Patents

Literature

58results about How to "Achieve efficient recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

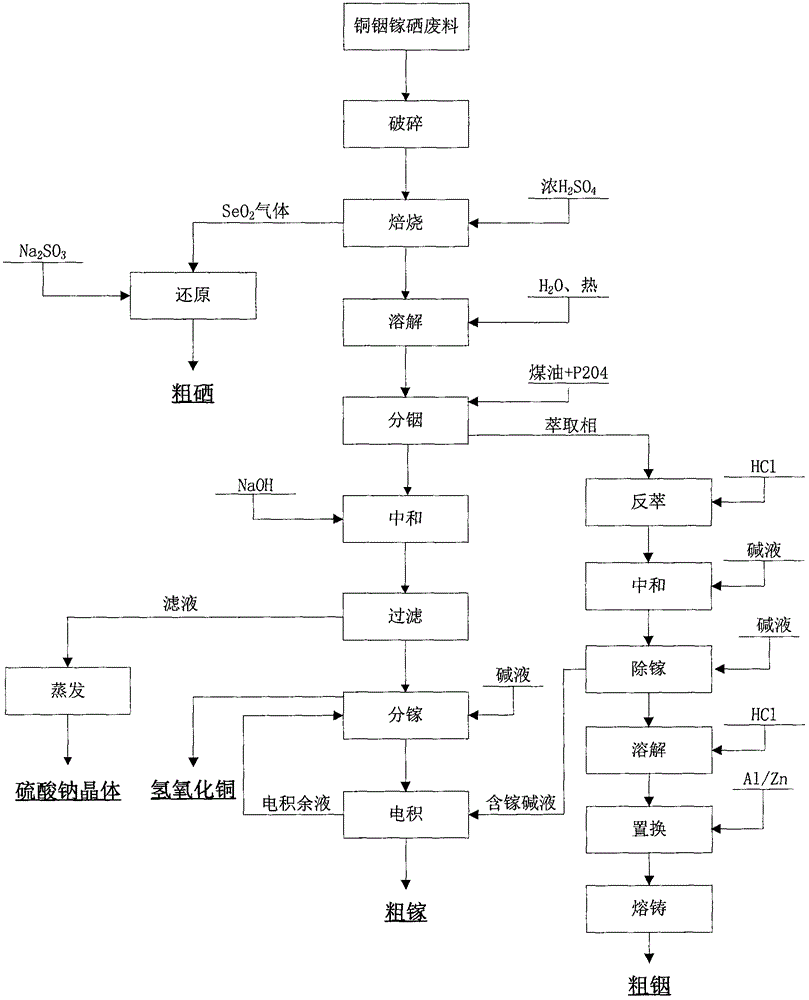

Recycling method for copper indium gallium selenide (CIGS) waste

ActiveCN105886767AAchieve efficient recyclingAchieving zero emissionsProcess efficiency improvementElemental selenium/telluriumRecovery methodIndium

The invention relates to a recycling method for copper indium gallium selenide (CIGS) waste. The recycling method comprises the steps that selenium in the CIGS waste is subjected to acidifying, roasting and volatilizing at first, SeO2 gas is reduced through a sodium sulfite solution, and crude selenium is obtained to achieve advance separation of the selenium, so that the problem that the selenium is always difficult to separate in the industry is solved; and then, the rest of three kinds of metal are separated, particularly, gallium-containing alkali liquor produced in the indium separation process and a gallium-containing solution obtained in the gallium separation process are combined, and electrodepositing residual liquor can be returned to the to-be-electrodeposited gallium-containing solution to be subjected to circulatory electrodepositing, so that efficient and circulatory recycling of gallium is achieved. According to the recycling scheme of the recycling method for the CIGS waste, the comprehensive recycling rate of the various materials is much higher than the existing level in the same industry; in addition, production wastewater zero discharge can be achieved in the whole recycling process, and the environment-friendly degree is high; and moreover, the whole recycling process is easy to operate, high in safety and reliability, low in cost and capable of achieving large-scale production easily and has broad application prospects.

Owner:HANERGY MOBILE ENERGY HLDG GRP CO LTD

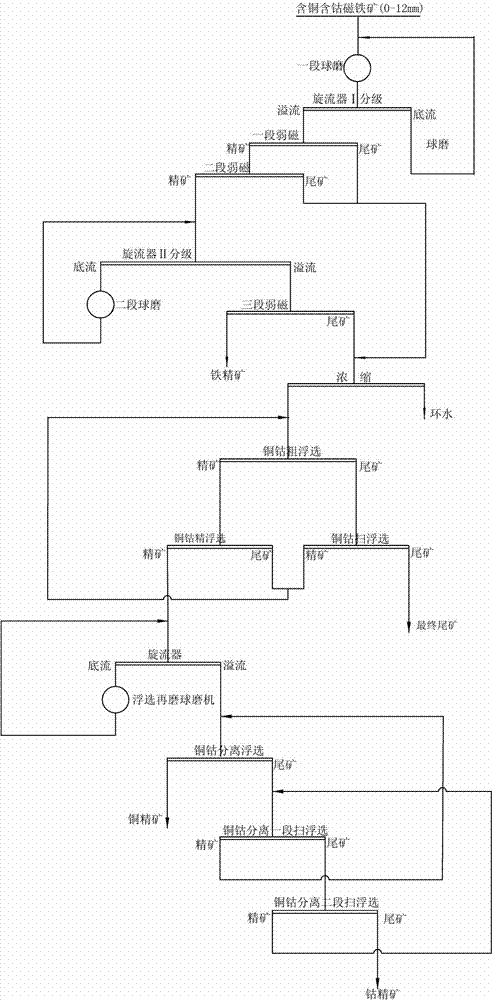

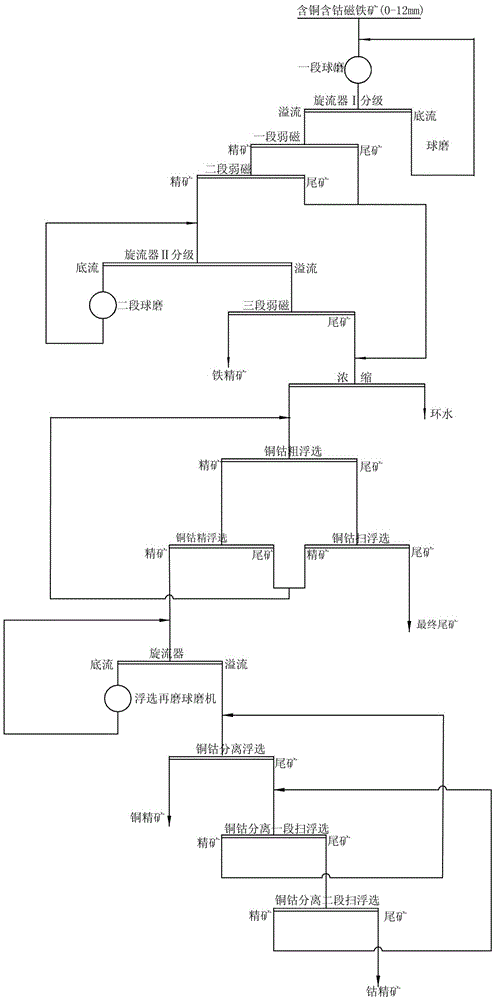

Sorting technology for iron ore containing copper, cobalt and magnetite

ActiveCN104258963AAchieve efficient recyclingReduce ore handlingFlotationMagnetic separationSeparation technologyEconomic benefits

The invention belongs to the technical field of ore dressing and in particular relates to a sorting technology for iron core containing copper, cobalt and magnetite. An ore grinding-grading-magnetic separation magnetite dressing technology is adopted for sorting magnetite, and a copper-cobalt bulk flotation and separation technology is adopted for sorting copper and cobalt. The sorting technology for the iron core containing copper, cobalt and magnetite has the advantages that three valuable minerals are respectively separated out by firstly adopting magnetic separation to obtain qualified iron ore concentrate and then adopting flotation for successively sorting qualified copper concentrate and cobalt concentrate, treatment ore quantity of the next sorting system is gradually reduced, energy consumption is effectively reduced, and production cost is reduced; meanwhile, three concentrates respectively reach an industrial utilization level, effective and comprehensive recycling of three elements is realized, and the economic benefit is increased.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

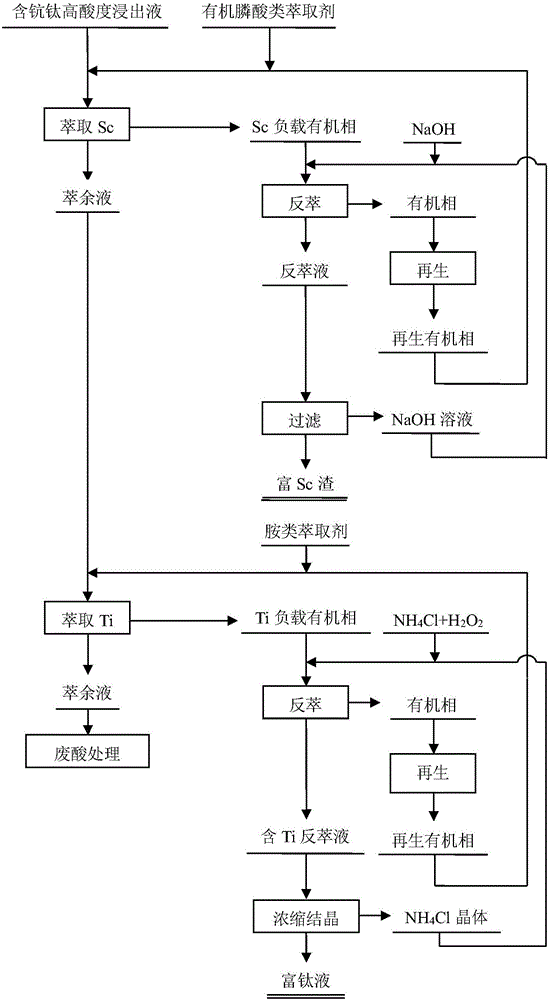

Method for extracting and recycling scandium and titanium from acid leaching solution containing scandium and titanium

ActiveCN106048257AHigh selectivityAchieve efficient recyclingProcess efficiency improvementConcentration ratioTitanium

Disclosed is a method for extracting and recycling scandium and titanium from an acid leaching solution containing scandium and titanium. When the acid solution containing both scandium and titanium is processed, scandium is preferentially extracted by making full use of the features that the concentration of the acid leaching solution is relatively high, and the high acidity can restrain iron and titanium and improve the selectivity of organic phosphonic acid extracting agents to scandium, a residue rich in scandium is obtained by the use of a NaOH solution through back extraction, titanium is extracted by the use of amine extracting agents which are high in selectivity to titanium after scandium is extracted, titanium is processed by a NH4Cl-H2O2 mixed solution through back extraction, a back extraction solution concentrates and crystallizes, NH4Cl crystals are separated out, and a solution rich in titanium is obtained. By the adoption of the method, effective recycling of scandium and titanium is achieved, the problem that when scandium and titanium are extracted by the use of the organic phosphonic acid extracting agents and the amine extracting agents respectively under the usual conditions, due to the fact that iron, scandium and titanium are not separated thoroughly, the follow-up separation process is tedious is solved, the process is short, the cost is low, comprehensive recovery of low-concentration scandium and titanium in the acid leaching solution and titanium dioxide production waste acid is achieved, and the method has the advantages of being simple in technological process, high in scandium and titanium concentration ratio, thorough in separation and low in production cost, and free of pollution.

Owner:贵州鑫亚矿业有限公司 +1

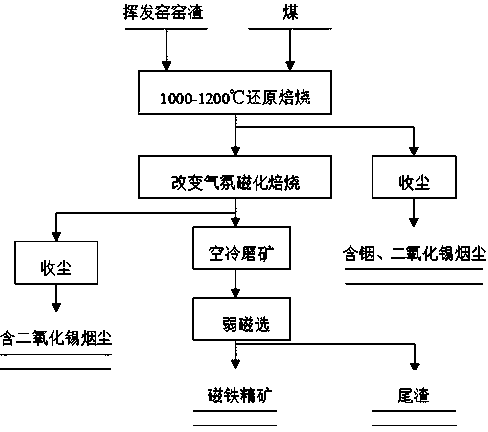

Method for recycling iron, indium and tine in zinc volatilizing kiln slag

ActiveCN103436707AAchieve efficient recyclingShort processMagnetic separationProcess efficiency improvementIndiumLower intensity

The invention provides a method for recycling iron, indium and tine in zinc volatilizing kiln slag. The method comprises the following steps: uniformly mixing zinc volatilizing kiln slag and a reducing agent, subsequently feeding the mixture into a rotary furnace to carry out reduction roasting, and at the same time capturing fume generated in the process; furthermore feeding oxidation gas into the rotary furnace, carrying out magnetic roasting and capturing the fume generated in the process at the same time; carrying out air-cooling on remaining materials inside the rotary furnace, grinding ore, and subsequently carrying out low intensity magnetic separation so as to obtain magnetite concentrate. The effective recycling of iron in the kiln slag is realized through the steps, and tail slag contains copper. The recycling rates of the iron, the indium and the zinc can be respectively 75-85%, 85-93% and 86-95%; through low intensity magnetic separation, the iron grade of the iron concentrate is improved while ensuring the recycling rate of the iron, the effective recycling of an iron resource is achieved, and the iron grade of the iron concentrate is improved to be 70-75% finally; the process is short, the operation is simple and feasible, economic cost is low and metal comprehensive recycling rate is high, a conventional process order of separation-first and smelting-later is broken, and the comprehensive utilization rate of a secondary resource is improved.

Owner:ZHAOQING FEINAN METAL

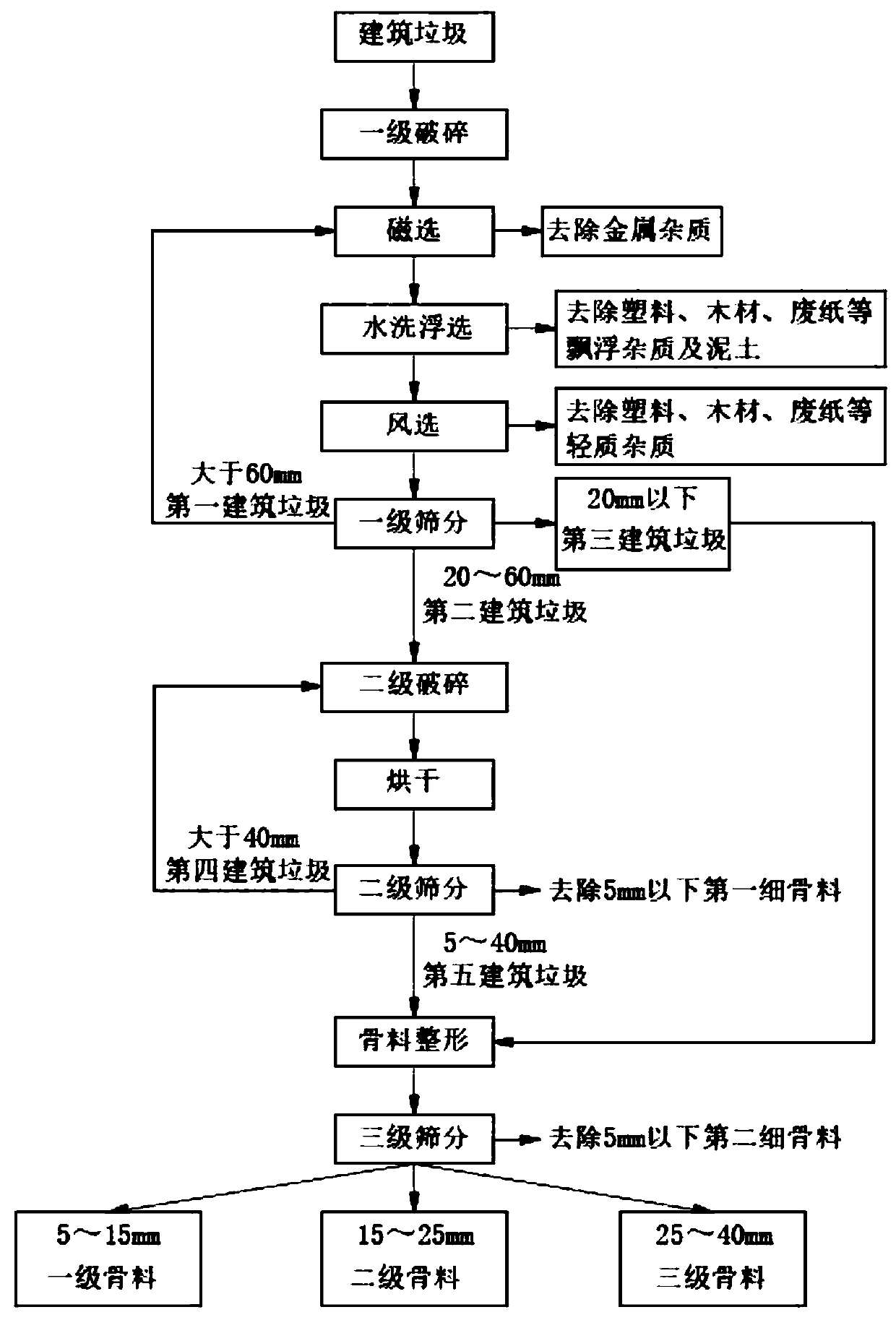

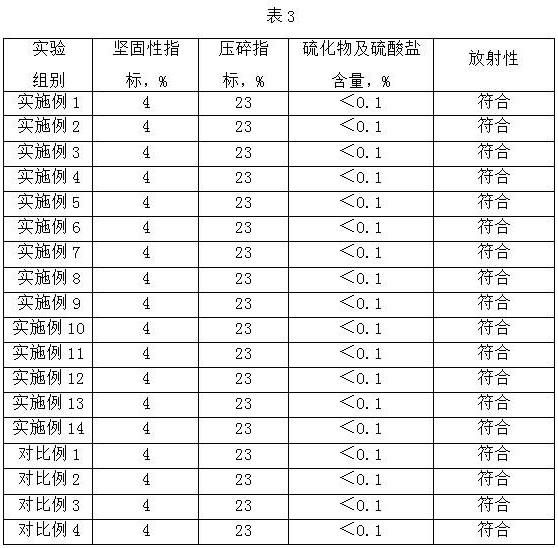

Construction waste recycling process

InactiveCN111482256AImprove qualityAchieve efficient recyclingSievingConstruction waste recoveryEngineeringEnvironmental engineering

The invention discloses a construction waste recycling process, and relates to the field of construction waste recycling treatment. The construction waste recycling process comprises the following steps of primary crushing, magnetic separation, washing flotation, winnowing, primary screening, secondary crushing, drying, secondary screening, aggregate shaping and tertiary screening. According to the construction waste treatment process disclosed by the invention, the construction waste is treated into the recycled aggregate, so that the quality of the aggregate is improved, the efficient recycling of resources is realized, and meanwhile, the pollution of landfill construction waste to the environment is avoided.

