Automatic control system of scraper reclaimer

An automatic control system and control system technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of high workload of operators, collision of scraper reclaimers, misoperation of operators, etc., and achieve significant social and economic benefits. , Reduce equipment damage and ensure stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the examples.

[0035] The invention discloses an automatic control system of a scraper reclaimer. Firstly, the scraper reclaimer is introduced. The scraper reclaimer is a common machine, including a walking mechanism, a winch lifting mechanism, a scraper reclaimer, a driver's cab, The electrical room, the specific structure will not be described in detail.

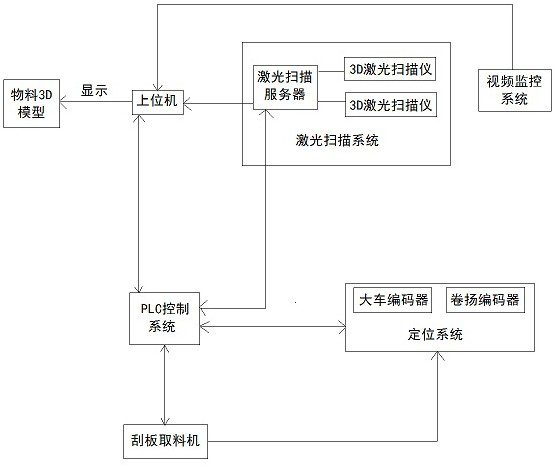

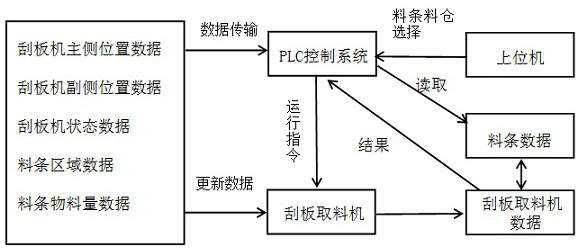

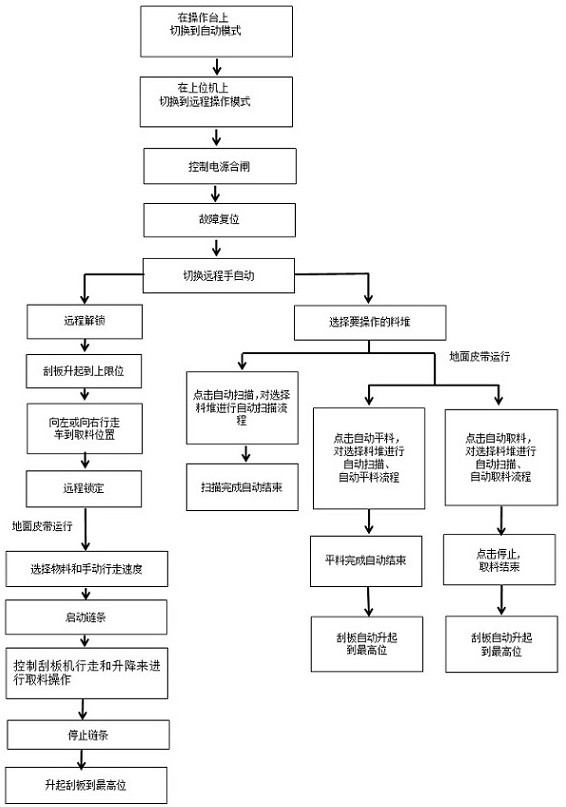

[0036] Specifically to the automatic control system of the present invention, see Figure 1-Figure 3 , used to achieve remote control, including laser scanning system, video monitoring system, positioning system, PLC control system, host computer, positioning system installed on the scraper reclaimer and used to obtain the positioning data of the scraper reclaimer, PLC control system It is used to control the scraper reclaimer. The upper computer is connected to the laser scanning system, video monitoring system, and PLC control sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com