Treatment method for aluminum-containing waste salt

A treatment method and technology of aluminum waste, which is applied in the field of treatment of aluminum-containing waste salt, can solve the problems of no equipment, equipment corrosion, low thermal cracking temperature, etc., and achieve effective treatment and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

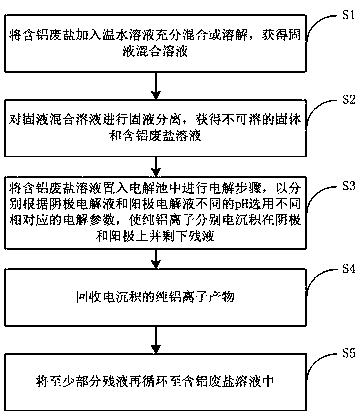

[0039] This embodiment provides a method for treating aluminum-containing waste salt, for example, a chemical waste salt whose main components are sodium salt, magnesium salt, calcium salt, aluminum salt, and the like. Such as figure 1 As shown, the method includes the following steps:

[0040] S1. Add aluminum-containing waste salt to a warm aqueous solution to fully mix or dissolve to obtain a solid-liquid mixed solution. The warm water solution is warm process water, warm dilute hydrochloric acid or pickling waste liquid. The mixing and stirring time is generally 10-30 minutes, so as to fully dissolve the soluble substances and ensure that the aluminum-containing metal salt is fully dissolved in the solution.

[0041] S2, performing solid-liquid separation on the solid-liquid mixed solution to obtain insoluble solid and aluminum-containing waste salt solution. Solid-liquid separation is performed by physical separation methods such as tilting, centrifugation, filtration,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com