Oil-gas field waste liquid treatment system and treatment method

A waste liquid treatment system and technology for oil and gas fields, applied in the field of oil and gas field water treatment, can solve the problems affecting the health of residents in the surrounding environment of the well site, pollution of crops and surface water systems, corrosion of gathering and transportation and water injection systems, etc., so as to reduce labor intensity. , Save the amount of dosing, and deal with the effect of stable indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

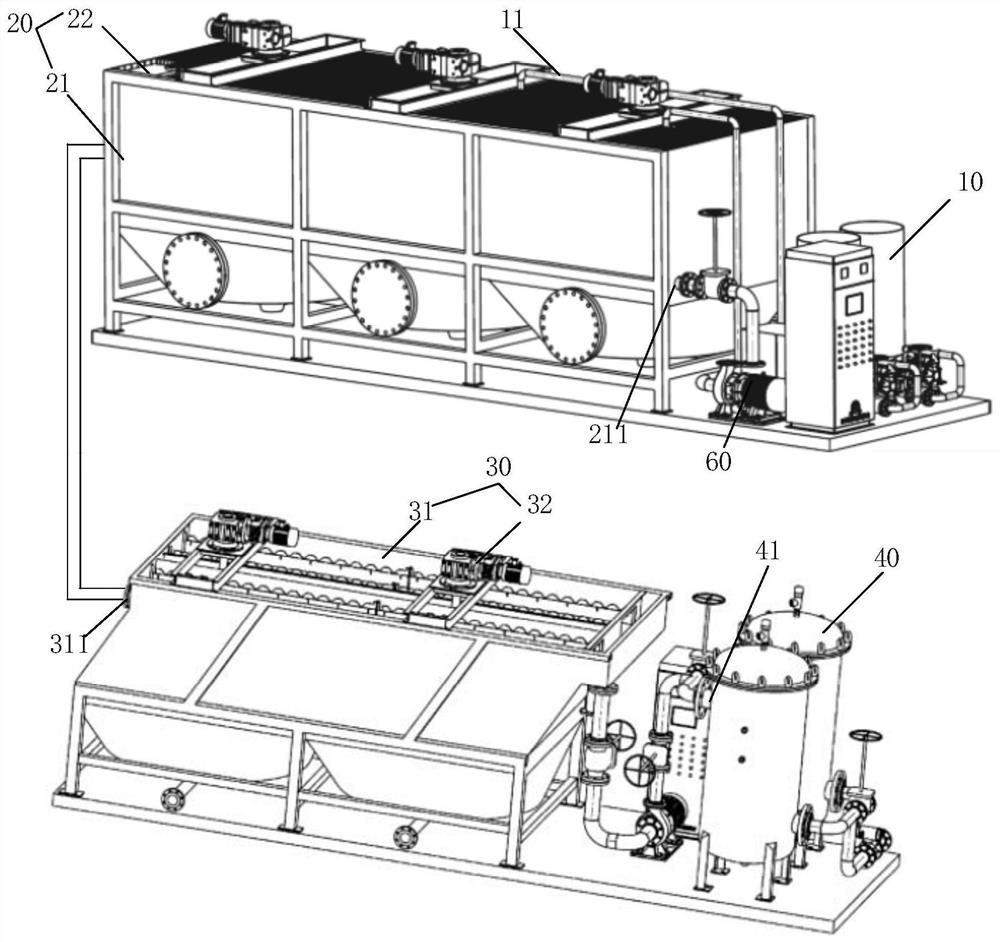

[0070] See figure 1 with figure 2 , an oil and gas field waste liquid treatment system, comprising: a dosing device 10 , an integrated reaction device 20 , an integrated separation device 30 and a filter device 40 . The integrated reaction device 20 includes: a reaction box 21 and an oil collection assembly 22 . The top of the reaction box 21 is open, and the opening communicates with the drug outlet of the dosing device 10 , and the first liquid inlet 211 of the reaction box 21 is connected with an external liquid supply device. The oil collecting assembly 22 is located in the reaction box 21 , and the oil collecting assembly 22 is close to the top of the reaction box 21 , and the oil inlet of the oil collecting assembly 22 can communicate with the inside of the reaction box 21 . The integrated separation device 30 includes a separation assembly 31 and at least one mud scraping assembly 32 . The second liquid inlet 311 of the separation assembly 31 is connected to the fir...