Owner:湖州恒通机械设备有限公司

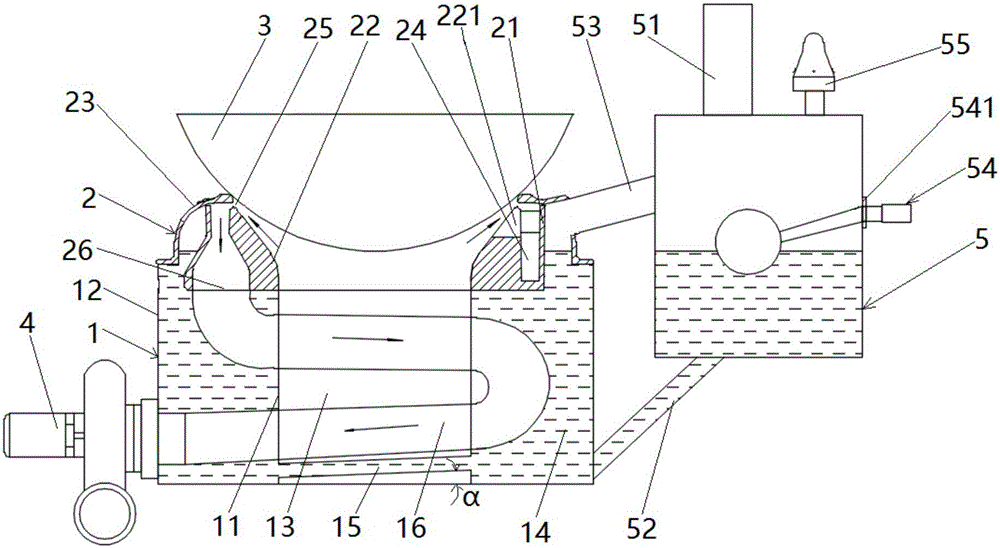

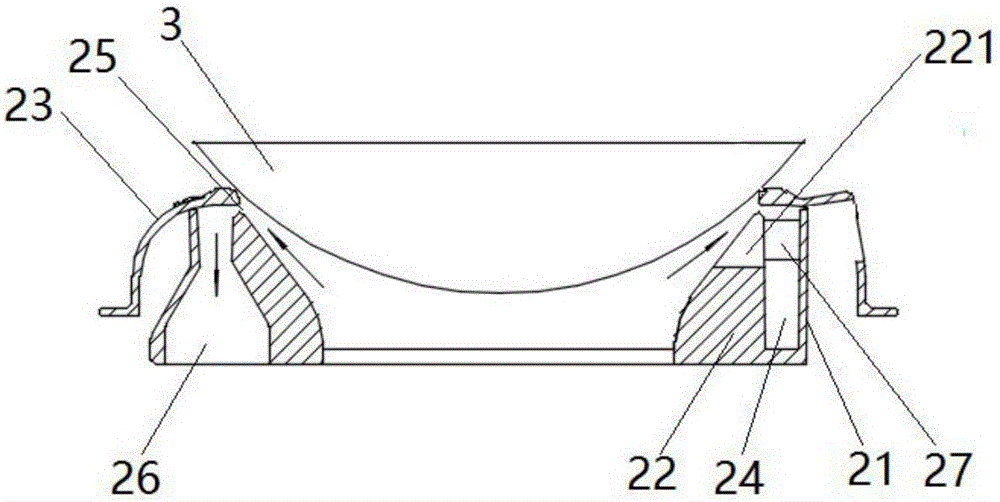

Cooking range generating steam by using waste heat

ActiveCN105841502AAchieve efficient recyclingGood promotion prospectDomestic stoves or rangesCooking fumes removalAutomatic controlEngineering

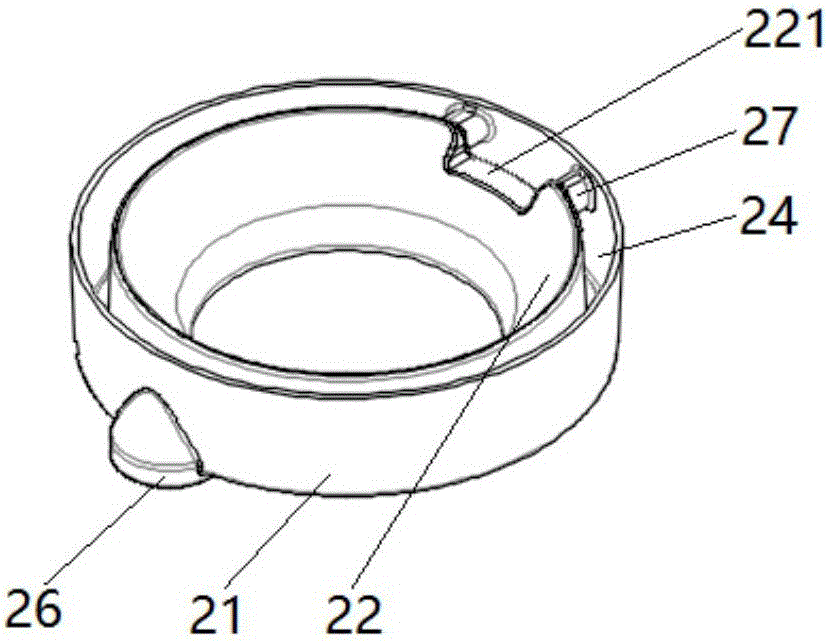

The invention relates to a cooking range generating steam by using waste heat. The cooking range a furnace body, a furnace head and a water tank, wherein the furnace body is combined by an inner furnace wall and an outer furnace wall; a hollow region surrounded by the inner furnace wall is a hearth; a plurality of tubular fire bars are uniformly arranged below the hearth at intervals in the furnace body; the furnace head comprises an outer furnace ring, an inner furnace ring and a pot body supporting ring; the lower end of the inner furnace ring is connected to the inner furnace wall; the lower end of the pot body supporting ring is connected to the outer furnace wall; a cavity among the inner wall furnace, the outer wall furnace and the furnace head is a heating cavity; a coil surrounding the hearth is arranged in the heating cavity; a steam pipe communicating with the top of the heating cavity is arranged in the upper part of the water tank; a water outlet pipe communicating with the bottom of the heating cavity is arranged in the lower part of the water tank; a gas outlet pipe is arranged on the top of the water tank; a water inlet is formed between the steam pipe and the water outlet pipe on the water tank; and a float ball water inlet valve is arranged on the water inlet. The cooking range provided by the invention realizes efficient recovery of smoke heat and automatic control of water inflow in a stove using process.

Owner:JIANGSU SHENGONG STOVE CO LTD

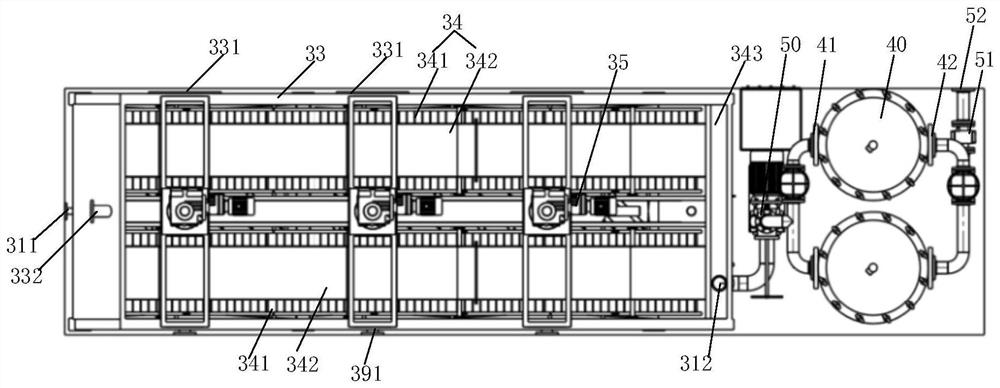

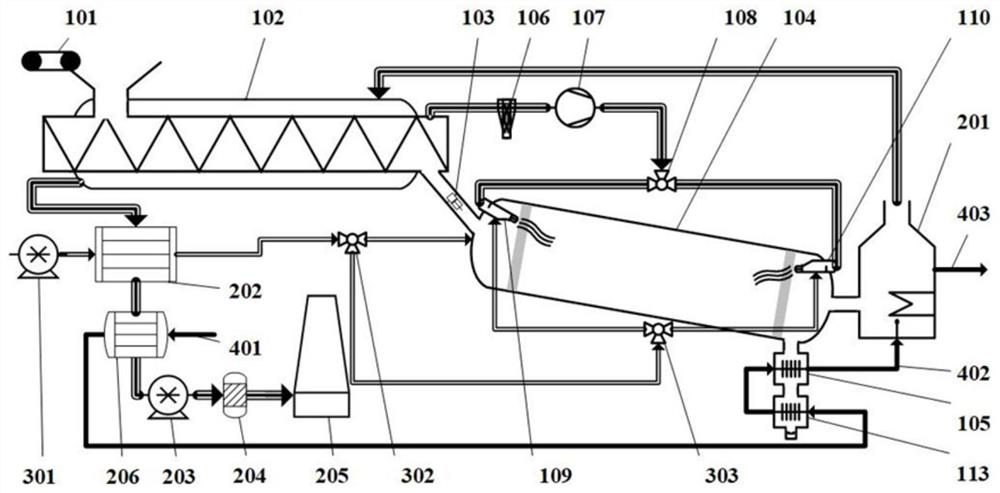

Highway pavement construction equipment and highway pavement construction method implemented by using same

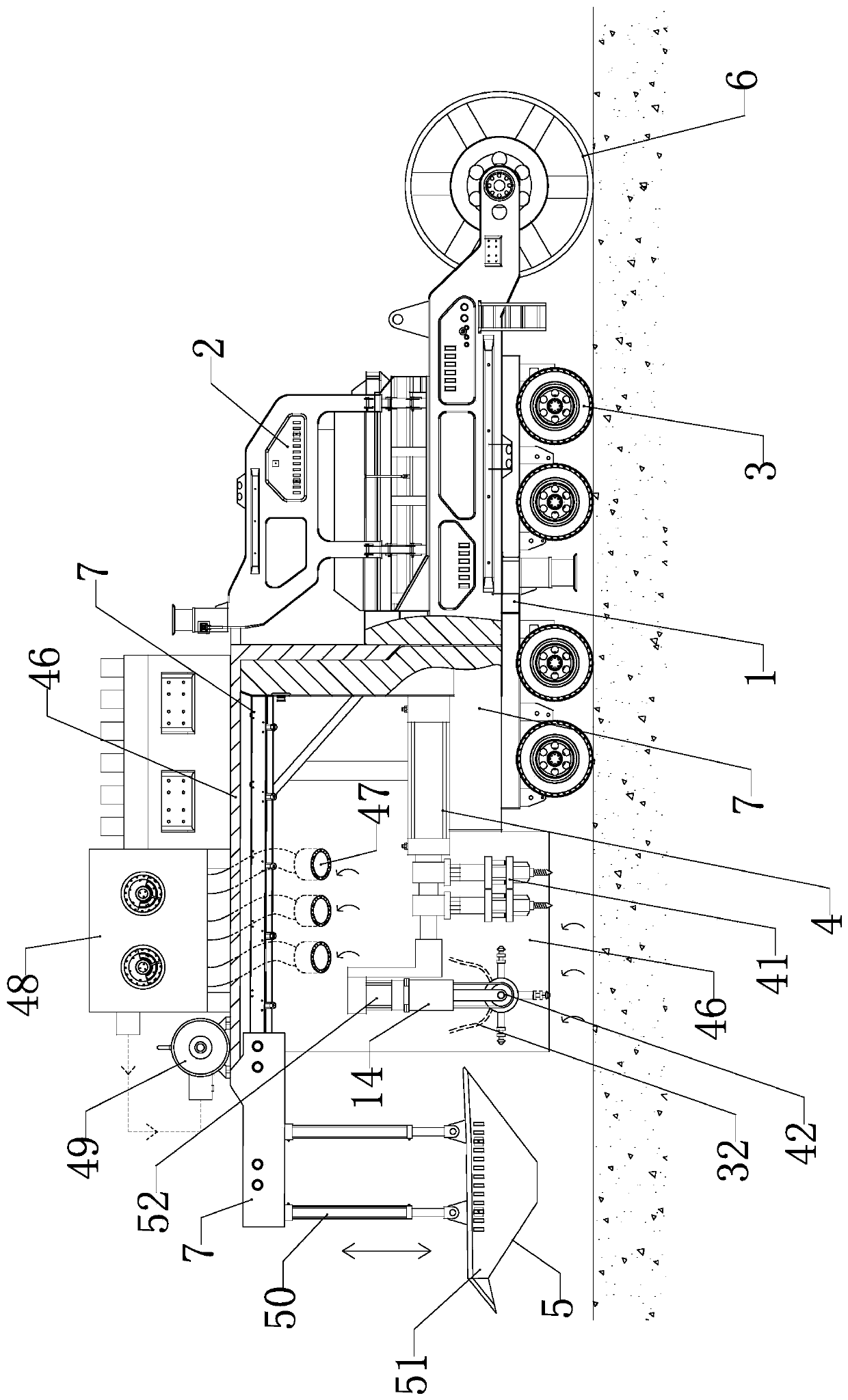

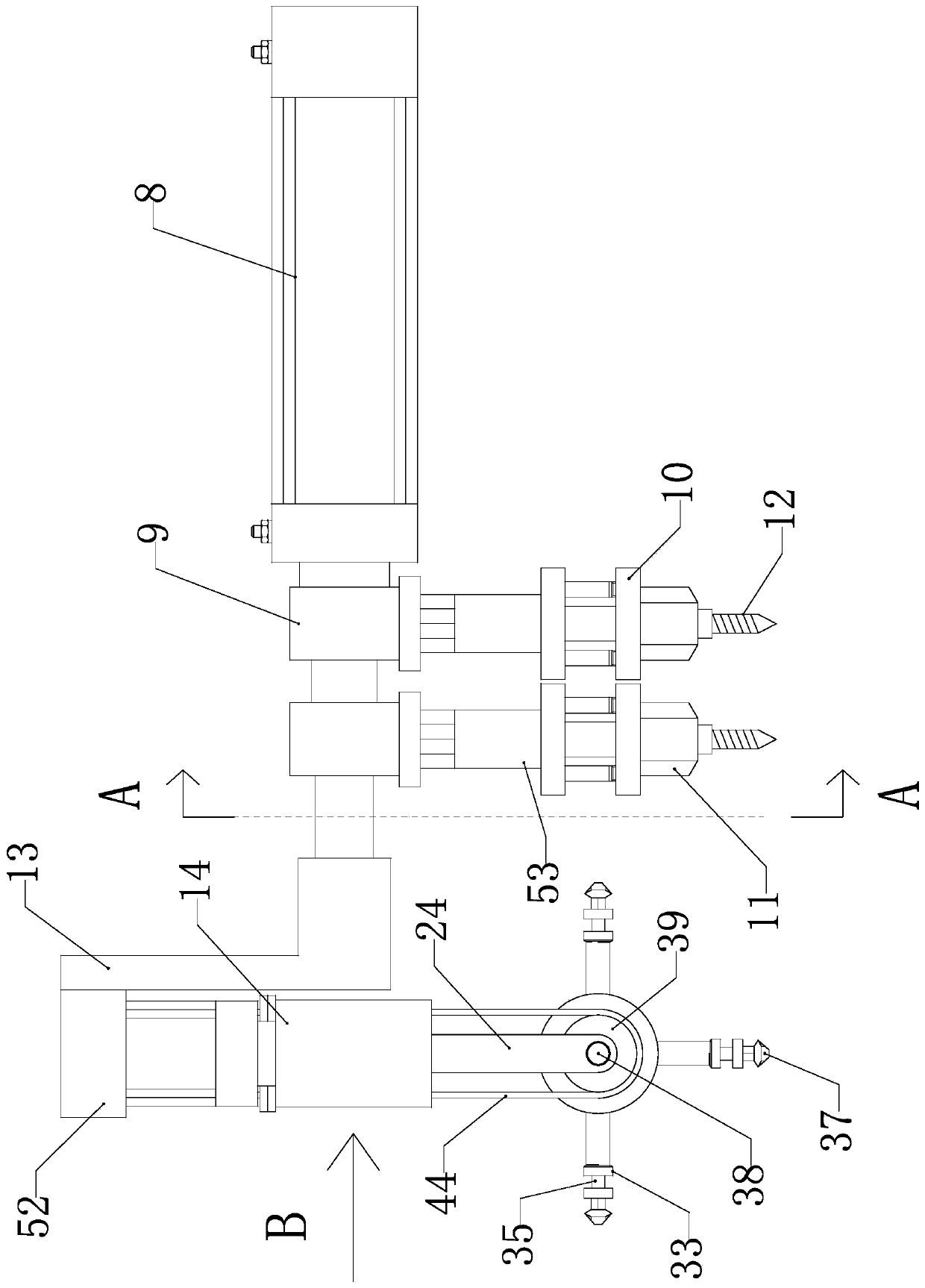

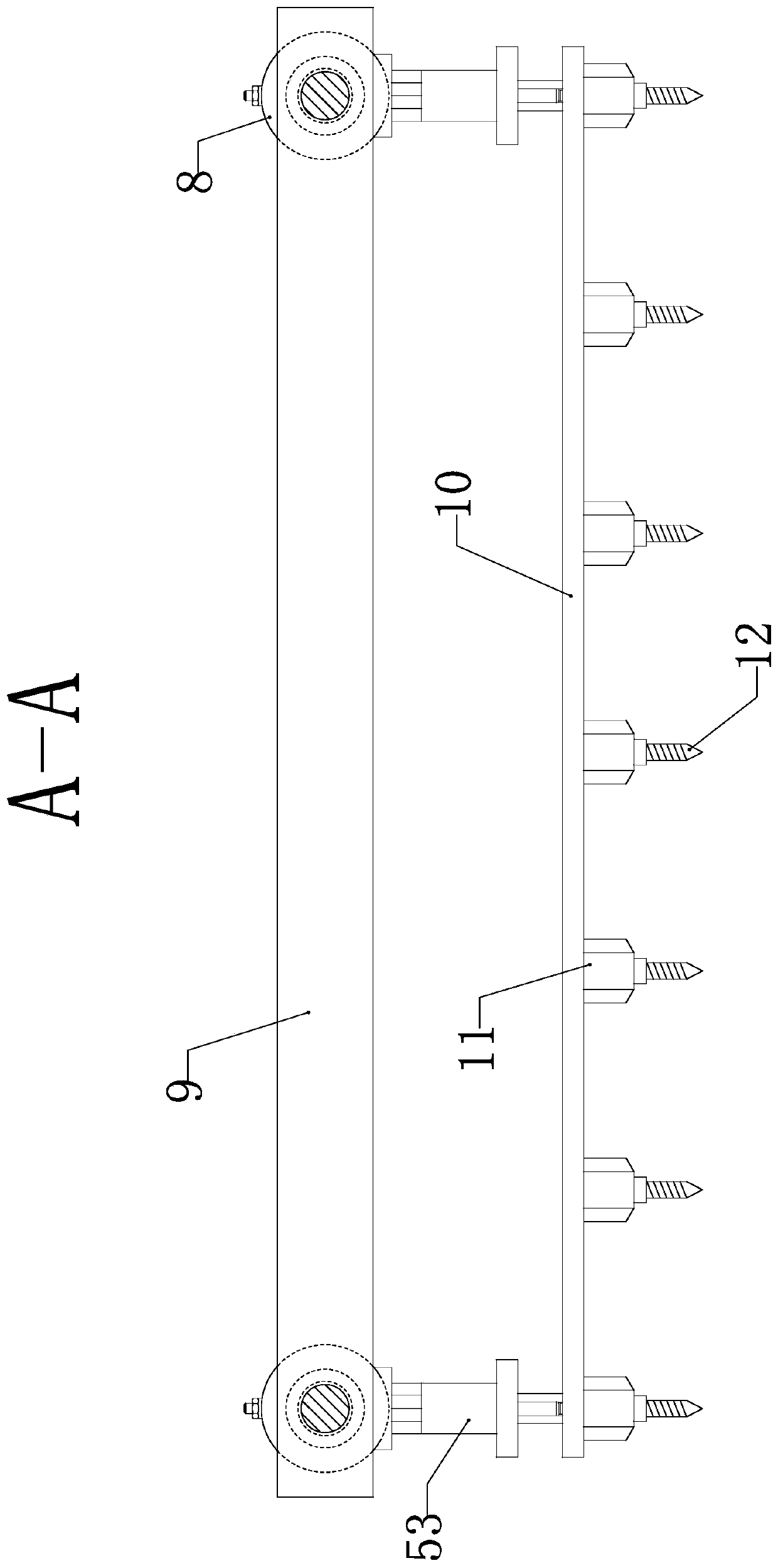

ActiveCN111005281AQuick break cleanupReduce in quantityIn situ pavingsFoundry mouldsDrive wheelRoad surface

The invention relates to the field of road and bridge infrastructure construction, in particular to efficient waste pavement cleaning construction equipment and a repair construction method. The invention relates to highway pavement construction equipment and a highway pavement construction method implemented by using same. The equipment comprises a driving chassis assembly, a cab and a pluralityof driving wheels, wherein the cab is arranged at the top of the front side of the driving chassis assembly, the driving wheels are installed below the driving chassis assembly, the front end of the driving chassis assembly is provided with an adjusting type planing device used for achieving planing and cleaning of waste road surfaces, and a waste collecting device is installed on the downstream portion of the planing device in a matched mode. By adopting the integrated and special structural design, the waste pavement can be effectively and quickly broken and cleaned, the number of engineering machines used in the construction process is reduced, and the problems of operation congestion and the like caused by construction of numerous engineering machines are relieved.

