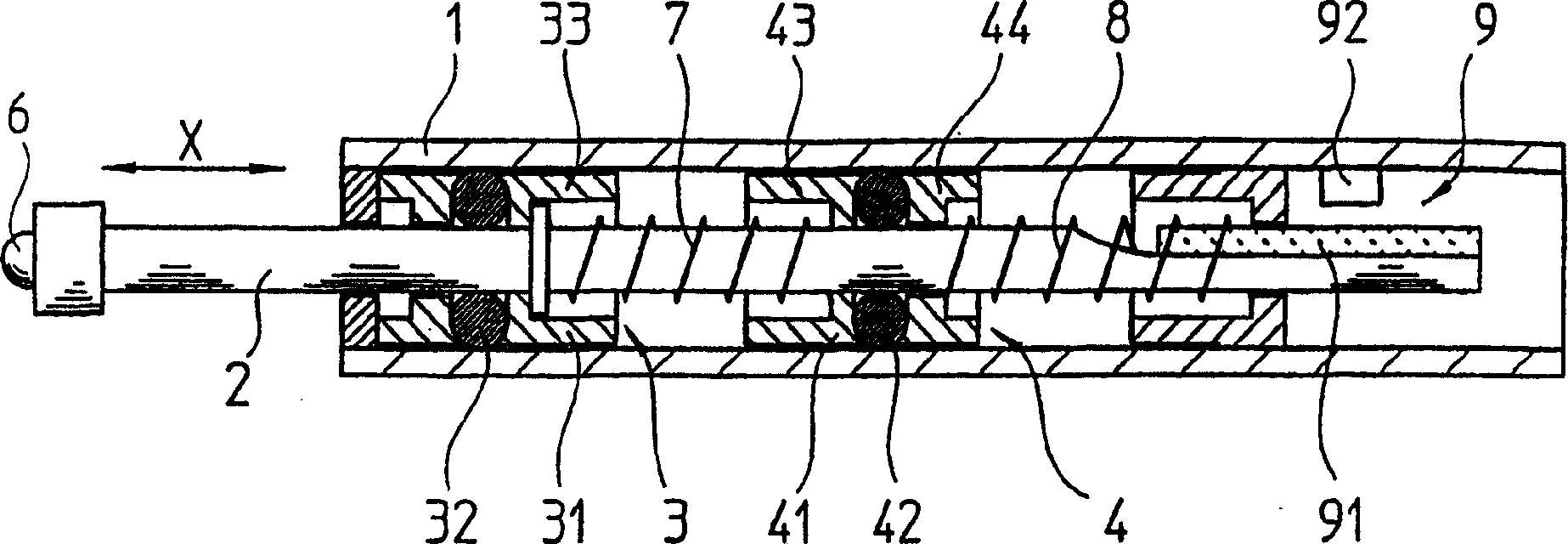

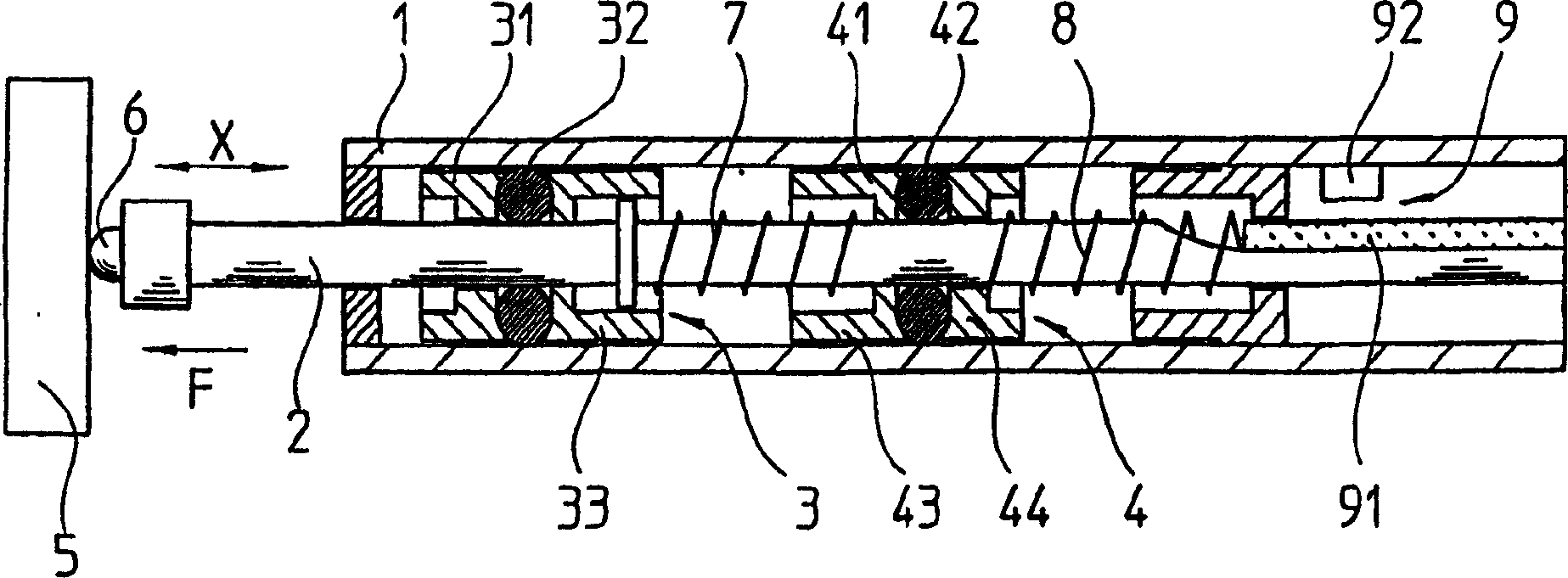

[0016] according to figure 1 and figure 2 The following describes an embodiment of a length measuring device designed according to the present invention. The figures schematically show a cross-sectional view of the entire length measuring device, which includes a base body 1 in which a rod-shaped measuring head 2 is supported, which is slidable in the measuring direction X.

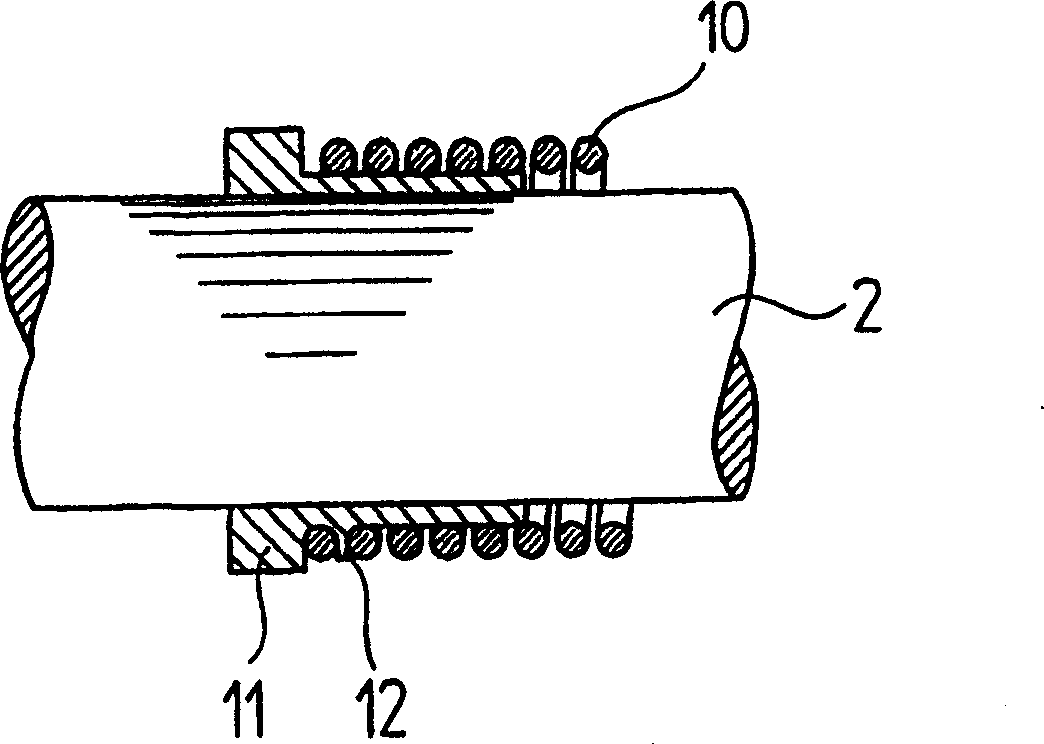

[0017] measure a for contact figure 2 For the workpiece 5 shown, the end of the measuring head 2 is designed as a ball contact 6 . During an abutment process, the measuring head 2 is pressed with a force F by the abutment element 6 on the surface of the workpiece 5 to be measured. This force F is generated by helical springs 7 and 8 , which are arranged one behind the other in the measuring direction X and press the abutment element 6 against the workpiece 5 . In order to make the structure compact, the coils of the coil springs 7 and 8 extend around the circumference of the circular measuring head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com