Crucible for point evaporation source

A technology of evaporation source and crucible, which is applied in the field of evaporation process, can solve the problems of waste of metal materials, failure to improve the utilization rate of metal materials of point evaporation sources, cleaning troubles, etc., and achieve the effect of avoiding the troubles of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

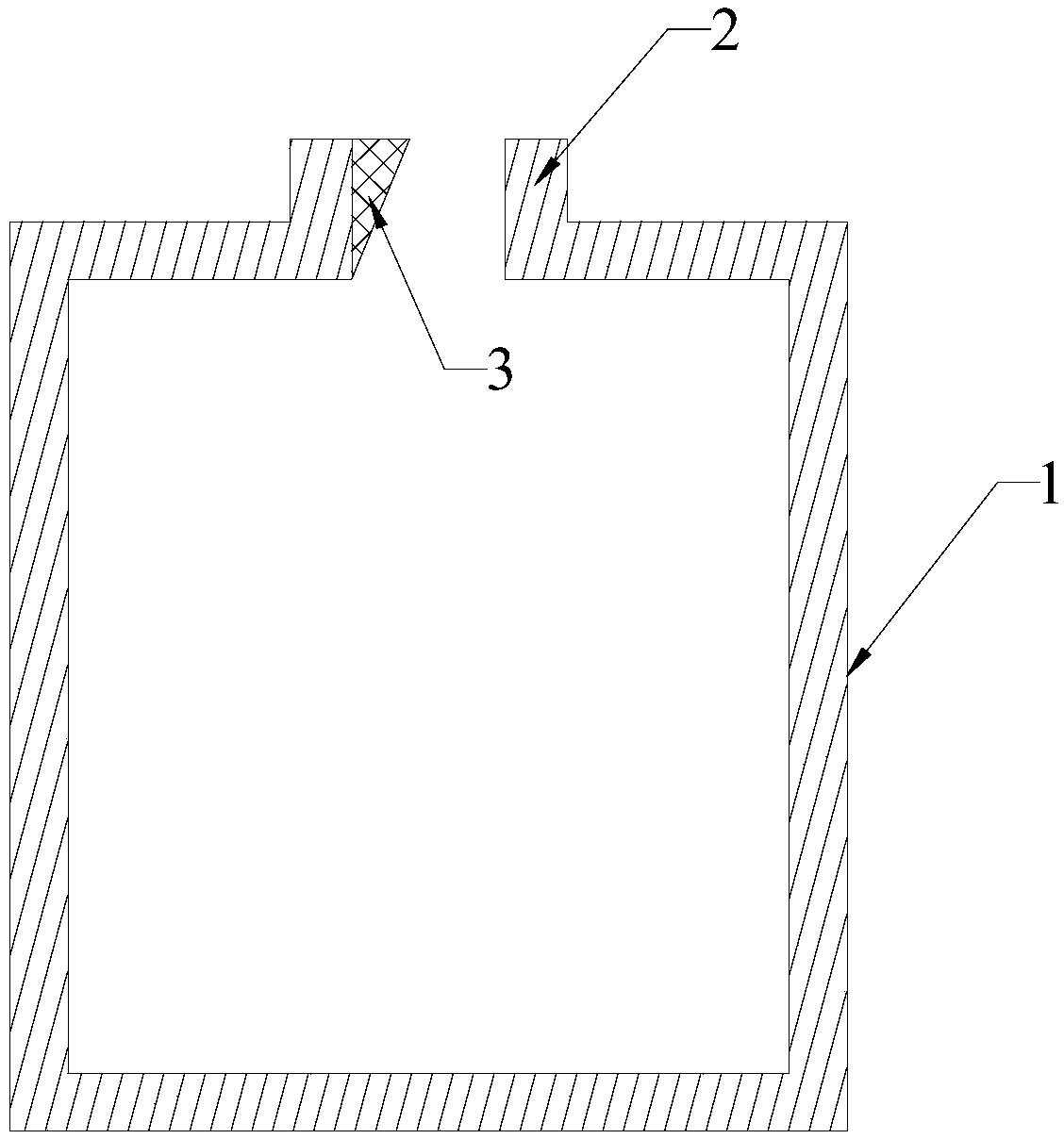

[0032] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0033] A crucible for a point evaporation source, comprising a hollow crucible body 1, the top of the crucible body 1 has an opening 2, the side wall where the opening 2 is located is provided with a guide part 3, the guide part The angle between 3 and the horizontal plane is configured so that the evaporated material loaded in the crucible body 1 can be guided to the external substrate through the guide part 3 .

[0034] The included angle between the guide part 3 and the horizontal plane is 45-65 degrees.

[0035] A plurality of crucible bodies 1 are arranged around the lower part of the substrate.

[0036] The air guiding part 3 is disposed away from the substrate.