Owner:济宁市公路工程总公司

Method for extracting valuable metals from mixed manganese-rich waste leachate of lithium ion battery

ActiveCN109136571AImplement extractionAchieve separationWaste accumulators reclaimingProcess efficiency improvementSludgeManganese

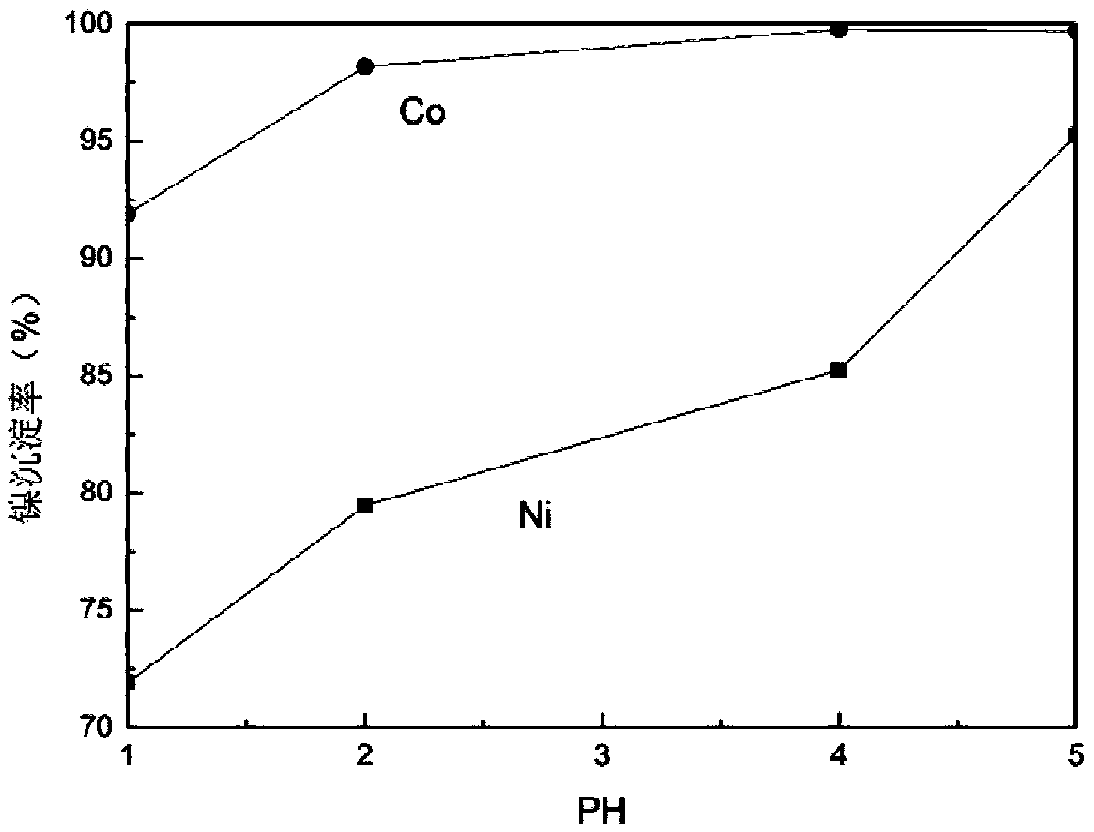

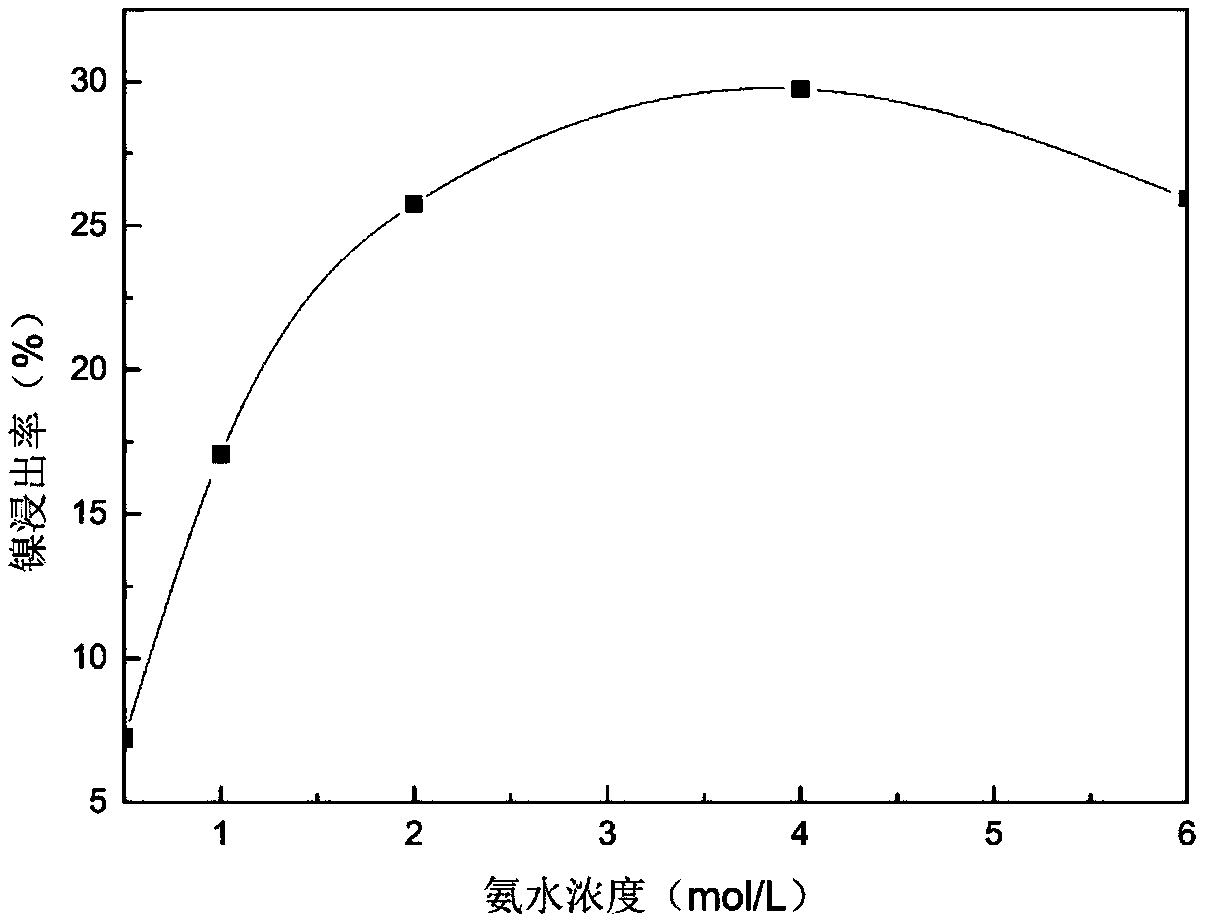

The invention discloses a method for efficiently separating valuable metals from mixed manganese-rich waste leachate of a lithium ion battery. The method comprises the following steps: firstly, nickel-cobalt components are selectively precipitated and separated from a manganese-rich solution with a precipitation method; then, by aid of difference of complexing bonding of ammonia with cobalt and nickel and of a precipitant with cobalt and nickel, an ammonia and ammonium salt mixed solution is adopted for selectively dissolving nickel component in nickel-cobalt precipitated sludge, and efficientseparation of nickel and cobalt is realized; finally, manganese component in the solution with nickel and cobalt precipitated is extracted selectively with a solvent extraction method, and efficientseparation of manganese and lithium is realized. According to the provided process of selective nickel-cobalt precipitation-raffinate manganese and lithium extraction and separation-precipitated sludge selective nickel dissolution and nickel-cobalt separation, operation is simple, flow is short, cost is low, and efficient separation and recovery of valuable component elements in the manganese-richleachate of the waste lithium ion battery can be realized.

Owner:广西埃索凯循环科技有限公司

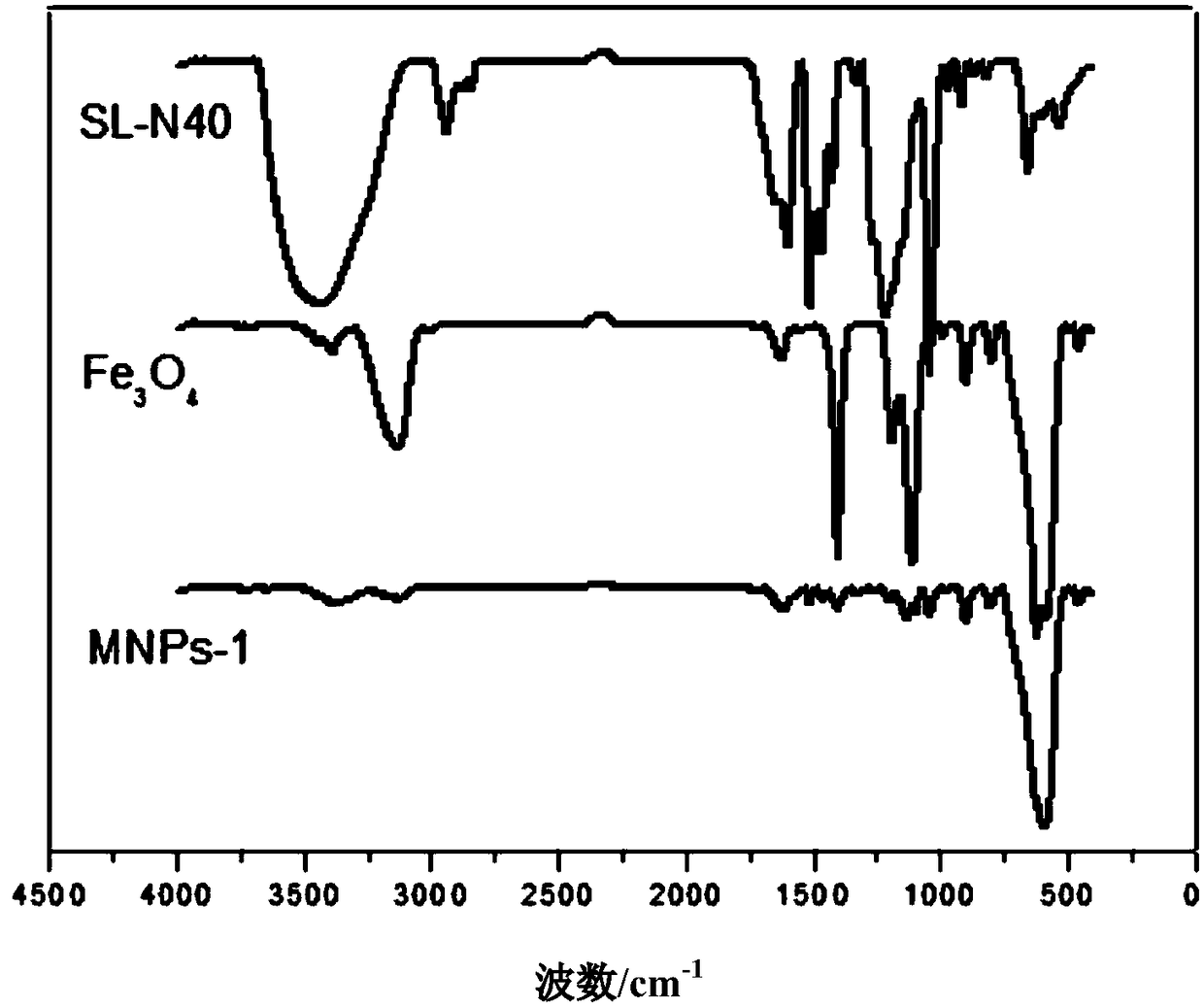

Magnetic lanthanum-loaded attapulgite clay dephosphorization adsorbent as well as preparation and application methods thereof

PendingCN113145063AHigh adsorption capacityAchieve recyclingOther chemical processesWater contaminantsPhosphorus adsorptionPhosphate

The invention provides a magnetic lanthanum-loaded attapulgite clay dephosphorization adsorbent, which comprises an attapulgite clay carrier, and lanthanum and ferroferric oxide are loaded on the attapulgite clay carrier. The attapulgite clay carrier provided by the invention provides an ideal structure without additional structural modification, and can ensure uniform distribution of lanthanum loaded in surface and internal mesh holes, thereby improving the adsorption capacity of the adsorbent. Meanwhile, the problem that the lanthanum modified adsorption material is easy to block in the modification process is also solved. According to the method disclosed by the invention, magnetic materials are added to the attapulgite clay by a method of adding Fe3O4, and the magnetic materials are easily separated from a water body, so that effective recovery of phosphate and reutilization of the materials are realized. Therefore, the magnetic lanthanum hydroxide modified attapulgite clay adsorbent (La-ATP-coated Fe3O4) provided by the invention can be used for efficiently adsorbing and recycling the phosphorus in the water body.