Embodiment 2

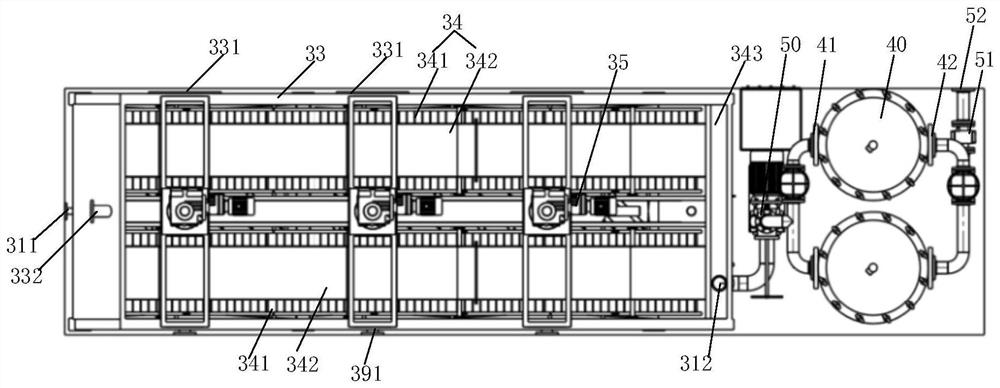

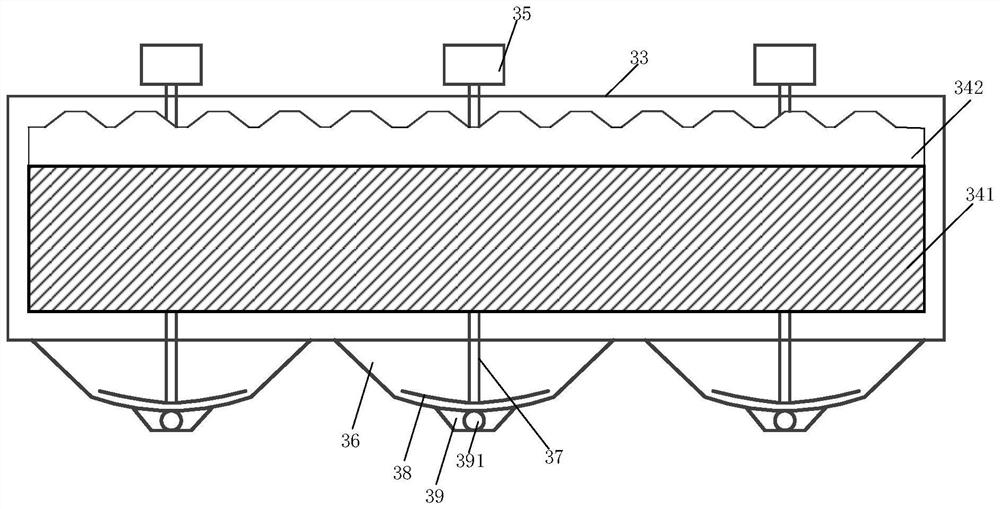

[0075] See figure 2 with Figure 3a , this embodiment is improved on the basis of Embodiment 1. The separation assembly 31 includes: a separation tank 33 and a sloping plate separation assembly 34 . The mud scraping assembly 32 includes: a driving motor 35 , a mud collecting bucket 36 , a connecting shaft 37 , a mud scraping plate 38 and a mud collecting bucket 39 . The second liquid inlet 311 and the second liquid outlet 312 are located on the separation tank 33 . The inclined plate separation assembly 34 is disposed in the separation tank 33 , and part of the inclined plate separation assembly 34 communicates with the second liquid outlet 312 . The liquid can continuously flow from the reaction tank 21 into the separation tank 33 , pass through the inclined plate separation assembly 34 for solid-liquid separation, and then flow out into the filter device 40 through the second liquid outlet 312 . The drive motor 35 is fixedly connected to the top of the separation tank 3...

Embodiment 3

[0092] See Figure 7 , the embodiment of the present invention also provides a treatment method for oil and gas field waste liquid, comprising:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com