Special tool for hot pressing of polymer soft-bag battery

A soft pack battery, polymer technology, applied in battery assembly, secondary battery manufacturing, non-aqueous electrolyte battery, etc., can solve the problem of limiting the use range of V-shaped mold chain, short service life of Teflon rubber strip, affecting the battery The quality of hot pressing can improve the quality consistency, improve the polymerization effect, and facilitate the production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

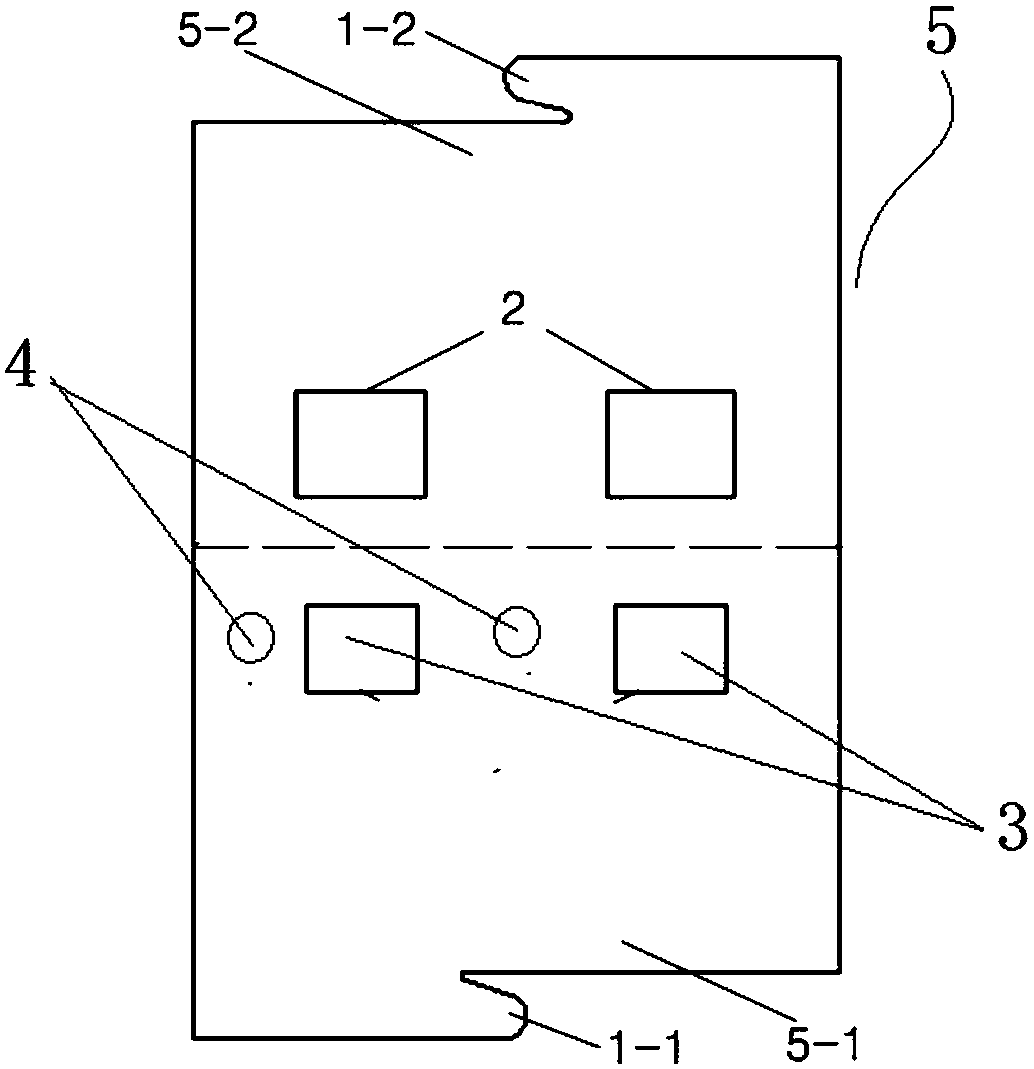

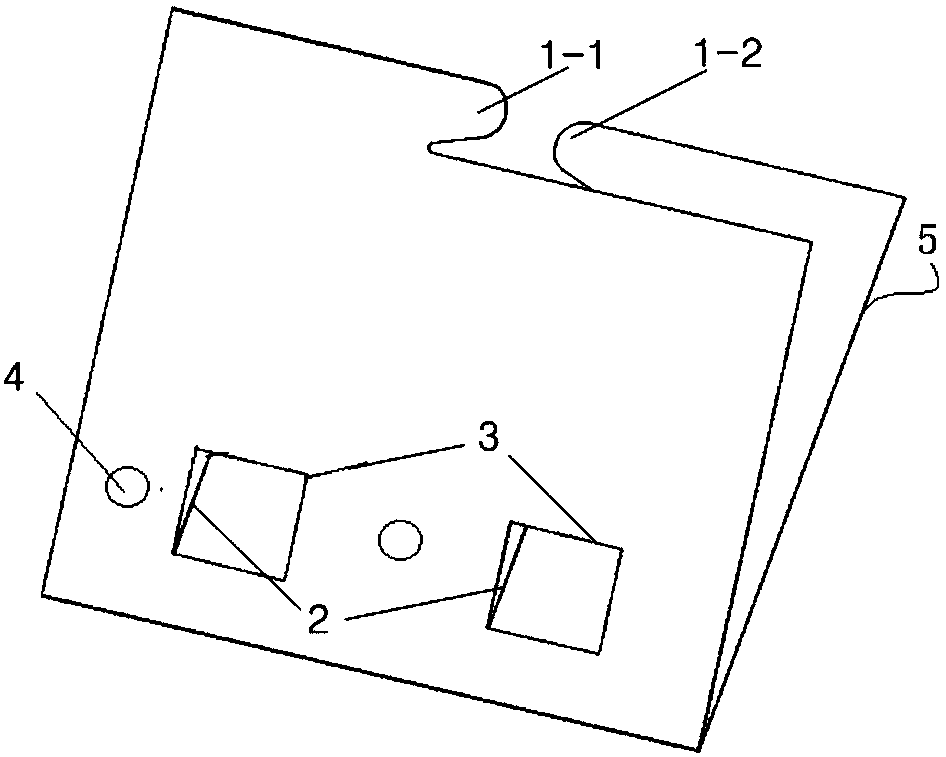

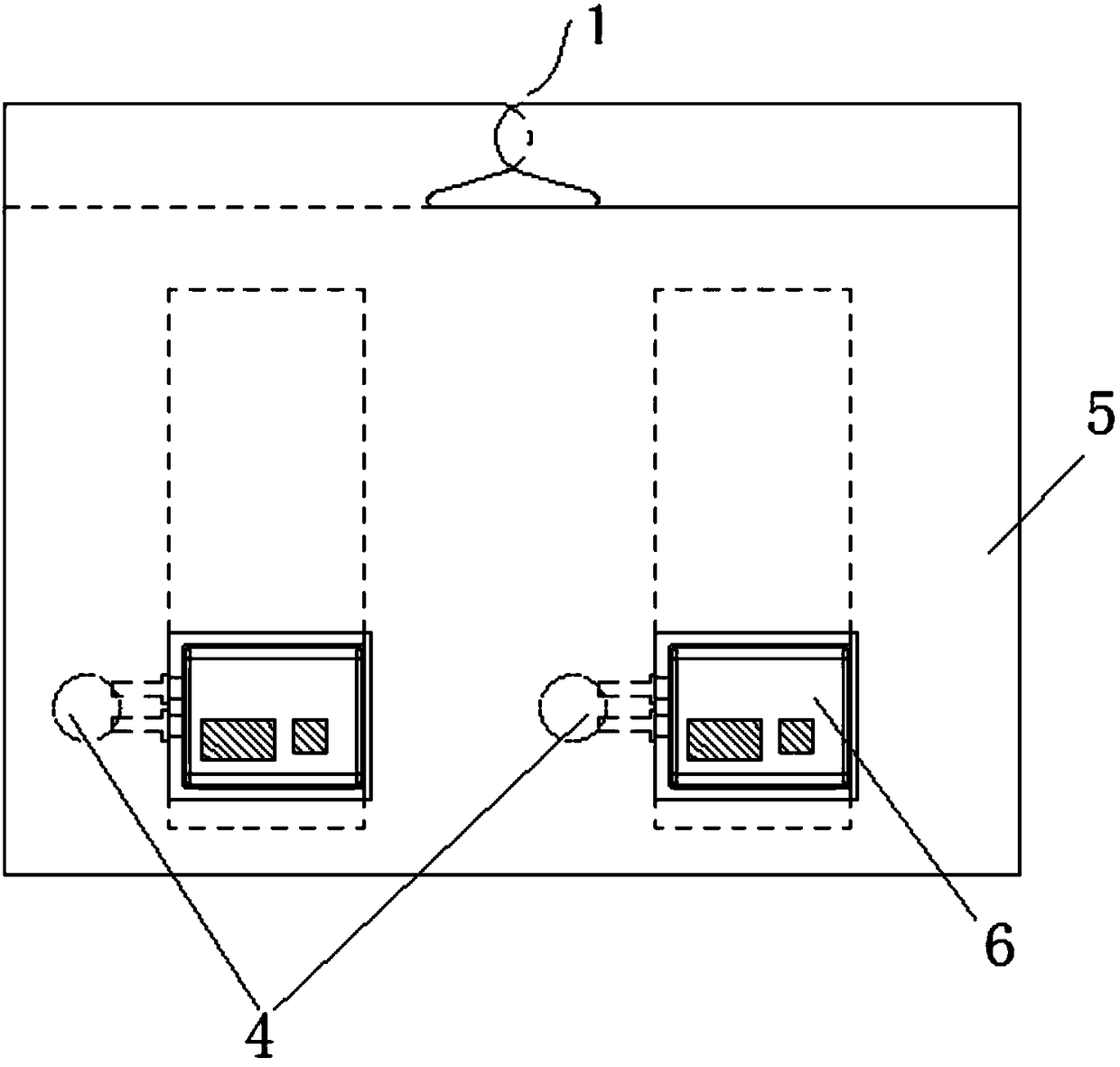

[0023] A hot-press tooling for polymer soft-pack batteries, including a main body of the tooling, which is a whole sheet structure similar to a rectangle after being unfolded, which are respectively an upper sheet body 5-2 and a lower sheet body 5-1, and the upper sheet body and the lower sheet body are respectively Contains two windows - the front window and the rear window, two buckles - the left buckle 1-1 and the right buckle 1-2, when the battery is hot-pressed, start the hot-pressing equipment, first confirm the equipment parameters, and then use the temperature Test the temperature of the two rows of hot platens with a pressure gauge, and check the pressure value between the platens with a pressure gauge. When the actual value matches the set value, start battery production. Take the case where each tooling carries 2 batteries as an example. , first confirm the front and back of the tooling according to the direction of the air inlet, then open the V-shaped tooling, put ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com