Ultrafine-grained ilmenite material pre-enrichment and selection process

An ultra-fine particle, pre-enrichment technology, applied in flotation, magnetic separation, solid separation and other directions, can solve the problem of low gravity separation processing capacity, achieve huge economic value, increase processing capacity, and improve magnetic separation enrichment ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

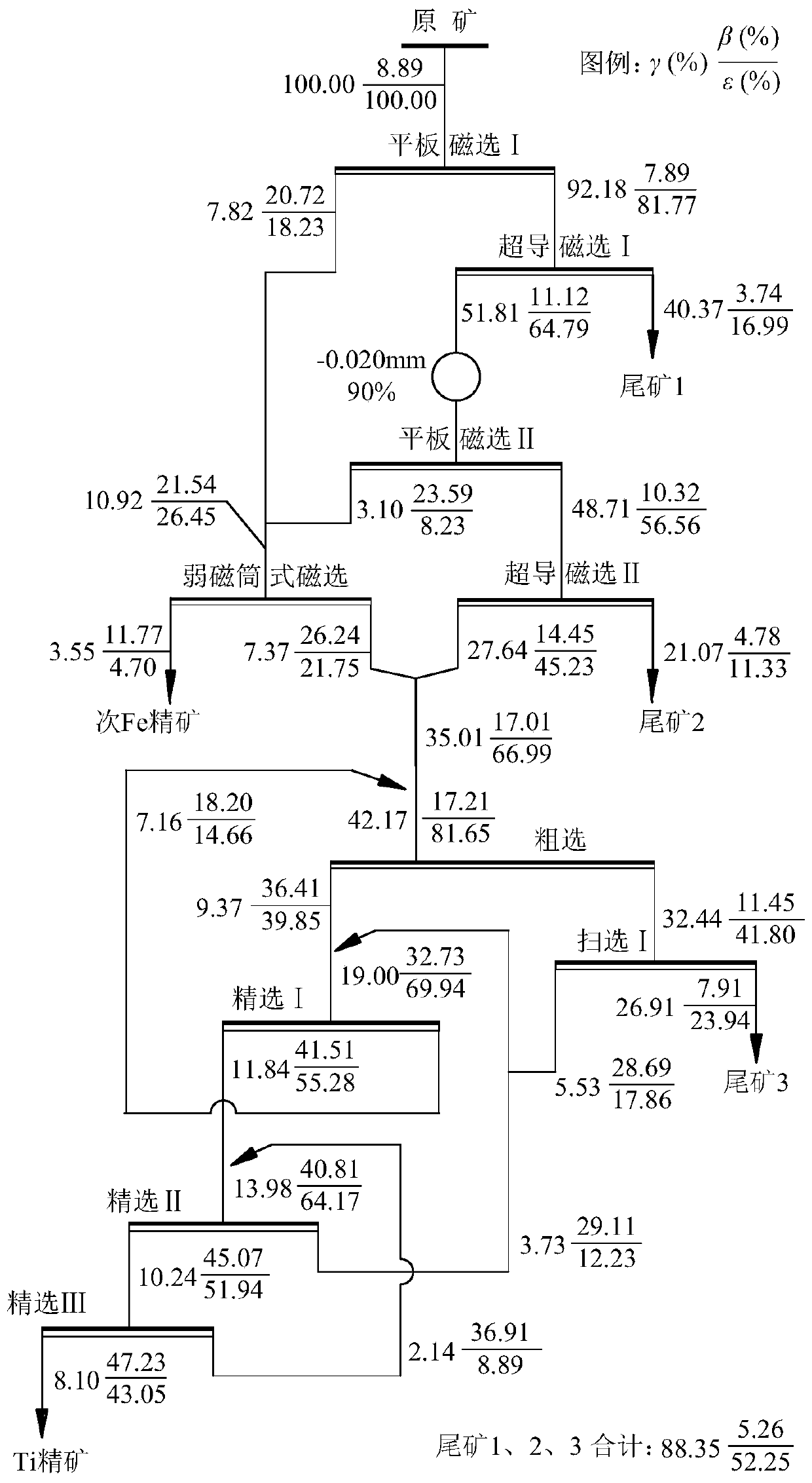

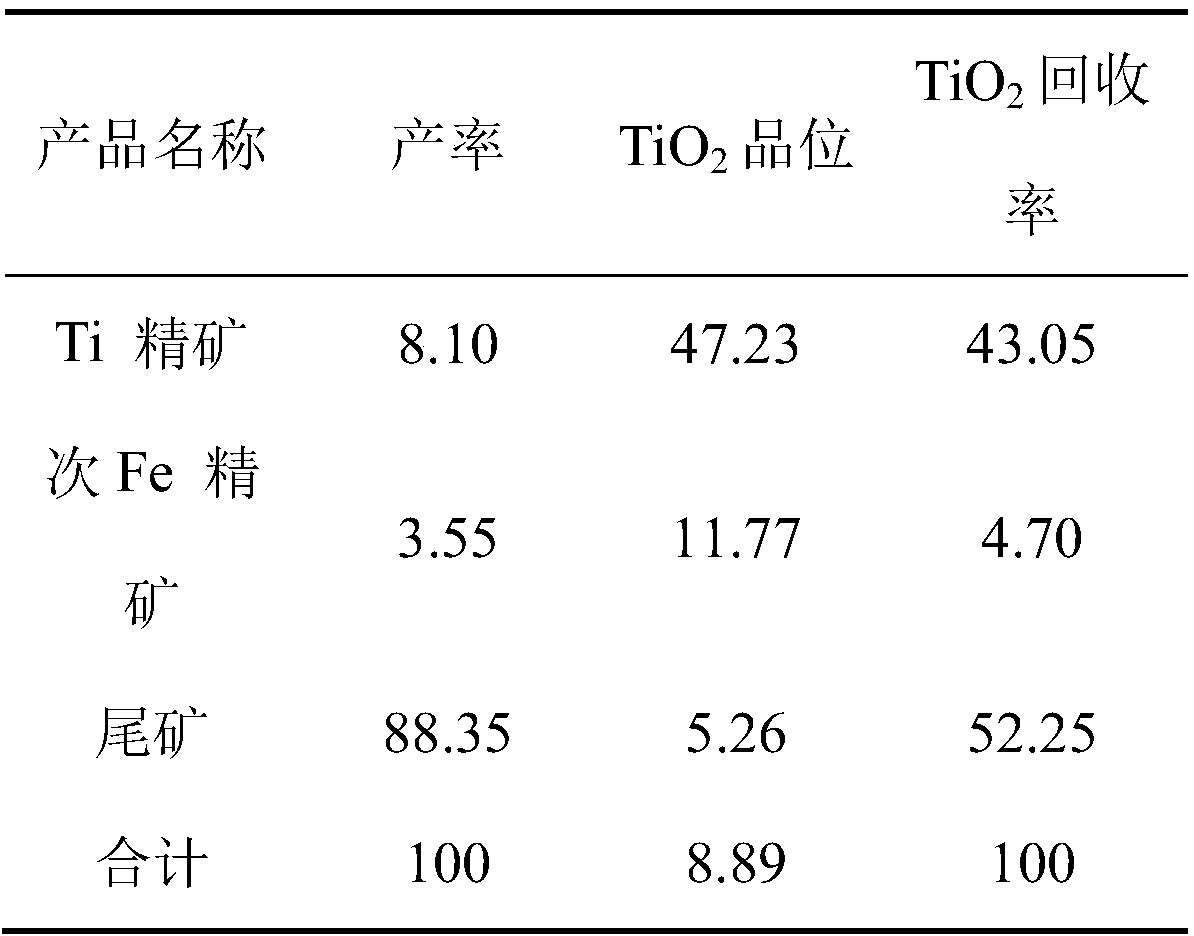

[0035] Raw materials: The ultra-fine ilmenite used in the test comes from a concentrator in Panzhihua area. 2 The grade is 8.89%.

