Loop control method capable of ensuring tension stability of strip steel processing line

A control method and processing line technology, applied in the direction of tension/pressure control, etc., can solve the problems affecting the normal operation of the processing line, poor quality of strip steel products, strip tension oscillation, etc., so as to avoid the impact of product quality, solve tension oscillation, Guarantee the effect of stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

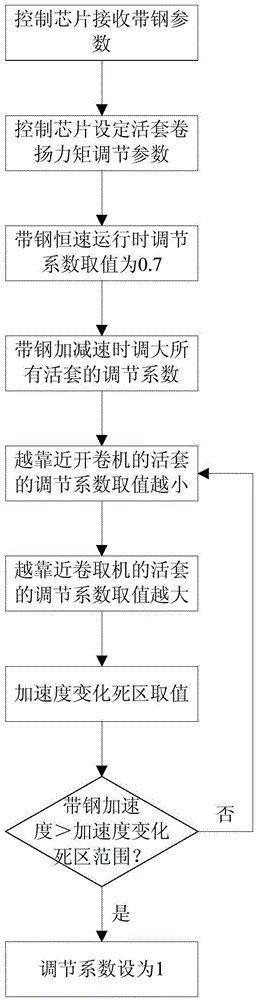

[0014] see figure 1 , the present invention guarantees the looper control method that handles line strip steel tension stability, comprises the following steps:

[0015] Step 1, the control chip receives the yield strength and thickness parameters of the running strip on the processing line;

[0016] Step 2. Set the looper hoisting torque adjustment parameters according to the aforementioned parameter control chip:

[0017] Q n =Q n-1 +A*GAIN*(T 0 / T n )*(DEV n +DEV n-1 +DEV n-2 ) / 3,

[0018] in,

[0019] Q n : is the output (0-1) of the looper hoisting torque controller at sampling time n,

[0020] Q n-1 : is the output (0-1) of the looper hoisting torque controller at sampling time n-1,

[0021] T 0 : is the program scan time (1-15ms),

[0022] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com