Coal gangue grading and quality-grading pyrolysis decarburization and waste heat gradient utilization system and operation method

A coal gangue and quality separation technology, which is applied in the large-scale consumption of coal gangue and coal gangue pyrolysis decarbonization, can solve the problems of inability to realize large-scale consumption of full-grade coal gangue, difficulty in realizing large-scale disposal of coal gangue, and heavy metal pollution in coal gangue. Seepage and other problems can be avoided to achieve the effect of avoiding conventional energy loss, improving heat utilization efficiency, and strengthening preheating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

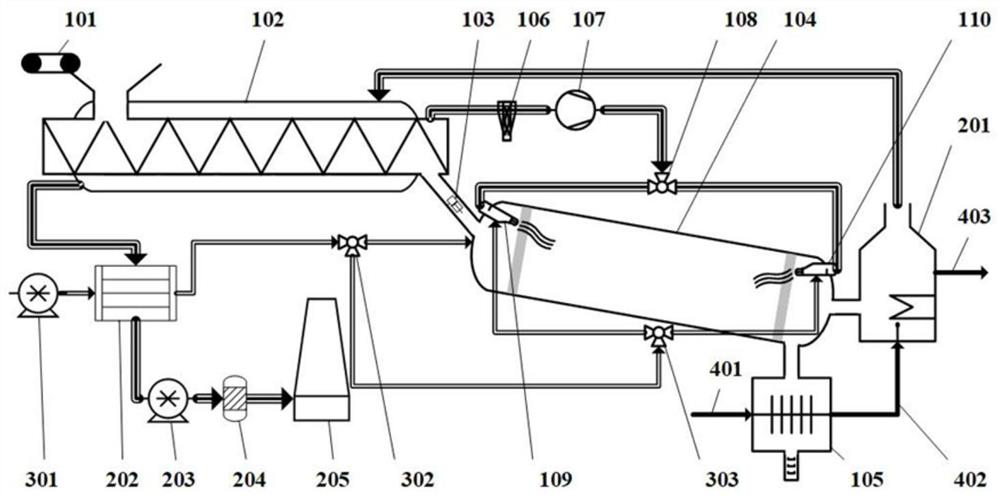

[0053] see figure 1 and Figure 4 , a coal gangue grading pyrolysis decarburization and waste heat cascade utilization system provided in Embodiment 1 of the present invention includes a feeding device 101, a pyrolysis furnace 102, a blanking port 103, a decarburization furnace 104, a slag cooler 105, Cyclone dust collector 106, conveying fan 107, oil and gas distribution valve 108, primary oil and gas burner 109, secondary oil and gas burner 110, waste heat boiler 201, air preheater 202, induced draft fan 203, desulfurization and denitration device 204, chimney 205, Blower 301 , primary air distribution valve 302 , secondary air distribution valve 303 , boiler feed water 401 , hot water piping 402 and steam piping 403 .

[0054] The pyrolysis furnace 102 uses the heat source provided by the high-temperature flue gas to pyrolyze the coal gangue from the feeding device 101, and the pyrolyzed solid materials with a certain temperature enter the decarburization furnace 104 throu...