[0037] During the production process, the flow guiding part 3 is integrally formed on the side wall where the opening 2 is located.

Embodiment 2

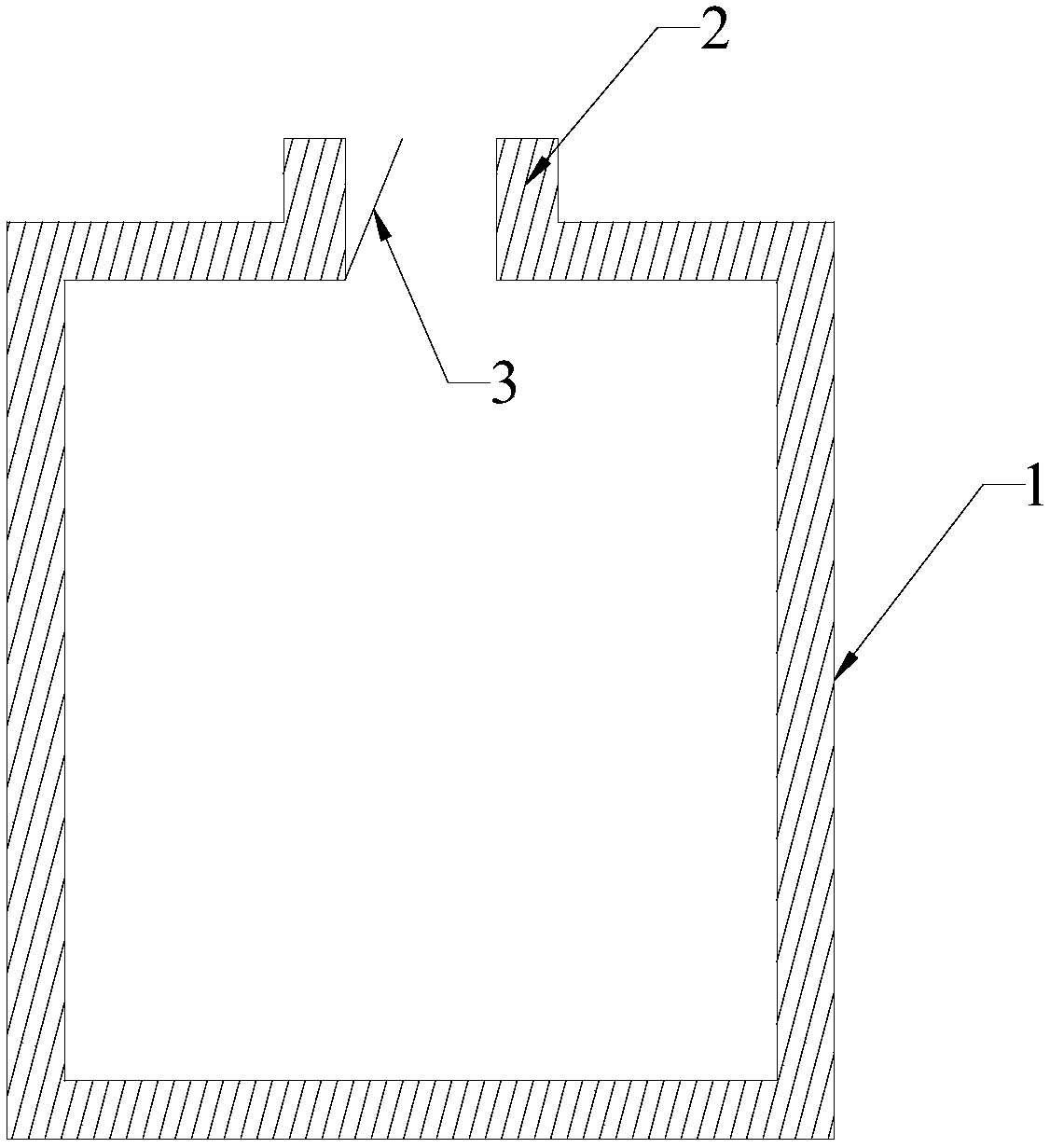

[0038] Please refer to figure 2 , the second embodiment of the present invention is:

[0039] The difference from the above-mentioned first embodiment is that the second embodiment is an improvement made on the existing crucible body 1 that has been produced, specifically, a guide part 3 is added on the side wall where the opening 2 is located, and the guide part 3 is added. The flow part 3 is a shielding piece, and one end of the shielding piece is connected to the side wall where the opening 2 is located.

[0040] When the melting point of the evaporated material is 100-300° C., the guide part 3 can be made of tempered glass.

[0041] When the melting point of the vapor deposition is 300-1800° C., the material of the guide portion 3 is graphite or ceramics.

[0042] It is also possible to uniformly use graphite or ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com