Filling control system and method for liquefied petroleum gas steel cylinder

A liquefied petroleum gas and control system technology, applied in container filling method, container discharge method, liquid bottling, etc., can solve the problems of lack of electronic management system, paralysis, safety hazards, etc., to standardize the operation process, reduce Hidden security risks and guaranteeing the effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

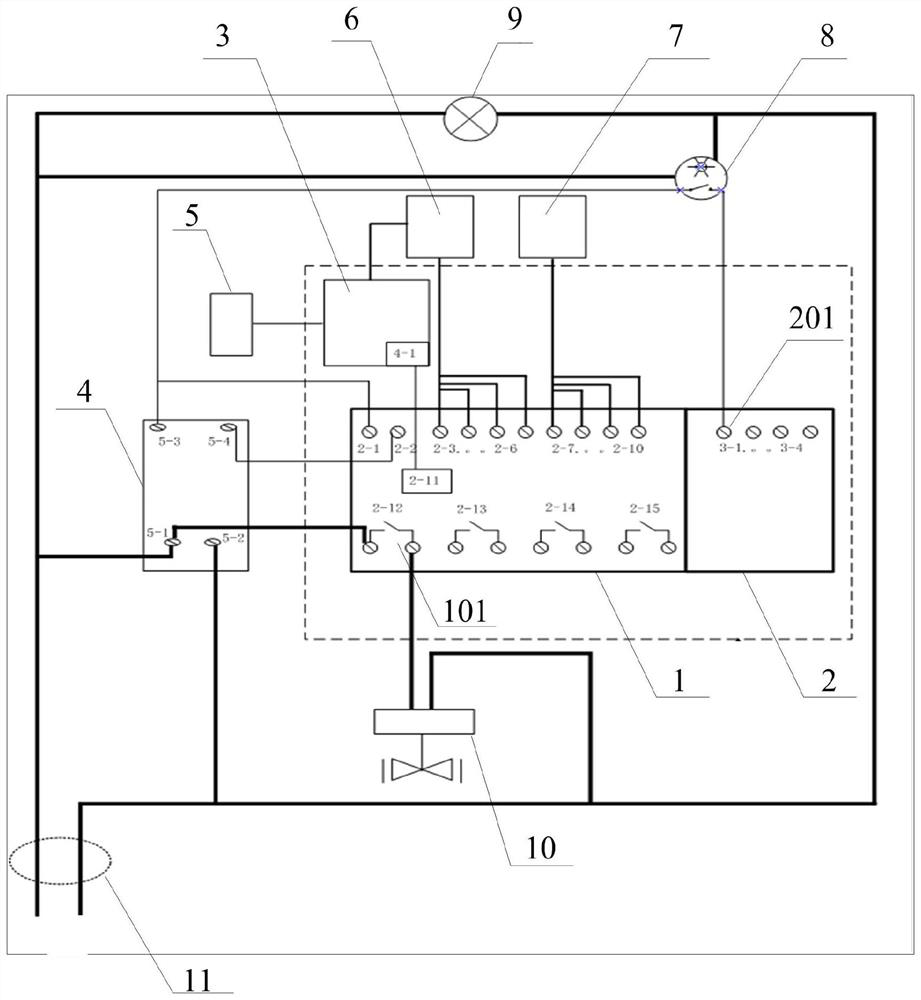

[0046] Such as figure 1 As shown, the filling control system of a kind of liquefied petroleum gas cylinder provided by the present invention comprises:

[0047] The control main part, peripheral auxiliary equipment and platform server module are composed. The main control part is installed in the filling control box in the filling station, including control module 1, control expansion module 2 and station control module 3; peripheral auxiliary equipment includes: power supply module 4. Handheld machine 5, wireless card reader 6, inflatable weighing instrument 7, emergency stop button 8, explosion-proof indicator light 9, solenoid valve 10 of filling gun and external 220V power supply 11.

[0048]Both the handheld device 5 and the wireless card reader 6 are respectively connected to the station control module 3 through wireless communication; the handheld device 5 is used to collect the personal information and steel cylinder information of the staff, and bind the personal info...

Embodiment 2

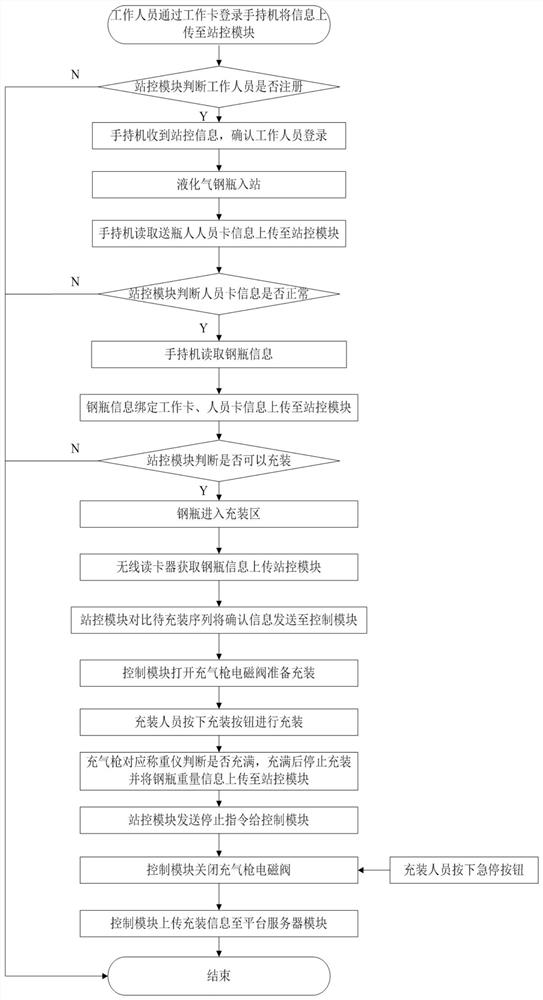

[0058] Such as figure 2 As shown, the present invention also provides a filling control method for liquefied petroleum gas cylinders, the method comprising:

[0059] S1. The staff on duty with a certificate log in to the handheld device through their work card (electronic label card) at the filling station, and the handheld device uploads the login information to the station control module through the wireless network (WiFi, 2.4G, 800M);

[0060] S2. The station control module compares the login information with the personal information in the platform server module to determine whether the staff is registered; if yes, sends the confirmation login information to the handset, confirms the staff login, and allows the filling operation of the day. A plurality of staff members carry out operations with personally logged-in handsets; if no (the work card information does not match the registration information of the platform server module, or disagrees with other management requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com