Embodiment 2

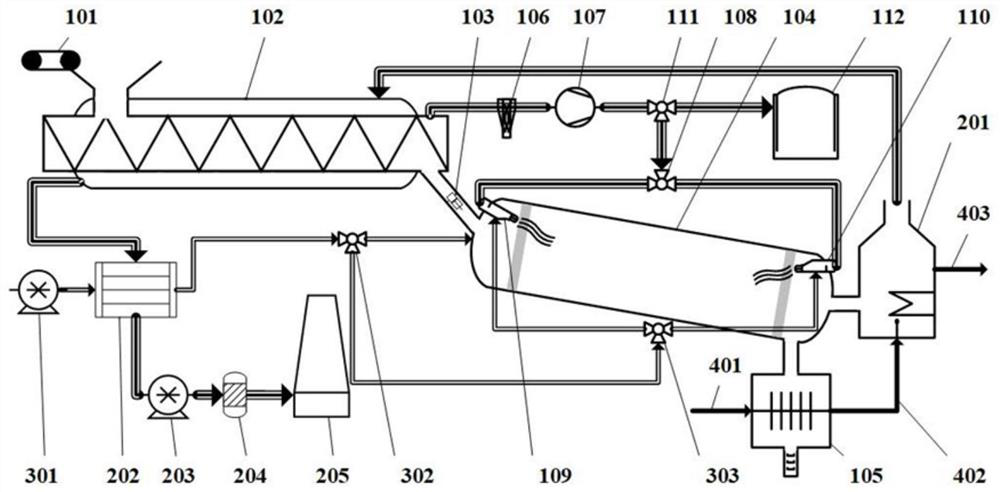

[0061] see figure 2 , A system for producing oil and gas from coal gangue, multi-quality decarbonized coal gangue and waste heat cascade utilization provided by Embodiment 2 of the present invention includes a feeding device 101, a pyrolysis furnace 102, a blanking port 103, a decarburization furnace 104, and a cold slag 105, cyclone dust collector 106, conveying fan 107, oil and gas distribution valve 108, primary oil and gas burner 109, secondary oil and gas burner 110, oil and gas collection valve 111, oil and gas storage tank 112, waste heat boiler 201, air preheater 202, induced draft fan 203, desulfurization and denitrification device 204, chimney 205, blower 301, primary air distribution valve 302, secondary air distribution valve 303, boiler water supply 401, hot water pipeline 402, steam pipeline 403.

[0062] Compared with Embodiment 1, the embodiment of the present invention can adjust the high temperature areas at both ends of the decarburization furnace by adjust...

Embodiment 3

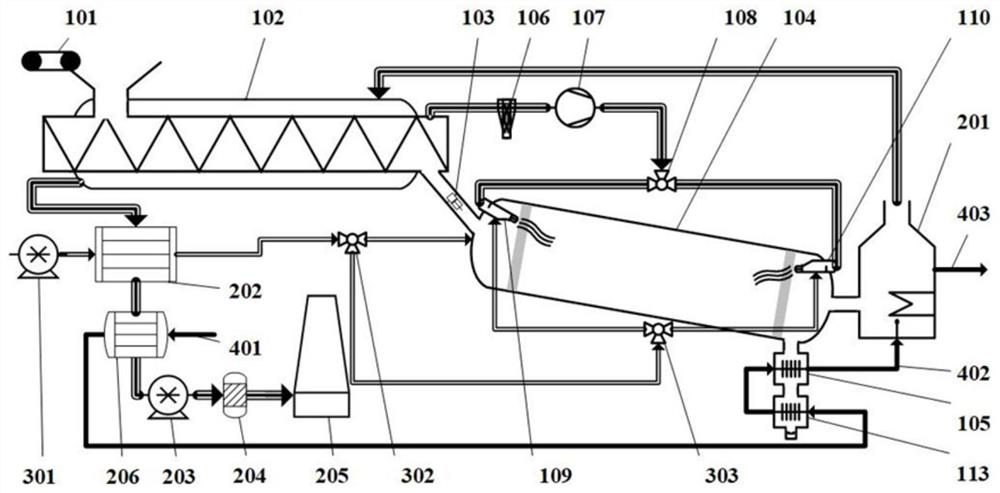

[0064] see image 3 , a coal gangue graded pyrolysis decarburization and ash slag waste heat secondary cascade utilization system provided in Embodiment 3 of the present invention includes a feeding device 101, a pyrolysis furnace 102, a blanking port 103, a decarburization furnace 104, a cooling Slag machine 105, cyclone dust collector 106, conveying fan 107, oil and gas distribution valve 108, primary oil and gas burner 109, secondary oil and gas burner 110, low temperature slag cooler 113, waste heat boiler 201, air preheater 202, induced draft fan 203. Desulfurization and denitrification device 204, chimney 205, low temperature economizer 206, blower 301, primary air distribution valve 302, secondary air distribution valve 303, boiler feed water 401, hot water pipeline 402, steam pipeline 403.

[0065] Compared with Embodiment 1, in order to realize the stepwise refinement and utilization of high-temperature slag energy in the embodiment of the present invention, a low-tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com