Owner:北京师范大学珠海校区

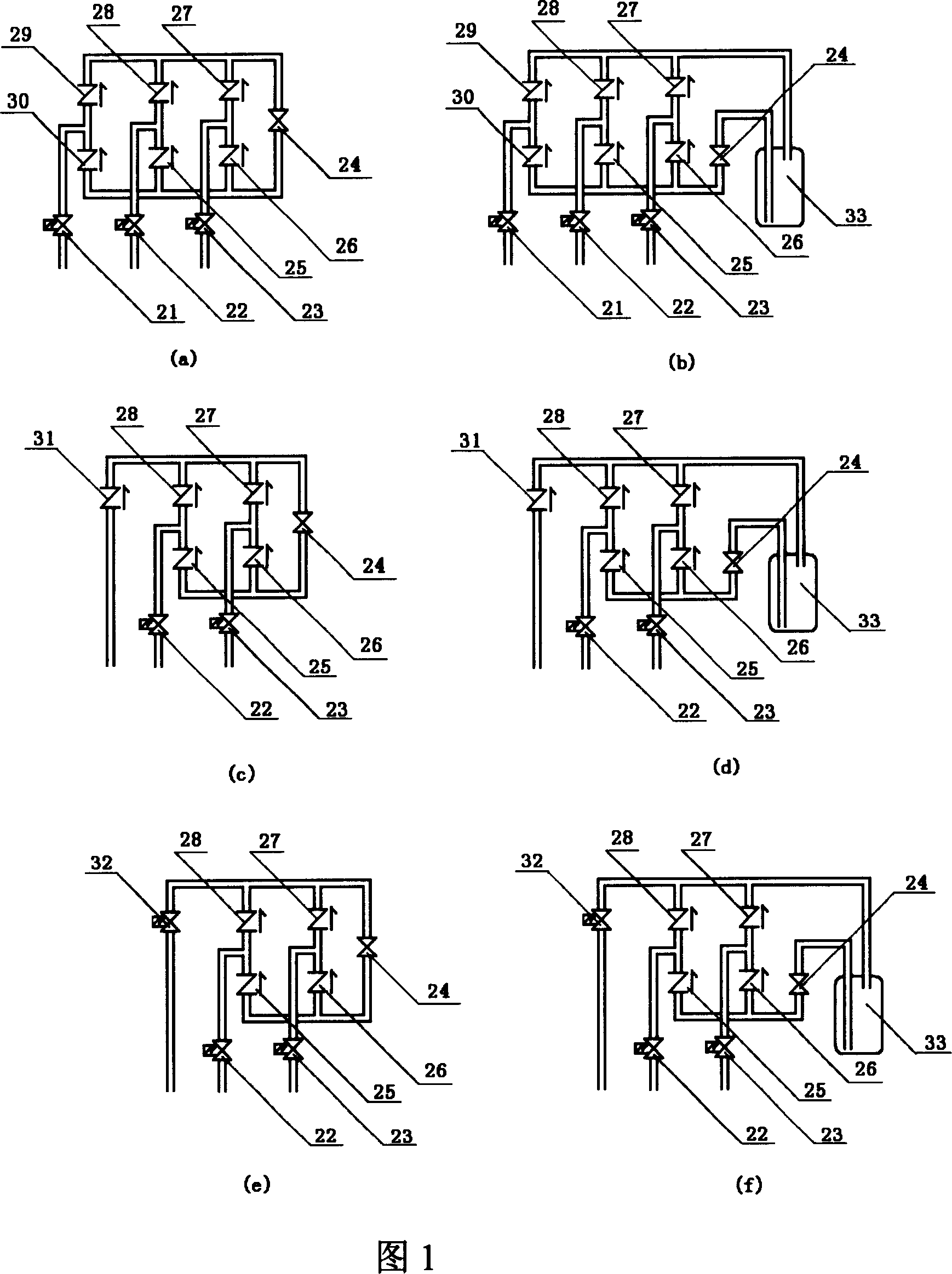

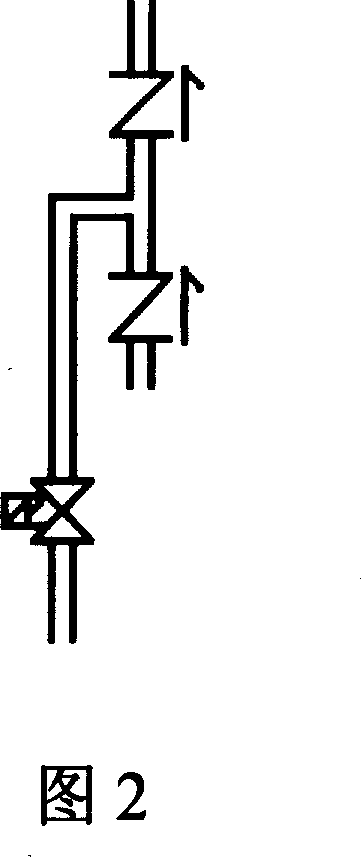

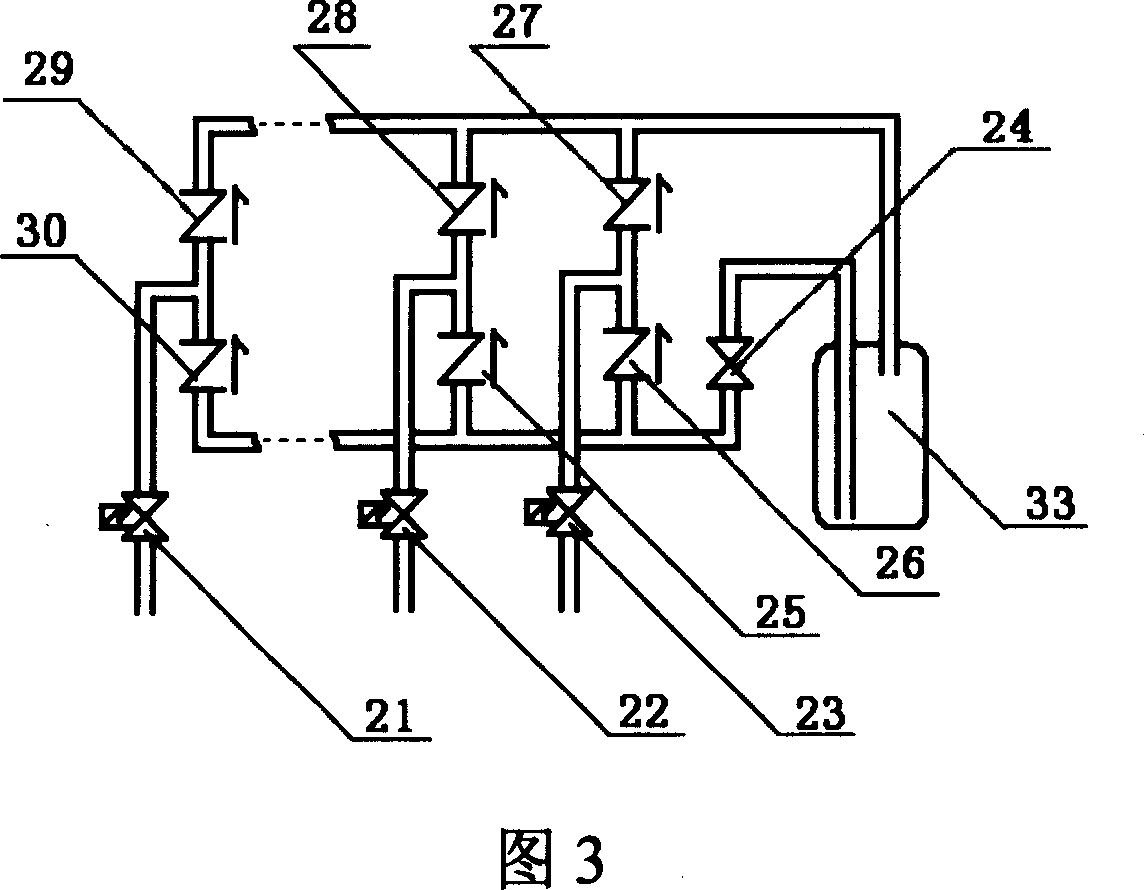

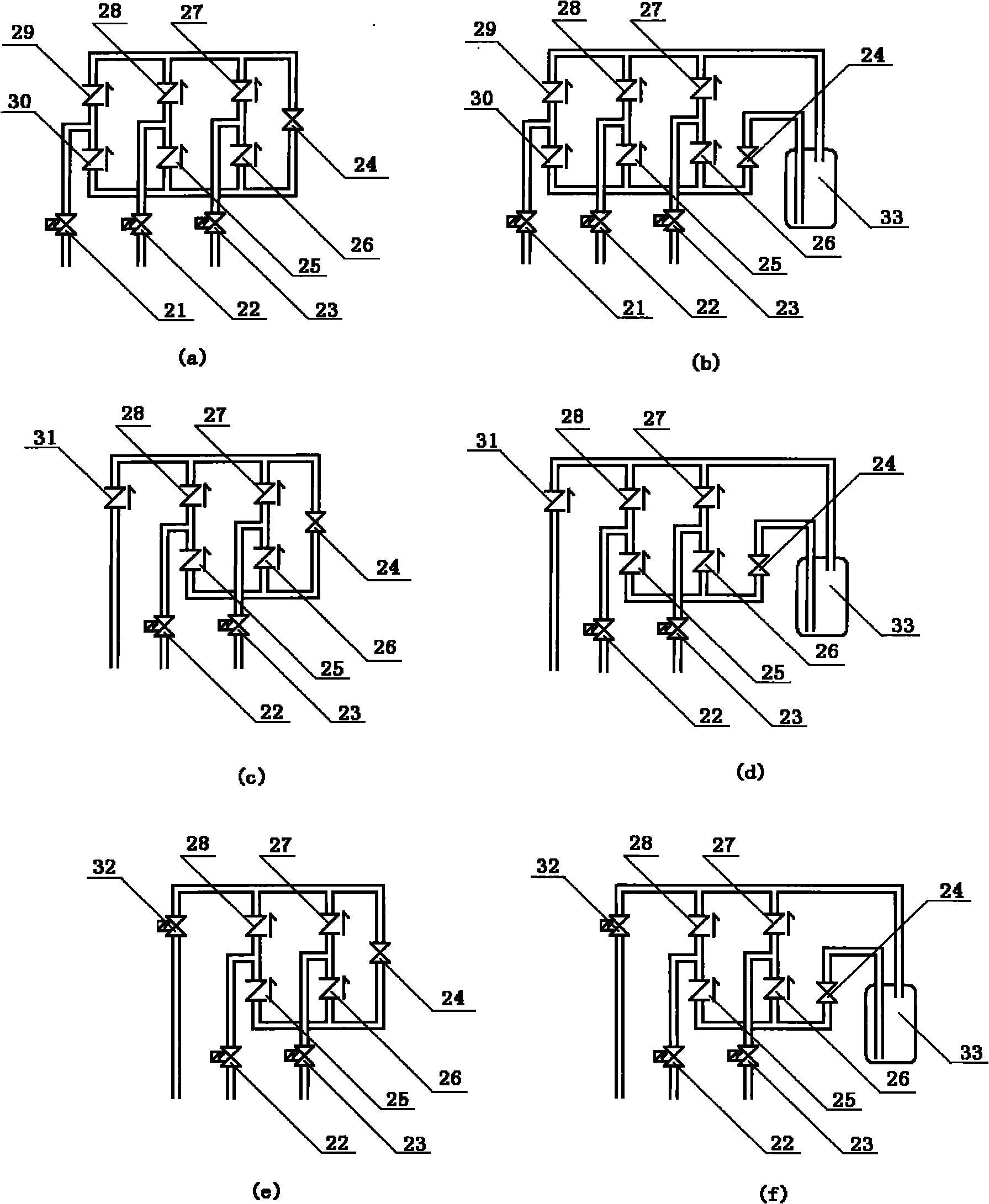

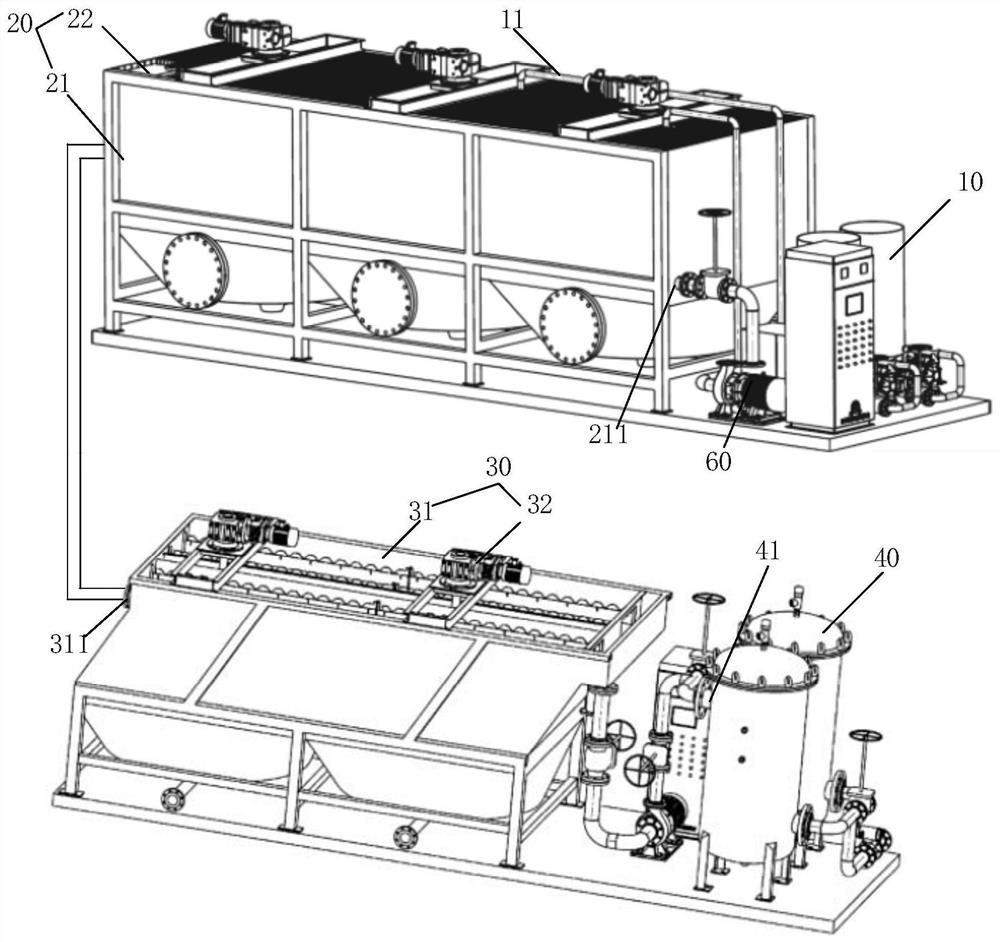

Multiple refrigeration and heating air conditioner and duplex heat reclamation device constituted by same

InactiveCN101078581AEasy to debugReduce manufacturing costHeat pumpsFluid circulation arrangementEngineeringRefrigeration

The invention relates to a multi-purpose refrigeration and heating air conditioner device and double heat recovering device constituted by it, comprising multi-purpose refrigeration and heating air conditioner device. Heat exchanger is connected between the exhaust port of compressor in the multi-purpose refrigeration and heating air conditioner device and the inlet port of multi-way reversing valve in series. The heat exchanger is used with a heat exchanger in the multi-purpose refrigeration and heating air conditioner device to realize double heat recovery and utilization. It is applied in the air conditioner with water heater function and is provided with refrigeration, heating, making hot water and making hot water and high-temperature hot water with refrigeration and heating at the same time so on. It is also provided with new and reliable structure, few modules, low cost and high commercial value so on.

Owner:林荣恒

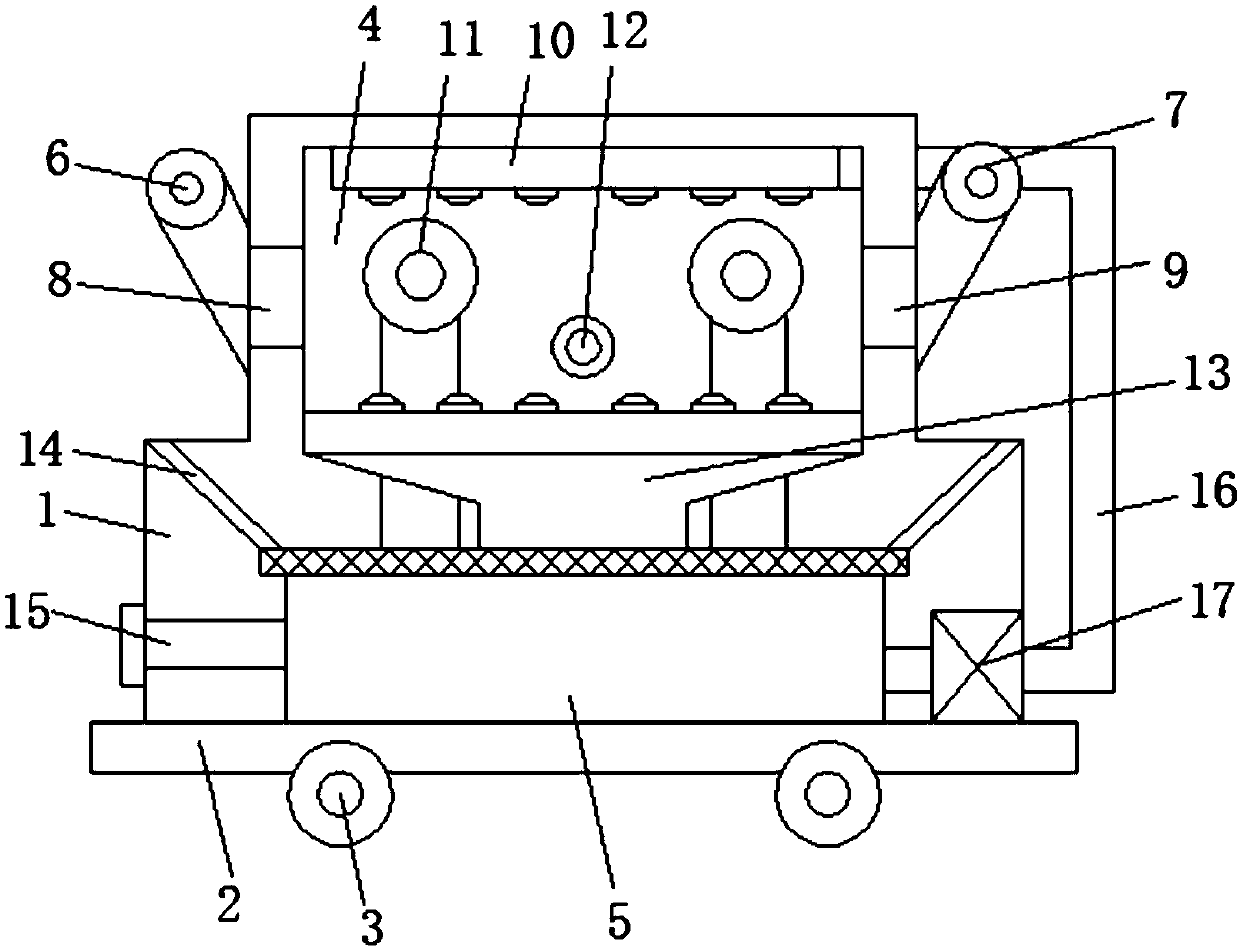

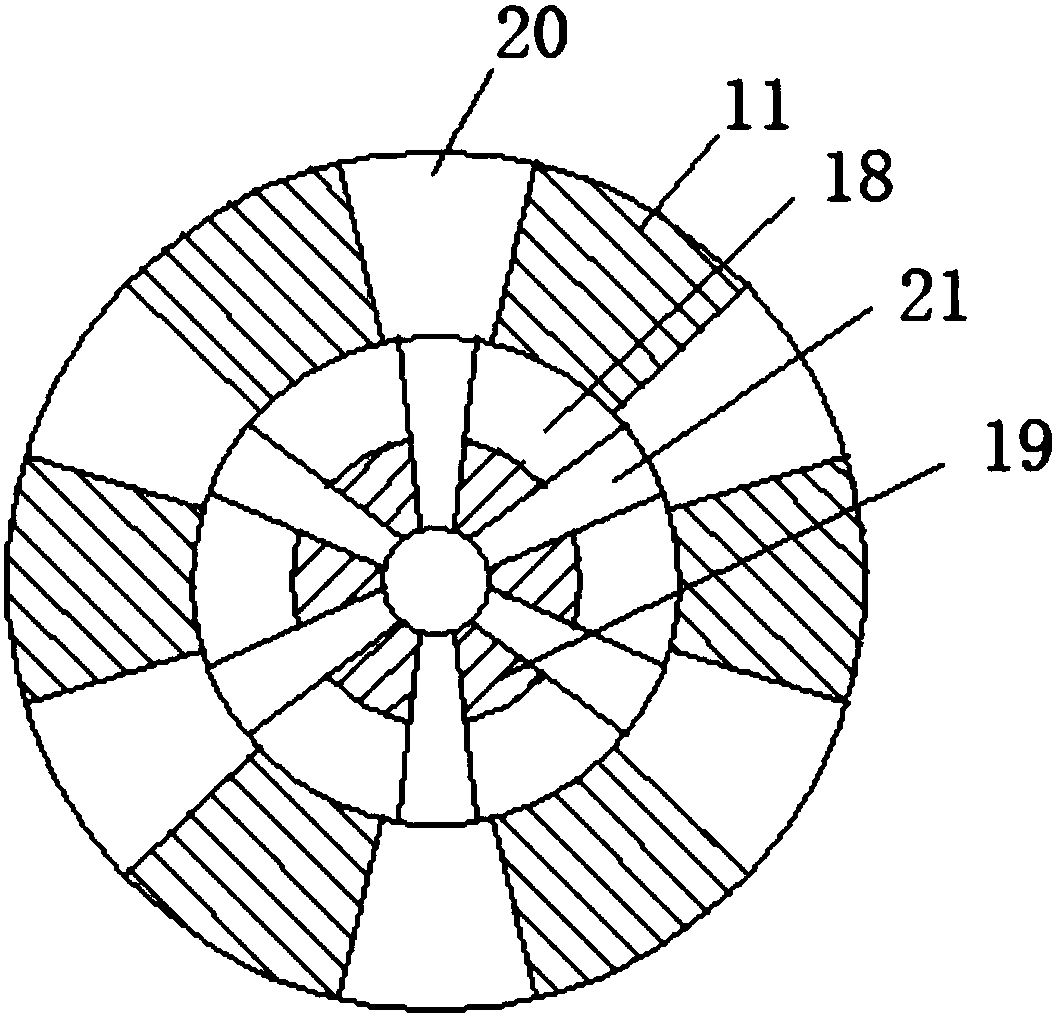

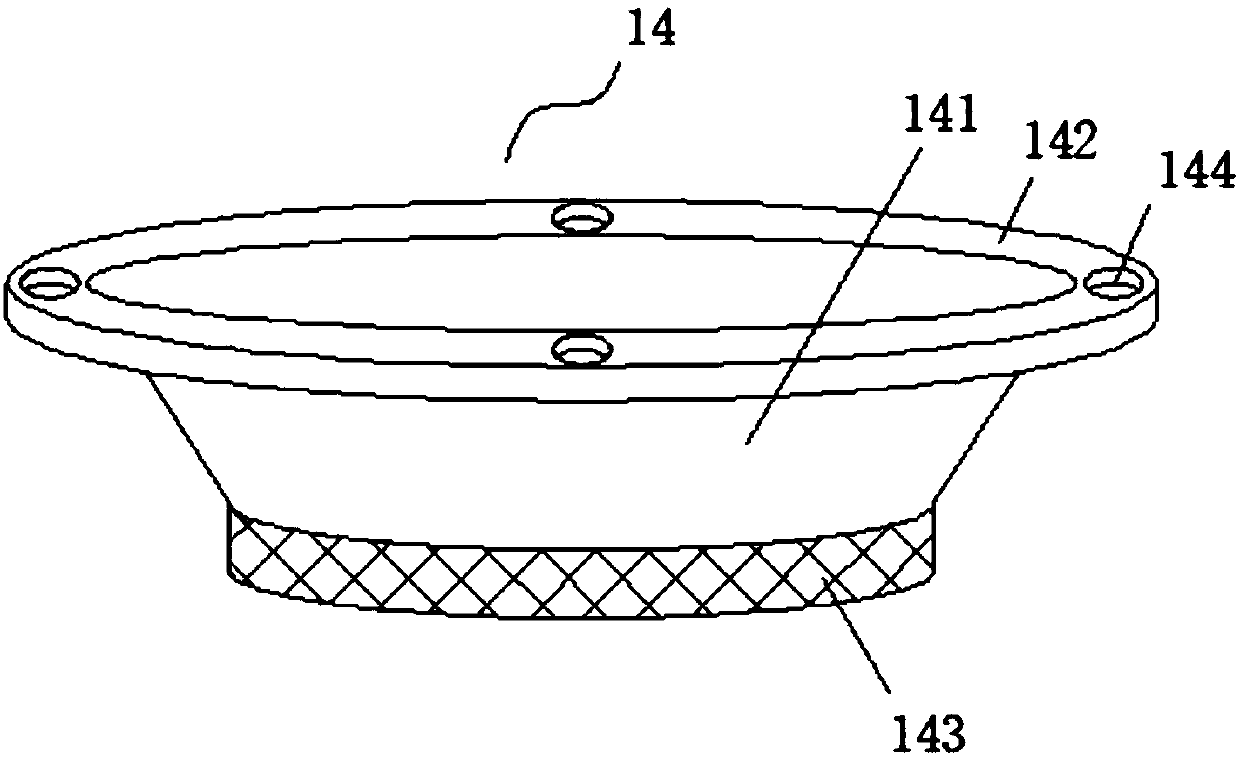

Humidification device and method for textiles

InactiveCN108049048AImprove uniformityAvoid inhomogeneityTextile treatment machine arrangementsTextile treatment by spraying/projectingWastewaterArchitectural engineering

The invention discloses a humidification device and method for textiles, and belongs to the technical field of textiles. The device comprises a humidifying box, the bottom of the humidifying box is provided with a base, and the four corners of the bottom of the base are each provided with a traveling wheel; the upper part and the lower part of an inner cavity of the humidifying box are provided with a humidifying chamber and a water tank respectively, the two outer sides of the humidifying box are provided with a feeding roller frame and a discharging roller frame respectively, and the two outer walls of the humidifying chamber are connected with a feeding port and a discharging port respectively; the top and the bottom of the inner cavity of the humidifying chamber are both provided witha humidifying spraying pipe, the top of the water tank is provided with a water collecting cavity, and the other side wall of a water injection pipeline is connected with a first water pump through acirculating water pipe; a waterproof installation groove is formed in the inner wall of a conveying roller, and a second water pump is arranged in an inner cavity of the waterproof installation groove. The humidification uniformity of textile fabric is improved, the humidifying efficiency is high, and wastewater is filtered, so that effective recycling of the wastewater and reasonable utilizationof resources are achieved.

