Flowing type high-temperature high-pressure solubility online measuring device and measuring method thereof

A high-temperature, high-pressure, measuring device technology, applied in thermal excitation analysis, material resistance, material excitation analysis, etc., to achieve accurate and reliable data, promote sufficient deposition, and facilitate data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

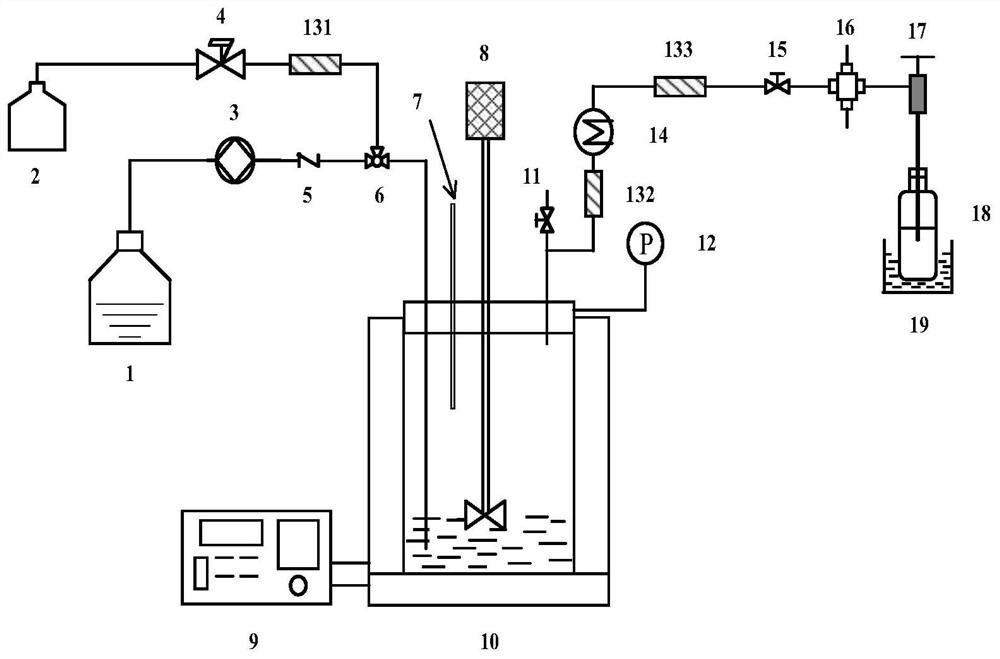

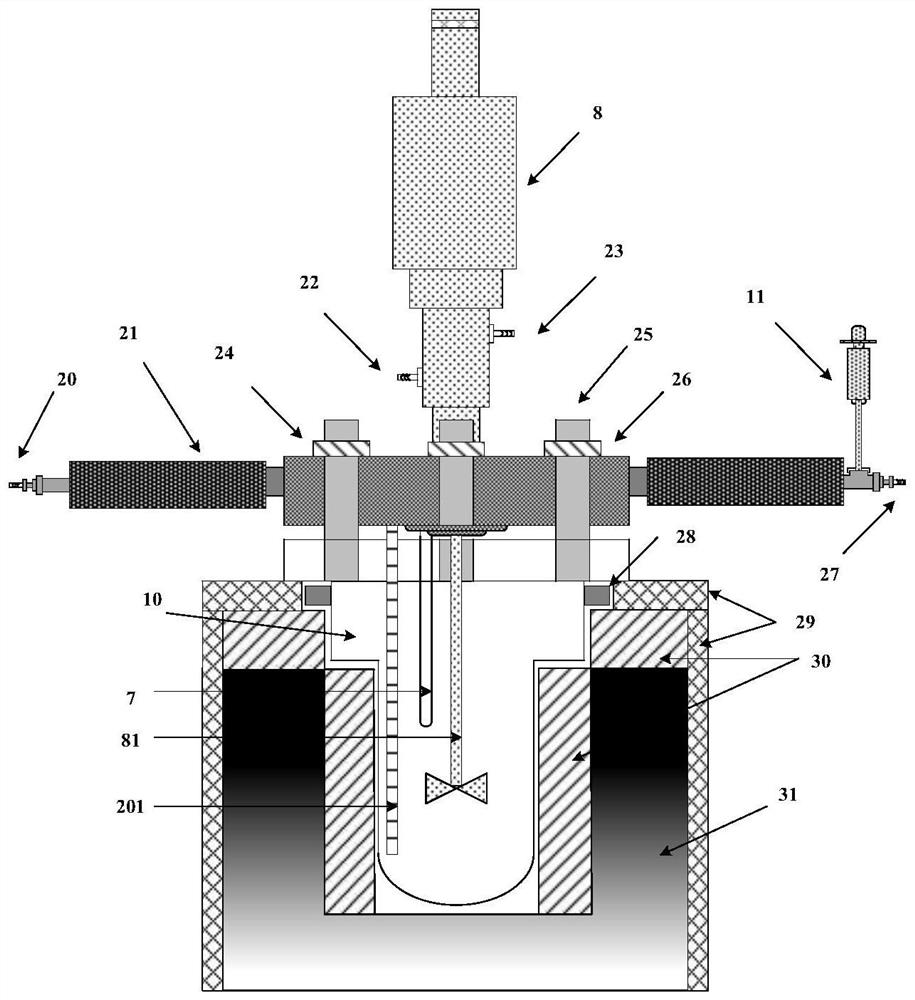

Method used

Image

Examples

Embodiment 1

[0056] (1) Fill the pre-prepared sodium sulfate solution (the molar concentration of sodium sulfate is 0.5 mol / L) in the raw material solution reagent bottle 1 .

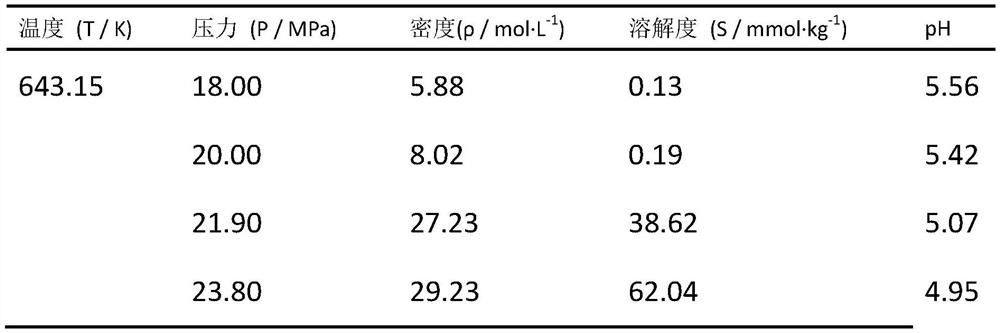

[0057] (2) extract sodium sulfate solution with feed pump 3, feed rate is 4-5mL / min, solution is sent in the equilibrium kettle 10; After the solution stays in the equilibrium kettle 10 for a long enough time, it flows out through the sampling system; Adjust the back pressure valve 4 to increase the pressure of the balance kettle 10 to the equilibrium pressure (18-26MPa) set in the experiment, and heat the balance kettle 10 to the equilibrium temperature (643.15-723.15K) set in the experiment. When the temperature fluctuation of the system does not exceed ±1K, when the pressure fluctuation does not exceed ±0.1MPa, continue to balance for a period of time; observe the conductivity value of the solution in real time through the high-voltage conductivity detection cell 16 .

[0058] (3) When the conductivity of the sam...

Embodiment 2

[0064] (1) Fill the pre-prepared potassium sulfate solution (the molar concentration of potassium sulfate is 0.5 mol / L) in the raw material solution reagent bottle 1 .

[0065] (2) extract potassium sulfate solution with feed pump 3, and feed rate is 4-5mL / min, and solution is sent in the equilibrium kettle 10; After the solution stays in the equilibrium kettle 10 for a long enough time, it flows out through the sampling system; Adjust the back pressure valve 4 to increase the pressure of the balance kettle 10 to the equilibrium pressure (18-26MPa) set in the experiment, and heat the balance kettle 10 to the equilibrium temperature (633.15-723.15K) set in the experiment. When the temperature fluctuation of the system does not exceed ±1K, when the pressure fluctuation does not exceed ±0.1MPa, continue to balance for a period of time; observe the conductivity value of the solution in real time through the high-voltage conductivity detection cell 16 .

[0066](3) When the conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com