Lignin magnetic nanoparticles with pH response, preparation method thereof and application of lignin magnetic nanoparticles in cellulase recycling

A technology for the recovery of magnetic nanoparticles and cellulase, applied in biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems of not exerting the value of lignin, environmental pollution, difficulties, etc., to promote development and high-value utilization , Widening the scope of application, the effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Parts by mass, g / mL:

[0061] Prepare 350 parts by mass of stone inkstone wood sodium aqueous solution (wood sodium content 20wt.%) at pH=12, after heating to 85°C, adjust the speed of the peristaltic pump to 6mL / min, and use the peristaltic pump to mix 43.08 parts by mass (3-chloro-2- Hydroxypropyl) trimethylammonium chloride (CHPTAC) solution (content 65wt.%) slowly drips, adds 14.88 mass parts 20wt.% sodium hydroxide aqueous solution when dripping 5min, after continuing to drop CHPTAC solution again, in React at 85°C for 4 hours, dialyze the reaction solution in deionized water with a dialysis membrane with a molecular weight of 1000, remove unreacted CHPTAC and small molecular impurities, and obtain the product concentrate (SL-N40) after rotary evaporation.

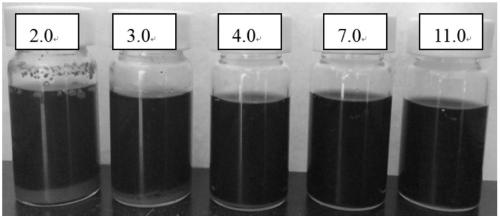

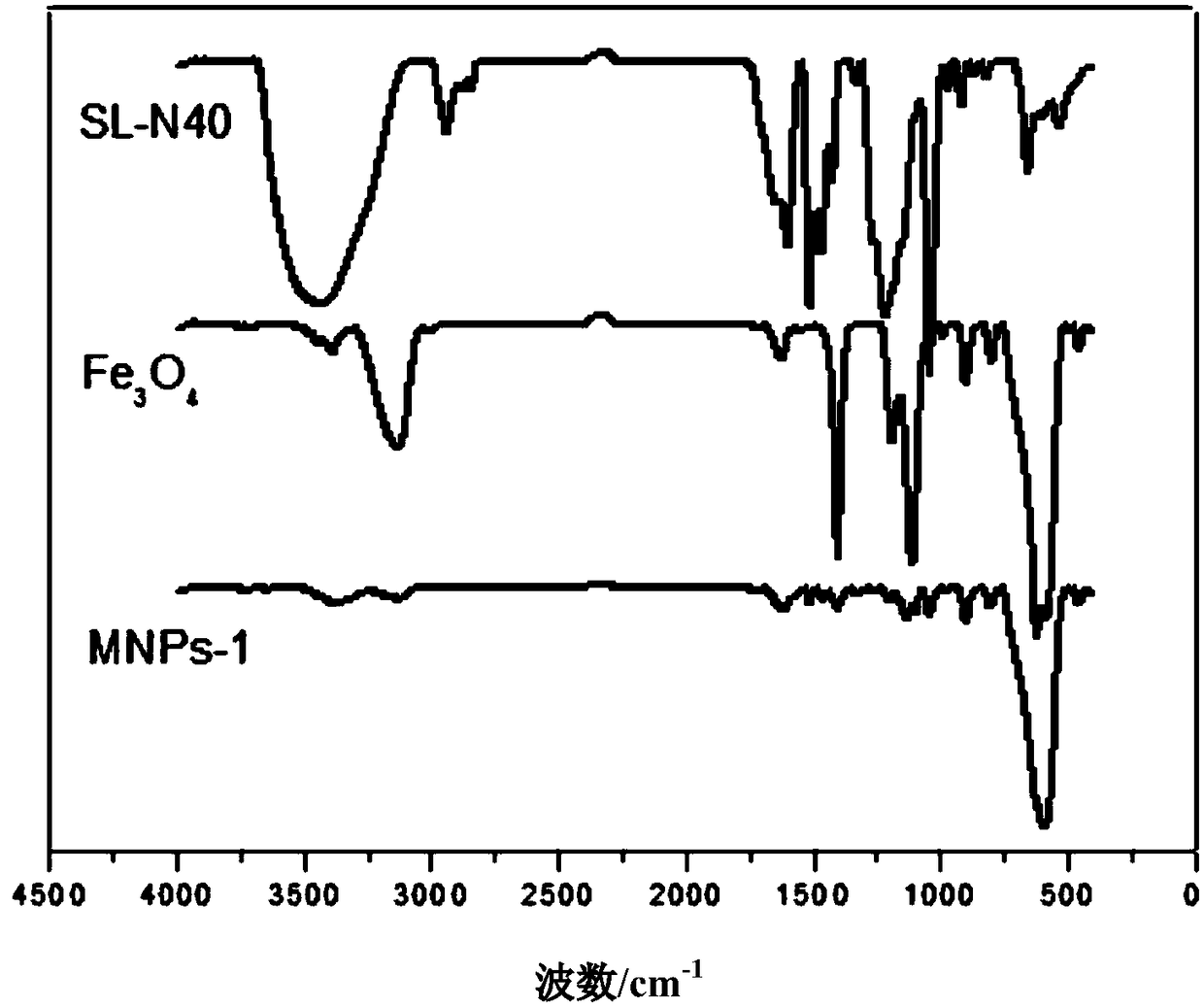

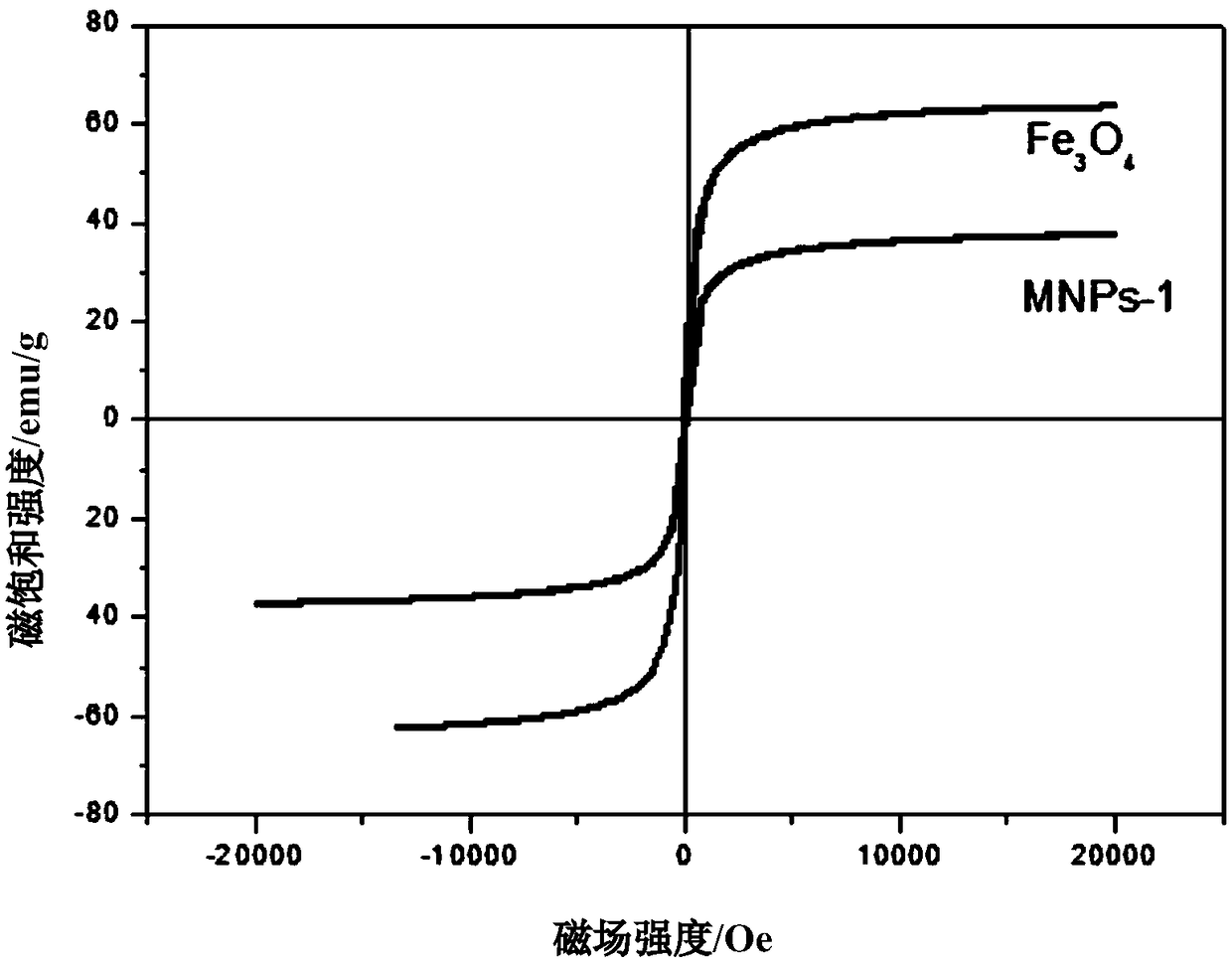

[0062] Dissolve ferric chloride and ferrous sulfate heptahydrate with a stoichiometric ratio of 2:1 in water, stir vigorously in a nitrogen atmosphere at a stirring rate of 450rpm, and slowly add 30 parts by vo...

Embodiment 2

[0065] Prepare 350 parts by mass of stone inkstone wood sodium aqueous solution (wood sodium content 20wt.%) at pH=12, after heating up to 85°C, adjust the speed of the peristaltic pump to 1.5mL / min, and 10.77 parts by mass (3-chloro-2 - Hydroxypropyl)trimethylammonium chloride (CHPTAC) solution (content 65wt.%) was slowly added dropwise, and 3.72 parts by mass of 20wt.% sodium hydroxide aqueous solution was added during the dropwise addition for 5 minutes, and then after the CHPTAC solution was continued to be added dropwise, React at 85°C for 4 hours, dialyze the reaction solution in deionized water with a dialysis membrane with a molecular weight of 1000, remove unreacted CHPTAC and small molecular impurities, and obtain the product concentrate (SL-N10) after rotary evaporation.

