Method for smelting weather-resistant steel in a converter using desulfurization slag and steel slag to replace part of scrap steel

A technology of converter smelting and replacing parts, which is applied in the field of converter smelting molten steel to achieve good air permeability and reduce steelmaking costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

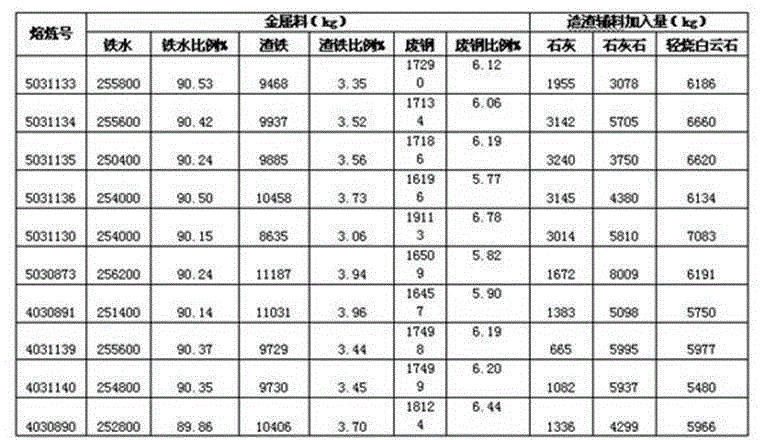

Image

Examples

Embodiment Construction

[0019] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0020] The type of steel produced is weathering steel, and the phosphorus content in the steel is required to be 0.075-0.114%. The method for smelting weathering steel in a converter using desulfurization slag and steel slag to replace part of scrap steel disclosed by the present invention includes the following steps:

[0021] a. Converter top-bottom compound smelting is adopted, and the mass percentage of the raw material composition of the metal main material is 85-95% of molten iron, 2-15% of desulfurization slag and steel slag, and the balance is light steel scrap;

[0022] b. Add converter slagging auxiliary materials for slagging when the converter oxygen lance is energized and ignited...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com