Total dose irradiation resistant SOI (Silicon On Insulator) device and preparation method thereof

An anti-total dose, device technology, applied in the direction of electric solid devices, semiconductor devices, semiconductor/solid device components, etc., can solve the problems of limited protection ability, complex coating process, lead toxicity, etc., to achieve excellent structural characteristics, simplification Preparation process, shielding effect of total dose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

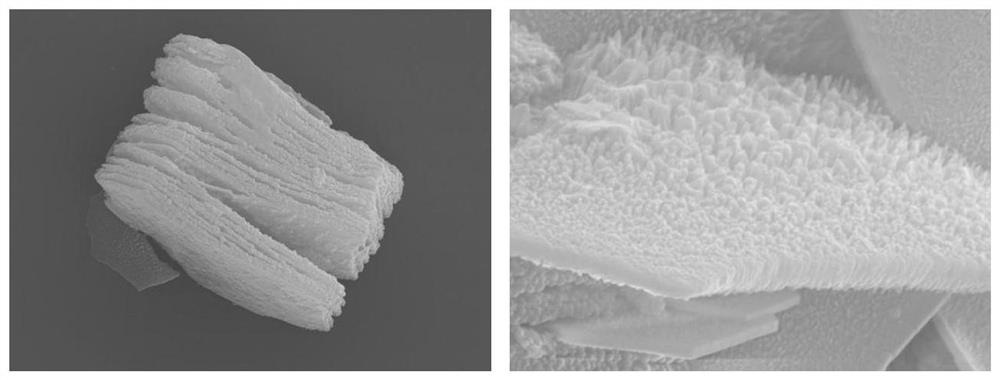

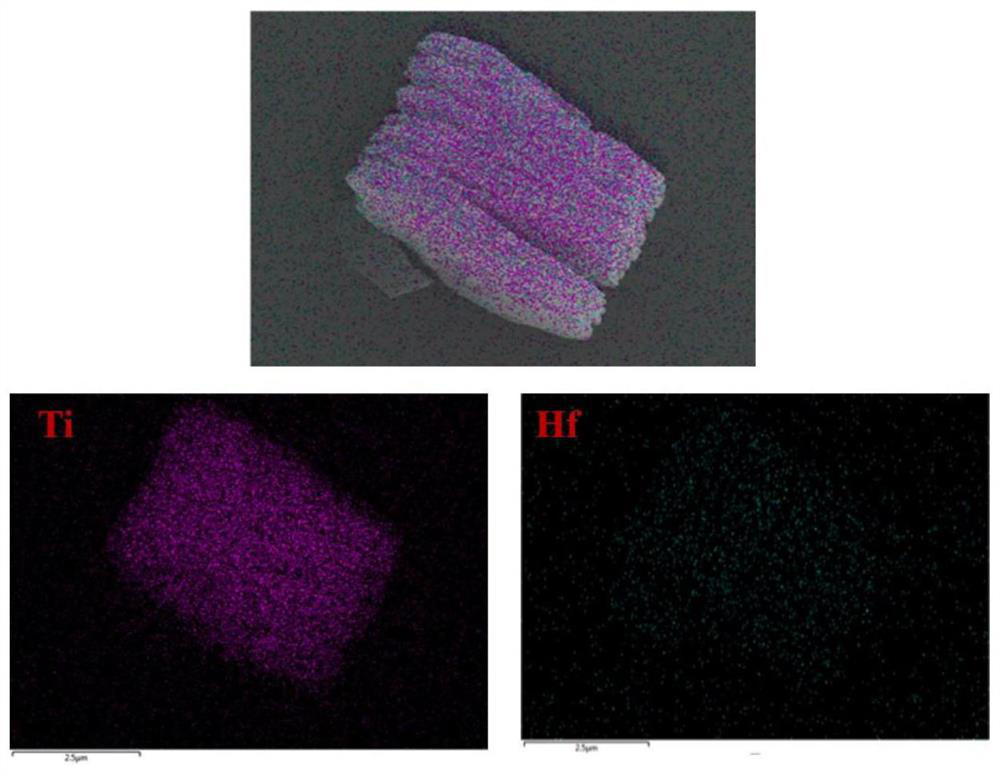

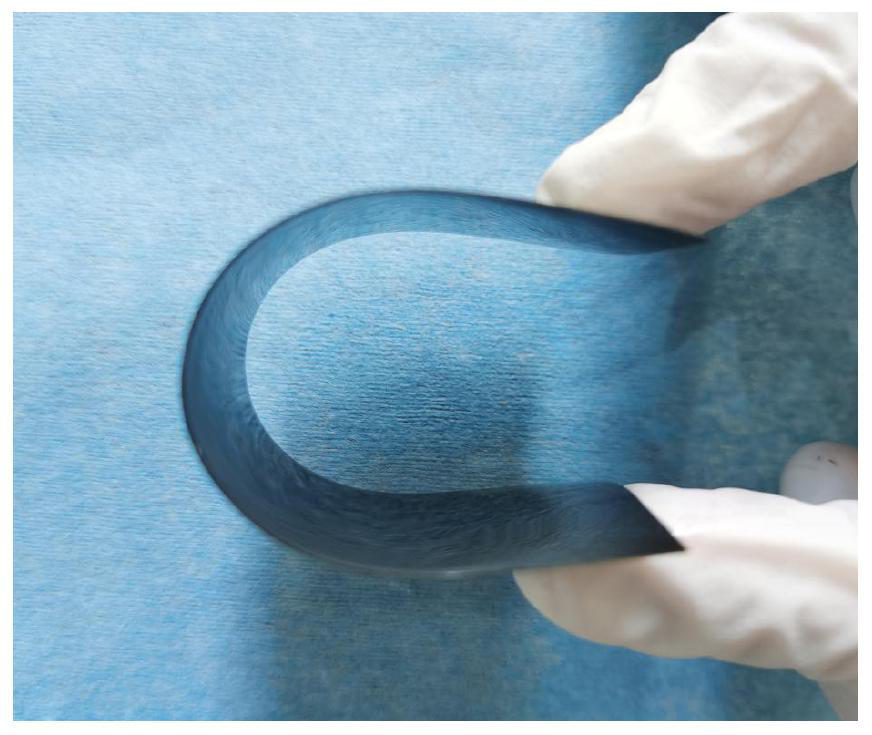

[0044] Use method 1 (hydrofluoric acid etching) to complete Mxene etching, then transfer Mxene to the chamber of the atomic layer deposition device, and perform high-Z metal oxide HfO on it 2 Coating modification. The reaction temperature should be controlled at 200°C, the pressure should be controlled at 0.155torr during the reaction, and the source of high Z metal oxides is [(CH 3 )C 2 h 5 )N] 4 Hf, the pulse time is 0.15s, and the reaction time is 6s. After the pulse and reaction are completed, use high-purity nitrogen (99.999%) to purge the residual reactants and by-products in the pipeline and cavity for 60s. Then high-purity water is used as the oxygen source, the pulse time is 0.015s, and the reaction time is 6s. After the pulse reaction is completed, the residual reactants and by-products in the pipeline and cavity are purged with high-purity nitrogen (99.999%) for 60s. The high-Z metal oxide source and the oxygen source are alternately fed into the reaction chambe...

Embodiment 2