Owner:尹义娜

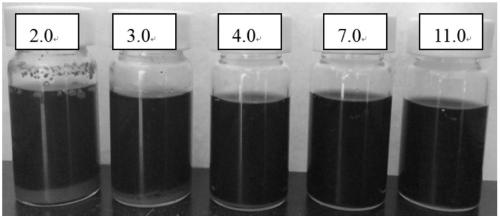

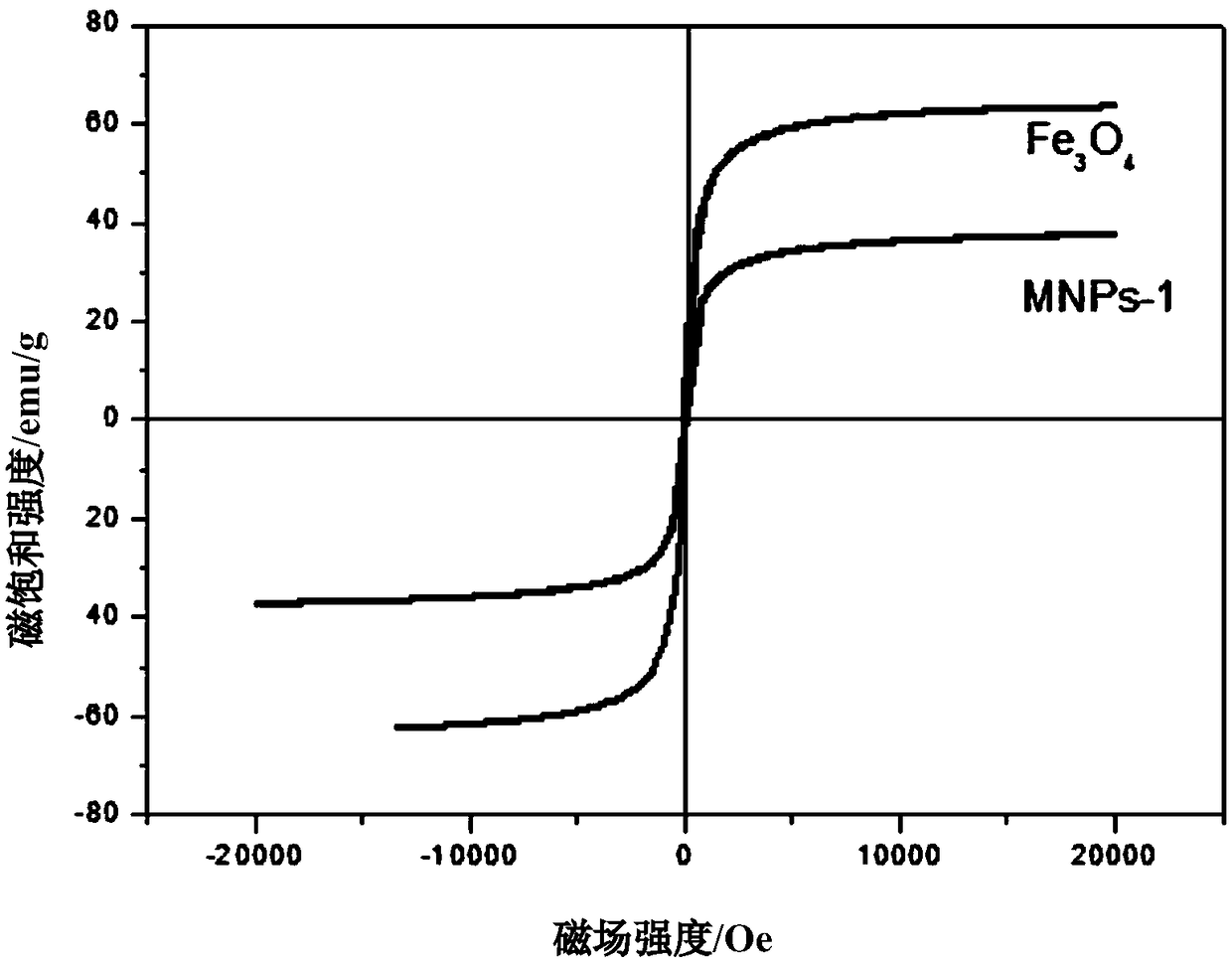

Lignin magnetic nanoparticles with pH response, preparation method thereof and application of lignin magnetic nanoparticles in cellulase recycling

InactiveCN109485872AOvercoming low productivityAchieve efficient recyclingGlycosylasesChemistryLignosulfonates

The invention belongs to the technical field of cellulase recycling and discloses lignin magnetic nanoparticles with pH response, a preparation method thereof and application of the lignin magnetic nanoparticles in cellulase recycling. The preparation method includes the steps of (1) subjecting a lignosulfonate and a quaternization reagent to reaction to obtain a lignin derivative with pH response; (2) subjecting the lignin derivative with pH response, a ferric salt and a ferrous salt to chemical co-precipitating reaction in the presence of a precipitating agent to obtain lignin magnetic nanoparticles with pH response. The invention also provides lignin magnetic nanoparticles with pH response prepared via the preparation method, and application of the lignin magnetic nanoparticles with pHresponse in cellulase recycling. The lignin magnetic nanoparticles with pH response are efficient in adsorbing and fixing cellulase and desorbing the cellulase by simple pH adjustment so as to efficiently recycle the cellulase; the recycled cellulase features high recycle rate and high activity and is reusable.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing mercury-containing catalyst by combining microwave with ultrasonic regenerated coal

InactiveCN109092284AHigh recovery rateSimple processCatalyst regeneration/reactivationProcess efficiency improvementActivated carbonMicrowave

The invention relates to a method for preparing a mercury-containing catalyst by combining microwave with ultrasonic regenerated coal, and belongs to the technical field of recycling of coal preparedwaste mercury catalysts. The method comprises the following steps: uniformly mixing a coal prepared waste mercury catalyst with ammonia water to obtain a mixture A; under ultrasonic conditions, carrying out leaching reaction on the mixture A for 20 to 240 minutes, filtering and drying; carrying out microwave drying on the obtained product under the conditions of 50 to 150 DEG C for 5 to 30 minutes; carrying out microwave heating under the conditions of 150 to 400 DEG C for 5 to 120 minutes to obtain a mercury demercurated waste catalyst and Hg vapor; condensing and recycling the obtained Hg vapor to obtain liquid pure mercury; introducing activated gas and carrying out microwave activation on the obtained mercury demercurated waste catalyst under the conditions of 500 to 800 DEG C for 10 to 100 minutes to obtain activated carbon for a regenerated mercury waste catalyst. The method disclosed by the invention has the advantages of simple overall process flow, low cost of raw materials, capability of achieving the regeneration of the activated carbon and efficient recovery of mercury, economic value and actual production significance.

Owner:KUNMING UNIV OF SCI & TECH

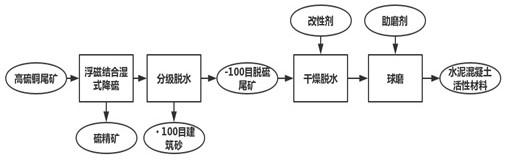

Resourceful treatment method of high-sulfur copper tailings, and product and application thereof

ActiveCN112264183ASimple processRelieve supply pressureGlass recyclingSolid waste disposalProcess engineeringSulfur containing

The invention provides a resourceful treatment method of high-sulfur copper tailings, and a product and application thereof, and relates to the technical field of resourceful treatment of tailings. The resourceful treatment method of the high-sulfur copper tailings includes the steps of desulfurizing the high-sulfur copper tailings to obtain sulfur concentrate and tailing pulp A; treating the tailing pulp A to obtain building sand and tailing pulp B; and treating the tailing pulp B to obtain a cement active admixture. According to the resourceful treatment method of the high-sulfur copper tailings, and the product and application thereof, all-component efficient recycling of the high-sulfur copper tailings is achieved while the adverse effect of sulfur-containing components in the high-sulfur, fine-fraction and high-moisture copper tailings which are difficult to utilize on downstream resource utilization products is avoided, and the raw material supply pressure of the building sandstone and cement industry is effectively relieved while the tailings treatment problem is solved; and meanwhile, the resourceful treatment method of the high-sulfur copper tailings does not generate secondary waste, and is suitable for industrial production.

Owner:铜陵有色金属集团股份有限公司 +1

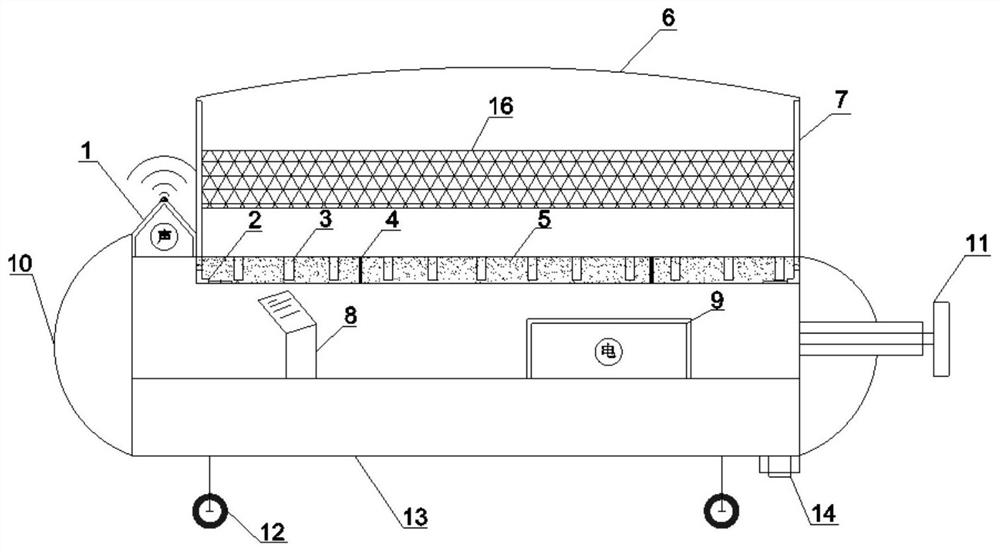

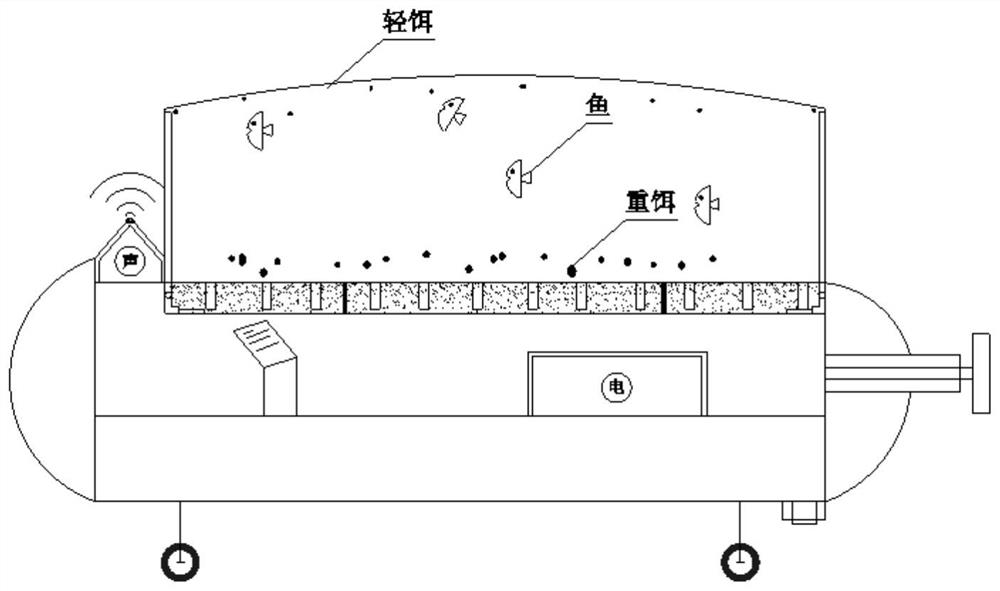

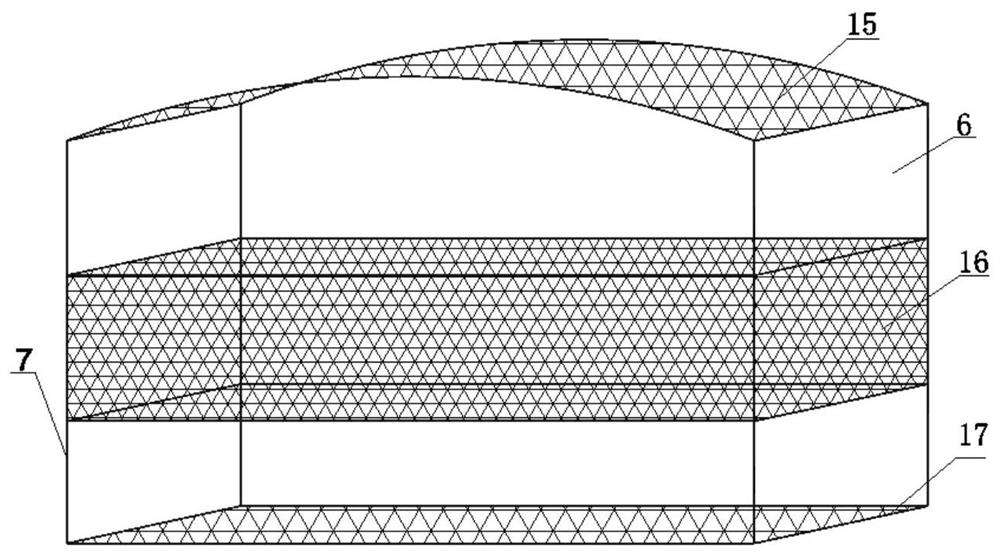

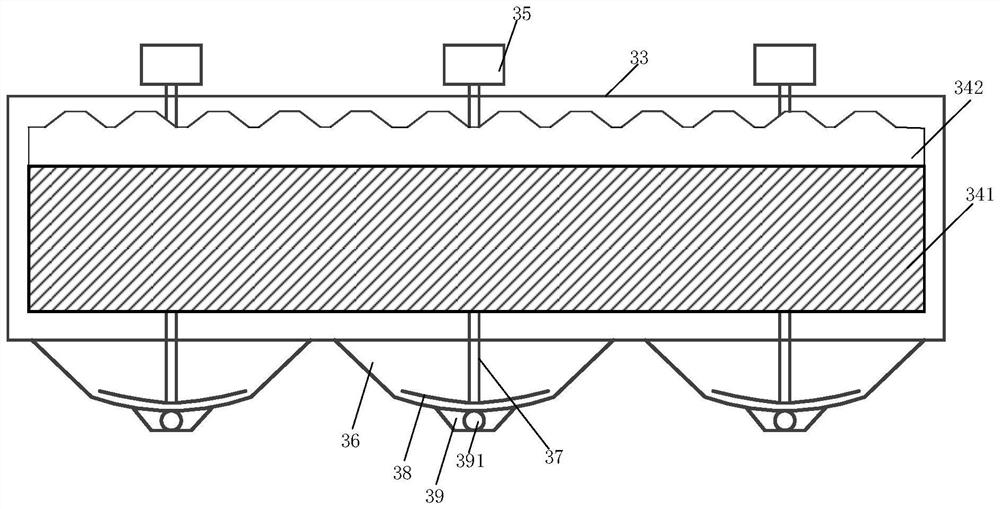

Intelligent bait casting device capable of identifying fish schools and recycling remnant bait and using method

ActiveCN112021236AIncrease profitReduce water and sediment pollutionClimate change adaptationPisciculture and aquariaWater storage tankWater tanks

The invention discloses an intelligent bait casting device capable of identifying fish schools and recycling remnant bait and a using method. The device comprises a material carrying cover, a bait binis arranged at the bottom of the material carrying cover, a water storage tank is arranged below the bait bin, the water storage tank is connected with a water pumping and draining device, a fish finder is arranged at one side of the material carrying cover, and a net door is arranged in the middle of the material carrying cover. An upper inner net is arranged at the top of the material carryingcover, a lower inner net is arranged at the bottom of the material carrying cover, and a plurality of light bait suction pumps and heavy bait suction pumps are arranged in the bait bin. By means of the device, quantitative bait casting can be conducted according to the fish schools, effective recycling of the remnant bait is achieved, the utilization rate of resources is increased, pollution of the bait to water and bottom mud of a culture pond can be reduced, and the culture environment is improved; and secondly, the device is convenient to operate, high in flexibility, wide in feeding area and high in use efficiency, and reference can be provided for mechanical and intelligent application of aquaculture in China.

