Construction waste recycling process

A technology of construction waste and technology, which is applied in the field of construction waste recycling and reuse technology, can solve the problems that it is difficult to prepare recycled aggregates and cannot realize high value-added utilization, so as to achieve good removal effect, reduce cracks, and avoid environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

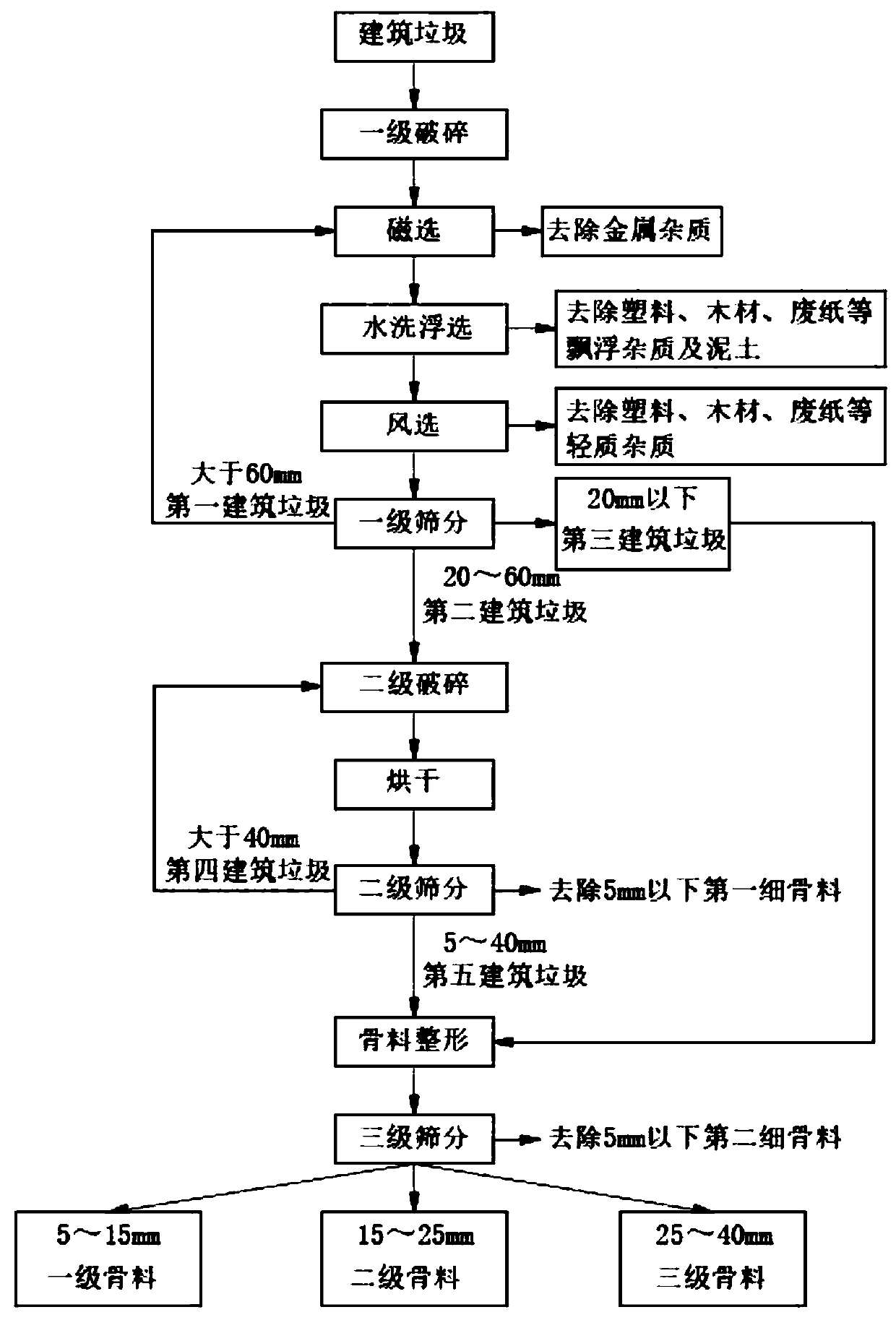

[0039] This embodiment provides a construction waste recycling process, comprising the following steps:

[0040] Step S1, primary crushing: sending the construction waste into the crusher A for crushing. In this embodiment, the crusher A is a jaw crusher;

[0041] Step S2, magnetic separation: passing the first-stage crushed construction waste through a magnetic separator to remove metal impurities in the construction waste;

[0042] Step S3, washing flotation: sending the construction waste after magnetic separation into the washing flotation machine to remove floating impurities such as plastics, wood, waste paper and soil in the construction waste;

[0043] The washing flotation machine is an existing technology, and its working principle is: construction waste passes through the water flow of the washing flotation machine, because some plastics, wood, waste paper and other impurities are relatively light in weight, and will float under the action of hydraulic force. Then ...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that the working temperature of the dryer is 300°C.

Embodiment 3

[0056] The difference between this embodiment and Embodiment 1 is that the working temperature of the dryer is 500°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com