[0047] Example 2: Using method 2 (HCl+LiF etching) to complete Mxene etching, then transfer Mxene to the chamber of the atomic layer deposition device, and perform high-Z metal oxide HfO on it 2 Coating modification. The reaction temperature should be controlled at 150°C, the pressure should be controlled at 0.155torr during the reaction, and the source of the high Z metal oxide is [(CH 3 )C 2 h 5 )N] 4 Hf, the pulse time is 0.15s, and the reaction time is 6s. After the pulse and reaction are completed, use high-purity nitrogen (99.999%) to purge the residual reactants and by-products in the pipeline and cavity for 60s. Then high-purity water is used as the oxygen source, the pulse time is 0.015s, and the reaction time is 6s. After the pulse reaction is completed, the residual reactants and by-products in the pipeline and cavity are purged with high-purity nitrogen (99.999%) for 60s. The high-Z metal oxide source and the oxygen source are alternately fed into the reaction ...

Embodiment 3

[0049] Example 3: Using method 3 (NaOH hydrothermal etching) to complete Mxene etching, then transfer Mxene to the chamber of the atomic layer deposition device, and perform high-Z metal oxide HfO on it 2 Coating modification. The reaction temperature should be controlled at 180°C, the pressure should be controlled at 0.155torr during the reaction, and the source of the high Z metal oxide is [(CH 3 )C 2 h 5 )N] 4 Hf, the pulse time is 0.15s, and the reaction time is 6s. After the pulse and reaction are completed, use high-purity nitrogen (99.999%) to purge the residual reactants and by-products in the pipeline and cavity for 60s. Then high-purity water is used as the oxygen source, the pulse time is 0.015s, and the reaction time is 6s. After the pulse reaction is completed, the residual reactants and by-products in the pipeline and cavity are purged with high-purity nitrogen (99.999%) for 60s. The high-Z metal oxide source and the oxygen source are alternately fed into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com