Neutralizing and concentrating device used for monoammonium phosphate production and using method thereof

A technology of monoammonium phosphate and raffinate acid, applied in the direction of phosphate, phosphorus oxyacid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

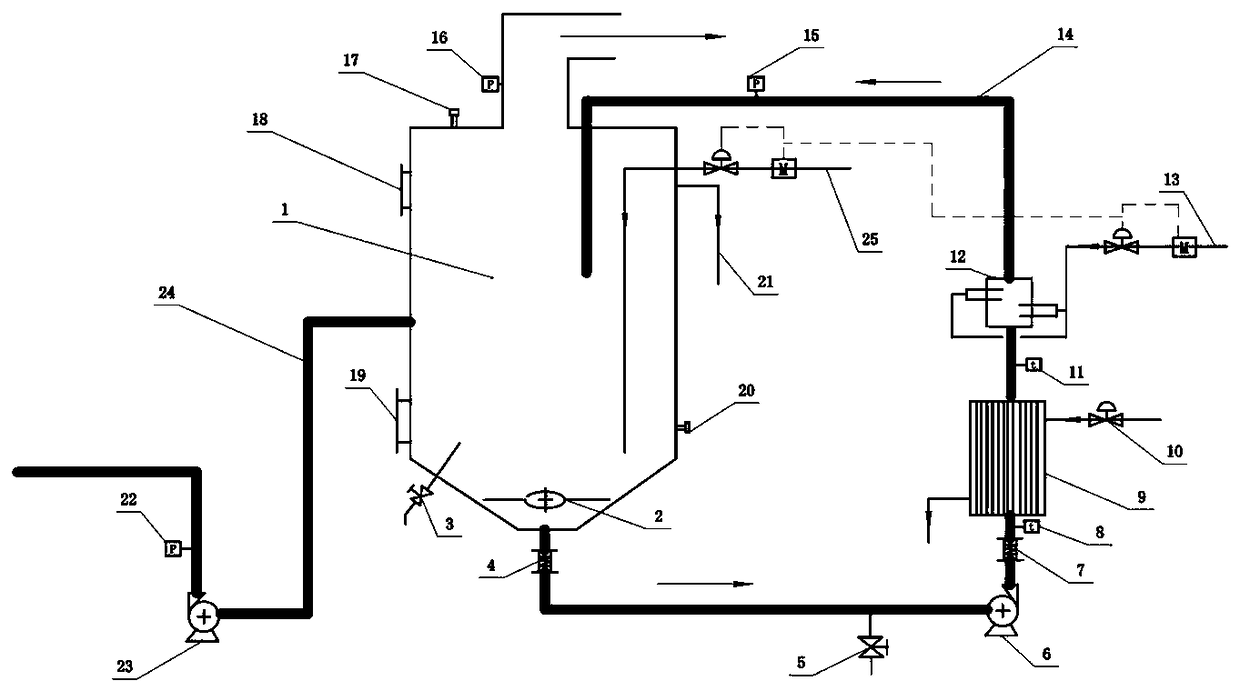

[0025] like figure 1 In, the present invention will be further described in conjunction with accompanying drawing:

[0026] A neutralization and concentration device for the production of monoammonium phosphate, the bottom of the reactor 1 is connected to the steam heat exchanger 9 through the circulation pump 6, the steam heat exchanger 9 is connected to the tubular reactor 12, and the tubular reactor 12 is reacted The slurry circulation pipe 14 is connected to the top of the reactor 1; the upper part of the reactor 1 is provided with a feeding pipe 25 for raffinate; the middle part of the reactor 1 passes through the slurry to the high-pressure pump delivery pipe 24 and is connected with the high-pressure pump 23 and then sent to the powder spraying tower .

[0027] The upper part of the reactor 1 is provided with an overflow pipe 21. The overflow pipe 21 is arranged at the 80-90% liquid level of the reactor 1 tower body. ; Insert the raffinate delivery pipe into the lower...

Embodiment 2

[0032] The process carried out using the device described in Example 1 is as follows:

[0033] Transport the raffinate with 40-44% acid concentration to the reactor tower body 1 through the raffinate delivery pipeline 25, and start the circulation pump 6 when the liquid level gauge 17 shows that the liquid level reaches 30%;

[0034] Intake ammonia through the intake ammonia delivery pipeline 13 to the tubular reactor 12, strengthen sampling analysis, and wait for the degree of neutralization to reach 0.92mol / mol, compare the intake ammonia delivery pipeline 13 inlet ammonia flow rate with the raffinate acid delivery pipeline inlet flow rate Put into automatic interlocking, set the neutralization degree of amino acid ratio to 0.95--1.02mol / mol;

[0035] Sampling and analyzing the specific gravity of the slurry, when the specific gravity is 1.5-1.55, it is not necessary to use its own concentrated steam heat exchanger 9; directly start the high-pressure pump 23 to transport the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com