Owner:HOHAI UNIV

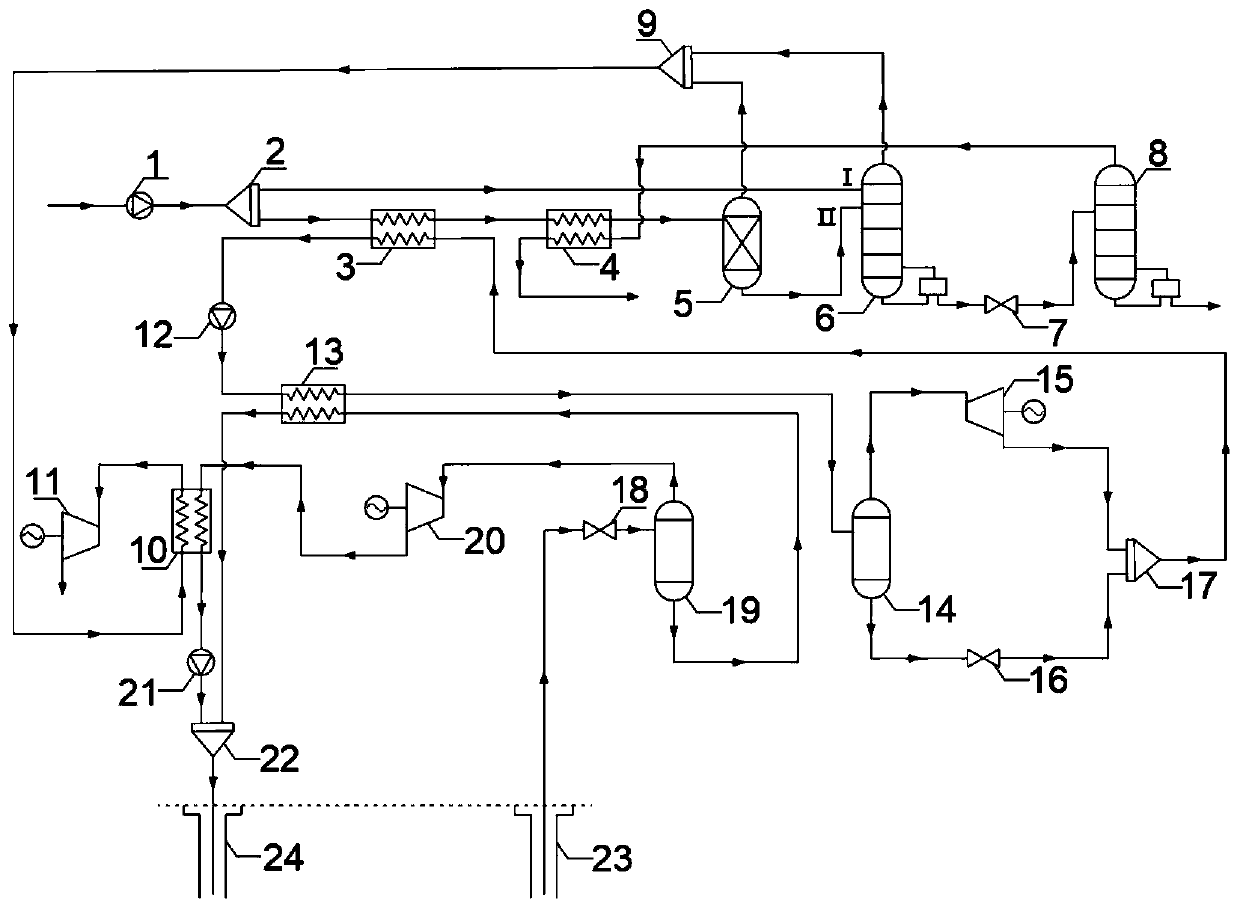

LNG light dydrocarbon separation coupled geotherm flash evaporation/Karina combined cycle power generation system

ActiveCN111577412AImprove efficiencyEfficient recyclingGeothermal energy generationGaseous fuelsProcess engineeringEnvironmental geology

The invention provides an LNG light dydrocarbon separation coupled geotherm flash evaporation / Karina combined cycle power generation system. The system comprises an LNG light dydrocarbon separation system, a geotherm flash evaporation cycle system, a Karina cycle system and a natural gas direct expansion system. The LNG light dydrocarbon separation system is used for recycling C2+ light dydrocarbon resources. The geotherm flash evaporation cycle system, the Karina cycle system and the natural gas direct expansion system are used for LNG cold energy and medium-low-temperature geothermal energycoupling power generation. While the geotherm flash evaporation / Karina combined cycle power generation efficiency is improved, effective recycling of the C2+ light dydrocarbon resources and efficientcomplementary use of LNG cold energy and geothermal energy are achieved, and the system has the beneficial effects of being reasonable and compact in structure, safe and flexible in control, efficient, high in practicality and low in cost and saving energy.

Owner:XI'AN PETROLEUM UNIVERSITY

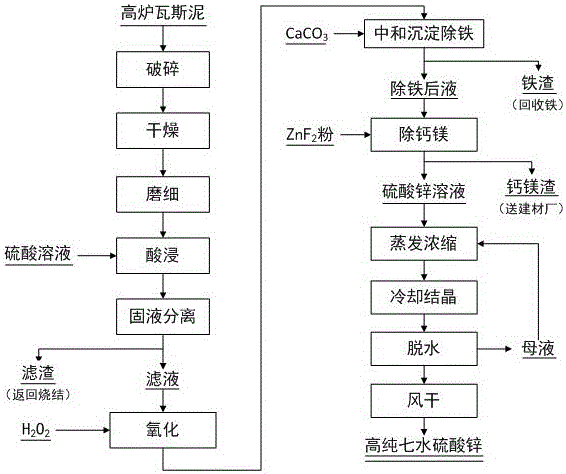

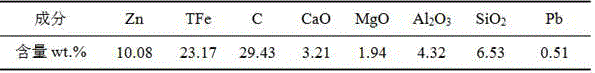

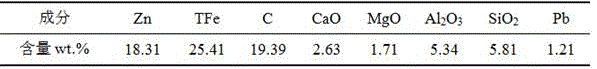

Method for preparing highly pure zinc sulfate heptahydrate from zinc-containing blast furnace gas sludge

ActiveCN106587136ASolve storage problemsAchieve efficient recyclingZinc sulatesSludgeZINC SULFATE HEPTAHYDRATE

The invention relates to a method for preparing highly pure zinc sulfate heptahydrate from zinc-containing blast furnace gas sludge, and belongs to the technical field of comprehensive utilization of metallurgical resources. The method comprises the following steps: breaking, drying and grinding block zinc-containing blast furnace gas sludge, adding the ground zinc-containing blast furnace gas sludge to a sulfuric acid solution to carry out acid dipping, carrying out solid-liquid separation to obtain filter residues and a filtrate, adding a hydrogen peroxide solution and limestone to the filtrate in order to carry out oxidation, neutralization and iron precipitation, filtering the obtained filtrate to obtain iron-containing residues used for iron recovery and an iron removed solution; adding ZnF2 powder to the iron removed solution, stirring, reacting and precipitating the iron removed solution and the ZnF2 powder for 1-2 h, and filtering the obtained solution to obtain calcium and magnesium residues and a zinc sulfate solution; and sequentially carrying out evaporative concentration, cooling crystallization, dehydration and air drying on the zinc sulfate solution to obtain the highly pure zinc sulfate heptahydrate, and returning a mother liquor obtained in the dehydration process to the evaporative concentration process. The method effectively recovers the valuable element zinc from the blast furnace gas sludge, and allows the highly pure zinc sulfate heptahydrate to be prepared.

Owner:KUNMING UNIV OF SCI & TECH

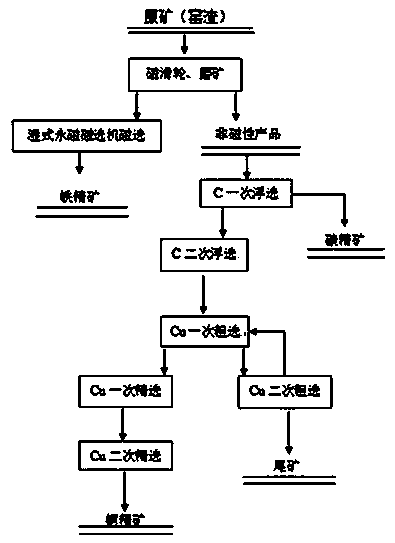

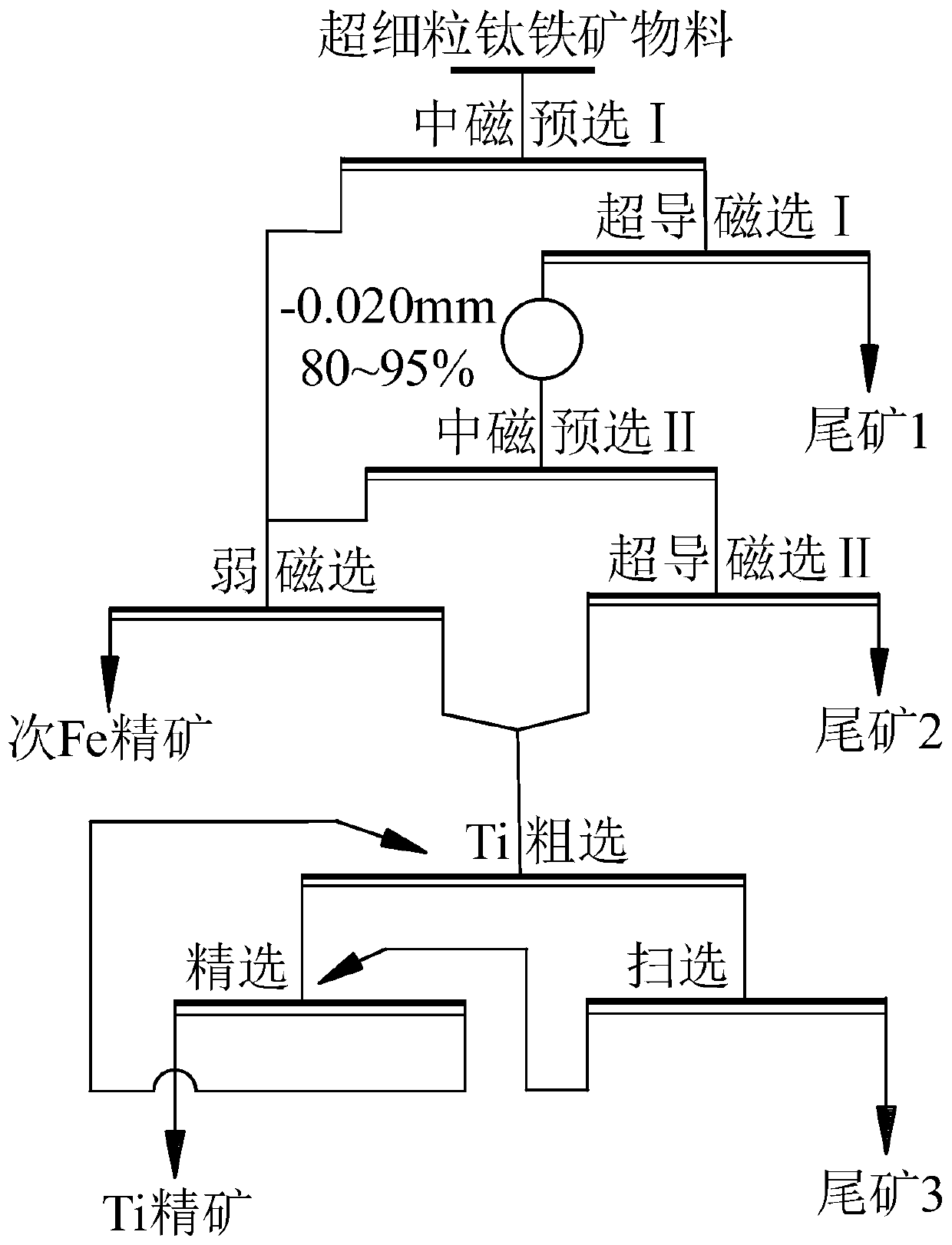

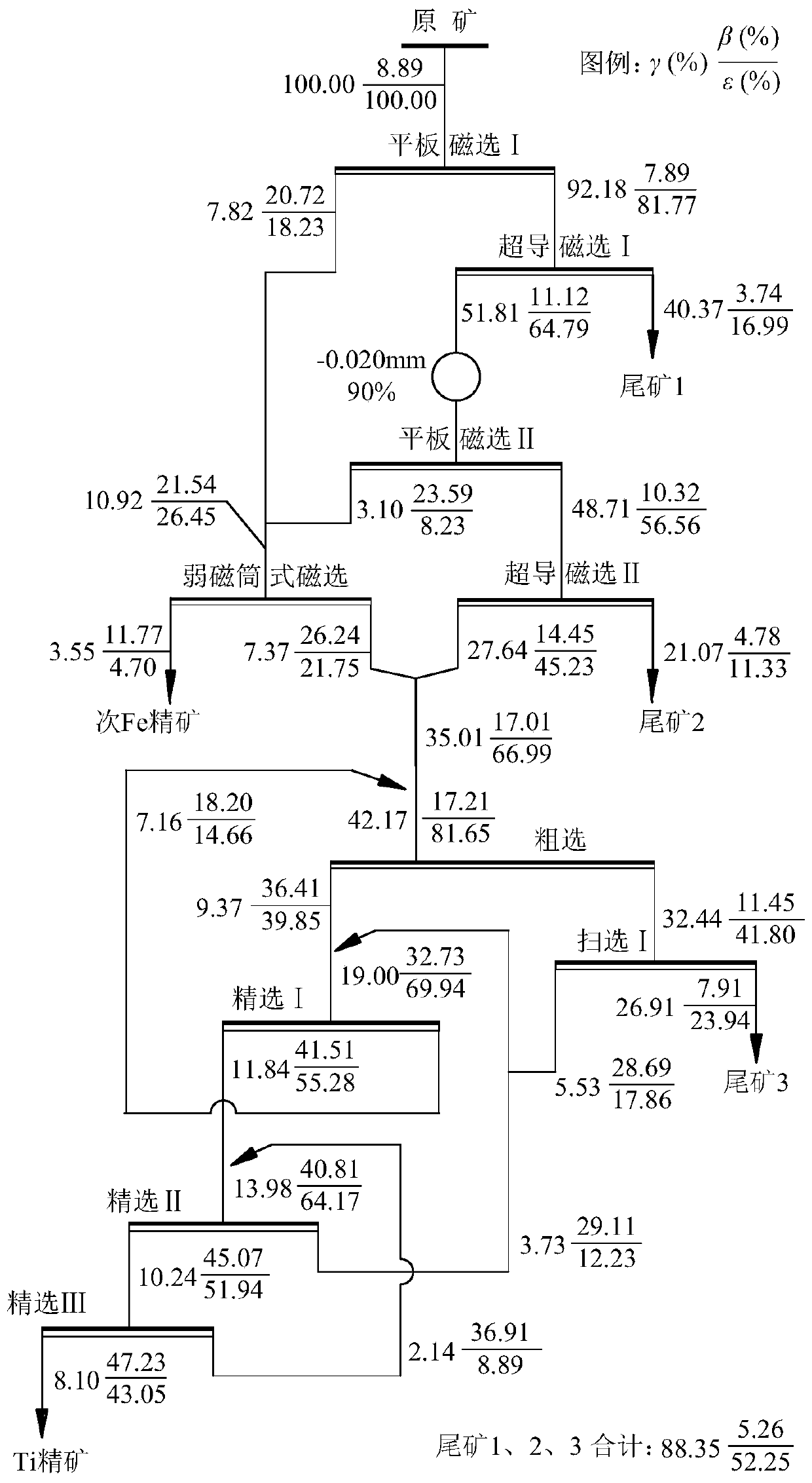

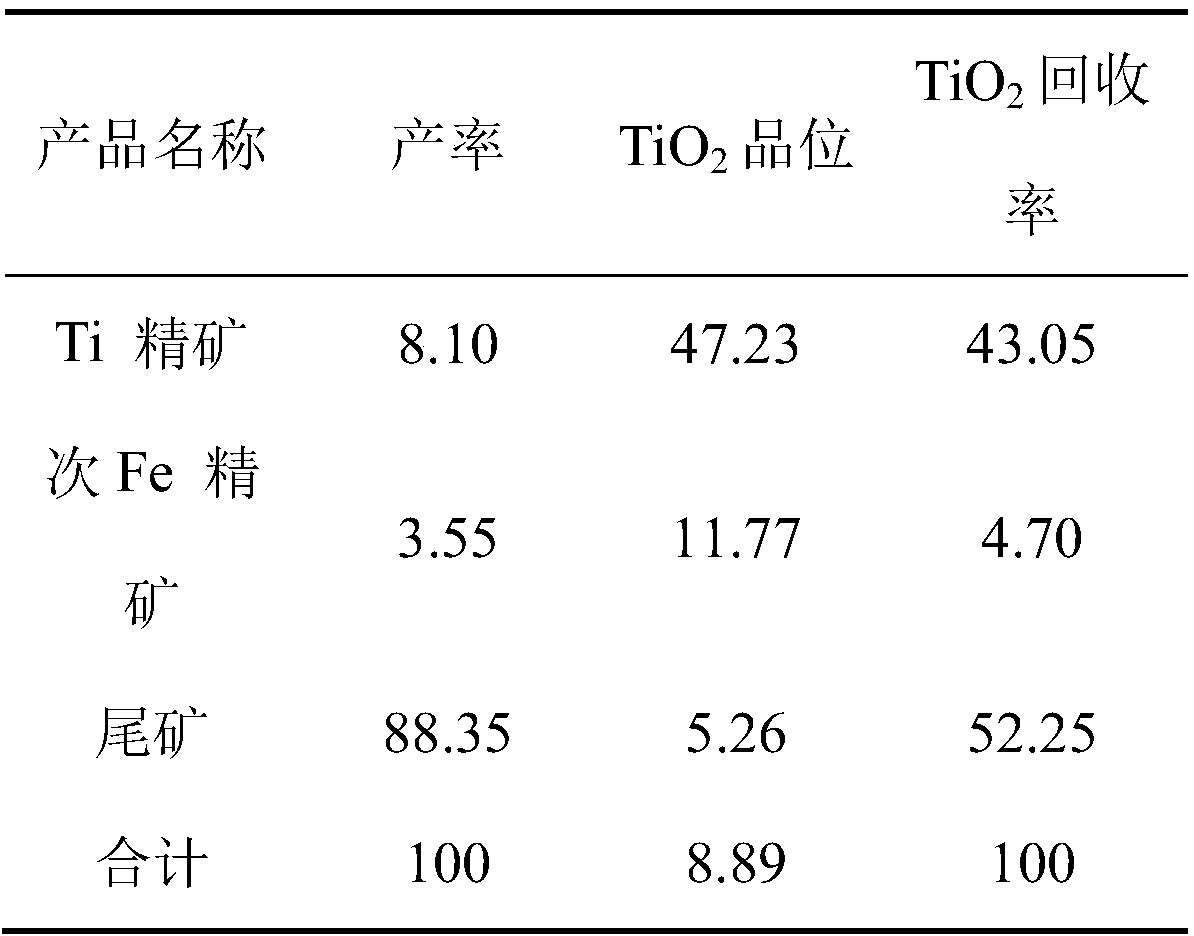

Ultrafine-grained ilmenite material pre-enrichment and selection process

InactiveCN110665640AEfficient removalHigh efficiency pre-enrichmentFlotationMagnetic separationIlmeniteEnergy consumption

The invention discloses an ultrafine-grained ilmenite material pre-enrichment and selection process. The process mainly comprises the following two parts of (1) realizing effective pre-enrichment of ultrafine-grained ilmenite by using a ''medium magnetic pre-selection-superconducting magnetic separation'' process to obtain a flotation raw material; and (2) using a ''flotation machine-flotation column'' combined process to select ilmenite after magnetic separation pre-enrichment, and finally acquiring ilmenite concentrate whose TiO2 grade is greater than 47% and a TiO2 recovery rate is greaterthan 40%. The method of the invention has the characteristics of low energy consumption, high efficiency, easy conversion into production practice and the like, and effective recovery of ultrafine-grained ilmenite is realized under a condition of ensuring quality of concentrate products.

