Mulching film and preparation method thereof

A mulching film and metallocene technology, which is applied in the field of mulching film without ultraviolet absorbent and its preparation, can solve the problems of inconsistent initial mechanical properties, difficult promotion and application, large cost increase, etc., achieve good aging resistance effect, reduce white Pollution, achieve the effect of effective recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Mulch composition

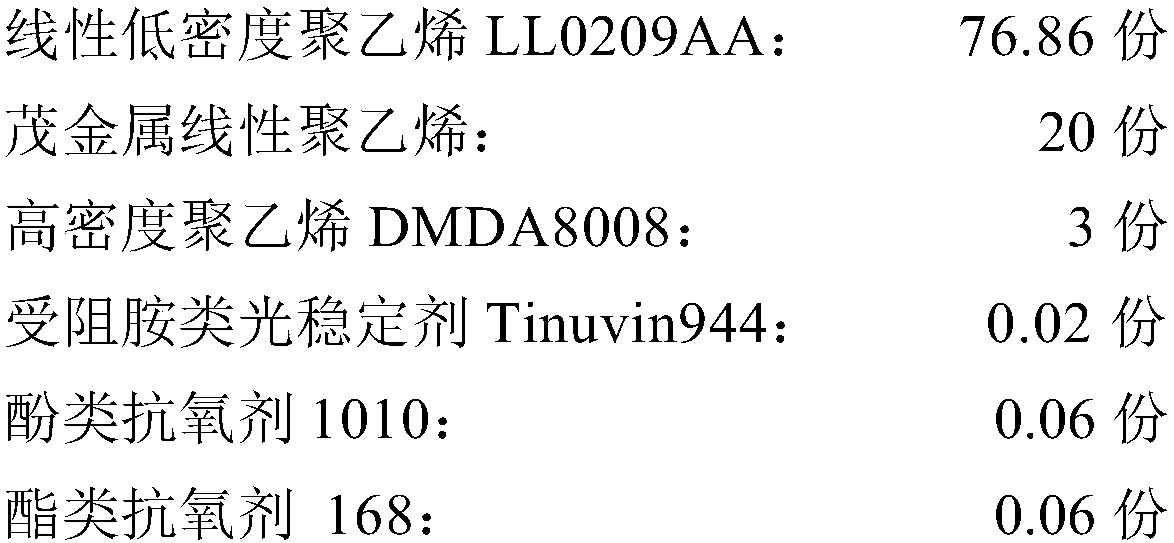

[0033] The mulch film of the present embodiment is made up of the following components by weight:

[0034]

[0035] Among them, the melt flow rate MFR of metallocene linear polyethylene is 1.0g / 10min, and the density is 0.918g / cm 3 , the weight average molecular weight is 89,000, and the molecular weight distribution is 2.0.

[0036] Second, the preparation method of the film

[0037] Mix linear low-density polyethylene, metallocene linear polyethylene, high-density polyethylene, hindered amine light stabilizer, phenolic antioxidant and ester antioxidant according to the above weight parts to prepare a mixture; subsequently, Put the uniformly mixed material into the plasticizing extruder hopper through the automatic feeder for automatic plasticizing extrusion and inflation traction; wherein, the temperature of plasticization extrusion is 190°C, and the inflation ratio of inflation traction is 3, The traction ratio is 4, and the mulch film wi...