[0066] Dissolve ferric chloride and ferrous sulfate heptahydrate with a stoichiometric ratio of 2:1 in water, stir vigorously in a nitrogen atmosphere at a stirring rate of 400rpm, and slowly add 3...

Embodiment 3

[0069] Prepare 350 parts by mass of stone inkstone wood sodium aqueous solution (wood sodium content 20wt.%) at pH=12, after heating up to 85°C, adjust the speed of the peristaltic pump to 12mL / min, and use the peristaltic pump to mix 86.15 parts by mass (3-chloro-2- Hydroxypropyl)trimethylammonium chloride (CHPTAC) solution (content 65wt.%) is slowly added dropwise to the flask, and 29.77 mass parts of 20wt.% sodium hydroxide aqueous solution are added during the dropwise addition of 5 minutes, and then the CHPTAC solution is continued to be added dropwise Finally, react at 85°C for 4 hours, dialyze the reaction solution in deionized water with a dialysis membrane with a molecular weight of 1000, remove unreacted CHPTAC and small molecular impurities, and obtain the product concentrate (SL-N80) after rotary evaporation .

[0070] Dissolve ferric chloride and ferrous sulfate heptahydrate with a stoichiometric ratio of 2:1 in water, stir vigorously in a nitrogen atmosphere at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com