A hydraulic fully automatic pile driver with a free lowering hoist to drive a heavy hammer

A technology for driving heavy hammers and winches, which is applied to sheet pile walls, buildings, and infrastructure engineering, and can solve problems such as safety, low efficiency, and hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

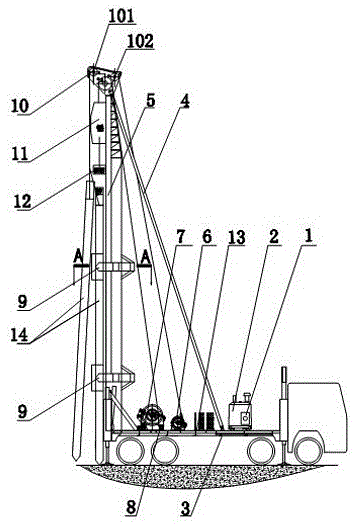

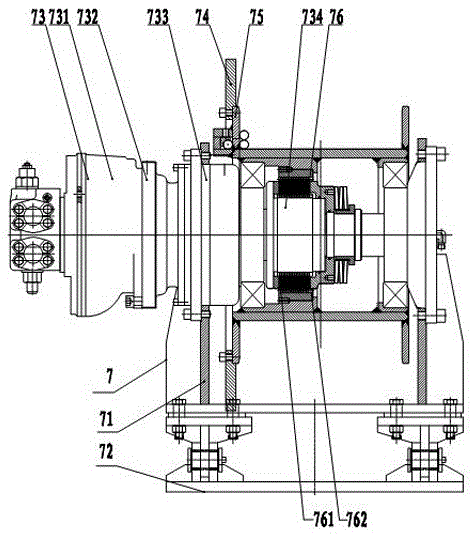

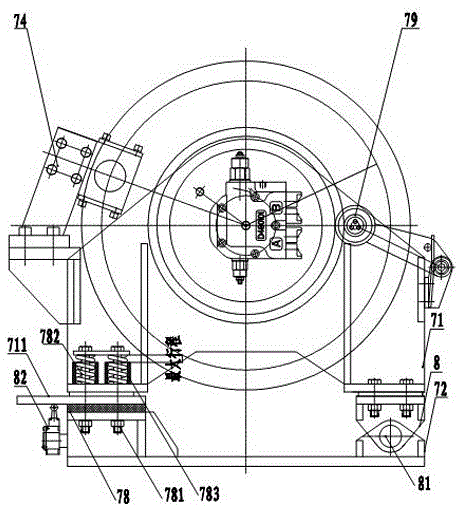

[0031] exist figure 1 In the shown embodiment, a hydraulic fully automatic piling machine that uses a free lowering winch to drive a heavy hammer includes a hydraulic pump station 1, an engine 2, a hydraulic control system, a circuit control system, a transport vehicle 3, a hydraulic control valve group 13, The main arm 5 of the pile driver twisted at the front end of the transport vehicle 3 is composed of two struts 4 connected with the main arm 5 in a triangular structure. The guide device is a guide slide rail arranged on the main arm 5. 2. It is connected with the hydraulic control system and the circuit control system. The circuit control system is provided with a PLC controller, and the control of the pile driver can be realized by operating the hydraulic control valve group 13. The platform of the transport vehicle 3 is provided with a pile hoist 6, a free lowering weight hoist 7 and an automatic pile clamping mechanism 9, and the pile hoist 6 and the free lowering weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com