Embodiment 2

[0040] 1. Mulch composition

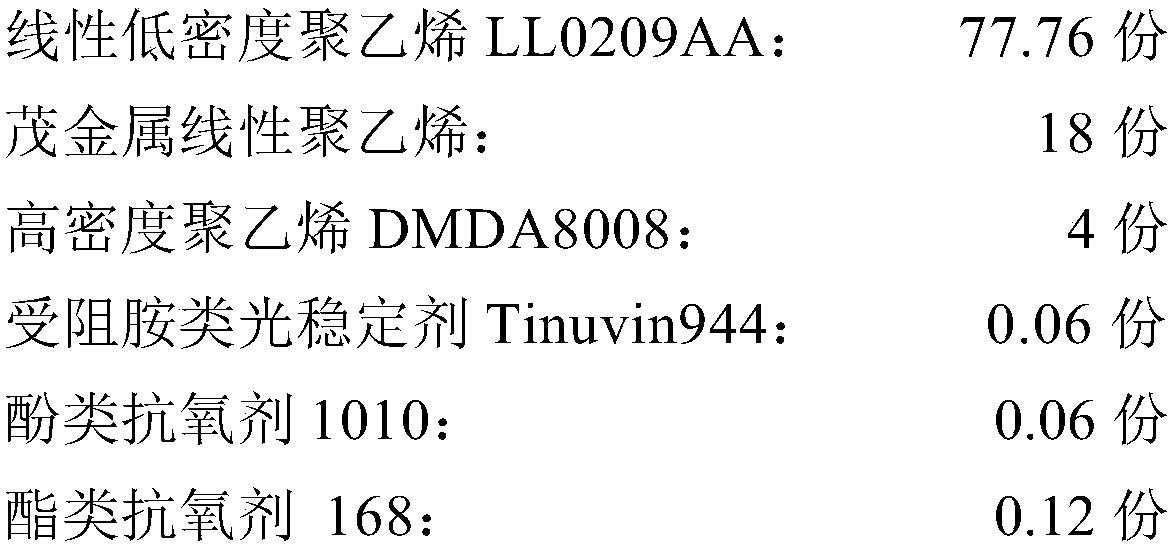

[0041] The mulch film of the present embodiment is made up of the following components by weight:

[0042]

[0043] Among them, the melt flow rate MFR of metallocene linear polyethylene is 0.5g / 10min, and the density is 0.916g / cm 3 , the weight average molecular weight is 100,000, and the molecular weight distribution is 2.2.

[0044] Second, the preparation method of the film

[0045] Mix linear low-density polyethylene, metallocene linear polyethylene, high-density polyethylene, hindered amine light stabilizer, phenolic antioxidant and ester antioxidant according to the above weight parts to prepare a mixture; subsequently, Put the uniformly mixed material into the hopper of the plasticizing extruder through the automatic feeder for automatic plasticizing extrusion and inflation traction; wherein, the temperature of plasticization extrusion is 210°C, and the inflation ratio of inflation traction is 2.8, The traction ratio is 5, and the mul...

Embodiment 3

[0048] 1. Mulch composition

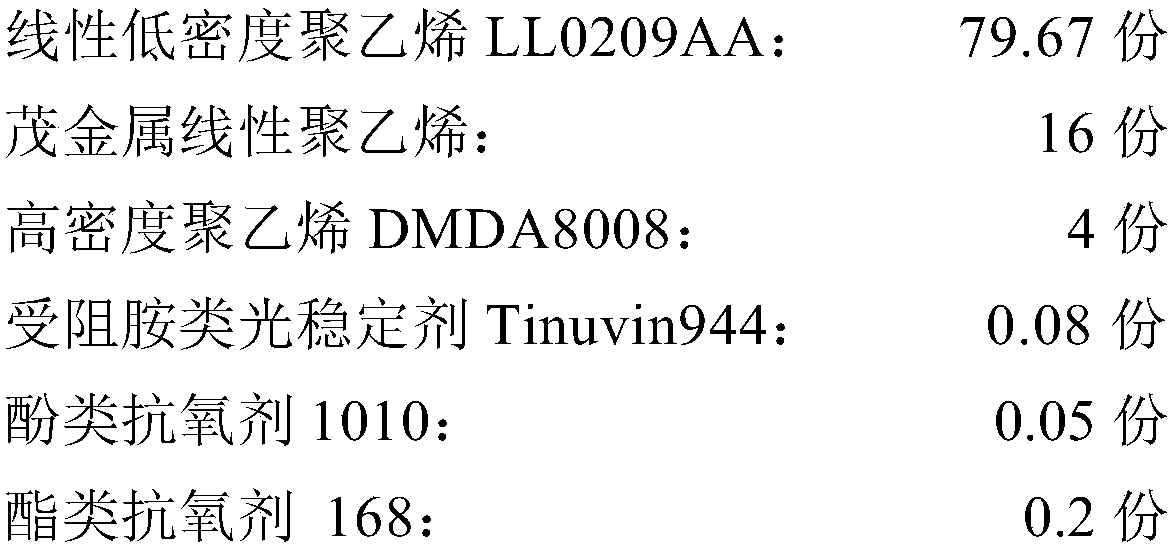

[0049] The mulch film of the present embodiment is made up of the following components by weight:

[0050]

[0051] Among them, the melt flow rate MFR of metallocene linear polyethylene is 0.9g / 10min, and the density is 0.918g / cm 3 , the weight average molecular weight is 91,000, and the molecular weight distribution is 2.5.

[0052] Second, the preparation method of the film

[0053] Mix linear low-density polyethylene, metallocene linear polyethylene, high-density polyethylene, hindered amine light stabilizer, phenolic antioxidant and ester antioxidant according to the above weight parts to prepare a mixture; subsequently, Put the uniformly mixed mixture into the hopper of the plasticizing extruder through the automatic feeder for automatic plasticizing extrusion and inflation traction; the temperature of plasticization extrusion is 220°C, and the inflation ratio of inflation traction is 2.5, The traction ratio is 5, and the mulch film (re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com