Method and apparatus for preparation of hydrogen peroxide p-menthane by non-catalytic oxidation of p-menthane

A technology of hydrogen peroxide and p-menthane, which is applied in the non-catalytic oxidation of p-menthane to prepare hydrogen peroxide p-menthane and the field of equipment, which can solve the problem that the continuous menthane oxidation process is not widely used in industrial production, expensive catalyst loss, catalyst Cleaning is complicated and other problems, to achieve the effect of overcoming low production efficiency, easy control, and high effective utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

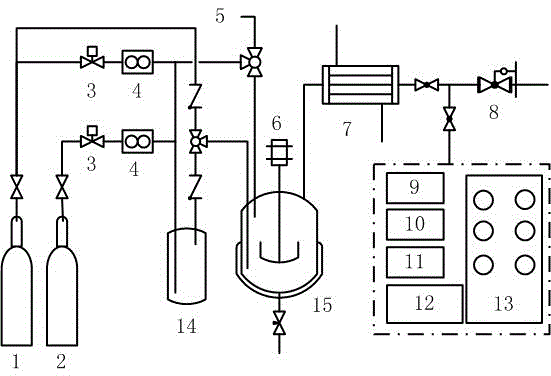

Image

Examples

Embodiment 1

[0015] At a temperature of 100°C and a pressure of 0.3 MPa, with oxygen as the oxidant, the alkaline washing solution NaCO 3 The mass fraction of the solution is 2%, the ventilation rate is 3L / min, and the p-menthane and hydrogen peroxide are reacted at a molar ratio of 50:1. The result of reacting for 5 hours is as follows: the conversion rate of p-menthane is 24%; the mass fraction of hydrogen peroxide to menthane is 19%.

Embodiment 2

[0017] At a temperature of 110°C and a pressure of 0.3 MPa, with oxygen as the oxidant, the alkaline washing solution NaCO 3 The mass fraction of the solution is 2%, the ventilation rate is 3L / min, and the p-menthane and hydrogen peroxide are reacted at a molar ratio of 50:1. The result of reacting for 5 hours is as follows: the conversion rate of p-menthane is 30%; the mass fraction of hydrogen peroxide to menthane is 20%.

Embodiment 3

[0019] At a temperature of 120°C and a pressure of 0.3 MPa, oxygen is used as the oxidant, the mass fraction of initiator hydrogen peroxide to menthane is 2%, and the ventilation rate is 3L / min. The reaction was carried out at a molar ratio of 50:1. The result of reacting for 5 hours is as follows: the conversion rate of p-menthane is 33%; the mass fraction of hydrogen peroxide to menthane is 23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com