Dehydrating device and dehydrating method

A dehydration device and drainage pipe technology, which is applied in the direction of the feeding/discharging device of the settling tank, the settling tank, etc., can solve the problems of difficult water removal and high moisture content of sludge, so as to avoid secondary pollution, reduce water content, reduce The effect of moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

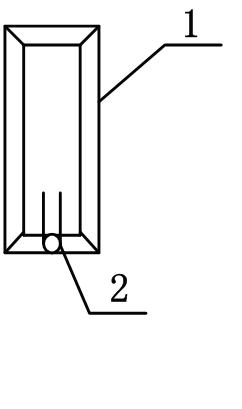

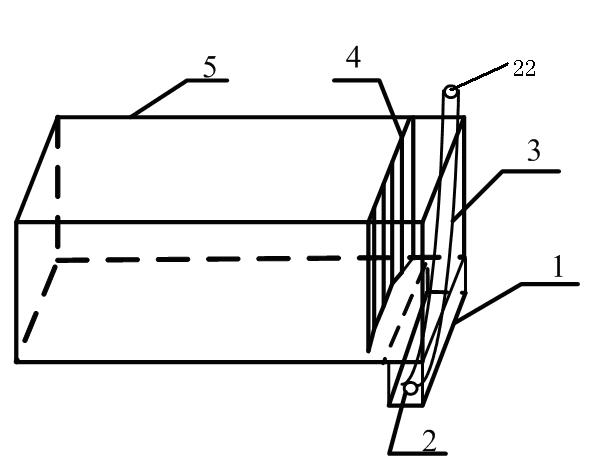

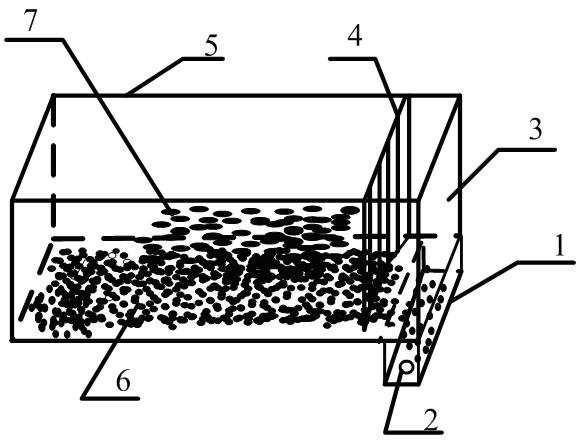

[0028] Combine below Figure 1 to Figure 3 , the present invention is further described:

[0029] figure 1 and figure 2 A dehydration device of the present invention is disclosed in , comprising a tank body 5, a bottom settling tank 1 is provided on one side of the bottom of the tank body 5, and a drain outlet 2 is provided on the side wall of the bottom settling tank 1; There is also a floating object baffle 4 inside, and the floating object baffle 4 is arranged at the front end opposite to the bottom settlement tank 1 .

[0030] The tank body 5 is a cuboid welded by common carbon steel plates, except that the other five sides of the upper end are completely closed. The tank body is 1200mm long, 400mm wide and 300mm high. A bottom settlement tank 1 with a length of 400mm, a width of 200mm and a height of 200mm is welded on the right bottom of the tank body 5, and the bottom settlement tank 1 is welded below the tank body 5 to effectively remove water in the tank body 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com