Multiple refrigeration and heating air conditioner and duplex heat reclamation device constituted by same

A heat recovery device, refrigeration and heating technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of a large decline in the comprehensive energy efficiency ratio, difficult to master manufacturing and application, and different throttling rates. Easy to debug, cost-effective, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] As shown in Figure 4, this embodiment of the present invention is applied to a single-cooling hot water and air-conditioning dual-purpose machine, and the steps are as follows:

[0037] 1. Selection of main components:

[0038] The heat exchanger 7 adopts a water heat exchanger, the heat exchanger 5 adopts an outdoor heat exchanger, and the heat exchanger 6 adopts an indoor heat exchanger;

[0039] The multi-way reversing valve adopts a combination structure of the reversing port of the four-way reversing valve 3 and the gas return port;

[0040] The cut-off throttle valve adopts a bridge-type cut-off throttle valve assembly;

[0041] Solenoid valve 23, solenoid valve 22 and independent solenoid valve 32 all adopt normally closed solenoid valves;

[0042] Throttle valve 24 adopts thermal expansion valve;

[0043] 2. Bridge cut-off throttle valve assembly structure:

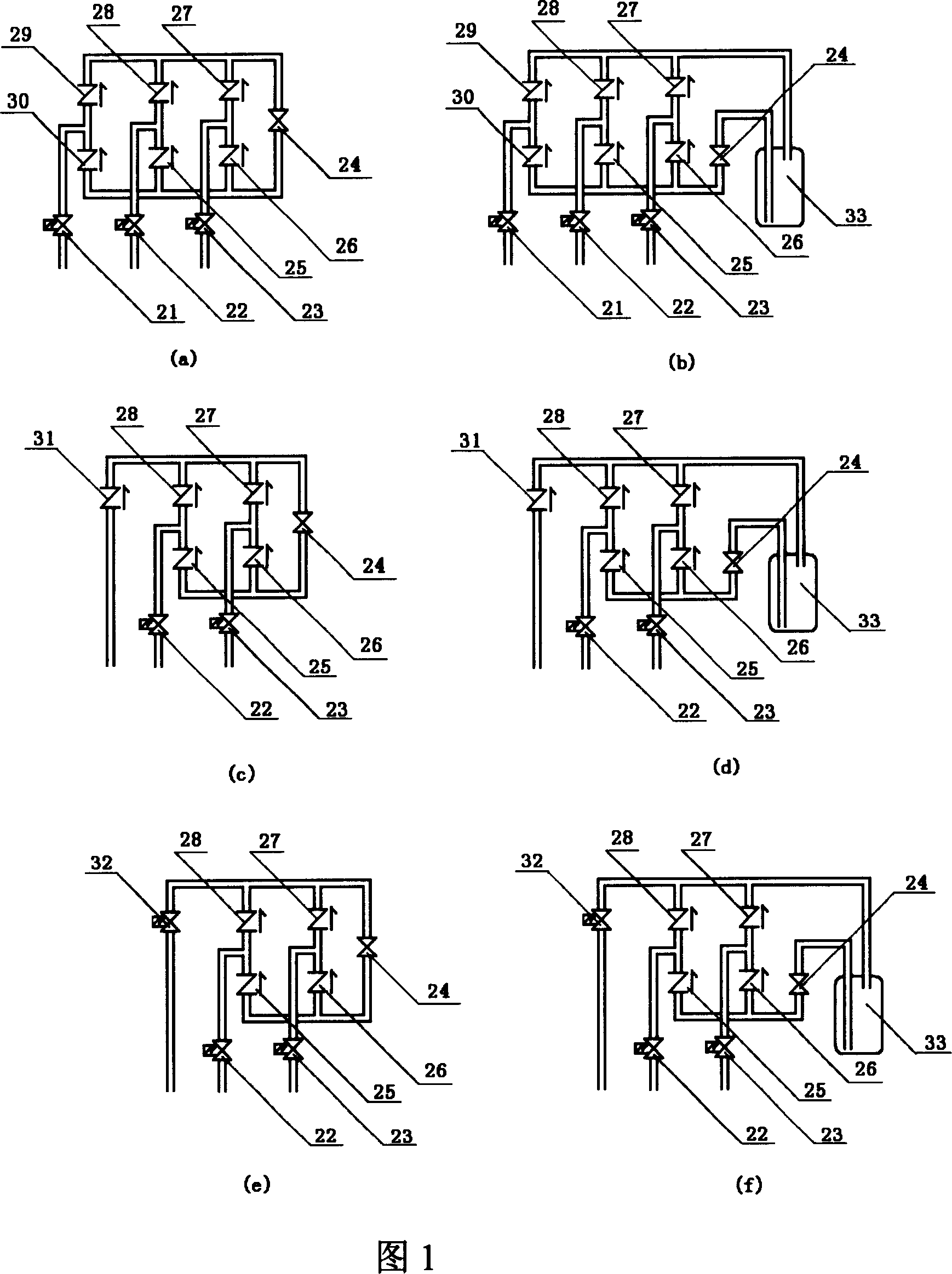

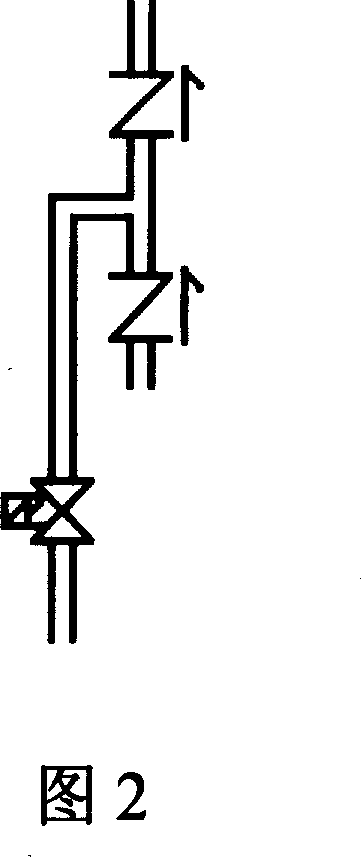

[0044]The bridge-type cut-off throttle valve assembly is shown in Figure 1(f), and consists of a thr...

