Method for recycling iron, indium and tine in zinc volatilizing kiln slag

A technology of zinc volatilization and kiln slag, applied in the field of comprehensive utilization of resources, can solve the problems of large corrosion of equipment, low utilization value of iron concentrate and copper concentrate, inability to achieve effective recovery of valuable metals, etc., and achieve comprehensive metal recovery rate. High, improve the comprehensive utilization rate, the effect of large-scale industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

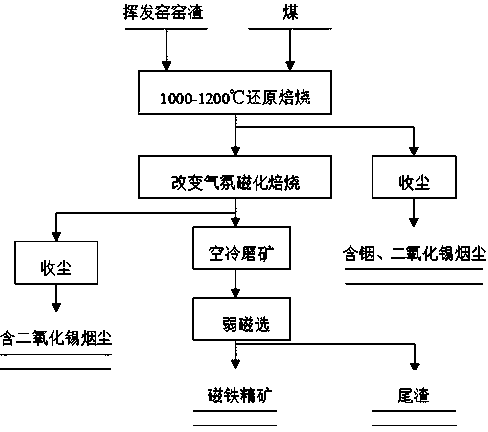

[0027] (1) Assuming that the reducing agent is 20% of the mass of the zinc volatilization kiln slag, mix the zinc volatilization kiln slag and pulverized coal evenly, put it into the rotary kiln, heat up to 1000°C for reduction roasting, and keep it warm for 180 minutes, and capture The flue gas produced in the process; the flue gas contains metal indium and tin dioxide, both of which can be recovered by conventional methods; at this reduction temperature, the copper-containing particles in the zinc volatilization kiln slag aggregate and grow up, realizing the copper , The effective separation of the iron phase is conducive to the recovery of iron in the next step, and most of the iron phase is reduced to metallic iron during the process;

[0028] (2) Step (1) After the heat preservation is completed, pass oxygen into the rotary kiln at a flow rate of 0.05L / min, continue to heat at 1000°C for 100min, and capture the flue gas generated during the process; the valuable components...

Embodiment 2

[0032] (1) According to the reducing agent being 25% of the mass of the zinc volatilization kiln slag, mix the pulverized coal evenly and put it into the rotary kiln, heat up to 1100°C for reduction roasting, and keep it warm for 150 minutes, and at the same time capture the flue gas generated during the process ; The flue gas contains metal indium and tin dioxide, both of which can be recovered by conventional methods; at this reduction temperature, the copper-containing particles in the zinc volatilization kiln slag aggregate and grow up, realizing the effective separation of copper and iron phases. Separation is beneficial to the recovery of iron in the next step. During the process, most of the iron phase is reduced to metallic iron;

[0033] (2) Step (1) After the heat preservation is completed, feed oxygen into the rotary kiln at a flow rate of 0.05L / min, continue to heat at 1100°C for 95 minutes, and capture the flue gas generated during the process; the valuable compone...

Embodiment 3

[0037] (1) Assuming that the reducing agent is 30% of the mass of the zinc volatilization kiln slag, mix the zinc volatilization kiln slag and pulverized coal evenly, put it into the rotary kiln, raise the temperature to 1150°C for reduction roasting, and keep it warm for 150 minutes, and capture The flue gas produced in the process; the flue gas contains metal indium and tin dioxide, both of which can be recovered by conventional methods; at this reduction temperature, the copper-containing particles in the zinc volatilization kiln slag aggregate and grow up, realizing the copper , The effective separation of the iron phase is conducive to the recovery of iron in the next step, and most of the iron phase is reduced to metallic iron during the process;

[0038](2) Step (1) After the heat preservation is completed, feed oxygen into the rotary kiln at a flow rate of 0.2L / min, continue to heat at 1150°C for 100min, and capture the flue gas generated during the process; the valuabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com