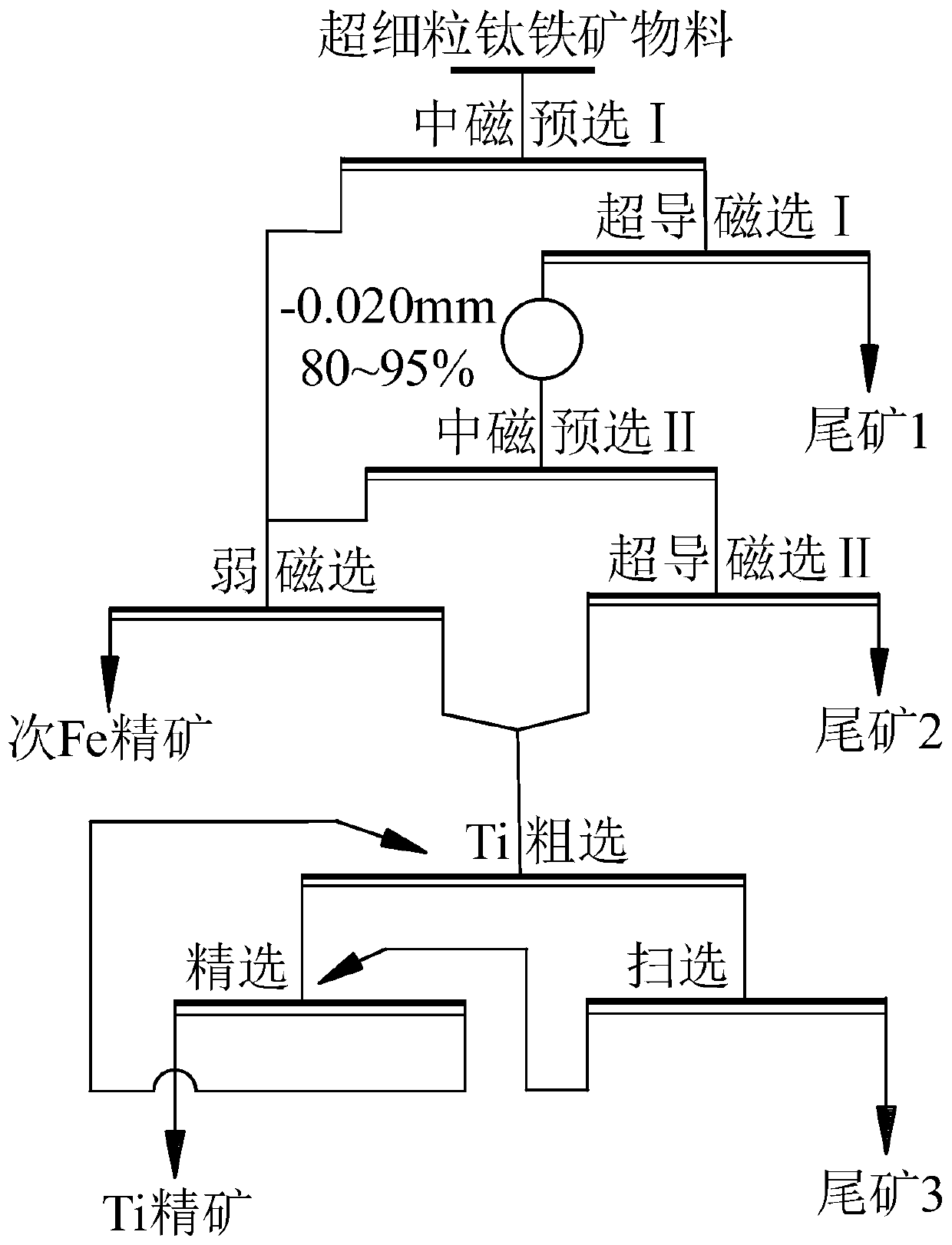

[0036] Such as figure 1 and 2 Shown, a kind of superfine ilmenite pre-enrichment and beneficiation process comprises the following steps:

[0037] (1) Magnetic separation pre-enrichment of ultra-fine ilmenite;

[0038] The magnetic separation pre-enrichment of ultra-fine ilmenite materials includes the first magnetic separation and the second magnetic separation in sequence. The first magnetic separation includes medium magnetic pre-separation I and superconducting magnetic The separation includes medium magnetic pre-separation II and superconducting magnetic separation II in turn, wherein, the tailings of medium magnetic pre-separation I are sent to superconducting magnetic separation I; the concentrate of superconducting magnetic separation I is fed into medium magnetic pre-separation II after regrinding; The tailings of magnetic pre-separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com