Owner:江苏旌凯中科超导高技术有限公司

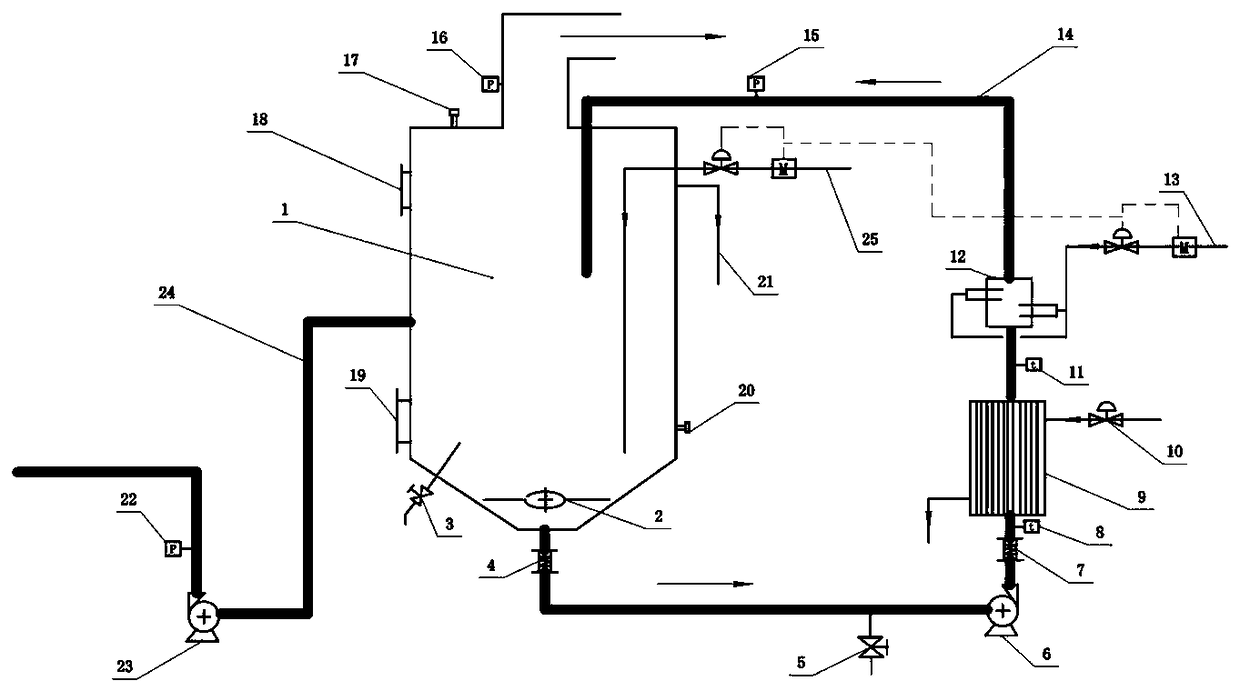

Neutralizing and concentrating device used for monoammonium phosphate production and using method thereof

ActiveCN108726497AAchieve efficient recyclingIncrease added valuePhosphatesPhosphate productEconomic benefits

The invention discloses a neutralizing and concentrating device used for monoammonium phosphate production and a using method thereof. Specifically, the bottom of a reactor is connected with a steam heat exchanger through a circulating pump; the steam heat exchanger is connected with a tubular reactor; the tubular reactor is connected with the top of the reactor through a reaction slurry circulating tube; the upper part of the reactor is equipped with an extracted residual acid conveying tube; the middle part of the reactor is connected with a high-pressure pump through a high-pressure pump conveying tube, and the slurry is fed to a powder spraying tower. Extracted residual acid or concentrated phosphoric acid performs neutral reaction with gas ammonium, so that monoammonium phosphate which meets powder-spraying indexes is conveyed to the powder spraying tower through the high-pressure pump to obtain a monoammonium phosphate finished product. When a slurry method is used for producingmonoammonium phosphate from extracted residual acid, concentration of acid needs to be reduced for follow-up production as concentration of the extracted residual acid is too high, so that steam consumption amount of slurry concentration can be reduced while the monoammonium phosphate product is produced through the slurry method; and 43200 tons of steam is saved per year according to the extracted residual acid consumption amount, so that the annular saved steam amount reaches economic benefits of 7.78 millions of yuan.

Owner:YIDU XINGFA CHEM COMPANY

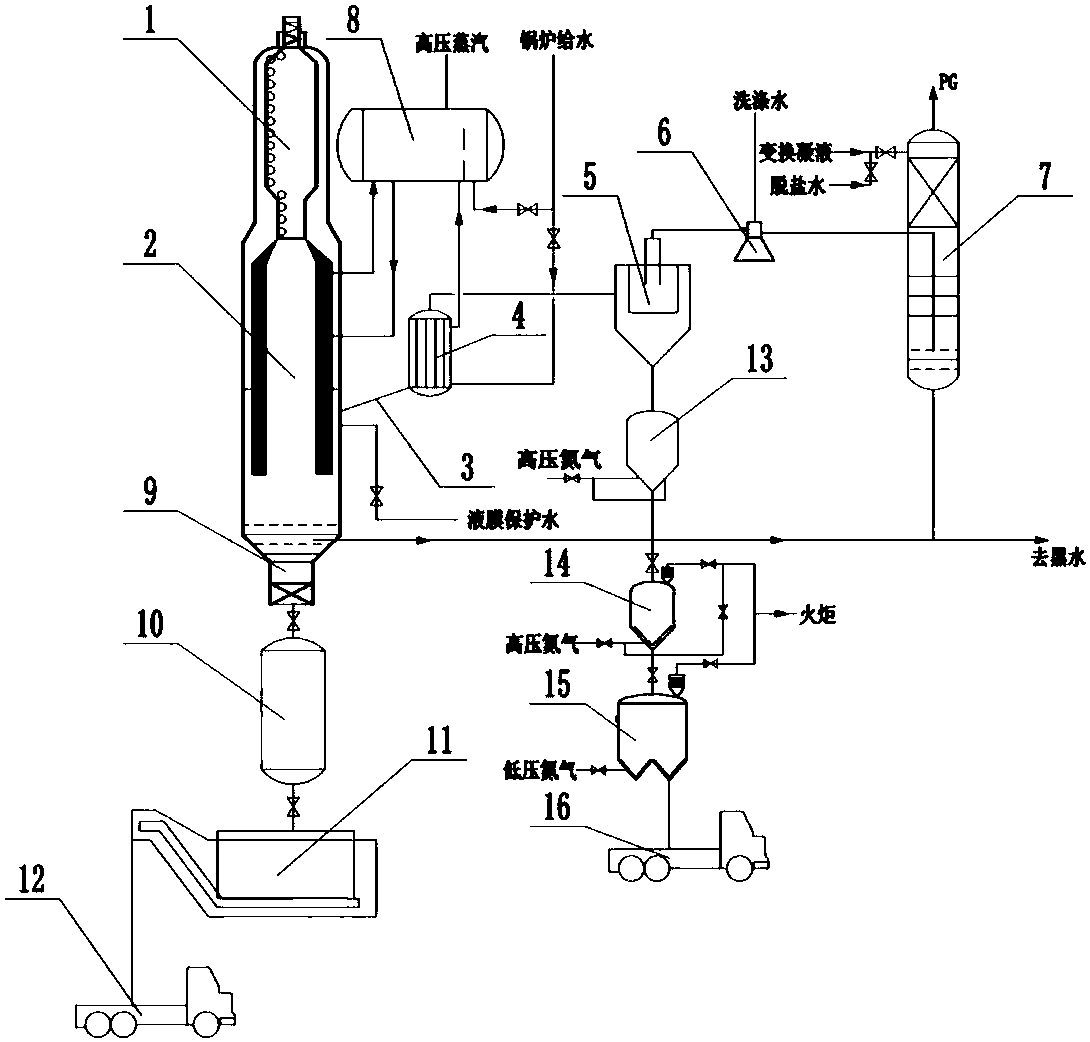

Energy-saving water-saving gas/steam cogeneration gasifying process

ActiveCN107641528AAchieve efficient recyclingRealize joint productionEnergy inputSteam generation using hot heat carriersSlagCogeneration

The invention belongs to the technical field of coal chemical industry, and relates to a gasifying process route for clean and efficient utilization of coal, in particular to an energy-saving water-saving gas / steam cogeneration gasifying process. The gasifying process includes that a carbon-containing powder material reacts with an oxidant in a gasifying furnace, generated high-temperature synthetic gas and waste residue are directly cooled by a radiation waste pot, and high-temperature sensible heat is recycled to generate high-quality steam; gas-solid separation is performed through a dry deashing process, and a downstream process is proceeded. By utilizing the gasifying process, sensible heat of high-temperature raw gas and high-temperature slag is recycled, high-temperature high-pressure steam can be obtained at the same time, gas-steam cogeneration is realized, water resources are saved, and energy utilization efficiency is improved; the gasifying process has good economic benefitand is reliable in running, environment-friendly and efficient.

Owner:宁夏神耀科技有限责任公司

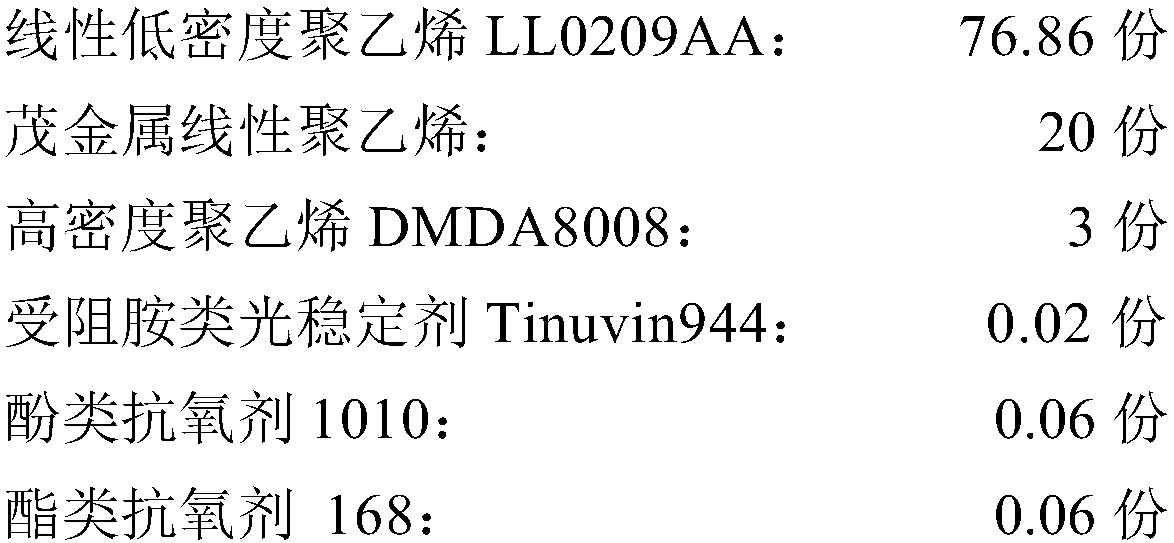

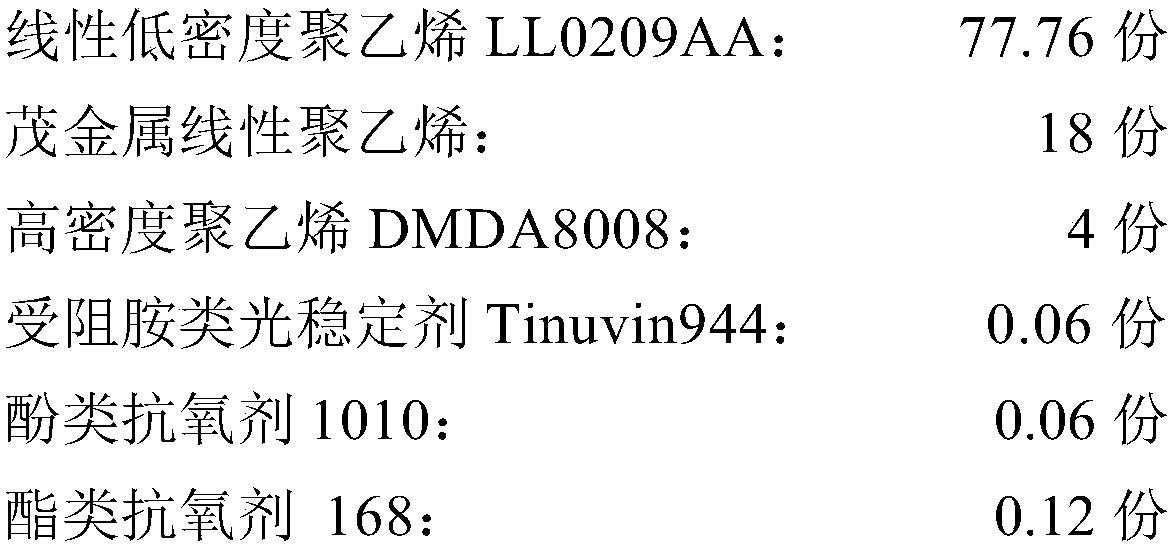

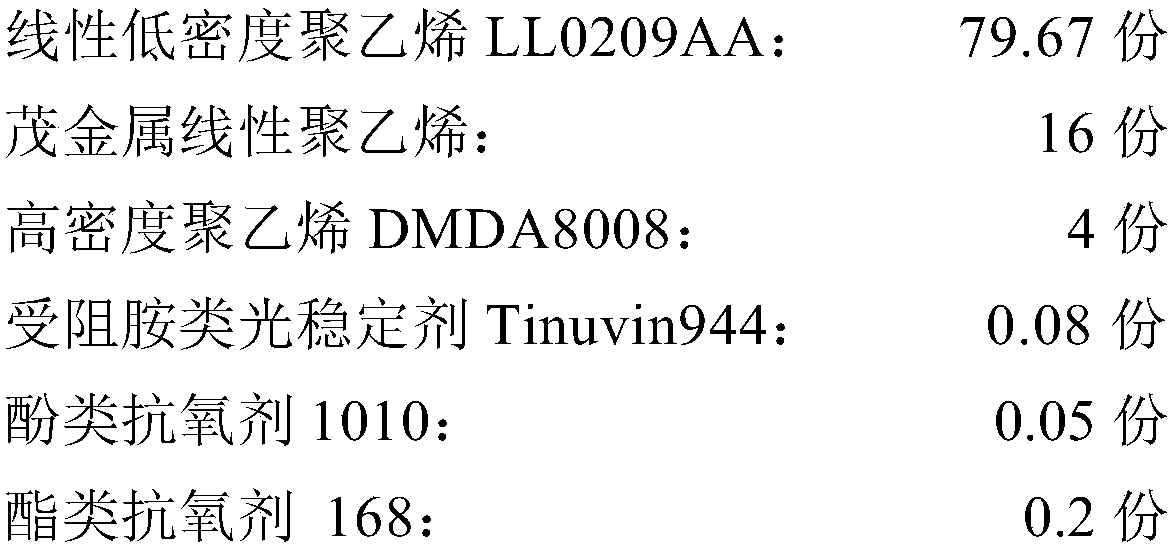

Mulching film and preparation method thereof

InactiveCN109749212AImprove aging resistanceConvenient and effective recyclingLinear low-density polyethyleneHindered amine light stabilizers

The invention provides a mulching film and a preparation method thereof. The mulching film comprises, by weight, 76.5-81.8 parts of linear low-density polyethylene, 15-20 parts of metallocene linear polyethylene, 3-5 parts of high-density polyethylene, 0.02-0.15 part of hindered amine light stabilizer, 0.05-0.15 part of phenolic antioxidant and 0.05-0.2 part of ester-type antioxidant; in particular, the melt flow rate (MFR) of the metallocene linear polyethylene is smaller than or equal to 1.0g / 10min, and the density thereof is 0.916-0.922g / cm<3>. The mulching film does not contain ultravioletabsorbing agents and dispersing agents, so that the anti-aging effect is achieved while the production cost is reduced; in particular, the mulching film meets the relevant requirements of the DB65 / 3189-2014 standard, and can be applied to harsh high-temperature and high-dryness environments such as Xinjiang, thereby having a wide application range.

Owner:PETROCHINA CO LTD

Solid fuel prepared from sewage plant sludge and preparation method and application thereof

InactiveCN109504485ARealize collaborative resource utilizationHigh value-added fuel utilizationBiofuelsSolid fuelsBrown coalGranularity

The invention relates to a solid fuel prepared from sewage plant sludge. Raw materials of the solid fuel comprise the sewage plant sludge of which the water content is 50-90 wt% and brown coal powderof which the particle size is less than or equal to 3 mm, wherein water content of the brown coal powder is less than or equal to 25 wt%, and a weight ratio of the sewage plant sludge and the brown coal powder is 1: (1 to 10). The invention further relates to a preparation method and application of the solid fuel.

