Resourceful treatment method of high-sulfur copper tailings, and product and application thereof

A treatment method and technology for copper tailings, applied in chemical instruments and methods, grain treatment, wet separation, etc., can solve the problems of fine particle size, complex copper tailings components, and difficulty in reducing and comprehensive utilization, etc. To achieve the effect of efficient recycling, convenient operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

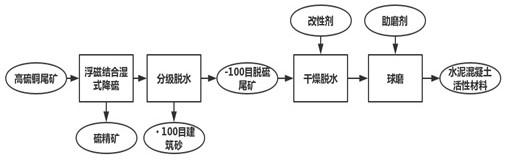

[0065]As an optional embodiment of the present invention, the tailings slurry B is dehydrated and then subjected to pulverization modification treatment, and grinding aids and modifiers are added during the pulverization modification treatment to obtain cement active mixed materials.

[0066]Since tailings slurry B contains a certain amount of water, it is necessary to dewater the tailings slurry B before pulverizing and modifying it to obtain a cement active mixture. The specific method of dehydration treatment can be a treatment method commonly used in the art, such as thickening, filtering or drying.

[0067]Since the tailings obtained after the dehydration treatment of the tailings slurry B are large in block or granular, which is not conducive to subsequent processing and utilization, it needs to be crushed. At the same time, because copper tailings have no pozzolanic activity compared with commonly used cement mixtures, certain physical or chemical methods are needed to modify them ...

Embodiment 1

[0105]This embodiment provides a resource treatment method for high-sulfur copper tailings, which includes the following steps:

[0106](A) The high-sulfur copper tailings are subjected to flotation desulfurization treatment to obtain sulfur concentrate and tailings slurry A; wherein the mass fraction of sulfur in the tailings slurry A is not more than 1.4%;

[0107]Flotation desulfurization includes the first roughing, second roughing and sweeping. The time of the first roughing, second roughing and sweeping is 5min, and the first roughing and second roughing Separately add desulfurization activator, regulator, collector and foaming agent for roughing and sweeping;

[0108]The desulfurization activator for the first rough selection is oxalic acid, its dosage is 3500g / t, the regulator is copper sulfate, its dosage is 100g / t, the collector is amylxanthate, its dosage is 200g / t, foaming agent BK202, its dosage is 112g / t; inhibitor is sodium hexametaphosphate, its dosage is 100g / t;

[0109]The des...

Embodiment 2

[0115]This embodiment provides a resource treatment method for high-sulfur copper tailings, except that in step (c), the grinding aid is polyethylene glycol monomethyl ether and sodium methacrylate sulfonate (the mass ratio of the two is 1:1 ), the remaining steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com