Embodiment 2

[0057] As shown in Figure 5, this embodiment of the present invention is applied to a dual-purpose machine of heating and cooling hot water and air conditioning, and the steps are as follows:

[0058] 1. Selection of main components:

[0059] The heat exchanger 7 adopts a water heat exchanger, the heat exchanger 5 adopts an outdoor heat exchanger, and the heat exchanger 6 adopts an indoor heat exchanger;

[0060] The multi-way reversing valve adopts the combination structure of four-way reversing valve 3 and four-way reversing valve 4;

[0061] The cut-off throttle valve adopts a bridge-type cut-off throttle valve assembly;

[0062] Solenoid valve 21, solenoid valve 22, solenoid valve 23, adopt normally closed solenoid valve;

[0063] Throttle valve 24 adopts thermal expansion valve;

[0064] 2. Bridge cut-off throttle valve assembly structure:

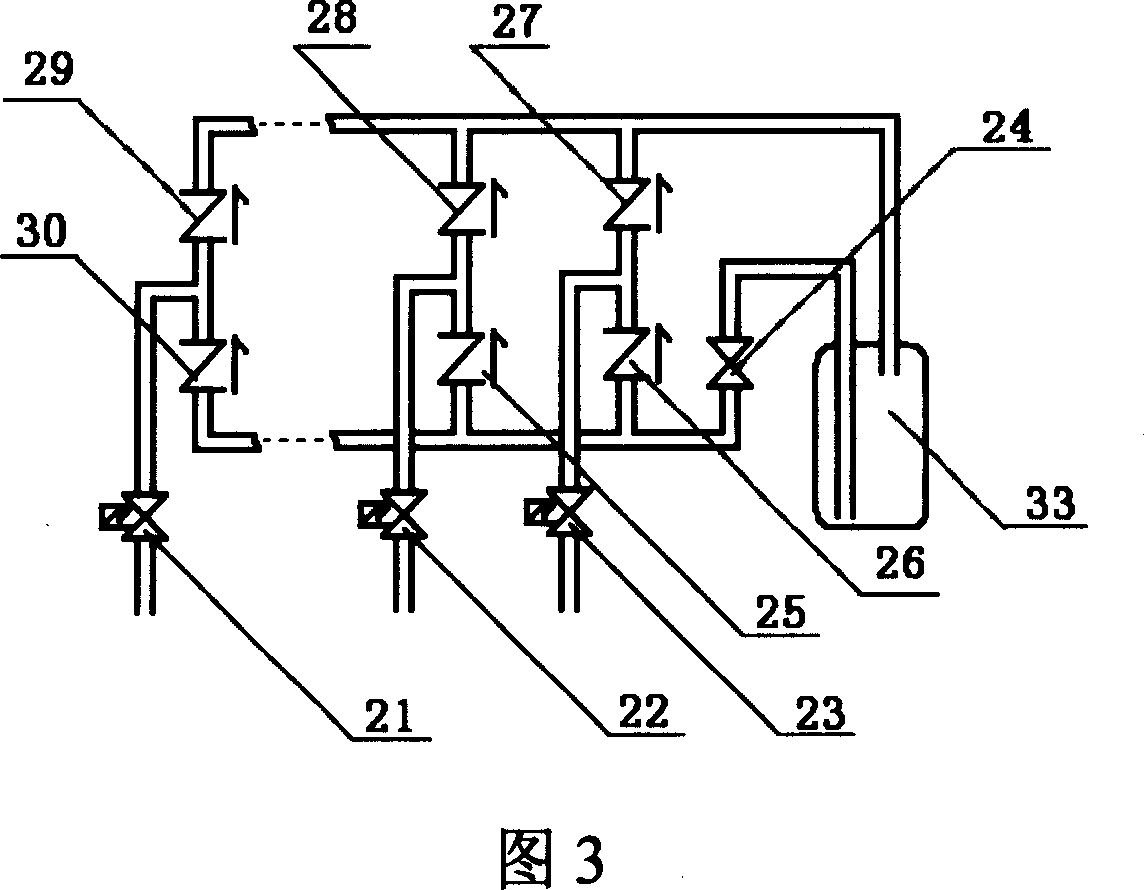

[0065] The bridge cut-off throttle valve assembly is composed of a throttle valve 24 and three bridge rectifier units connected....

Embodiment 3

[0072] As shown in Figure 6, this embodiment of the present invention is applied to a dual-purpose machine with dual heat recovery, hot water, and air conditioner of the heating and cooling type, and the steps are as follows:

[0073] 1. Selection of main components:

[0074] Heat exchanger 5 is an outdoor heat exchanger, heat exchanger 6 is an indoor heat exchanger, and heat exchangers 7 and 8 are water heat exchangers;

[0075] The multi-way reversing valve adopts the combination structure of four-way reversing valve 3 and four-way reversing valve 4;

[0076] Cut-off throttle valves 10, 11, 12 adopt a structure of normally closed solenoid valves and capillary tubes connected in series;

[0077] 2. The overall connection relationship:

[0078] A heat exchanger 8 is connected in series between the exhaust port of the compressor and the input port of the multi-way reversing valve, and the output of the four-way reversing valve 3 is connected to the gas port of the heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com