Automatic joint debugging system for multiple air blower units and control method thereof

A technology of joint adjustment system and control method, applied in electric controllers, controllers with specific characteristics, chemical instruments and methods, etc., can solve the problems of delay in air volume adjustment, increased labor cost, inaccuracy, etc. Adjust precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

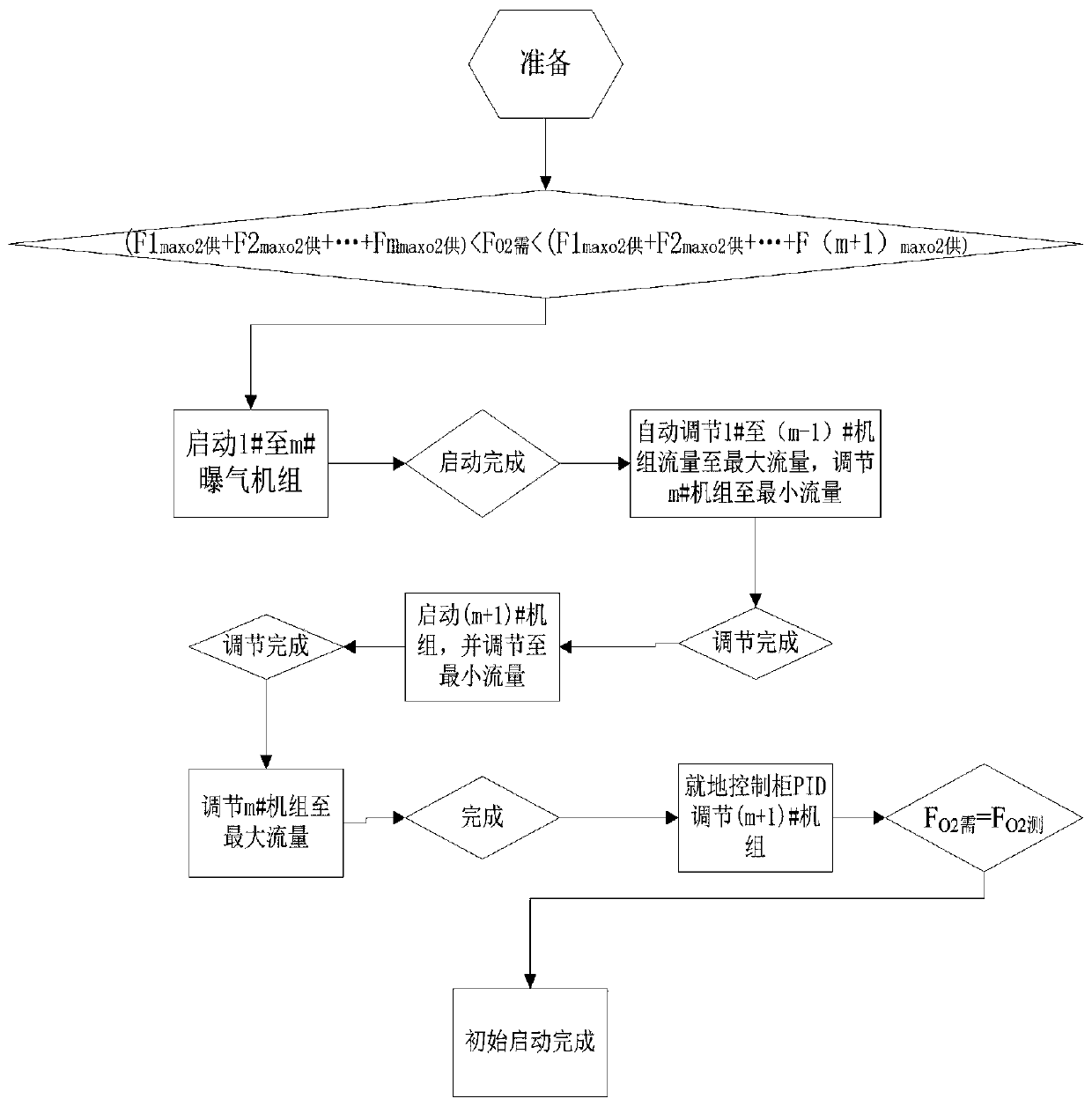

[0018] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

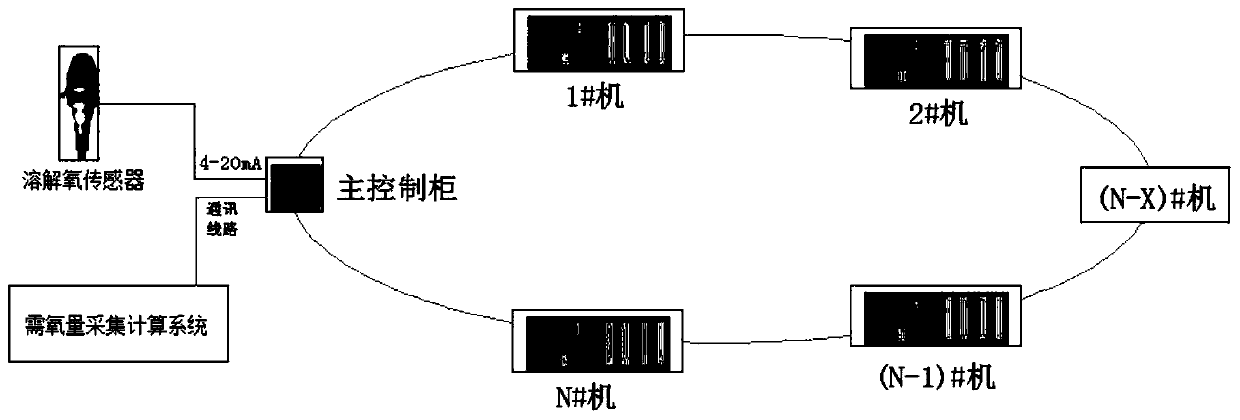

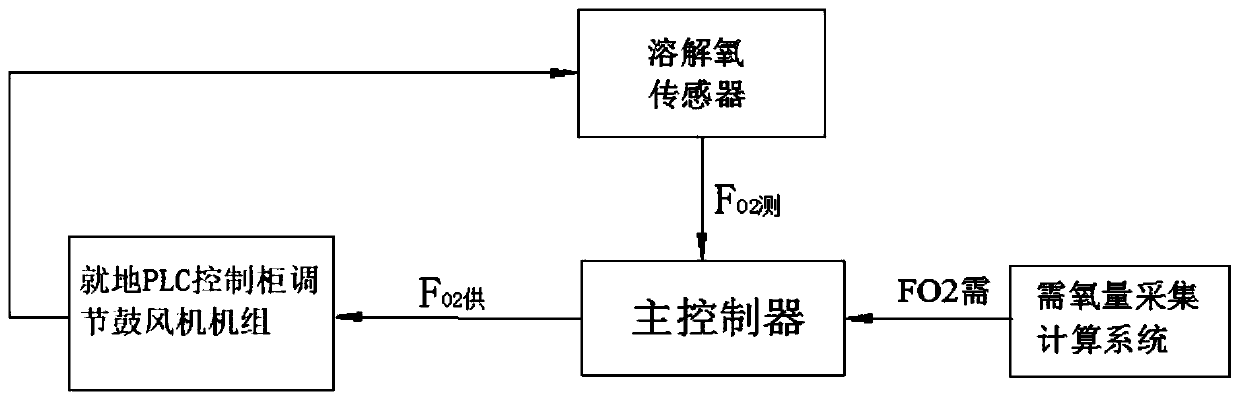

[0019] see figure 1 , an embodiment of the automatic joint debugging system of multiple blower units, including multiple blower units, a main control cabinet, a dissolved oxygen sensor and an oxygen demand acquisition and calculation system respectively connected to the main control cabinet, each blower unit All are equipped with an on-site PLC control cabinet to control it, and the on-site PLC control cabinet is gas-connected to the main control cabinet through a ring network optical fiber. The dissolved oxygen sensor is used to measure the oxygen content of sewage, and the oxygen demand The acquisition and calculation system is used to collect various parameter values in the sewage and calculate the oxygen demand of the sewage, and then transmit the oxygen demand value of the sewage to the main control cabinet through the communication bus....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com