Energy-saving water-saving gas/steam cogeneration gasifying process

A process and process technology, which is applied in the fields of energy-saving and water-saving gas/steam co-production gasification process, clean and efficient utilization of coal gasification process route, and can solve the problem of low load capacity of single furnace, low thermal efficiency of gasifier, and low energy utilization rate and other problems, to achieve the effect of reducing equipment investment, reliable operation and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

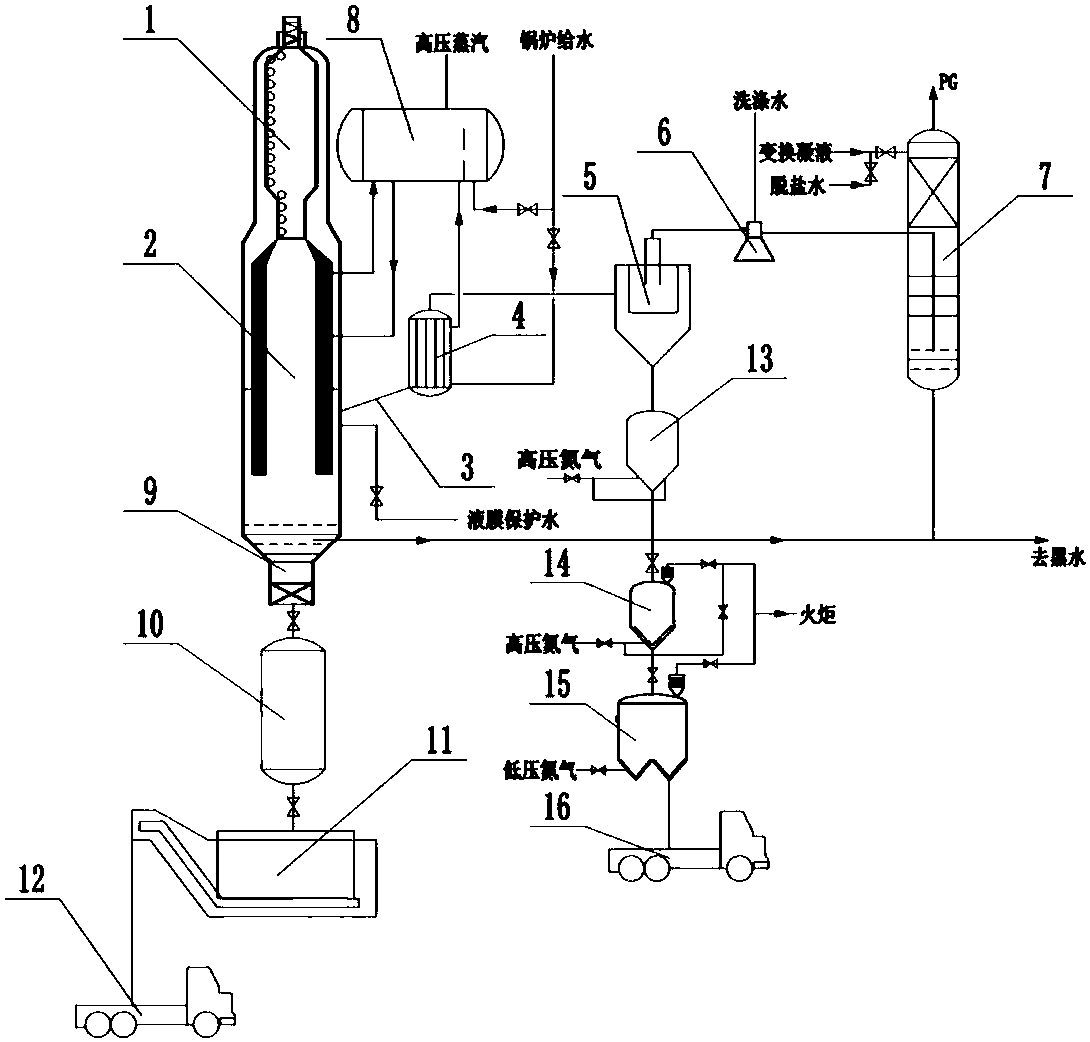

[0027] Such as figure 1 As shown, a device used in an energy-saving water-saving gas / steam cogeneration gasification process includes a gasifier 1, a radiation waste pot 2, a connecting pipe 3, a convection waste pot 4, a cyclone separator 5, and a Venturi Scrubber 6 and carbon washing tower 7; including steam drum 8, steam drum 8 is respectively connected with radiation waste pot 2 and convection waste pot 4; includes chilling pool 9 and slag lock bucket 10 located at the bottom of radiation waste pot 2 and connected in sequence , slag pool 11 and the first tank car 12; comprise coal ash temporary storage tank 13, coal ash lock bucket 14, coal ash cooling collection bin 15, the second tank car 16 that are positioned at the bottom of cyclone separator 5 and connect successively; Wherein, connecting pipe 3. The included angle with the horizontal line is 45°; in addition, the bottom of the coal ash temporary storage tank 13 is also equipped with a high-pressure nitrogen fluidiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com