Owner:辽宁大唐国际阜新煤制天然气有限责任公司

A clean production method for reusing residual activated sludge in a sewage treatment plant

InactiveCN105084686BAchieve efficient recyclingGood environmental benefitsWaste based fuelBiological sludge treatmentActivated sludgeMagnesium salt

Disclosed is a sanitary production method for recycling residual activated sludge in a sewage treatment plant. The method comprises the steps that residual activated sludge in a secondary sedimentation tank of the urban sewage treatment plant is naturally sedimented to reach the sludge sedimentation ratio of 50-60% and then directly added into an aeration stirring tank through no pretreatment, aeration stirring treatment is performed for 110-120 h, and then natural sedimentation is performed; 2, a supernate obtained through natural sedimentation is drained into an MAP sedimentation reactor, the P / Mg / N molar ratio is adjusted to be 1 / 1.2 / 1 by adding a magnesium salt solution and a phosphor salt solution, the pH value of a reaction solution is adjusted to be 8.9+ / -0.1 through 5M NaOH, a supernate obtained after sedimentation is drained into an anaerobic adjusting tank, and generated sediments are discharged into a separation recycling device; 3, sedimentation bottom mud obtained after natural sedimentation in the step 1 is discharged into the anaerobic adjusting tank, a supernate obtained after MAP sedimentation in the step 2 is drained into the anaerobic adjusting tank, and then further fermentation is performed to produce methane and recycle energy. Operation is convenient and easy to implement, no new chemical substances are introduced, follow-up slurry anaerobic digestion treatment is facilitated, and the recycling cost of phosphorus resources and energy is low.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

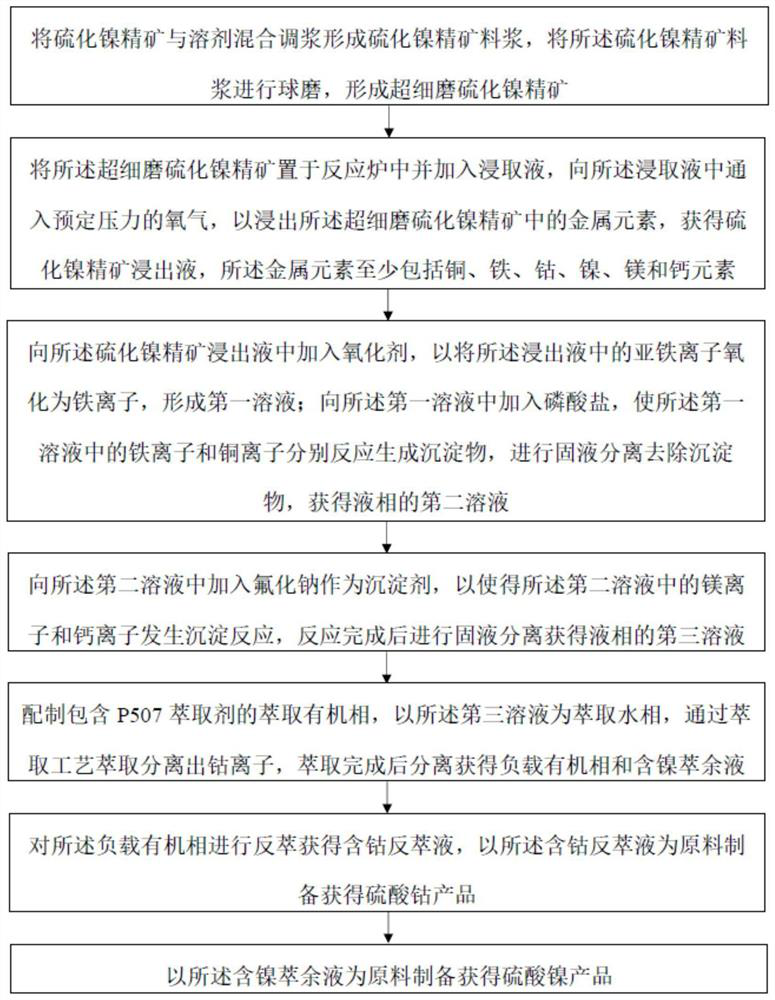

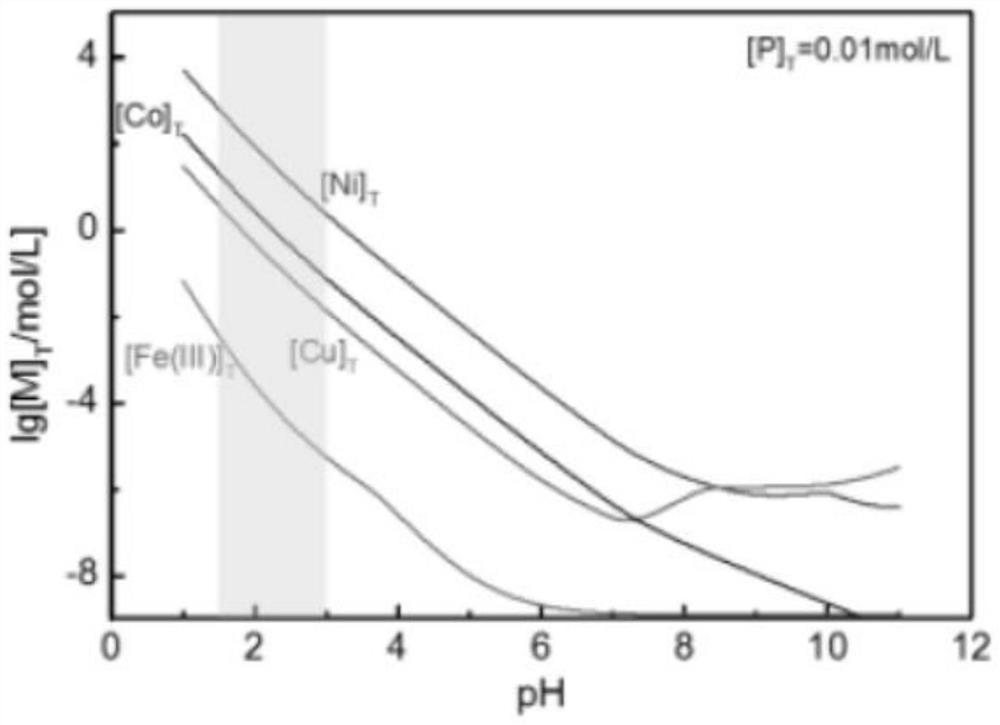

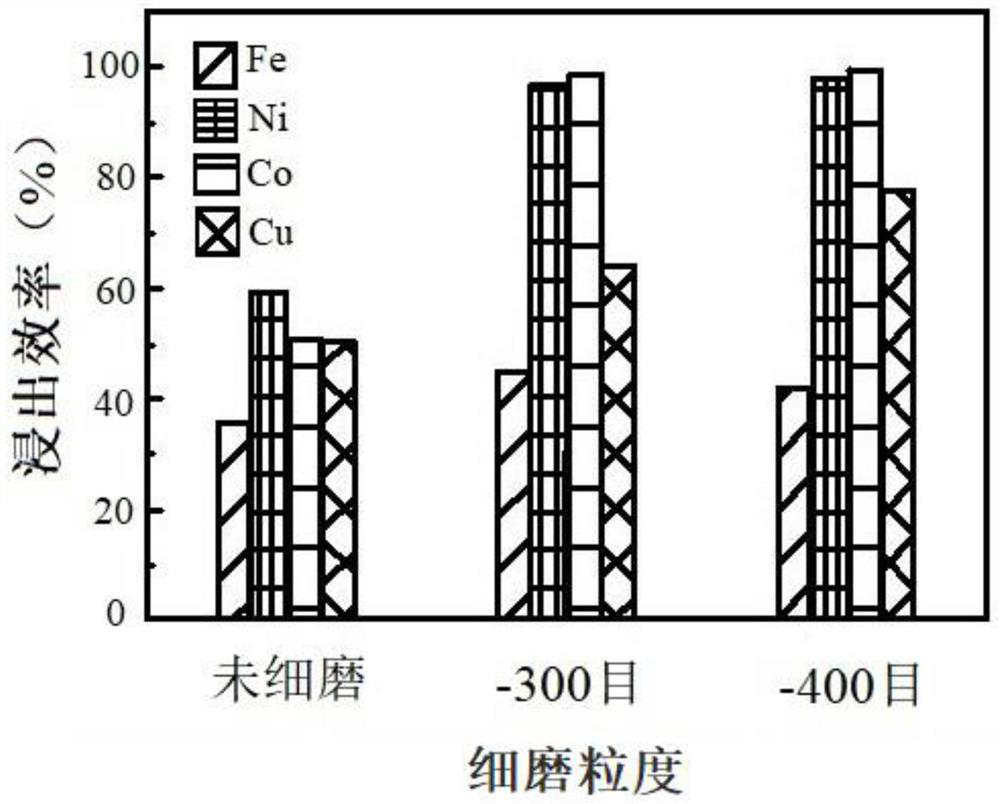

Method for selectively extracting cobalt and nickel from nickel sulfide concentrate

PendingCN113430370ALow leaching temperatureReduce leaching energy consumptionCobalt sulfatesNickel sulfatesPhosphateSlag

The invention provides a method for selectively extracting cobalt and nickel from nickel sulfide concentrate. The method comprises the following steps: metal elements in the nickel sulfide concentrate are selectively leached through a superfine grinding-oxygen pressure leaching process to obtain nickel sulfide concentrate leachate, wherein the metal elements at least comprise copper, iron, cobalt, nickel, magnesium and calcium elements; phosphate is added into the nickel sulfide concentrate leachate to generate iron phosphate slag and phosphate slag precipitates so as to remove iron ions and copper ions in the leachate; sodium fluoride is added as a precipitant to carry out precipitation reaction so as to remove calcium ions and magnesium ions in the leachate; and cobalt ions and nickel ions are extracted and separated through an extraction process correspondingly to prepare a cobalt sulfate product and a nickel sulfate product. According to the method, efficient recycling of the nickel element in the nickel sulfide concentrate is achieved, other metal elements are further utilized to reduce environmental pollution, and the resource utilization rate and the utilization value of raw materials are improved.

Owner:NAT ELECTRIC POWER INVESTMENT GRP YELLOW RIVER UPSTREAM HYDROPOWER DEV CO LTD +3

Heating and cooling air conditioner heat recovery device and air conditioner heat recovery system

ActiveCN101968254AIncrease cooling powerHigh comprehensive energy efficiency ratioEnergy recovery in ventilation and heatingHeat recovery systemsEngineeringThrottle

The invention relates to a heating and cooling air conditioner heat recovery device, which is used for recovering heat energy generated during the operation of a heating and cooling air conditioner so as to heat water. The heating and cooling air conditioner heat recovery device is provided to improve the energy efficiency of heating the water by the heat recovery of the heating and cooling air conditioner and realize a plurality of states such as independent cooling, independent heating, independent water heating, the combination of the three functions, and the like, wherein a first water heat exchanger for heating the water is connected between an exhaust port of a compressor and an input port of a multi-port reversing valve; and an independent water heat exchanging branch is also connected between another reversing port of the multi-port reversing valve and a stop-throttle valve component. The invention also provides an air conditioner heat recovery system consisting of the heating and cooling air conditioner heat recovery device and bearing / guiding water.

Owner:广东志高新能源科技有限公司

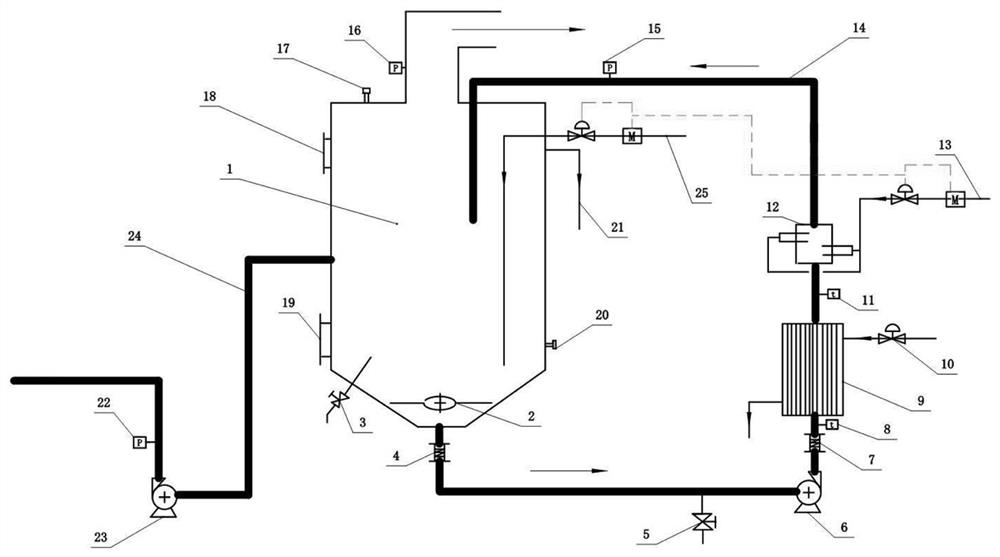

Oil-gas field waste liquid treatment system and treatment method

PendingCN111689620AAchieve efficient recyclingLarge amount of processingWater treatment parameter controlFatty/oily/floating substances removal devicesChemical reactionProcess engineering

The invention discloses an oil-gas field waste liquid treatment system, which comprises: a dosing device, an integrated reaction device, an integrated separation device and a filtering device. The integrated reaction device comprises a reaction box and an oil collecting assembly; the integrated separation device comprises a separation assembly and at least one mud scraping assembly. The inventionfurther provides an oil-gas field waste liquid treatment method. A large amount of production waste liquid and measure waste liquid are generated in the oil-gas field production gathering and transportation process, factors like oil, suspended solids, particle size median, pH value, bacteria and influencing ions in the wastewater are removed by combining chemical reaction and physical separation,oil-gas field waste liquid treatment can reach reuse or reinjection water quality standards, effective recovery and water recycling of the oil-gas field waste liquid are achieved, and the system and method have the advantages of large treatment amount, high adaptability, low treatment cost, stable treatment index and low energy consumption.

Owner:SHAANXI HAIMO OILFIELD SERVICE +1

A neutralization and concentration device and method for use in the production of monoammonium phosphate

ActiveCN108726497BAchieve efficient recyclingIncrease added valuePhosphatesO-Phosphoric AcidPhosphate product

The invention discloses a device for neutralization and concentration in the production of monoammonium phosphate and a method for using it. Specifically, the bottom of the reactor is connected with a steam heat exchanger through a circulation pump, the steam heat exchanger is connected with a tubular reactor, and the tubular reactor undergoes reaction The slurry circulation pipe is connected to the top of the reactor; the upper part of the reactor is provided with a feeding pipe for raffinate; the middle part of the reactor is connected to the high-pressure pump through the slurry-to-high-pressure pump delivery pipe and then sent to the powder spraying tower. Neutralize raffinate or concentrated phosphoric acid with ammonia gas to obtain monoammonium phosphate slurry that meets the powder spraying index, and then use a high-pressure pump to transport it to the powder spraying tower to obtain monoammonium phosphate products. Solve the technical problem that when using raffinate acid to produce monoammonium phosphate products by slurry method, because the acid concentration of raffinate acid is too high, the acid concentration needs to be reduced before subsequent production can be carried out, which can save the time for producing monoammonium phosphate products by slurry method According to the current raffinate consumption, the steam consumption for slurry concentration can save 43,200 tons of steam per year, and the direct economic benefit of saving steam consumption is 7.78 million yuan.

Owner:YIDU XINGFA CHEM COMPANY

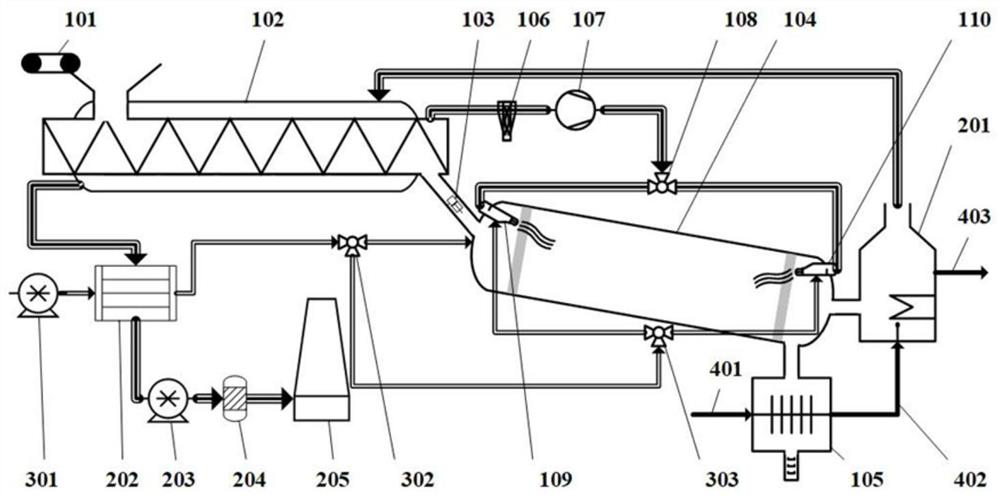

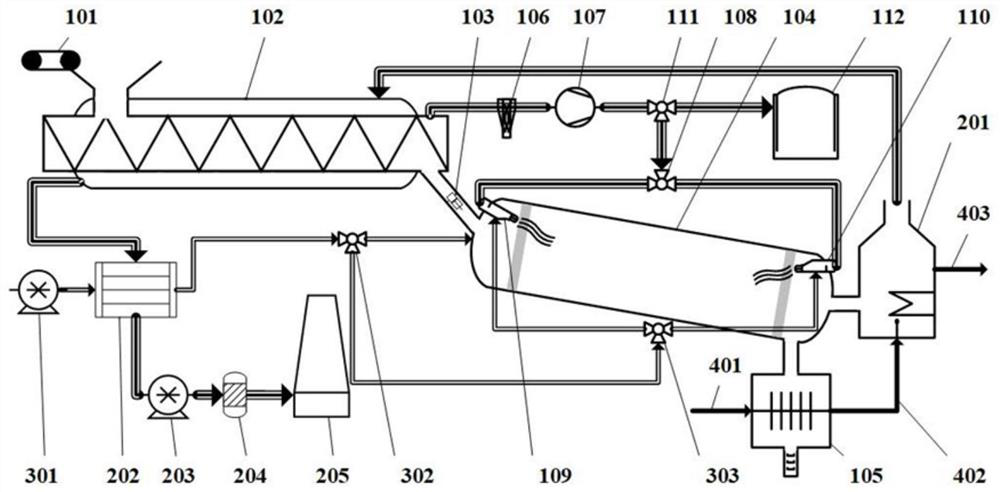

Coal gangue grading and quality-grading pyrolysis decarburization and waste heat gradient utilization system and operation method

PendingCN114838342AImprove warm-up effectAchieve efficient recyclingCombustion processEnergy inputCoal gangueDirect combustion

The invention discloses a coal gangue grading and quality-grading pyrolysis decarburization and waste heat gradient utilization system and an operation method, and the coal gangue grading and quality-grading pyrolysis decarburization and waste heat gradient utilization system comprises a pyrolysis furnace used for inputting coal gangue and carrying out pyrolysis; an air preheater; the decarburization furnace is used for inputting preheated air; the combustion device is used for inputting pyrolyzed solid materials for combustion decarburization; the pyrolysis gas input device is used for inputting pyrolysis gas and combusting in the oil-gas combustor; the decarburization furnace is used for outputting decarburized ash and flue gas; a slag cooler; a waste heat boiler; heat-exchanged flue gas output by the waste heat boiler is used as a heat source for pyrolysis of the pyrolyzing furnace, and flue gas used after pyrolysis is used as a heat source for preheating of the air preheater. According to the invention, superior combustion conditions are ensured through graded and quality-divided utilization of pyrolysis oil gas and solid materials and gradient utilization of waste heat, and the technical problems of stable ignition and sufficient decarburization of large-scale direct combustion of full-grade coal gangue in the prior art can be solved.

Owner:XI AN JIAOTONG UNIV

A sorting process for ores containing copper, cobalt and magnetite

ActiveCN104258963BAchieve efficient recyclingReduce ore handlingFlotationMagnetic separationSeparation technologyMagnetite

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

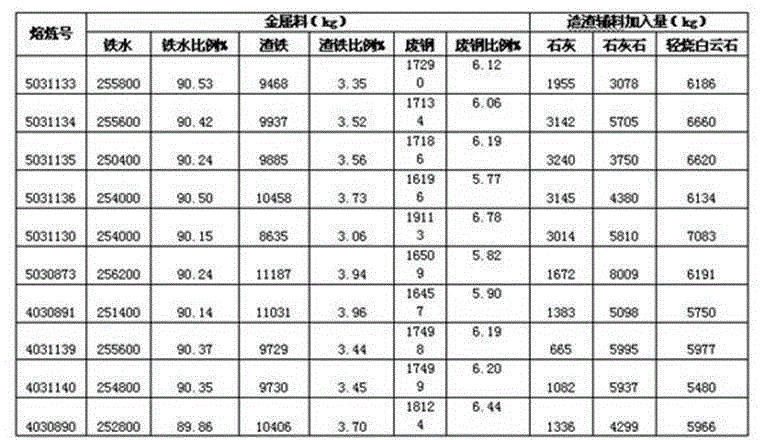

Method for smelting weather-resistant steel in a converter using desulfurization slag and steel slag to replace part of scrap steel

ActiveCN104060016BAchieve recyclingAchieve efficient recyclingManufacturing convertersSlagMolten steel

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com