Crane girder

A technology for cranes and main girders, applied in the field of cranes, can solve problems such as the easy failure of the supporter, and achieve the effects of good creep resistance, obvious effect, and long maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

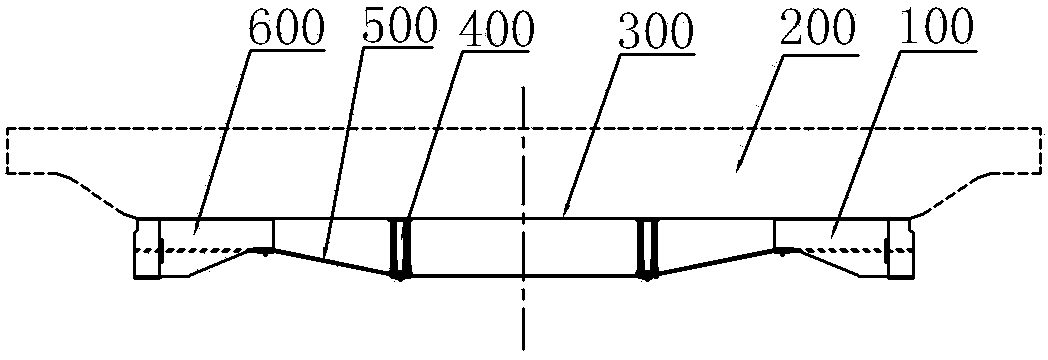

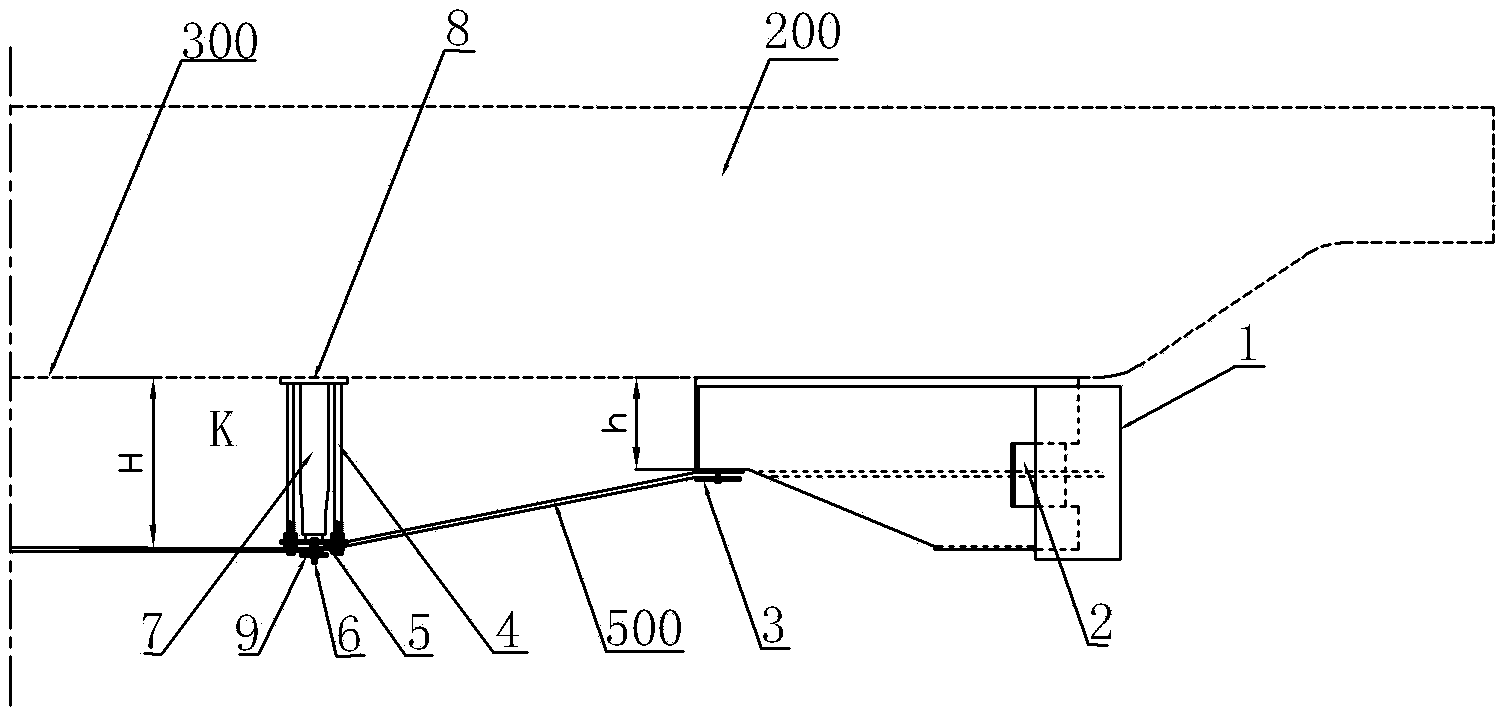

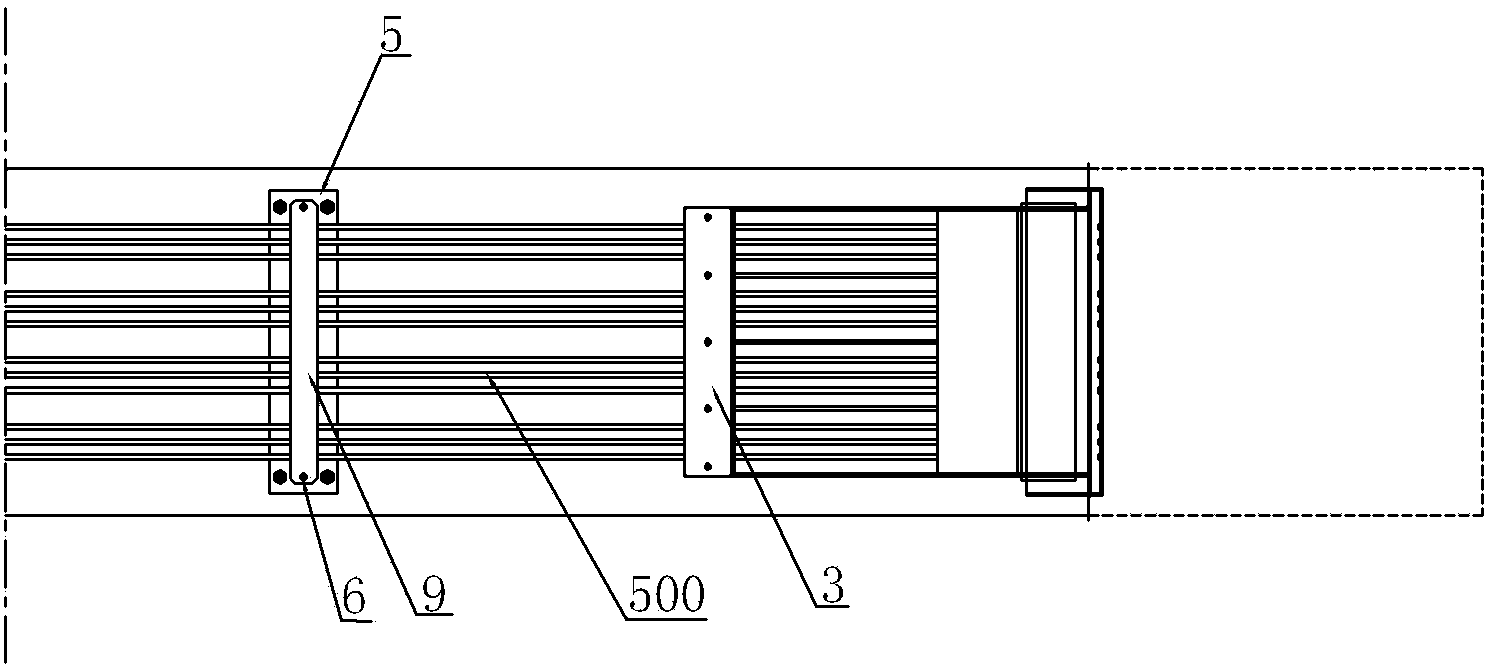

[0031] Such as Figure 1 to Figure 7 As shown, an embodiment of a crane girder, the crane girder 200 in this embodiment includes a lower cover plate 300, and a repair device for repairing the deflection of the main girder is installed on the side of the lower cover plate 300 away from the main girder, The repair device includes a first base 100 and a second base 600 fixed at both ends of the lower cover plate, where the first base 100 is a tension base equipped with tension anchors, and the second base 600 is a fixed The base, between the tension base and the fixed base, can be tensioned and equipped with a plurality of steel strands 500 extending in parallel, one end of the steel strands 500 is fixed in the fixed base, and the other end is in the fixed base. After passing through the tension anchor of the tension base, it is connected with the tension device 11 arranged on the tension base. The tension device 11 here is a hollow hydraulic jack tension device. When in use, the...

Embodiment 2

[0041] The difference between embodiment 2 and embodiment 1 mainly lies in the difference of the middle pushing structure, such as Figure 10 , Figure 11 , Figure 12 As shown, the upper connecting part in the present embodiment is an upper connecting plate 14, the lower connecting part is a round steel 19, and the middle pushing structure is a vertical plate 15, and the lower side of the vertical plate 15 is welded and fixed with the round steel 19, and the upper side is connected with the round steel 19. The upper connecting plate 14 is welded and fixed, and the two ends of the vertical plate 15 along the extension direction of the main beam are respectively welded and fixed with the corresponding supporting studs 18 , and the round steel 19 is fixedly matched with the supporting studs 18 through the vertical plate 15 . Between the round steel 19 and the upper connecting plate 14, two oblique supporting plates 16 are respectively positioned on the left and right sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com