Extensible high-altitude conjoined steel structure

A technology of conjoined steel and fixed mechanism, which is applied in the direction of building construction and construction, can solve the problems of steel structure erection, thermal expansion and contraction, etc., and achieve low noise, good economic benefits, and less waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

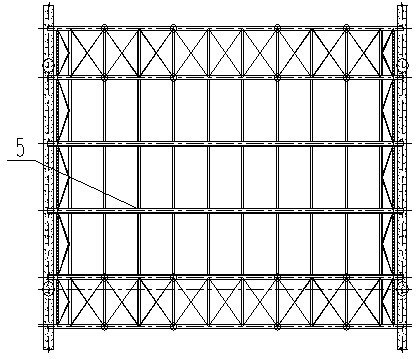

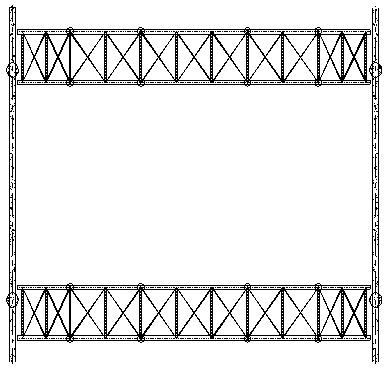

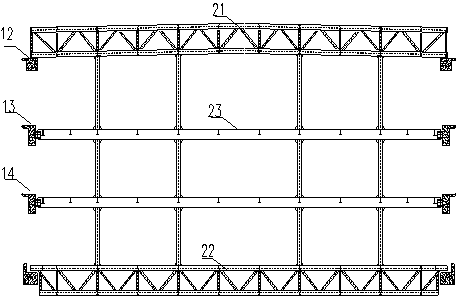

[0067] A scalable high-altitude conjoined steel structure, which is composed of an upper-tension truss beam fixing mechanism 12, a middle-level beam fixing mechanism 13, a lower-supporting truss beam fixing mechanism 14, a top-level truss beam 21, a bottom-level truss beam 22, a middle-level beam 23 and The filling support 5 constitutes;

[0068] The top truss beams 21, bottom truss beams 22, and middle truss beams 23 are arranged horizontally in pairs, and each pair of top truss beams and bottom truss beams are connected by connectors.

[0069] The upper pull truss beam fixing mechanism 12 , the middle layer beam fixing mechanism 13 and the lower supporting truss beam fixing mechanism 14 are respectively embedded in the fixing bases of the two main bodies.

[0070] The top floor truss beam 21, the bottom floor truss beam 22, and the middle floor beam 23 are respectively connected with the upper pull truss beam fixing mechanism 12, the lower supporting truss beam fixing mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com